The operating temperature range must be taken into account when designing, manufacturing and operating rubber seals. Information on the maximum operating temperatures of rubber given in technical literature and specialized reference books is based on a fairly long service life. However, it should be noted that some fluids degrade below the maximum elastomer temperature limit, so the seal system must consider the temperature limits of both the seal itself and the working fluid. If the compatibility of the seal material with the working environment is unsatisfactory, an increase in temperature significantly reduces its reliability and service life. Loss of tightness at low temperatures can also be associated with the chemical action of the liquid, causing shrinkage of the rubber sealing ring or cuff.

Natural rubber

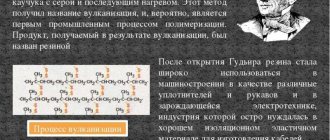

The sap of rubber trees was widely used by the aborigines to make waterproof shoes, cover boats, protect huts from rain and solve other everyday problems. They extract it from rubber plants in a similar way to collecting birch sap in the spring. Polyisoprene, the carbohydrate that makes up most of natural latex, combines with oxygen in heat and becomes brittle over time. After heating, the molecular bonds become stable, and the substance does not react even to acidic solutions.

The value of rubber based on technical characteristics:

- high resistance to abrasion;

- good thermal insulation properties;

- does not dissolve in water and most aggressive liquids;

- plastic;

- elasticity.

The addition of plasticizers and river sand allows you to create a material with the planned qualities and color. Raw rubber is transformed into a product that retains its shape for a long time through vulcanization - heating under pressure to a temperature of 150 degrees.

1.6. Rubber and caoutchoucs (plugs and hoses). Part 1

Rubber is a product of vulcanization of rubber, which has the ability to undergo large, reversible deformations. The operating temperature of ordinary rubber ranges from -50 to 150 °C. Heat-resistant rubbers can withstand temperatures up to 200 °C, and frost-resistant ones up to -150 °C.

The thermal destruction of rubber is greatly accelerated in the presence of oxygen and other oxidizing agents. At temperatures below -20 °C, ordinary rubber becomes brittle. At temperatures below +70 °C, it is not affected by concentrated aqueous solutions of bases and acids, except sulfuric and nitric. Rubber is destroyed by oxidizing agents such as hydrogen peroxide, halogens, and aqueous solutions of alkali metal dichromates and permanganates.

Rubber swells in organic solvents and is capable of dissolving gases in noticeable quantities, especially such as SO2) NH3, H2S, CO2, N20, CH4, O2, CO and N2, and to a lesser extent H2 and He. These gases slowly penetrate the rubber. It is also permeable to water vapor, so its use in vacuum technology is limited.

Rubber ages in an O2 atmosphere and in light, and its surface first becomes sticky and then brittle, after which the rubber cracks.

Organosilicon rubber (siloxane, silicone rubber) is a polymer (-R2SiO-)n. This rubber is more thermally stable than rubber made from natural or synthetic rubber. The service life of products made from organosilicon rubber in air at 120 °C is 10-20 years, and at 200 °C - 1 year. However, the gas permeability of this rubber is tens of times higher than that of natural rubber. Silastic LS-53 (methyl-3,3,3-trifluoropropyl silicone rubber) is even more heat-resistant and does not lose elasticity in the temperature range from -68 to +205 °C.

Silicone rubber is stable in most acids, except hydrofluoric and concentrated nitric and sulfuric acids. The polymer is gradually destroyed by concentrated aqueous solutions of KOH and NaOH, swells and dissolves in CCl4, CHCl3, ethers and esters, and hydrocarbons.

Organosilicon rubber is resistant to atmospheric oxygen, and when burned, it releases SiC2 and a large amount of energy in the form of heat. At temperatures below -50 °C the polymer becomes brittle.

Viton-A (fluorel) - a copolymer of vinylidene fluoride with per-fluoropropylene - is one of the most heat-resistant rubbers, operating in the temperature range from -44 to +315 ° C. Even at 315 °C it retains elasticity for 24 hours, and at 200 °C for 2400 hours. Viton is resistant to oils and organic solvents. All these materials, but mainly rubber, are used to make hoses, plugs, gloves, aprons, etc.

Rubber stoppers are used in cases where the substance in the container being closed does not affect the rubber and does not cause it to swell.

Before use, new rubber stoppers are heated in a 2-5% aqueous solution of KOH or NaOH, and then in clean water and stored in a closed dark glass container.

To protect plugs from hardening and cracking during long-term operation at temperatures of 80-100 ° C, they are impregnated with paraffin. The plugs are immersed in molten paraffin (“100 °C) for 30-60 s, and then placed in a porcelain cup in a drying cabinet heated to 100-105 °C. Paraffin gradually dissolves in rubber and maintains its elasticity.

In addition to regular rubber stoppers, some companies produce hollow stoppers with internal pockets. In particular, (USA) produces rubber stoppers with two pockets (Fig. 5, a). These stoppers are used to close ampoules, tubes and test tubes. The septum is used for sampling using a syringe without opening the vessel. The upper pocket can be closed with a glass or polymer stopper for tightness. Similar plugs are also used to connect glass tubes of different diameters, after first cutting out the partition or drilling it. In the latter case, it will act as a diaphragm.

For a more reliable and airtight fastening of the rubber stopper 3 (Fig. 5, b) with a glass tube in the neck 4 of the vessel, use a piece of rubber hose 2, pressed in the upper and lower parts to the tube and neck of the vessel with copper or aluminum wire 1.

