The concept of vacuum metallization

Using this technology, product surfaces are processed by transferring small metal particles in a vacuum. They cover the products with a dense layer. For this purpose, special equipment is used, quite expensive, which requires a suitable production facility. In a small workshop, such a work process cannot be performed.

Vacuum metallization has become widely used relatively recently, but has already shown that this method, despite the use of expensive equipment, is much cheaper than galvanic coating, and compared to paint and varnish coatings, the layer is much richer and the surface is more beautiful.

Why should you contact us for chrome plating of parts?

The main advantage of contacting PKF START LLC is the quality of vacuum chrome plating work. This is achieved through the use of modern equipment and highly qualified specialists working on it.

A large fleet of vacuum installations, which are serviced by highly qualified specialists, as well as an optimized area for applying paint and varnish materials, allow us to freely compete with domestic and foreign companies offering similar services.

A wide selection of colors and a professional approach to any problem gives us the opportunity to work with the largest manufacturers of television and radio equipment, accessories, containers, packaging, perfumes, and sanitary products. technical products, dishes, souvenirs, consumer goods, etc. The company has developed and implemented new technological solutions.

What surfaces can it be applied to?

Using the method of vacuum metal deposition, you can coat objects made of metals, ceramics, glass, and plastics. At the same time, in contrast to galvanic application, to create the effect of glossy chrome plating, copper plating, gold plating, and nickel plating of surfaces, preliminary polishing of parts is not required.

Metallization methods are easiest to classify according to the technological methods for obtaining the coating.

In general, any materials that are resistant to heating up to +80 and the effects of special varnishes can be metalized in this way. And also, the materials should not be porous, so that during the metallization process in the vacuum chamber no atmospheric or other gas is released, which will lead to poor-quality coating. These include poorly processed ceramics, wood, and concrete. But even decorative coatings can be applied to them in this way, if they are first primed with special compounds.

Most often today, objects made of plastics and metals are processed in this way. This process only enhances their positive properties. Spraying is applied to metal surfaces of products consisting of various alloys. At the same time, protection against corrosion is created, the electrical conductivity properties of the metal change upward, and the appearance of objects improves.

Metallization of plastics makes it possible to produce beautiful, practical products from cheap raw materials. In the automotive industry, plastic parts are installed to reduce weight. Radiator grilles, housings, wheel caps and other parts that do not require increased strength are made from durable plastics and processed to resemble metal.

Cold spray equipment

There are two options for protecting metals from the negative effects of external and working factors - alloying and sputtering with vacuum equipment. That is, atoms of chemical elements are added to the alloy, giving the products the required characteristics, or a protective coating is applied to the base surface.

Most often in the metallization industry they use the technology of applying galvanic coatings, use methods of immersing parts in the melt, use a vacuum environment in processing processes, and use magnetron equipment.

Sometimes detonation gas spraying is used, which accelerates particles to incredible speeds. Plasmatrons, electric arc metallization, gas-flame processing, and ion sputtering are widely used. Industry challenges dictate their conditions, and engineers have faced the need to create inexpensive, easy-to-use equipment that can use the properties of heated compressed air.

The results of the experiments exceeded expectations, allowing us to solve the following problems:

- Heating of the compressed air in the chamber leads to an increase in pressure, which causes an increase in the rate of flow of deposits from the nozzle in installations.

- When metal particles are collected in a high-speed gas environment, they hit the substrate, soften and stick to it. And ceramic particles compact the resulting layer.

- The use of powder technology is suitable for metallization of ductile metals - copper, aluminum, nickel, zinc. After spraying, the products can be processed mechanically.

Thanks to the successful work of engineers, it was possible to create a portable device that allows metallization of coatings at all industrial enterprises and at home. Requirements for successful operation of the equipment are the presence of a compressor unit (or air network) with a compressed air pressure of five to six atmospheres and power supply.

The table below shows data for chrome plating aluminum at home. Before applying galvanic coating, it is necessary to “put” an intermediate metal layer on the part, and then spray aluminum.

Table 1. Chrome plating of aluminum

The use of advanced equipment for metallization of products makes it possible to solve technical issues related to increasing anti-corrosion, strength, and performance characteristics, as well as giving machines, parts and mechanisms the required properties for operation in difficult operating conditions.

https://youtube.com/watch?v=eivXKfNn-Rs

https://youtube.com/watch?v=ns7JRPRsJ3A

Equipment for vacuum metallization

This technology, like other equally complex ones, has its pros and cons:

Coating apparatus - diagram

- the need to use expensive equipment;

- high energy costs;

- the need for a spacious production facility to accommodate all devices and for the full technological manufacturing cycle.

Additional costs are required for the technical process of applying an additional layer - protective varnish.

Vacuum deposition installations are a set of devices that consistently and independently perform a number of functions necessary for the metallization process.

Main functions:

- pumping out air to obtain rarefaction conditions;

- spraying metal particles onto the surface of objects under certain conditions;

- transportation of processed parts;

- control of the modes of ongoing vacuum deposition processes;

- power supply and other auxiliary devices.

