The scope of application of a milling machine is practically unlimited if it is equipped with a modern CNC system. This is one of the most versatile types of machining equipment.

A modern machining center is capable of producing parts and products of high complexity and for a wide variety of purposes. It is noteworthy that even the developer of the machine may not know all its capabilities, and they are revealed only in “field conditions,” that is, in production.

We invite you to familiarize yourself with the areas of application of equipment and the characteristic features of organizing the production of products on CNC with narrow specialization and universal milling machines.

Application of CNC in various production areas

To realize the full potential of existing CNC equipment or, conversely, to equip a line in accordance with the assigned technical tasks, more than just ideas are needed. The full potential of the machine is revealed in the interaction of the operator, technologist, programmer and enterprise manager.

With a competent approach, spindle power, working field dimensions, and movement speeds are not limiting factors. The correct choice of cutting tool, sequence of operations, number of passes, as well as maximum implementation of software capabilities can significantly expand the range of processed materials and finished products on CNC milling machines.

Take the test

What is CNC: all about CNC machines

Computer numerical control, or CNC for short, is a modern trend in the development of equipment for various purposes, based on the use of digital electronic devices in the control system. In Russia it is known as numerical control (CNC).

In essence, CNC is a computerized complex that controls the working parts of the equipment and controls the execution of the task. Any movements of the executive bodies are set by a special control program (CP) for this machine. It is composed of the necessary commands written in the CNC programming language (G- and M-codes). The computer stores the program program in its memory, and the operator can always use it to perform a specific job.

The modern CNC system has significantly expanded the capabilities of the previously used NC system. It is based on microcontrollers, programmable logic controllers, and microprocessor-based computers.

Feasibility of use

The CNC system significantly increases labor productivity and contributes to the reduction of workers, but its implementation requires significant costs and specially trained workers, which is not always economically justified. The use of CNC is advisable in the following circumstances:

- Production of high-value products when expensive and scarce raw materials are used. In this case, it is necessary to minimize errors and eliminate defects, which is what CNC provides.

- Production of similar products in large series. A proven program allows you to reduce costs and there is no need to change software, and the initial costs pay off fairly quickly.

- Manufacturing of complex parts requiring numerous technological operations.

- The need to ensure the production of numerous products that are absolutely identical in processing accuracy. The program ensures such production with a deviation of no more than 3 microns.

- Manufacture of products in the design of which minor changes are often made. When using CNC, they are easily entered into the NC from the machine operator console.

Important! Automation of production is a modern approach to its organization, but it requires an economic justification.

Functions

The CNC system is capable of performing the following functions:

- Management of processing processes for parts made of various materials (metals, wood, plastic, etc.). For this purpose, this system provides a machine park (CNC machines).

- Control of asynchronous electric motors. Their smooth adjustment is extremely difficult, and the CNC allows the use of “vector control”.

- Control of industrial robots.

- Management of peripheral devices for various purposes. Typical examples: 3D printers and scanners.

Some equipment is provided by centralized, automated workstations, where the desired program is installed via an industrial network. In this case, CNC allows you to control the operation of not just one machine, but the entire section, workshop (ABB Robot Studio, Microsoft Robotics Developer Studio).

Peculiarities

CNC machines have a number of attractive features:

- High level of automation. The operator only controls the process on the monitor. His participation in the process is kept to a minimum.

- Ensure repeatability. The equipment does not depend on the mood and physical condition of the operator. It produces identical products with consistent high quality for months, or even years.

- One operator is able to operate several machines.

- Flexibility. With minor changes in process parameters, adjustments are made to the program, and with significant changes, a new program is loaded. Such procedures do not take much time.

- Processing accuracy and repeatability. The program ensures the production of many identical parts with the highest accuracy.

- Using CNC machines, it is possible to produce products of complex shapes that can only be done by highly professional workers, and even then using special devices.

Important! CNC machines are versatile and can replace 4-5 simple machines. In this case, there is no need to look for experienced workers in a specific specialty; it is enough to train an operator of CNC equipment.

Classification

CNC machines are divided into several categories. This is reflected in the alphanumeric designation of the brand. The technological category is determined by the purpose of the equipment. It is determined by the possibility of carrying out basic operations. Main types: lathes (group number - 1), milling machines (number 6), drilling and boring machines (number 2), multi-purpose equipment (number 9). This number comes first in the marking.