Rice. 5. Stoppers for vessels: rubber (a - c), glass (d), fluoroplastic (th) and polymer, insulating from air (e):

e. 1 - bakelite cover; 2, 4 — fluoroplastic gaskets; 3 — aluminum clamping plug; 5 - neck of the vessel with thread

The destructive effect of the vapor of certain substances on the rubber stopper 1 is prevented by using a thin film of fluoroplastic or polyethylene 2 (Fig. 5, c), which simultaneously insulates the stopper from the walls of the vessel. The film is preheated in boiling water, then inserted into the neck of the vessel and pressed carefully with a stopper.

Rubber and polymer tubes (hoses) that have not yet been used should be rinsed with clean water or a diluted aqueous NaOH solution before use. If chlorine or acidic gases (HCl, SO2, etc.) were passed through a rubber tube, then after work it must be washed with water, then with a solution of sodium carbonate and again with water. Otherwise, small cracks will form on the inner surface of the tube.

The rubber tube through which mercury will move should be pre-treated for 1 hour with a 20% aqueous solution of NaOH heated to 70 °C, and then with warm clean water. This treatment allows you to remove sulfur from the surface layer of the rubber tube, which interacts with mercury. The mercury in a cleaned hose remains shiny even after using it for a year.

When putting a rubber tube on a glass one, lightly moisten the latter with water or glycerin. You cannot lubricate the rubber tube with any oils, as this will cause the rubber to swell and become less elastic.

Before putting it on the glass tube, the end of the polyethylene or PVC hose is immersed in hot water, which makes it more elastic and easy to put on the glass tube. When working with vacuum or pressure, glass tubes should be connected to each other end-to-end whenever possible. A thick-walled vacuum hose must strictly fit in size to a glass tube, equipped at the end with a series of contractions and expansions (“olive”, see Fig. 52, d). The vacuum hose must be pulled onto the tube by at least 2-3 cm, having previously lubricated the end of the tube with a thin layer of silicone oil or anhydrous glycerin, to which up to 30% talc is added. This prevents the hose from sticking to the tube.

When using hoses made of polymeric materials, one must not forget that organic solvents wash out plasticizers from them (with the exception of fluoroplastic hoses) and the hoses become hard and brittle over time. The advantage of such hoses over rubber ones is their transparency and higher chemical resistance.

Rubber tubing should be stored in a cool, dark place and in a humid atmosphere. They oxidize more easily in the light, especially if they are in boxes made of resinous wood, which emits traces of ozone. In such boxes, rubber tubes become completely unusable after a month. It is best to store rubber hoses in an aqueous solution of glycerin (100 ml of glycerin in 1 liter of water) or in a solution of Ca(OH)2, or at least in clean water.

In addition to rubber, chemical vessels are closed with glass stoppers and stoppers made of polymeric materials.

Glass stoppers (see Fig. 5, d) are an integral part of the vessel and are always ground to its neck. In order not to confuse the plugs, the same numbers must be put on them and on the vessels. When the vessel is not filled with anything, a strip of filter paper is placed between the stopper and the neck of the vessel so that the stopper does not jam, and when storing volatile substances, the ground part of the stopper is lubricated with Vaseline or silicone oil.

When storing a vessel with a particular substance for a long time, the glass stoppers often become jammed. To remove such a plug, you should first of all try to rotate it around its axis or swing it, pressing it from the side, now to the right, now to the left, carefully tapping it with some wooden object. This way you can almost always remove stuck plugs. If this technique does not produce results, you should carefully heat the neck of the vessel on a small smoky flame of a burner, candle, or match.

or under running hot water, rotating the vessel. (If there is a flammable substance in the vessel, then the neck is heated only with hot water.) The heating should be short-term so that only the neck of the vessel is heated, and not the stopper itself. After such heating, the throat expands somewhat, and when tapping on the side, the cork can be removed.

When the substance has crystallized in the thin section, the vessel is placed with the stopper down in warm water for an hour or two. After this treatment, the cork is usually easily removed. It is possible to remove a plug that is severely stuck only with sufficient patience.

Alkalies and their aqueous solutions should not be stored in containers with glass stoppers. Plugs from such vessels are often not removed by any of the above methods.

Stoppers made of polymeric materials (fluoroplastic, polyethylene and polypropylene) are very convenient for closing glass vessels. These plugs never jam in throats, they are more chemically resistant and create a reliable seal.

For ease of removal from the neck of the vessel, some fluoroplastic plugs are equipped with a threaded rod and a round nut with a notch (see Fig. 5, e). By tightening the nut resting on the upper edge of the neck of the vessel, you can safely remove the stopper without shaking the contents of the vessel.

For hermetically sealed long-term isolation of a substance from the effects of oxygen and air moisture, composite polymer plugs are used, the design of which is shown in Fig. 5, e.

Drilling of rubber plugs is carried out using a set of hand drills (Fig. 6, a), which are thin-walled metal tubes with a handle or hole at one end into which a rod is inserted. The other end of the tube is sharpened. To sharpen the tube, it is placed tightly on the conical part of a special knife (Fig. 6, b), the knife is pressed with the thumb of the left hand to the drill, and the drill tube is turned with the right hand around the cone (Fig. 6, c), without pressing hard on the knife, otherwise, the drill may become nicked. For the drill point, you can also use a block or file with a fine notch. In all cases, only the outer part of the drill is sharpened.