Components of a vacuum installation:

Vacuum conveying devices

- Working chamber. The metallization process itself takes place in it.

- A source of evaporated metals along with control and energy supply devices.

- Monitoring and control systems for adjusting temperature, deposition speed, film thickness, and its physical properties.

- Pumping and gas distribution system, providing vacuum and regulating gas flows.

- Working unit blocking systems, power supply units.

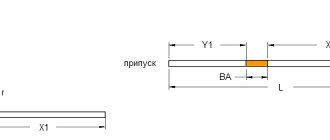

- A transport device that determines the supply and removal from the vacuum chamber, changing the positions of parts when applying a metal coating.

- Auxiliary devices – dampers, in-chamber manipulators, gas filters, etc.

Equipment Features

Magnetron sputtering process

Installations for the vacuum process of applying a metal layer are magnetron and ion-plasma. In any of them, it is necessary to achieve evaporation of the substance from the surface of the metal blanks, bypassing the stage of molten metal.

With the sublimation method, the heating process occurs quickly to the evaporation temperature, preventing melting. For this purpose, heaters are used that can increase kinetic energy up to the destruction of the crystal lattice. But some metals do not sublimate in a vacuum, and therefore the melt stage cannot be avoided with them. Therefore, in such cases, additional filter systems are used.

Using the method of vacuum deposition of a metal layer, products of different sizes are coated: large (up to 1 m) and very small. There are technologies for metal coating of multi-meter fabrics and films - they are rewound from one roll to another during the deposition process in a vacuum chamber. Therefore, there are installations with working chambers of different sizes:

- small - several liters;

- large - several cubic meters.

other services

Sputtering titanium aluminum nitride Sputtering titanium carbonitride Sputtering titanium nitride Ion sputtering in a vacuum Plasma sputtering in a vacuum Ion-plasma sputtering in a vacuum Magnetron sputtering in a vacuum Metal sputtering in a vacuum Sputtering of aluminum in a vacuum Sputtering of silver in a vacuum "

Plasmacenter" offers

- services for restoration of parts, coating, vacuum sputtering, microplasma sputtering, electric spark alloying, plasma processing, coating certification, titanium nitride sputtering, shaft repair, corrosion coating, protective coating, hardening of parts;

- supply of equipment for the processes of finishing plasma hardening, welding, soldering, surfacing, spraying (for example, gas-thermal, gas-flame, microplasma, high-speed and detonation spraying), electric spark alloying, control devices, powder dispensers, plasma torches and other equipment;

- supply of consumables such as welding wire, electrodes, welding rods, spraying powders, surfacing powders, additive manufacturing powders, surfacing wire and other materials for welding, surfacing, spraying, additive manufacturing and hardening processes;

- conducting R&D in the field of surface engineering, coating tribology, plasma processing methods, selection of optimal coatings and methods of their application;

- training, consulting in the field of surfacing, sputtering, hardening, modification, hardening.

Contact us by phone: +7 (812) 679-46-74, +7 (921) 973-46-74, or write to us by email.

Our managers will tell you in detail about the technologies we have for coating, hardening, restoring, imparting surface properties, as well as the cost of the company’s services.

Technological process

Vacuum metallization, based on the evaporation and precipitation of metal particles onto the substrate, is a series of sequential processes. They are quite complex.

When metal is heated, it undergoes a number of changes before becoming a coating. First, it evaporates, then is adsorbed, after which it precipitates as condensation and crystallizes on the surface, forming a metal film. Each process is quite complex.

The quality of the finished product is influenced by many factors. The main ones are the physical and technical characteristics of the workpiece materials and the maintained conditions of the metallization process. The formation of the coating layer occurs in two main stages. This is the transfer of mass and energy from the source and their uniform distribution over the surface of the workpiece.

Preparation for chrome plating

To chrome plating plastic with your own hands at home, you need to prepare the following materials and tools:

- a container of suitable size into which the dielectric solution will be poured, it can be a glass jar or a plastic bucket;

- electrolyte solution;

- a plastic bucket or plastic basin in which the container is placed;

- a box made of plywood or wood, which must first be insulated with fiberglass and insulated with mineral wool or sand - this is necessary for good thermal insulation;

- a special brush for applying the solution;

- heating element - an ordinary heating element is best suited for this;

- power source of the required voltage, power and current (transformer or car battery);

- a thermometer that can be used to measure liquids with temperatures up to 1000 C;

- a bracket necessary for freely hanging the workpiece in a container;

- a shield for tightly covering the container - this can be a sheet of plywood;

- clamp

Chrome parts

First of all, it is necessary to prepare a special electrolytic solution, without which the entire process is impossible. You can make it at home. To do this you will need the following ingredients:

- distilled water (the volume depends on the volume of the container and the size of the workpiece);

- chromic anhydrite (250 g/liter of water);

- sulfuric acid H2SO4 (2.5 g/l).

Regardless of the choice of method for chrome plating parts at home, you will need an electrolytic solution to carry it out.