According to the degree of automation, the following types are established:

- F1 - motion coordinates are set using the computer keyboard (one press - 1 frame of the program). A digital display device is provided.

- F2 - a portion or rectangular control system is used. The first is typical for drilling and boring machines, and the second is typical for milling and turning machines.

- F3 - a contour or continuous CNC system is installed. It allows you to process workpieces of almost any complexity.

- F4 is a multi-operational, combined CNC system. It combines the best qualities of the contour and positioning system.

- C - cyclic CNC. This is the simplest automated system for serial production of fairly simple, similar products.

Machines are also classified according to the method of changing the working tool. The labeling may include the following options:

- R – turret heads are used to change and fasten tools.

- M – a special tool magazine is installed, from where the necessary tools are automatically supplied.

The indicated marking indicates the presence of an automatic tool changer (ATC). In addition to the above modifications, the machines differ in the type of drive control: stepper, stepped, continuously variable.

Main settings

When choosing CNC equipment, main attention should be paid to the following parameters:

- Accuracy class. The permissible error can be determined by the markings: P - increased accuracy, B - high accuracy.

- Operating parameters. They are installed for each technology category separately. So for drilling equipment the maximum diameter of the hole is important, for milling machines - the size of the working area, for boring machines - the spindle diameter, for lathes - the dimensions of the workpiece, etc. Common to all types of equipment include: electric motor power, processing speed ( productivity), supply voltage (220 or 380 V), dimensions and weight of the machine.

- The number of simultaneously controlled coordinates and the accuracy of their setting. Modern machines provide 5-axis control.

Depending on the purpose of the equipment, other important parameters may be set that must be taken into account when organizing production.

Programming principle

The operation of a CNC machine depends on the NC. It can be based on the following programming principles:

- Manual method. The programmer creates the software part of the machine by entering digital information about the coordinates of movement of the working tool, obtained during manual movement. Many points are required, which delays the programming process. This method is used when there are only 1–2 CNC machines used for the manufacture of simple, similar products.

- Shop-floor – programming from the remote control of the CNC operating system. In this case, the program is compiled using a touch screen and a joystick on the machine stand. The latest machine models use an interactive mode.

- Programming using CAD and CAM systems. The CAD system (AutoCAD, Solid, Catia, Compass) allows you to construct an electronic drawing of the product, and the CAM system (SheetCam, Kcam. MeshCam, CorelDraw) based on it describes the tool trajectory. The graphic file is first converted to DXF, Exeilon, HPGL or Gerber format. The programming process is reflected on the screen. A Cl file is issued. To convert it into a form understandable for the machine, a special program (postprocessor or passport) is used. It provides commands in the form of G- and M-codes.

The program can be loaded onto the machine in finished form from external media (floppy disks, flash media, magnetic tapes, punched paper tapes). It fits in RAM, memory card, hard drive or solid state drive.

Design features

The functioning of the CNC system is ensured by the following main components:

- Operator console, input/output console. This design element is intended for entering the NC, setting process parameters, as well as manual control of the operation.

- Operator panel, display. Allows you to visually monitor the process and make adjustments to the program.

- Controller. This is a computer-type device for putting into operation the software, forming the trajectory of the working body, issuing the necessary commands, carrying out general control, carrying out diagnostics and additional calculations.

- ROM. This is a memory that allows you to store a program for a long time. Information from the ROM is only read.

- RAM. This RAM is intended for programs currently in use, as well as for short-term storage of information.

Industrial ready-made models, embedded devices based on microprocessors, a programmable logic-type controller, and an industrial computer can serve as controllers. The role of actuators is performed by servos and stepper motors.

Types of CNC machines

The most common CNC equipment includes milling and lathes, as well as multi-purpose units. They are selected taking into account what work is planned to be carried out and in what volumes.

Milling machines

CNC milling machines can be used only for milling or with extended functionality (drilling, cutting sheets, processing at different angles, forming grooves, etc.). Main varieties:

- Vertical milling machines. In them the spindle is installed vertically. May have bottom or top drive. Processing is provided on one side.

- Horizontal milling machines. The spindle is installed parallel to the base. The machine can perform all-round processing.