Other parts:

1.6. Rubber and caoutchoucs (plugs and hoses). Part 1

1.6. Rubber and caoutchoucs (plugs and hoses). Part 2

To contents

Insulation tape

Insulating electrical wires with electrical tape does not lose its relevance. Insulating tape is inexpensive and is sold at any hardware store in a wide variety.

It must be wound at an angle, starting from the edge of the original wire insulation. With a parallel connection, an empty winding tube is made at the end of the twist, bent and continued movement in the opposite direction.

Common PVC insulating tape melts when exposed to high heat, but does not allow moisture to pass through. Cotton insulating tape, on the other hand, can withstand high temperatures, but dries out over time and can peel off when wet.

PVC is also used to make cambrics - tubes for insulating wires and cables. In order for the tube to fit tightly, you need to choose the correct diameter of the tube.

How to properly insulate twisted wires, watch the video:

Silicones and rubbers

Unlike conventional rubber materials, which during long-term use undergo destruction already at +150 ℃, non-flammable products can withstand +180 and even + 280 ℃.

Heat resistance of this level significantly expands the scope of application of non-flammable rubber. There are many products that have the properties of rubber, but only two types are considered heat-resistant - silicone polymers and fluorinated rubbers.

Heat-resistant materials have the following advantages:

- inertness towards most chemicals, including aggressive substances;

- preservation of properties in a vacuum, magnetic field, under the influence of ultraviolet and radiation;

- possibility of long-term operation at high temperatures.

Silicone products are additionally characterized by environmental friendliness and absolute safety. All heat-resistant food rubber is organosilicon polymers. Its safety is confirmed by the results of repeated tests and international certificates.

Heat-resistant fluorinated rubber, when heated above 300 ℃, can release carcinogen vapors. The danger of evaporation of toxic substances remains even after the polymer has cooled.

Therefore, accompanying recommendations for the use of heat-resistant fluorine rubbers necessarily contain the requirement not to exceed the operating temperature above 300 °C.

The heat resistance of silicone products is slightly higher. Special types can retain properties at +400 ℃.

Raw Rubber Components

Natural and synthetic rubber, when heated to 50 degrees, turns into a soft mass that mixes well with other components:

- gray;

- gas soot;

- sand (silicon dioxide);

- oils;

- resins;

- dyes;

- softeners;

- accelerators.

The composition of the components varies and depends on the qualities that the resulting raw rubber must have. Sulfur is part of molecular compounds, and the hardness of rubber depends on it. Accelerators reduce vulcanization time. Soot and oil impart plasticity to the finished product. Sand and other organic substances make it harder, reduce abrasion, and increase tearing force.

Mechanical and physical properties of shoe rubber

It is known that all types of rubber under the influence of oxygen, ozone, heat and light are capable of aging with changes in mechanical properties. The destruction of rubber usually occurs under the influence of several causes acting simultaneously, and the main reason causing the aging of rubber is their oxidation, which during their storage and operation is activated and accelerated under the influence of not only heat and light, but also mechanical deformations (static and especially repeated ).

With intensive aging of a material, indicators of its consumer properties, characterizing the quality immediately after release from production, can no longer serve as a guarantee for its normal operation.

It should be taken into account that after the release of the material from production before the start of use of the product made from it, a significant period of time passes, and shoes are worn for a long time in different climatic conditions.

There are known cases of sudden aging of shoe rubber during storage and wear, which leads to breakage of the soles in bundles when shoes are worn or to the formation of small external cracks along the entire surface of the sole, as well as in places of fastening (with a nail).

When the extensibility of the sole decreases and the hardness increases without changing the amount of deformation of the outer layer during bending, as happens when wearing shoes, the stresses may become higher than permissible, and cracks will appear in the sole. Therefore, aging is more dangerous for less tensile hard type rubbers, such as screw and nail rubbers.

To test rubber for thermal aging, it is kept at a temperature of 70 ° C in a thermostat for 72 hours (GOST 271-53).

During light aging, rubber is exposed to quartz lamps, and during “light weather” - solar insolation in the open air.

The aging indicator is the ratio (in %) of the loss of strength and elongation during testing to their values before the experiment or a decrease in the number of deformations during repeated bending to fracture.

Shoe rubbers based on synthetic rubbers during thermal aging usually increase tensile strength and hardness, but reduce elongation, unlike rubbers made from NC, in which strength also decreases.

Obviously, in rubbers made from synthetic rubbers in this case, simultaneously with the destruction of the rubber, i.e., a decrease in the length of the chains, its structuring also occurs with an increase in cross-links, which is not observed in rubbers made from NC.

During light aging of rubber made from synthetic rubbers, the same changes in indicators occur as in rubber from NC during thermal aging. In this case, it is primarily the outer layers exposed to light that undergo aging, which become harder. It is known from the literature that the rate of aging of rubber increases greatly when it is deformed. Therefore, aging tests are also carried out in a stretched or bent state (GOST 271-53).

It was found that when exposed to light weather on screw rubber in a bent state, surface cracks appeared on the side stretched from bending, primarily on those samples where there were similar cracks on the soles of worn shoes.

Although artificial aging indicators are not included in GOST and TU for shoe rubber, they are used in the development of new types of rubber, especially for critical types of footwear that are worn in difficult conditions.

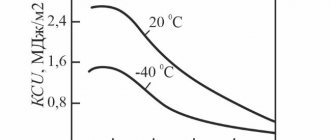

In addition to studying changes in the properties of materials over time under different conditions, indicators of their properties at low and high temperatures are of great practical interest for determining quality, since shoes are used in different climatic conditions, and in some cases (work shoes) at high temperatures, for example in hot shops at metallurgical enterprises.