To prepare the electrolyte, you need to add chromic anhydrite to distilled water, preheated to 600 C, and stir thoroughly, then add and stir sulfuric acid. We run an electric current through the resulting solution for 2–3 hours until it acquires a dark burgundy hue. We calculate the current strength based on the amount of liquid, it should be 6.5 A./liter of liquid. Let the prepared solution infuse for 24 hours.

Stages of vacuum metallization

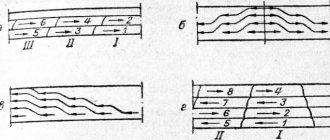

Metal deposition on the surface of products using the vacuum metallization method is carried out using a technology consisting of several stages:

Metallization goals

- The part is prepared for the coating process. For this purpose, only blanks of simple shapes that do not have sharp corners or areas that are difficult to reach for direct condensate ingress are suitable.

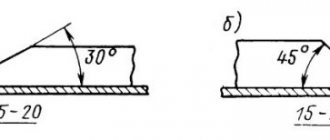

- The process of applying a protective layer. Polymers containing low-molecular fillers are preliminarily coated with layers of anti-diffusion varnish coatings.

- Drying and degreasing. The workpieces undergo the stage of drying the adsorbed moisture for three hours at a temperature of +80.

- The degreasing process occurs already at the preparatory stage in a vacuum chamber by exposure to a glow discharge.

- Annealing at this stage is especially beneficial for polymer materials - it has a positive effect on their structure, and the internal stress is reduced.

- Activation treatment is carried out before applying a metal layer to the surface to increase its adhesion. The methods used depend on the workpiece material.

- Application of metal coating. In this case, the coating layer is formed by condensation of supersaturated metal vapors onto the cold surface of the workpiece.

- Then a control check of the quality of the metal layer is carried out. For decorative products, it consists of inspecting the surface to determine the strength and uniformity of the layer. For technical details, additional tests are used. In practice, methods of peeling with adhesive tape, abrasion, destruction by ultrasonic vibrations, etc. are used.

Products after vacuum metallization

Magnetron sputtering

Coating in a vacuum using magnetron systems involves sputtering a solid target of the sputtered material with inert gas ions formed in the plasma of an anomalous glow discharge when a magnetic field is applied to it, the field lines of which orthogonally intersect the magnetic field lines.

The main elements of a magnetron are a target cathode, an anode and a magnetic system. The magnetic field lines are closed between the poles of the magnetic system. The surface of the target, located between the input and output systems of the magnetic field lines, is intensively sputtered and has the appearance of a closed path, the geometry of which is determined by the shape of the poles of the magnetic system. When a constant voltage is applied between the target (negative potential) and the anode (positive potential), a non-uniform electric field arises and a glow discharge is excited. The presence of a closed magnetic field near the sputtered surface of the target makes it possible to localize the discharge plasma directly at the target. Electrons emitted from the cathode under the influence of ion bombardment are captured by a magnetic field, and they are subjected to complex cycloidal motion along closed trajectories near the target surfaces. The electrons find themselves in a trap, created on the one hand by a magnetic field that returns them to the cathode, and on the other hand by the surface of the target, which repels them. The electron circulates in this trap until several ionizing collisions occur with atoms of the working gas, as a result of which it loses the energy received from the electric field. Thus, most of the electron energy, before it hits the anode, is used for ionization and excitation, which significantly increases the efficiency of the ionization process and leads to an increase in the concentration of positive ions at the target surface. This, in turn, leads to an increase in the intensity of ion bombardment of the target and a significant increase in the rate of coating deposition.

Areas of application

The technology of surface treatment using vacuum metallization is used in the production of many products:

- Plumbing fittings - bellows, flush buttons, etc. The most common metallization is aluminum, giving the products a chrome-plated appearance.

- Furniture fittings – handles for furniture doors and drawers, decorative finishing parts, clothes hangers, etc.

- Mirror coatings. Unbreakable mirrors are made by metallizing polymer films stretched over frames.

- Leather goods - belt buckles, buttons, eyelets.

- Packaging materials – caps for perfume bottles, cosmetic dispensers, decorative boxes for jewelry, etc.

- In the production of costume jewelry, decorative souvenirs and similar products.

- In the manufacture of heraldry items - coats of arms and other items.

- Radio electronics – TV dashboards, monitor covers, buttons, etc.

- Microelectronics – manufacturing of integrated circuits, semiconductors and other parts. Copper plating is usually used.

- Automotive industry - internal reflective part of headlights and many decorative parts on the outside and inside of the car.

- Lighting products – for decorating lamp parts.

Visually, you can make an imitation of any precious or semi-precious metal. Vacuum metallization gives products not only beautiful decorative properties, but also creates a protective layer against corrosion for metals and wear for other materials. Metallization of plastics allows you to create practical and beautiful products from cheap materials. Durable coating ensures long service life of products.

Target materials for metallization

First of all, metal blanks, which can be made from special alloys, are subjected to the procedure. Additional coating is required to provide an anti-corrosion layer, improve the quality of electrical wiring, or change decorative properties. In recent years, vacuum metallization has been increasingly used in relation to polymer products. This process has its own specifics, determined by the characteristics of the structure of objects of this kind. The technology is less commonly used for products that have low hardness values. This applies to wood and some synthetic materials.