Both types of machines can have 1 or 2 spindles. Control is provided in 3–5 coordinates. According to the control method, the following options are distinguished: with positional, contour, combined control. Basic parameters of the machines: work table dimensions, milling depth, power, spindle speed, transmission type.

Among the design features, we should highlight the presence of a powerful frame, a body with stiffening ribs, a spindle with increased rigidity to eliminate vibrations, and high-precision guide rails. To increase productivity, ASIs are installed in the form of a turret-type spindle head or a tool magazine. A large number of different models are produced for processing wood, metal, plastic and other materials.

Turning

A CNC lathe uses cutters with replaceable inserts. The tool is mounted in a tool holder located in the caliper assembly. To carry out various processes, cassette-type tool holders with the ability to attach up to 12 different cutters are often used.

The most popular varieties:

- Centering machines. Processing is carried out by turning along the contour of the workpiece. Parts of cylindrical and conical shapes, as well as shaped products are manufactured.

- Cartridge machines. They can be used to process both the outside and the inside of the workpiece. Basic operations: threading, countersinking, drilling, turning to install flanges, discs, bushings and gears.

- Combined (chuck-center) machines. Combines the capabilities of both types.

- Carousel machines. They are necessary for processing large parts and irregularly shaped workpieces.

The design features of CNC lathes are: vertical or inclined layout, increased rigidity of elements, ASI system.

Multipurpose

Complex processing of parts is carried out on multi-purpose machines (machining centers) with CNC. For them, special mixed UEs are used. The machines provide the following operations: milling, countersinking, boring, cutting, threading and chamfering. They can belong to the drilling-boring or turning-grinding group.

Multi-tasking machines differ in types:

- Horizontal machines. They carry out one-sided processing of large workpieces.

- Vertical machines. Capable of processing from 3 to 5 sides using a rotating spindle.

Among the design features, the following stand out: the presence of tool stores for ASI, rotary tables for moving workpieces, devices for changing workpieces. Most often, high-torque electric motors with low inertia are used.

Making souvenirs

For many representatives of small and medium-sized businesses, their acquaintance with the capabilities of CNC began with the production of souvenirs. To start earning money, all you need to do is purchase a small desktop model and master the very basics of programming.

Making crafts on CNC machines provides the following advantages:

- Unlimited batch size.

Thanks to the high processing speed, small souvenirs literally “fly out” from under the cutter. You can send one batch of goods for sale and immediately begin producing completely different products. - Rapid reformatting of production.

Wood, acrylic artificial stone and other polymers are usually used to produce souvenirs. To switch from one product to another, simply download a new program. In most cases, you will not have to buy a new cutting tool. - Reliable imitation of handmade work.

Crafts made using CNC milling and engraving are distinguished by high detail, which puts them on a par with hand-made products.

There is a huge amount of free and shareware software with a design focus for creating control programs. Souvenir shops willingly accept products for sale, and they can also be sold online.

Why do you need a CNC router?

CNC milling equipment is universal and allows you to solve a wide variety of problems: from mass production of the same type of product, while ensuring high reproducibility of results, to the production of original products in one-piece quantities.

CNC machines are purchased both by industrial enterprises with large production volumes and by owners of private workshops that are more focused on producing unique products for individual orders. Milling cutters can process a wide range of materials, including metals, regardless of hardness, wood, plastic, rubber and much more, even paper. Drawings, logos, and inscriptions are engraved on it with special thin cutters.

Due to their high precision and performance, milling cutters are used in the following areas of activity:

Woodworking

In the production of doors and furniture, a CNC milling complex is an integral attribute. Using cutters of different types, on one machine you can cut the material to the desired size, make a groove, drill, trim, and engrave an image.

In addition, milling machines are widely used for the manufacture and processing of skirting boards, balusters, and other wood products. A variety of patterns are applied with high precision. In some cases, the ornament produced during processing cannot be reproduced manually.

Metal processing

CNC milling machines allow you to perform any technological operations used in metalworking, without regard to the strength of the metal:

- turning works

- engraving of metal surfaces

- grinding

- production of blanks according to specified dimensions

- thread cutting

- boring

- roughing and finishing

- application of relief images, and much more.