It was found that a change in the properties of rubber occurs after 5-10 minutes of heating or cooling and is completely reversible with short-term exposure. The breaking stress for all tested materials decreases with increasing temperature. Relative elongation increases within temperatures from -50° to +20° C. In the future it also decreases (Fig. 14). The reduction in elongation is especially strong for colored porous rubber.

Rice. 14. The influence of temperature changes on the properties of rubber: 1 - stress at break of screw rubber, 2 - the same, porous rubber, 3 - elongation at break of screw rubber, 4 - the same, porous rubber.

At low temperatures, black microporous rubber showed good properties, which, even at -58 ° C, still had about 180% elongation at break, which was about 50% of the elongation at a temperature of 20 ° C, and almost did not increase hardness.

Sole leather, plastic leather and dense rubber, even at -45° C, show a significant increase in rigidity and give cracks and breaks when bending.

Colored porous rubber, although it greatly increases its rigidity, does not cause kinks or cracks. Thus, the structure (porosity) in this case has a greater effect on the frost resistance of the material than its formulation (chemical composition).

- Back

- Forward

Low-pressure polyethylene

Each type of material has special qualities. This expands the range of applications that polyethylene has. Melting point (high density) is 120-135 °C. Some brands have a heat resistance of 110 °C. High molecular density improves thermal and impact resistance.

In addition to the listed qualities, low-density polyethylene is less susceptible to chemical influences. However, the excessive density of molecules at low temperatures makes the material brittle and becomes permeable to vapors and gases.

This type of material has good dielectric characteristics. It is biologically inactive, but is easily processed in industrial production.

Types of rubber

Based on hardness, there are three main groups:

- soft – latex;

- average;

- hard – ebonite.

The natural component has the best performance qualities, which is why car tires are made from natural rubber. In small enterprises, rubber production involves cheaper synthetic material.

Latex is used to make gloves, toys, various insulating materials, waterproof clothing, and shoe soles. Medium density rubber is widely used in everyday life and in production. These are all kinds of gaskets in taps, mats, couplings in cars and mechanisms. Ebonite is used to make parts that require high hardness and abrasion resistance. These are elements of bearings, wheels, bushings.

Heat shrink tubing

Heat-shrinkable tubes are made from polymers (PVDF, PET, silicone and others). They are used mainly on low-voltage equipment, when the DC voltage does not exceed 1 kV.

If you want to use heat shrink for wires, then you need to perform a number of steps.

- Cut off a piece of heat-shrink tubing that completely covers the exposed section of the wire (connection), with a margin of about 2 cm.

- Then you need to put a tube on one of the ends of the wires to be connected.

- Twist the conductors.

- After this, the tube is moved to twist and heated with a construction hairdryer.

As a result of heat shrinking, the insulation is pressed tightly against the wires. If you don’t have a hairdryer, you can use a lighter, carefully holding it at a short distance. This is done when insulating twisted wires connected in series. If the connection of wires is parallel (the so-called bundle of wires), then first twist it and then put on the tube. In most cases, heat shrink tubing is easier to use than electrical tape. The tube can be quickly put on; it fits the wire connection more tightly and does not unwind. But it is more difficult to remove it if necessary. You just have to peel it off or cut it off. Manufacturers put markings on the tubes that show what temperature it can withstand and what voltage it is suitable for. Tubes are produced in different diameters and colors, so for different brands and cable sections it is always possible to select the appropriate insulation and color marking. How to properly insulate wires using heat shrink tube, watch the video:

Rubber manufacturing

There are three main unchanging stages when preparing raw rubber. The instructions and technology are simple, requiring simple equipment. The following are executed sequentially:

- rubber heating;

- mixing with additives;

- molding

Natural rubber, after standing for some time and fermenting, turns into a thick viscous mass. The artificial one is immediately produced in this form. Before use, it is kneaded like dough and heated to 50 degrees. In this state, it loses its elasticity, becomes pliable and soft and is able to mix with other substances.

The components of the future rubber are poured into a screw machine for mixing. Proportions and additives are taken depending on the planned qualities. All grades of raw rubber produced are standardized and the amount of each material is stated as a percentage. All that remains is to recalculate in relation to the available mass of rubber.

The resulting homogeneous mass remains heated, since friction against the machine part and particles against each other occurs with the release of temperature. As a result of the process, raw rubber is formed. It is shaped into strips of specified sizes (less often a cord) and packaged between polyethylene.

Insulation resistance

Current leakage may occur between cable cores and the external environment. One of the goals of isolation is to prevent their occurrence. The value that shows how well a wire is insulated is called insulation resistance. The higher the resistance, the more reliably the wires through which current flows are protected. Each brand of cable has its own value for this indicator. Insulation resistance is established by GOST or technical specifications (TU). The resistance is measured at a given temperature (about +20°) with a special device (megaohmmeter). If measurements are taken at subzero temperatures, its value will be underestimated, and in hot conditions it will be overestimated. After readings are taken, they are entered into the “Wire Insulation Measurement” protocol, compared with standard values and conclusions are drawn about whether the cables are suitable or not for further use. Electrical wiring that fails the test must be repaired or replaced. The periodicity of testing wire insulation is stipulated by the Rules. Also, checking the insulation of wires is carried out after completion of electrical installation work, repair work, after the wiring gets wet or overheated. How to correctly check the insulation resistance of conductors using a megohmmeter, watch the video:

Manufacturing of rubber products

To make products, the raw mass, after mixing, is placed in special molds, pressure is created and heated to 135-150 degrees. The process is called vulcanization. For small parts these are closed dies. Products such as rugs can be passed through hot drums with a shaped surface.

