When processing metal parts in a modest production space, it is very important to select functional equipment that will allow you to quickly and efficiently solve emerging problems. An excellent example of such a technique is a garage lathe. This small equipment provides the ability to perform not only turning, but also milling and drilling. Thanks to its small overall dimensions, modest electrical energy consumption and low noise, the lathe from Metal Master occupies one of the leading positions among similar equipment presented on the domestic market.

General design and purpose

The main element of a lathe is the spindle. It rotates with the workpiece, and the cutting tool moves due to transverse or longitudinal feed. Each machine has a different spindle speed range. The more speeds, the higher the performance of the equipment.

Other components of the lathe:

- The bed is the basis of the equipment on which all the mechanisms are located.

- Front headstock - the spindle and gearbox are located inside, a three-jaw chuck is attached to the outside.

- Tailstock - a center is inserted into it for additional fixation of the workpiece, drill, reamer, countersink.

- Caliper - a carriage with a tool holder is installed on it, which rotates at different angles depending on the task being performed.

- Feed box - provides different speeds of movement of the cutting tool.

Reference!

The standard components of universal machine tools were listed above. The unit may be equipped with additional accessories depending on the specific modification. List of basic turning operations:

- Trimming and end processing.

- External turning to the required diameter.

- Boring holes.

- Processing of internal and external conical surfaces.

- Drilling holes.

- Cutting internal and external threads.

- Turning internal and external grooves.

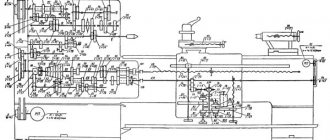

Lathe device

In order to choose a lathe, it is advisable to know its structure, purpose, functions and possible parameters of each part. First, let's look at the main components.

- Base or bed. Preferably a heavy, cast iron stove. Even desktop models. Very light machines will be unstable, making even acceptable accuracy difficult to achieve.

- Engine and gearbox. The engine can be powered by 220 V or 380 V. Gearbox is a device for ensuring rotation of the spindle and support (on automatic and semi-automatic machines). The machine will last longer if the transmission gears are made of metal (some are plastic).

- Headstock. The main function is reliable fixation and rotation of the workpiece. Usually this is a massive metal cylinder, rigidly fixed in the body. Sometimes the headstock and gearbox are combined; in some models, the headstock can move the caliper or machining head.

The device of a metal lathe - Tailstock. This part is also necessary for reliable fixation of parts relative to the spindle. It is rarely used when processing small parts, more often with long or massive ones. In some models, additional equipment can be mounted on the tailstock - a cutter, drill, etc. - for the possibility of processing on both sides without changing the position of the part.

- Caliper. This is a whole unit, the design of which determines the list of operations performed by the machine. The support holds the cutting tool, shifting it when processing a part in several planes at once (the simplest ones - only in one plane). Can be controlled automatically or manually.

These are the main components of a lathe. It makes sense to take a closer look at complex components, since the capabilities and operation of the equipment depend on their execution.

bed

Most often these are two parallel massive metal beams/walls connected by cross members to provide greater rigidity. The caliper and tailstock move along the frame. For this purpose, guide slides are machined on the frame. The tailstock moves along flat guides, the caliper moves along prismatic ones. Prismatic guides for the tailstock are very rare.

Bed for a metal lathe - factory and homemade

When choosing a used machine, pay attention to the condition of the slide and the smooth movement of parts along it.

Front (spindle) headstock

The headstock in modern lathes most often combines a workpiece holder and a device for changing the spindle speed. There are several types of rotation speed control - by moving the levers to a certain position, using a regulator.

Headstock device

The controller with a smooth change in rotation speed is controlled by a microprocessor. In this case, there is a liquid crystal display on the headstock body that displays the current speed.

The main part of the headstock is the spindle, which on one side is connected to the electric drive pulley, on the other has a thread onto which chucks are screwed to hold the workpiece. The accuracy of turning work directly depends on the condition of the spindle. There should be no beats or backlash in this unit.

Guitar of gears - for transmitting rotation and changing its speed

The headstock contains a system of replaceable gears for transmitting and changing rotation to the gearbox shaft. When choosing a lathe for your garage, pay attention to the condition of the gears and the absence of spindle play. The accuracy of workpiece processing depends on this.