Design and architecture, prototyping

A CNC router allows you to create three-dimensional and flat logos, advertising and design objects, building models, elements of street architecture, bas-reliefs, and pseudo 3D panels. Objects can be made from various materials, including stone, glass, wood, etc. jewelry industry

CNC machines have no competitors in the field of gemstone processing. Manual labor cannot provide comparable productivity and accuracy. Jewelry milling machines allow you to perform the following work:

- engraving;

- creation of collectible coins;

- production of souvenirs;

- making wax molds.

Orthopedics

The production of dental prostheses using CNC milling machines makes it possible to achieve the most accurate correspondence of the product to the casts, therefore, in the field of dental prosthetics, equipment of this type is used quite intensively. Manufactured prostheses (bridges, implants, crowns) do not require long-term adaptation.

Mechanical engineering

Many machine components and parts are processed using milling machines. The work includes the manufacture of gears, bushings, processing of cylinders, including for internal combustion engines, and the like.

PCB milling

A specific task for machines with small working areas can be a profitable business. The control program includes only two types of operations:

- milling (removing the foil layer);

- drilling holes.

Relatively inexpensive and compact equipment can be placed in a garage, workshop, or private home. For large electronics manufacturing facilities, switching from electrochemical or chemical etching of printed circuit boards to milling provides the following advantages:

- reducing the number of operations in the production cycle;

- reduction in defect rate;

- no costs for disposal of galvanic sludge and used reagents.

Furniture manufacturing

Manufacturing cabinet furniture is one of the most promising types of small and medium-sized businesses. Portal-type machines and machining centers are used in this area. The range of products produced on such CNC machines includes:

- details of “boxes” made of chipboard and fiberboard;

- facades made of MDF;

- carved mirrors.

Contour processing, through milling, engraving, and hole drilling are performed in one control program without changing the base. The productivity of the installation depends on the size of the working field, power and spindle speed. There are multi-spindle machines capable of operating in copier modes or sequential processing with different cutters. A 3-axis machine is sufficient to execute most programs.

Most materials for furniture production are composites. For their processing, cutters made of hard alloys or high-speed steels with a ceramic layer are most often used. To solve specific problems, such as, for example, processing highly abrasive laminates, select tools with monocrystalline diamond or CVD coating.

Peripheral devices have a great influence on machine performance. Since the machine works primarily with sheet materials, a vacuum table is needed to quickly and reliably secure the workpiece. You also need a reliable aspiration system that will remove fine sawdust.

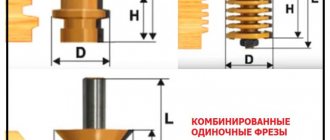

Types of milling cutters depending on the working material

CNC milling machines are designed for processing various materials:

- wood, MDF, chipboard, plywood;

- non-ferrous and ferrous metal;

- glass and plexiglass;

- plastic or acrylic.

To make the right choice, you should consider in detail the features of the equipment in accordance with the material intended for work.

Metal cutting

CNC milling machines for metalworking are distinguished by their robust design and high power.

To reduce wear or avoid jamming of the cutter, machines are equipped with a system for supplying coolant to the point of working contact. Water or machine oil is used as a coolant.

To automatically remove waste from the processed surfaces during the milling process, the machines are designed to install an air suction system. To do this, install the bell of a powerful industrial vacuum cleaner on special mounts.

The choice of a metal milling machine depends on the type of material and the task at hand:

- A desktop CNC metal engraving machine is used for milling and engraving items made of soft metals, such as brass.

- For rough and finishing processing of non-ferrous metals, a milling and engraving machine with a 3D function is suitable. It is used for serial work with cast workpieces, production of products from aluminum plates and sheets. To speed up the production process, it is possible to equip it with an automatic tool change system.

- For the production of advertising structures and 3D processing, the 2500 series is suitable, where there are 4 working field sizes for the X and Y coordinates to choose from.

- For cutting sheet metals, milling and 3D processing of aluminum and its composites (panels), the series 3000, 3200, 4000 (reinforced with higher productivity), 4400 (with 4D processing function) and 5000 (with automatic tool change) are intended.

The technical characteristics of CNC equipment for metal allow it to work with other materials.

Wood industry

General features of woodworking machines:

- Their design is simpler than that of metal milling cutters.

- Their price and maintenance costs are lower.

- They are easier to handle and repair.

- They have low requirements for power and strength indicators.

- Some models do not have a cutter cooling function.