When exposed to high temperatures for a long time, rubber dries out and becomes brittle. Therefore, sulfur and other accelerators are introduced into the composition, which can significantly reduce the vulcanization process.

Melting process at home

Melting is a rather dangerous process. You must first take care of the means of protection against various toxic substances that will be formed, and also prepare the casting mold.

Means of protection

- You cannot do without special gloves even if you only need to melt aluminum once. This is perhaps the main means of protection, since the molten mass can most likely get on your hands, and then a burn will inevitably appear on the skin, since the temperature of the liquid metal exceeds 600 degrees.

- The next part of the body that also needs to be protected from hot aluminum is the eyes. If you swim frequently, you cannot do without a special protective mask, or at least glasses. But it is best to work in a suit that is resistant to high temperatures of several hundred degrees.

- If it is necessary to obtain pure aluminum, a refining flux will be required. And then you need to work in a chemical respirator.

https://youtube.com/watch?v=cIlonSuReH0

Selecting a mold for casting

In order to cast aluminum, it is not necessary to stock up on a casting mold. It is enough just to purchase a sheet of a more refractory metal - steel, pour molten aluminum onto it and wait until the latter hardens. But to produce any part from aluminum, you will definitely have to purchase a casting mold.

You can make it yourself at home. Sculpting plaster is usually used for this purpose. It is poured into a mold, then cooled for some time. After this, the model is inserted into it and a second container with plaster is placed on top.

In this case, it is important not to forget to make a hole in the plaster using some cylindrical object. Hot aluminum will be poured through this hole.

When melting aluminum, you cannot do without a so-called crucible: that is, a container made of refractory metal. It can be made of porcelain, quartz, steel, cast iron. However, it is not at all necessary to make a crucible yourself, because you can simply buy it in a special store. The volume of the crucible depends on how much metal is required to be obtained.

Aluminum production and use

The production process is very energy-intensive and therefore the first large plant in our country was built and launched in the 20th century. The main raw material for the production of this metal is aluminum oxide. To obtain it, it is necessary to remove impurities from minerals containing aluminum or bauxite. Next, natural or artificially produced cryolite is melted using an electrolytic method at a temperature just below 1000 ºС. Then they begin to gradually add aluminum oxide and related substances necessary to improve the quality of the metal. In the process, the oxide begins to decompose and aluminum is released. The purity of the resulting metal is 99.7% or higher.

What is the melting temperature of metals?

The melting temperature of metals is the value of the heating temperature of the metal at which the process of transition from the initial state to another begins, that is, the process opposite to crystallization (solidification), but inextricably linked with it.

So, to melt, the metal is heated from the outside to the melting temperature and continues to be heated to overcome the phase transition boundary. The bottom line is that the melting temperature indicator means the temperature at which the metal is in phase equilibrium, that is, between a liquid and a solid. In other words, it exists simultaneously in both states. And to melt it, you need to heat it above the boundary temperature so that the process goes in the right direction.

It is worth saying that only for pure compositions the melting temperature is constant. If the metal contains impurities, this will shift the phase transition boundary, and, accordingly, the melting temperature will be different. This is explained by the fact that the composition with impurities has a different crystal structure, in which the atoms interact with each other differently. Based on this principle, metals can be divided into:

- easy melting, such as mercury and gallium, for example (melting temperature up to 600°C)

- medium-melting ones are aluminum and copper (600-1600°C)

- refractory - molybdenum, tungsten (more than 1600°C).

Knowledge of the melting temperature indicator is necessary both in the production of alloys for the correct calculation of their parameters, and in the operation of products made from them, since this indicator determines the limitations of their use. A long time ago, for convenience, physicists compiled this data into one table. There are tables of melting temperatures for both metals and their alloys.

Hot repair of tire surface damage:

- Rubber is cut into strips 1–2 cm wide.

- The material is heated to 50 - 55°C to facilitate pressing.

- The vulcanization process is carried out in a vulcanizer at a temperature of 149°C and a pressure of 3 kg/cm2. The holding time is determined at the rate of 10 minutes. into strips 3 mm thick.

If the pressure is insufficient, the rubber will have a porous structure. Hot melt adhesive is used to connect the material to the tire. A two-component mixture of 858 A and B with increased hardness is used to repair damage to rubber on the sides of cars using cold vulcanization to restore the tightness of the seating areas on the rim.

Silicone materials

Organosilicon polymers serve as the basis for the production of aircraft, automotive, and electrical products; various types of food equipment; numerous medical and hygiene products; children's goods.

Heat-resistant silicone rubber is available in several colors and with different hardness ratings.

There are different types of heat-resistant rubber products. Monolithic silicone rubber has a uniform structure and smooth surface. Its hardness on the standard Shore scale is 40 units, density is 1.15 g/cm3.

Foamed fire-resistant rubber is characterized, for obvious reasons, by a low density of 0.5 g/cm3. A large number of pores reduces the heat-resistant properties to some extent.

The maximum temperature that the foam material can withstand without changes is less than the values permissible for monoliths.

Porous types of heat-resistant silicone rubber have very good shock-absorbing ability due to the presence of many small cavities with air.