Tailstock

The tailstock is movable - it moves along guides on the bed. It is brought to the part, its position is adjusted, the quill rests on the part, holding it in the desired position, the position of the quill is fixed by turning the corresponding handle. After which the position of the tailstock is secured with another locking handle.

In some models, the tailstock is designed not only to support massive or long parts in a given direction, but also to process them.

Tailstock device of a lathe

To do this, depending on the operations performed, the corresponding equipment is attached to the quills - cutters, taps, drills. The additional center of the machine on the tailstock can be stationary or rotating. The rotating rear center is made on high-speed machines for removing large chips and turning cones.

Caliper

A lathe support is a moving part on which tools for processing parts are mounted. Thanks to the special design of this unit, the cutter can move in three planes. Horizontal movement is ensured by guides on the frame, longitudinal and transverse slides.

Caliper device

The position of the cutter relative to the surface of the machine (and the part) is set by a rotary tool holder. In each of the planes there is a lock that ensures retention in a given position.

The cutter holder can be single or multiple. The tool holder is most often made in the form of a cylinder with a side slot into which a tool is inserted and secured with bolts. On simple machines, the support has a special groove into which a recess on the bottom of the holder is inserted. This is how the cutting tool is fixed on the machine.

Varieties

There are many types of lathes. Before purchasing, it is important to familiarize yourself with the features of each type in order to make the right choice.

Find out why the LT-10M universal lathe is so good

Tabletop for home workshop

A small machine is fixed on a special table. It is lightweight and small in size, but allows you to perform a large number of operations. In addition to external processing, drilling and boring can be performed. Its advantages are low cost and energy consumption. There is almost no noise during operation.

Household, miniature (mini), small-sized

The weight of such machines often does not exceed 50 kg, but the technical characteristics of many models are not inferior to large-sized analogues. The bed is made mainly of cast iron - this reduces vibration during operation. The working diameter of the chuck is 50–100 mm, the spindle speed is 100–3800 rpm, and the motor power varies from 0.55 to 2.25 kW.

Screw-cutting

A common group of lathes of various modifications. They were popular back in Soviet times in large industries. They differ in dimensions, length and diameter of the processed parts. Modifications 16K20, 1K62 are often found in factories.

Lathe for the garage - features and benefits!

- Simple operation that does not require special skills from the worker. It is enough just to know the basics of metal turning, and you will be able to begin performing the required operations;

- Ergonomic 3-jaw chuck protection, steel gear mechanism, induction-hardened bed guides. The proposed equipment is durable and wear-resistant;

- At the end of the spindle head cover there is a table indicating the selection of cutting modes. This will allow you to competently approach the solution of emerging production problems;

- The presence of a digital spindle speed indicator, which is located on the control panel of the milling head;

- The milling and drilling part of the machine is highly rigid. Reliable protection from the destructive effects of industrial vibrations.

The machine is an ideal solution for working with small workpieces. It will allow you to complete the necessary operations as quickly as possible. The presented models are equipped with economical asynchronous motors that have increased wear resistance and are protected from possible overloads. To install the machine, experts recommend using a workbench or stand, which makes it possible to adjust the height of the workpiece.

Work with the equipment in question is carried out using standard cutting tools (no need to purchase special expensive equipment). In order to be able to process workpieces of considerable length, you can use a movable and fixed steady rest. Each machine is made in full compliance with European quality standards and meets the required electrical safety standards.

Review of modern manufacturers

The production of lathes is represented by Russian and foreign manufacturers. Germany and Japan are the leaders in the global metalworking equipment market.

They produce various modifications of lathes, accessories and spare parts, and also work with individual orders.

Brands:

- Siemens.

- Vollmer.

- Okuma.

- Yamazaki Mazak.

Reference! No less popular is the equipment of the Chinese company Jet. The manufacturer offers both desktop and industrial machines.

Current Russian manufacturers:

- Moscow plant Red Proletarian.

- Ulyanovsk plant of heavy machine tools.

- Baltic Engineering Company.

Metal Master company is a supplier of reliable metalworking equipment!

For 20 years, we have been supplying high-quality metalworking equipment to the Russian market. Among the wide range of machines, you can choose professional equipment or a mini lathe for the garage.