- Automatic waste collection is not necessary since the operator can handle this task.

Such devices are used for the production of:

- decorative legs, balusters and slotted decor;

- facades for furniture and figured consoles;

- overhead carved elements;

- souvenirs, picture frames and photographs.

The choice of wood milling machine depends on the application:

To ensure the ability to process large parts, when manufacturing cabinet furniture, machines with large dimensions of the milling area are chosen (series: 3000, 3200, 4000, 4400 and 5000). Such devices differ in size and increased complexity of guides and frames.

To make shaped furniture, they use the technique of automatic cutting of patterns and 3D milling. Program-controlled installations provide increased clarity and speed of execution of complex elements.

A desktop milling and engraving machine can cope well with tasks such as producing small carved parts and engraving decors and bas-reliefs. Thanks to its compact size and shape, it can be used as home equipment.

The production process in this case is usually accompanied by a large amount of dust. To absorb it, a vacuum aspiration system must be provided.

To perform carpentry work (tenon-mortise joints, holes for locks, cutting contours, etc.), a CNC wood tenoning and slotting machine is used.

CNC equipment is widely used in factories and workshops in the manufacture of furniture, windows, doors, facades and decorative wood products.

Machines for plexiglass and plastic

These machines use cutters with carbide, corundum or diamond working surfaces. They come in two types:

- Sprayed.

- Whole sintered. They are characterized by high strength and durability. They are produced at high temperature and high pressure by baking diamond chips.

A prerequisite for working with such equipment is the supply of liquid to the point of contact of the cutter with the processing surface. It promotes not only cooling, but also the rapid removal of dust and fragments that interfere with the process and can ruin the workpiece if it gets under the cutter.

Don't miss: Metal milling cutter: design, types, principle of operation

For 3D milling, planar cutting and engraving, machines from the following series are used:

- 3000 (classic 3D machine),

- 3200 (assumes fast and frequent tool changes),

- 4000 (strengthened version of model 3000 with higher performance),

- 4400 (with 4D processing function),

- 5000 (with automatic tool change).

These machines are designed to work with the following materials:

- polyvinyl chloride,

- acrylic glass,

- polycarbonate,

- mock-up plastics,

- different types of fiberglass.

In addition, such equipment is capable of processing other hard materials and metal workpieces.

Woodworking

Solid wood is one of the popular materials for the production of volumetric carved products of high complexity: cabriole legs, balusters, columns, and entry posts.

Parts often have an asymmetrical shape and require 4- and 5-axis setups to process them. In practice, it looks like this: a mechanism for rotating the workpiece and/or a drive for tilting the spindle axis is installed on the portal milling and engraving machine.

It is worth noting that it is also possible to produce complex wood products on a CNC machine with three axes. This will require experience in creating control programs and ingenuity. The square workpiece can be turned over manually. For precise positioning, stops are installed on the table. In a 3D editor, 4 projections of a three-dimensional model of the future part are created and exported to a CAM system for writing a control program. If four revolutions are not enough, take a hexagonal blank and create 6 projections.

Jewelry production

Milling model wax, making molds and microengraving are not all that can be done with a CNC machine. Simple 3-axis models are often used to create cliches, die-cutting dies and other equipment for working with leather.

Complex work with jewelry materials requires the use of 4 and 5 controlled coordinate axes. To increase the processing accuracy, the jewelry CNC bed is made of cast iron, and the ball screw design uses two preloaded nuts.

MULTICUT machines – flexible configuration to achieve your goal!

Our company is considered one of the leaders in the production of coordinate units with numerical control. One of the basic advantages of our equipment is its configuration flexibility. The customer can independently select the spindle power, the design of the travel drives, other options, or entrust this to us. Experienced specialists will equip the machine in accordance with the range and production volumes.

We have developed seven series of milling and engraving processing centers and a universal tenoning and slotting machine for the manufacture of CNC wood products. Within the series, models differ in the dimensions of the working field.

With our machines you will solve the following problems:

- 500 - production of small souvenirs;

- 3000 - cutting, three-dimensional processing and engraving of polymers, composites, wood, non-ferrous metals and alloys;

- 4400 - complex milling and engraving work in 4 coordinates.

Employees of the company's design department are constantly working to improve the technological and software capabilities of the machine. This year we introduced our own CNC system, which set a new bar in the flexibility of controlling the working parts of the machine and optimizing multi-axis processing.