Monolithic and foamed products are produced in the form of plates, cords, profiles in the usual design and together with fixed adhesive tape. The adhesive layer provides reliable attachment to the base and seals the joint.

Sheets and rolls of heat-resistant silicone rubber have the following thickness: minimum - 1 mm, maximum - 60 mm. The width range of porous sheet products is smaller.

The minimum is 2 mm, the maximum is 10 mm. Foamed heat-resistant profiles vary in thickness from 10 mm to 20 mm. Self-adhesive types are produced with thicknesses from 1 mm to 5 mm.

Heat-resistant silicone cords are available in several types: round, square and rectangular. Heat-resistant silicone profiles have a wide variety of sizes.

All specifications should be carefully discussed with suppliers before placing orders.

Homemade raw rubber production

Rubber, especially artificial rubber, requires a lot of effort to knead. A person does not have enough strength to knead it with his hands like dough. A special device is made for this. Mixing with additives is a labor-intensive and time-consuming process. Substances with different dispersion, specific gravity and physical state must be converted into a homogeneous mass.

You prepare raw rubber yourself in a machine with screw shafts. The screw protrusions grind everything that is put into the container and mix it. The production speed depends on the number of shafts. He is usually alone at home, and it takes a lot of time to bring the mixture to the desired state.

For molding into sheets and strips, two shafts are sufficient, one of which moves, changing the size of the gap, and therefore the thickness of the finished raw rubber. The mass is placed in a storage tank and goes to molding. When deformed, it cools down and loses its ability to flow, becoming tensile.

Equipment for a home workshop can be purchased at a store or made independently. Take the equipment available in the kitchen as samples. The engine will fit from a broken washing machine or any other machine. Automotive belts and pulleys.

Tire temperature

Home / Useful articles / Tire temperature

Any car tire, despite its apparent simplicity, is a rather complex product that consists of many parts that differ in configuration and composition. While driving, all the energy spent on rolling tires is converted into heat, thereby causing the tire to heat up. The normal tire temperature when driving is in the range of 70-80 C. The maximum temperature in the hottest place is 120-125 O C, at which point the tire begins to deteriorate. As the temperature rises, the strength of the tire's resistance to destruction noticeably decreases, and the connection between all elements of the tire deteriorates. When the strength of the connection between the tread and the belt is completely insufficient, the tire tread begins to peel off.

As the load and speed increase, the frequency and degree of deformation increases proportionally, and the temperature of the internal elements of the tire increases accordingly. At the same time, the destruction and obsolescence of all components from which the tire is made noticeably accelerates. To avoid overheating of the tire, it is necessary not to exceed the maximum load. The load rate and maximum permissible speed are indicated in the tire markings. If you look at the tire markings in detail, you can see something similar to P240/75R15 90H. In order: P means that the specified tire is intended for use in passenger cars, however, there are tires that do not have the letter P in the marking; the number 240 indicates the profile width (mm) of the tire. Next, 75 is the ratio of the profile width and its height, which is multiplied by 100. In the marking, the letter R indicates that the model in question carries a radial structure, that is, a low-layer frame consisting of threads (rubber-coated) and a metal cord breaker. The number 15 just determines the diameter (in inches) of the rim for the specified model. In the marking, the number 90 with the letter H is a characteristic of the theoretical performance of the tire in question.

The number 90 is a load index that determines the maximum permissible load on a tire. Example: a load of 90 corresponds to a weight of 600 kg. In passenger car tires, the load level index is usually 70-95, that is, this corresponds to a weight from 335 to 690 kg. In other cases of using cars (sports, trucks), the permissible load on a tire can be 1.5 tons. The letter H in the marking (or R/S/V), called the speed rating designation, characterizes the theoretical performance of the tire. Before mass production, any model must undergo bench testing. During the tests, the rolling speed of the tires constantly increases until the tire breaks down.. This way the speed rating of the tire is determined. In the series under consideration R

Ftoroplast-4

Most often, when fluoroplastics are mentioned, they mean fluoroplast-4. This is the most common and cheapest type of plastic to produce, known in Europe under several names. In the USA it is called “Teflon” or “Halon”, in the UK – “Flubon”, in Germany – “Gostaflon TF”, in Japan – “Polyflon”, in Italy – “Algoflon”, in France – “Soreflon” or “Gaflon” "

It is manufactured and sold both in “pure” form and with fillers: graphite, metal powders and fiberglass. Additives can enhance certain properties by tailoring the polymer to specific needs. Blanks are usually sold in the form of disks, rods, plates and pieces .

Fluoroplast-4 has excellent heat-resistant and anti-friction properties, is an excellent current insulator and can easily withstand even aggressive chemical environments. This allows the material to be used in the creation of the primary winding of high-voltage wires, conductive and heating cores, heating cables, in the manufacture of gaskets, washers, hoses for hydraulic systems and for heated floor equipment.

Crude rubber: application

At home, rubber is widely used for repairing rubber products. These are tires and tubes of bicycles and cars, shoes. Using vulcanization, gaskets for taps and various small parts are created.

For patches on punctured wheels, raw rubber sheets are most often used. Instructions for use:

- Clean the edges of the chamber at the cut site with sandpaper so that their ends do not touch. Cut off torn protrusions.

- The area around the cut is degreased and processed with a file.

- A patch is cut from raw rubber and applied to the camera.

- It is clamped with a clamp and heated.