- Our clients were able to appreciate the machines we sell and this is confirmed by numerous positive reviews;

- The offered metalworking equipment is manufactured under the strict control of enterprises from Russia, the USA and Europe. A wide selection of machines that have been carefully selected from the best manufacturers from around the world;

- In order to obtain the necessary information, you can always contact our company’s technical specialists, who are highly qualified. Call the phone number provided on the website;

- If you need to evaluate the operation of the machine in order to understand how accurately it will correspond to the realities of your production, then visit our demo room - this guarantees that the choice you make will not disappoint you in the future;

Equipment delivery is carried out in a short time to any point in Russia. Free delivery is carried out to the transport company.

What cheap used machines can you find, how much can they cost, price

You can find various models of Soviet-made lathes relatively inexpensively. Universal equipment 16T04P, 1K62, K-162, 16K20 is sold in the range of 100–150 thousand rubles. The average price of used desktop models is 28–35 thousand rubles.

Important!

You cannot be guided only by the declared characteristics and photographs of the equipment. It is better to inspect the equipment in person and check the operation of all mechanisms.

Recommendations for choosing a lathe

Price issue

. The place to start when looking for a lathe is your budget. Since there are many professional models on sale, with the help of the upper price bar it will be possible to cut off complex, high-performance equipment for metalworking plants. However, it is important to consider the functionality and completeness of the package. Otherwise, purchasing additional devices and equipment will cost a pretty penny.

Weight and dimensions.

Depending on the installation location of the lathe, the weight of the model and its overall dimensions are selected.

- The heaviest floor-mounted machines weighing more than 100 kg are intended for stationary use. They are characterized by good stability and processing accuracy.

- Mobile models are lightweight (30-80 kg); they can be installed on a table or workbench or moved to other rooms. Such models are not highly accurate, but are simple and easy to use.

engine's type

. All lathes are equipped with electric motors.

- Motors with a voltage of 380 V have the maximum power (up to 5 kW). But not all consumers have a power supply, which makes the scope of application limited.

- Models with 220 V motors have an affordable price and a wide range of applications. But such engines require smooth feeding, since they have a small power reserve (up to 1.5 kW).

Spindle speed adjustment.

Depending on the operation being performed, the turner selects the optimal operating modes of the machine. To achieve this, manufacturers equip their products with smooth adjustment of spindle speed. Typically the upper limit reaches 3000 rpm. Unfortunately, many household models with 220 V engines do not allow processing metal at low speeds (300-500).

The size of the workpieces.

When choosing a lathe, you should know the size of the workpieces being processed. First of all, it is important to take into account the maximum diameter of metal semi-finished products. Serious equipment can handle workpieces with a diameter of up to 350 mm when working on the bed and up to 200 mm when working on the support. For household models, these indicators look more modest.

Control

. To obtain a part, it is not enough just to turn on the lathe. You need to learn how to manage it.

- The simplest budget models are equipped with mechanical controls; the feed amount is determined on a metric scale.

- More modern models are equipped with a digital spindle speed display and automatic feed (longitudinal and/or transverse). These functions make the turner's work easier.

Main selection criteria

The machine is a long-term and expensive purchase. For occasional use, a home desktop machine will suffice. For constant work in a garage or workshop, it is better to look at an industrial model.

What to pay attention to when choosing:

- Spindle diameter - determines the maximum diameter of the bar.

- The bed - the more massive and heavier it is, the fewer errors in processing.

- The height above the frame and support - the maximum diameter of future products depends on it.

- The distance between centers is important if you plan to process long shafts.

- Possibility to use additional equipment that increases functionality.

- Automatic caliper feed.

- The weight of the unit is enough for a workshop to be up to 80 kg.

- Manufacturer - if possible, it is better to buy Russian models in order to avoid problems with finding spare parts in the future.

Reference! You need to focus on the above parameters based on your work needs.

Bottom line

When choosing a metal lathe for your garage, you should pay attention to several factors. First of all, the dimensions and weight of the equipment are important. Tabletop units are perfect for a garage space.

Despite their light weight, they act as a mini copy of a full-fledged factory model and allow you to perform the necessary work efficiently. The only difference is the processing speed of the part.

Also, you should not buy the smallest model, as this may affect the stability of the garage machine and cause vibration during operation. When choosing, be sure to pay attention to the power of the unit, its functionality, materials, components, speed and type of connection.