You can objectively evaluate the high class of our machines by testing them in the company’s showroom in Moscow. We will be happy to demonstrate their capabilities.

You can get advice on any questions regarding our equipment by calling our contact numbers during business hours.

Mechanical engineering

Everything that can be done on a CNC milling machine for metal is unlikely to fit into one article, so we will limit ourselves to a list of the main operations that are involved in the processing cycle:

- turning and boring;

- trimming;

- chamfering;

- drilling holes, including complex shapes;

- thread cutting;

- milling.

Stationary machining centers are used to produce new parts. But besides this, there is another area of application of CNC - repair and restoration of equipment. Non-standard solutions and mobile machines are very often used here.

As an illustration, we will describe a specific situation at a large metallurgical plant. The support bearing on the drive side of the converter collapsed and the seat was damaged. Replacing the damaged shaft required a complete shutdown of production for a long period. It was decided to restore the seat without disassembling the drive. After surfacing, the damaged section of the shaft was processed using a mobile CNC milling machine. A multi-insert end mill was used.

The non-standard nature of this solution was that the outer cylindrical surface is usually processed by turning, but in conditions of limited space, milling turned out to be the only possible method of restoration. The part remained motionless, and the machine portal rotated around its axis. The maximum deviations were only 20 microns with a diameter of 1150 mm.

Machine tools for mechanical engineering are distinguished by increased accuracy and a high margin of safety of load-bearing elements. They use powerful spindles and displacement drives.

Control and Connectivity

Unlike older machines, the TS1325 Prom does not involve a direct connection to a working computer and therefore there are no special places in the control cabinet to place it. Also, the control is divided between a remote DSP remote control capable of reading USB flash drives and the main controls/buttons on the top panel of the cabinet.

As we have already noted, the main control of the machine is the DSP remote control, and on the top panel of the cabinet there is a spindle speed controller, an inverter power button, an on/off key for the entire machine and an emergency stop button.

The spindle speed control panel contains the regulator itself, a set of indicators for the on/off and scrolling buttons. There is a digital display on top.

TS1325 Prom is equipped with a Richauto A11 DSP remote control, which is well known to us from previous reviews. Using the keys, you can program the movements of the working tool, adjust the spindle relative to the position of the workpiece, set local and global zero and carry out many more operations, including easy programming of machine actions. The main function can be considered launching a control task from a flash drive to the machine itself.

Dentistry

Dental prosthetics is one of those areas where the complexity of shapes and precision are achieved manually (with multiple fittings and intermediate adjustments) or using CNC. To create crowns and implants, highly specialized machines and cutters are used.

The task of the equipment includes complex milling of materials with a hardness of up to 60 HRC: press ceramics, wax, polymethyl acrylate (PMMA), chromium-cobalt-molybdenum alloys, zirconium, titanium and other biocompatible metals. In this case, the required processing accuracy is 5-50 microns.

To be able to do this, the CNC dental milling machine is equipped with a high-speed (50 thousand rpm and above) spindle with five controlled axes. The possibility of expanding the range of processed materials depends on the type of software architecture. With an “open” type system, you can switch to blanks from other manufacturers, as well as offer customers a wider range of dentures.

The equipment market includes tabletop models for dental offices and floor-standing units for large dental prosthetics centers.

CNC classification

The following software is used to control the operation of the machine:

- Positional - working parts move to points with specific coordinates. They differ in the accuracy of stopping at a given point.

- Contour rectangular (collinear) - moving elements move in a straight line. The speed is determined by the specified cutting modes, in turn for each coordinate axis. Making curved surfaces is not possible.

- Contour (continuous) - elements move in space along a predefined path, shape and end points. Volumetric parts of complex configuration are created.

- Adaptive (self-adjusting) - the work process automatically adjusts to speed, cutting force, and feed. The motor and feed drive automatically protected It is distinguished by high-quality processing and increased reliability.

Contour and adaptive controls are based on 4 and 5 coordinate systems, providing a complex trajectory of movement of moving elements. Processing is carried out along at least 2 axes simultaneously.

Conversion of a 3-axis machine into a 4- or 5-axis machine occurs by installing an additional rotary surface. At the same time, the work area is reduced.