A ready-made vulcanizer is used for heating, but you can make it yourself. In the case of an industrial installation, one millimeter of thickness should be heated for 4 minutes. In a homemade device, the time increases to 10 minutes; it is more accurately determined in a practical way.

Rubber production

When producing hot vulcanized silicone rubber, specialized equipment is used, including mixing rollers, plasticizer, heating channels, extruder, calenders and vulcanization presses.

Liquid silicone rubber is obtained from an initial mixture consisting of silicone rubber, active and semi-active fillers and auxiliary substances. By adding appropriate components for the vulcanization of silicone rubber, it is possible to produce elastic rubber products under the influence of temperatures above +100 ° C. Moreover, we should not forget that even a small amount of sulfur catalysts and antioxidants used to make traditional rubber getting into the mixture can ruin silicone rubber. Therefore, in the production of silicone rubber sheets, separate equipment is used.

In the molding or injection molding process, the mixture is placed in a mold to hold under pressure for a certain time. In this case, the temperature reaches the value at which vulcanization begins. In the production of silicone rubber, an aqueous solution of detergent is used as a lubricant for molds. During injection molding, the mixture is fed using a roller belt loader mounted on the injection molding machine. Profile parts such as tapes, cable sheaths, rods and hoses are produced by extrusion. In this case, vulcanization usually occurs in the channel when heated air is supplied; a process with steam vulcanization is also possible.

Silicone elastomers have increased anti-adhesive characteristics, for this reason it is quite difficult to glue silicone rubber and parts made from it to each other or to other materials. Two methods are used for gluing. The first is to use a vulcanizing agent with adhesive properties, and the second involves the use of a special glue for silicone rubber, since traditional adhesives are not suitable for this. When deciding on the question of how to glue silicone rubber, experts have developed special silicone-based primers that can provide the required bonding effect.

Initial mixtures with silicone rubber are stored in tightly closed containers, protected from light. Storage of mixtures prepared for vulcanization is permissible at a temperature not exceeding +30 °C. Their shelf life should not be more than 4 months, and that of the original mixtures – a year.

Overheating of wires - melting of insulation

First of all, the insulation of the wires melts, and they become very dangerous, especially for workers who repair and maintain the lines. When an electric current with a constant value passes through the cable, heating occurs only to a certain limit. Thus, if you control the current value, you can ensure the safety of the insulation. Severe overheating of the insulation can cause ignition and lead to a fire. If wires without insulation overheat, they may develop too much tension, leading to...

In modern conditions, the laying of electrical lines, in most cases, is done with wire with copper conductors. Aluminum wires, due to many negative qualities, are practically not used, although they are found in old lines. The ideal option is to use a multi-core cable that can withstand significant short-term loads.

It should be remembered that overheating of the wire in many cases does not occur along the cable line, but in places of twisting and soldering in sockets, junction boxes and electrical panels.

Composition and structure of natural rubber

Natural rubber (NR) is a high-molecular unsaturated hydrocarbon, the molecules of which contain a large number of double bonds; its composition can be expressed by the formula (C5H8)n (where the value of n ranges from 1000 to 3000); it is a polymer of isoprene.

Natural rubber is found in the milky sap of rubber-bearing plants, mainly tropical ones (for example, the Brazilian Hevea tree). Another natural product, gutta-percha, is also a polymer of isoprene, but with a different molecular configuration.

A long rubber molecule could be observed directly using modern microscopes, but this is not possible because the chain is too thin: its diameter corresponds to the diameter of one molecule. If a rubber macromolecule is stretched to the limit, it will have the appearance of a zigzag, which is explained by the nature of the chemical bonds between the carbon atoms that make up the skeleton of the molecule.

The units of a rubber molecule cannot rotate freely in any direction, but only to a limited extent - only around single bonds. Thermal vibrations of the links cause the molecule to bend, while its ends are brought closer together in a calm state.

When rubber is stretched, the ends of the molecules move apart and the molecules are oriented in the direction of the tensile force. If the force that caused the stretching of the rubber is removed, the ends of its molecules come closer together again and the sample takes on its original shape and size.

A rubber molecule can be thought of as a round, open spring that can be greatly stretched by spreading its ends apart. The released spring returns to its previous position. Some researchers imagine the rubber molecule in the form of a springy spiral. Qualitative analysis shows that rubber consists of two elements - carbon and hydrogen, that is, it belongs to the class of hydrocarbons.

The initially accepted formula for rubber was C5H8, but it is too simple for such a complex substance as rubber. Determination of molecular weight shows that it reaches several hundred thousand (150,000 - 500,000). Rubber is therefore a natural polymer.

It has been experimentally proven that the macromolecules of natural rubber mainly consist of residues of isoprene molecules, and natural rubber itself is a natural polymer cis-1,4-polyisoprene.

The natural rubber molecule consists of several thousand initial chemical groups (links) connected to each other and in continuous vibrational-rotational motion. Such a molecule is similar to a tangled ball, in which its constituent threads in places form regularly oriented sections.

The main product of rubber decomposition is a hydrocarbon, the molecular formula of which is unambiguous with the simplest formula of rubber. We can assume that rubber macromolecules are formed by isoprene molecules. There are similar polymers that do not exhibit the same elasticity as rubber. What explains this special property?

Rubber molecules, although they have a linear structure, are not elongated in a line, but are repeatedly bent, as if rolled into balls. When the rubber is stretched, such molecules straighten, and the rubber sample becomes longer. When the load is removed, due to internal thermal movement, the molecule links return to their previous folded state, and the size of the rubber is reduced. If the rubber is stretched with a sufficiently large force, then not only the molecules will straighten, but also they will shift relative to each other - the rubber sample may tear.

Making a vulcanization device

Homemade vulcanizers are divided into electric and gasoline. They are made from parts that have served their useful life. Main nodes:

- fixed table;

- a heating element;

- clamp.

The simplest electric model is made from an old iron that has a working coil. This option has a regulator, which means it is more convenient than others. The working surface is the sole. It is better to remove the handle, turn the iron over, and install it on a bracket made of thick sheet. The item to be repaired is placed on top and clamped with a clamp.

For the gasoline version, it is convenient to use the engine piston. Gasoline is poured into it and set on fire. To control, place paper on the patch. It begins to turn yellow at a temperature critical for rubber.

At what temperature does plastic melt?

If you ask consultants selling plastic windows how to care for their products, they will answer you: wash, periodically lubricate metal and rubber parts. In principle, care is not that difficult.

Everyone understands how to wash plastic windows; lubricating metal mechanisms (fittings) is also not very difficult, but it’s not entirely clear about rubber bands.

Everyone says that they need to be lubricated, but no one explains how to lubricate the rubber bands (seal) on plastic windows, how to do it and why is it even necessary?

Changes in rubber properties depending on temperature

With a change in temperature, the properties of rubber change greatly, and the performance of parts made from it, for various reasons, decreases both when heated and when cooled.

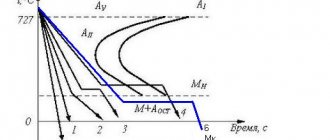

As follows from Fig. 11.4, as the rubber temperature decreases, the tensile strength increases, and the elasticity decreases and at -80°C it becomes almost equal to zero.

Note that the strength of rubber, which increases with decreasing temperature to a first approximation according to a linear law (Fig. 11.4), reaches at -80°C approximately the same value as vulcanizate, ebonite, which is completely devoid of elasticity, has at room temperature.

Thus, the main unfavorable consequence of lowering the temperature is a decrease in the elasticity of rubber, which, as it cools, approaches the fragility of ebonite. Already at -4 °C, the most common types of rubber are not capable of reversibly deforming within the required limits, and only vulcanizates based on special frost-resistant rubbers retain the required elasticity at temperatures of -50 °C and below. From which it follows that rubber products require close attention and careful handling in winter.

Rice. 11.4. Dependences of tensile strength σz and relative elongation εz

rubber from natural rubber on temperature

All work related to the installation or dismantling of rubber parts in winter must be carried out after warming them up to room temperature. It is especially important to warm up pneumatic tires that have become very cold during long-term parking or prolonged stopping of vehicles in the cold. Such heating occurs on its own while the vehicle is moving due to the conversion of the energy of continuous deformation of rolling tires into heat. However, the first time after starting off, cold tires have insufficient elasticity and, as a result, can easily be damaged as a result of large dynamic loads. Therefore, at first the car should move at low speed along the smoothest parts of the terrain or road, avoid sharp turns, sharp braking, etc.

Extremely careful handling during winter operation of vehicles is required with parts made of petrol and oil-resistant rubber. Compared to ordinary rubber, it has reduced frost resistance, and therefore, even at -20 ° C, products made from it become brittle.

With an increase in temperature to PO. At 120°C, the relative elongation of rubber increases, and with further heating, as can be seen from Fig. 11.4, begins to decrease. The transition from an increase in relative elongation to its decline is explained by the partial rupture of sulfur bridges between rubber macromolecules that occurs at these temperatures, accompanied by a simultaneous sharp decrease in its elasticity and an increase in ductility.

Other operationally important properties of rubber change only for the worse with increasing temperature: strength, wear resistance and hardness decrease, while residual elongation and the ability to undergo irreversible deformation increase. Thus, heating rubber from 20 to 100 °C corresponds to a twofold or even threefold decrease in tensile strength. In this case, the wear resistance and hardness of the rubber are reduced even more. As a result, at elevated temperatures, the mileage of car tires decreases (Fig. 11.5).

In addition, due to a strong decrease in the hardness and strength of rubber with increasing temperature, the possibility of cuts and tearouts of entire pieces of tire tread increases when cars collide with all kinds of bumps and obstacles.

Rice. 11.5. Dependence of tire mileage τpr on air temperature tb

So, all rubber parts, and especially those that are deformed during operation, in some cases need to be heated in winter and cooled in summer, and also measures must be taken to reduce their heating. Car tires must be maintained at normal pressure and not overloaded. Failure to comply with these basic rules for tire operation leads to excessive heat generation in them with all the ensuing harmful consequences (Fig. 11.6, 11.7).

In the heat of summer, even normally inflated, non-overloaded tires can become significantly warmer. In this case, it is recommended to periodically make stops along the way to cool them, and sometimes, in order not to bring the tire into an emergency state due to overheating, to reduce the speed of movement, on which the thermal conditions of the tires strongly depend (Fig. 11.8).

Rice. 11.6. Dependence of air temperature in the tire t Ш

from travel time τpr:

1 —

at normal pressure;

2

- at a pressure lower than normal by 30%

Rice. 11.7. Temperature dependence of tire parts t w

on travel time τpr under various loads:

1

- in the cell;

2

- in the shoulder part of the tire

Rice. 11.8. Temperature dependence of tire parts t Ш

on travel time τpr at different speeds:

1

- in the middle of the treadmill;

2 -

on the side