Features of screw compressors

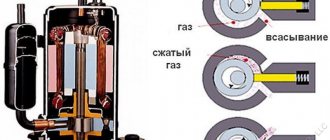

Screw compressors are rotary equipment. The principle of their operation is based on the rotation of two rotors, which are screws. The first such machine was developed by Swedish engineer Eliot Lysholn in 1934. Since that time, the invention has been modernized and changed many times, but its operating principle has remained the same.

The engine drives the screw pair using a drive system. Then air purified by a filter enters it, where it is mixed with oil. This creates an oil wedge between the rotors. When these screws rotate, the gas is compressed and the pressure increases. After this, the gas-oil mixture enters a special container, where the air is separated, cooled and supplied to the outlet of the compressor equipment. After cooling, the oil is additionally filtered and then fed into the block by rotors.

Any model of a modern screw compressor includes the following basic elements:

- Air filter

- Inlet valve

- Main screw block

- Electric motor

- Belt drive

- Oil separator

- Oil filter and cooler

- Thermostat

- Pipelines

- Safety valve and pressure switch

- Control block

- Fan

- Aftercooler

There are a large number of modifications of screw compressors. Based on the type of chamber filling, a distinction is made between oil-filled and oil-free (dry compression) machines. The former use oil to soften the rotor operation process and require a separation system. The latter do not use oil lubricant to fill cavities.

According to the type of compressed medium, compressors are air (air only), gas (ammonia, hydrogen, oxygen, do not use air), multi-purpose (alternating use of gas and air), multi-service (simultaneous use of several types of gas).

Depending on the type of drive, belt and direct compressors are distinguished. In the first, torque is transmitted by a belt, which is located between the engine and the rotors. In direct ones, the motor and screws are connected by a special coupling.

Depending on the type of energy consumed, equipment can be autonomous, fuel-powered, or electric. There are also compressors with low (up to 1 MN/m2), medium (up to 10 MN/m2) and high (more than 10 MN/m2) compression ratios.

Oil-free screw compressor maintenance

First of all, it should be noted that rotary compressors of any type, and oil-free ones in the first place, are not intended for very dusty rooms.

Abrasive particles entering the screw block damage the surfaces of the rotors and disrupt the geometry of their shapes. As a result, the rotating screws begin to touch, which causes increased friction, scoring and seizing.

Many manufacturers apply special protective coatings to rotors to protect against wear and corrosion.

Foreign manufacturers were the first to do this. Treating the rotors with special polymer compounds made it possible not only to reduce the likelihood of their contact with the subsequent formation of scuffing, but also to reduce the cost of precision machining of surfaces.

Due to the inclusion of tiny particles of solid lubricants, polymer coatings have high antifriction properties, which allows them to effectively reduce friction and prevent the formation of scuffing.

The coatings level the surfaces of the rotors, thereby simplifying their running-in and providing dynamic compaction. The protective layer that these materials create on the screw pair prevents metal corrosion that can be caused by the ingress of water or aggressive cooling solutions.

Over time, factory coatings wear out, and in order to solve the issue of restoring them, it is necessary to use ready-made antifriction materials. Previously, such compounds were exclusively imported, but today their production has been established in our country.

The Russian company has developed a series of anti-friction solid lubricant coatings for screw compressors, which can be used both in the production and repair of rotors.

MODENGY coatings are applied to the surfaces of parts in a layer of up to 100 microns, then, after running-in, the thickness decreases by 2-2.5 times and becomes optimal.

The polymer matrix of the coating firmly holds particles of solid lubricants in its cells, which perform anti-friction and extreme pressure functions.

When servicing oil-free screw compressors, MODENGY 1007, MODENGY 1014 and MODENGY 1066 coatings are used.

MODENGY 1007 is produced on the basis of graphite, therefore it has a characteristic gray-black color. The coating works stably at temperatures of -50…+350 °C, and has a load-bearing capacity of 1300 MPa (SRV test).

The bearing capacity of MODENGY 1014 is even higher, it is 2700 MPa. The operating temperature range of the coating with molybdenum disulfide and polytetrafluoroethylene is -75...+255 °C. The composition has high anti-corrosion properties - >672 hours (salt fog test).

MODENGY 1066 with graphite and molybdenum disulfide can withstand temperatures from -70 to +315 °C. The coating also has anti-corrosion properties (>300 h in salt fog) and high load-bearing capacity (9900 H according to the Falex method).

Before applying the coating, the remains of old lubricants, dust and other contaminants are removed from the rotor surfaces. To completely clean and degrease the screw pair, use the MODENGY Special Cleaner-Activator. Its use promotes high adhesion of the future coating and guarantees its long service life.

Antifriction compounds are applied to the rotors in several layers, then the parts are heated to polymerize the coatings. All materials are cured when heated above +200 °C for 20-40 minutes (the exact time depends on the type of coating).

Rotors coated with MODENGY do not require re-treatment in the future - a correctly applied protective layer does not wear off, as it does not allow the screw surfaces to come into contact.

Oil functions

Compressor oil is a complex synthetic or mineral material that simultaneously performs several functions. All of them are very important for the stable operation of the equipment. If at least one of them is not fulfilled, the efficiency of the compressor will decrease, and in some cases, failure is possible.

The functions of the oil are as follows:

- Lubrication of compressor rubbing parts

- Reduced wear

- Cooling and heat removal

- Sealing gaps

- Reduced detonation during engine operation

- Ensuring tightness in compression chambers

Lack of sealing of gaps or poor tightness simply reduces the performance of the compressor, and lack of lubrication and cooling increases wear on parts, and the compressor fails.

What oil to fill in a screw compressor

The question of what oil to pour into a screw compressor is very important, since the liquid performs the following functions:

- reduces friction of contacting parts;

- protects surfaces from scratches when exposed to dust;

- cools and removes heat from rubbing elements;

- seals gaps and ensures tightness.

If you fill a screw compressor with the wrong oil, it will quickly fail. In order to avoid equipment downtime and lengthy and expensive repairs, you need to figure out what kind of oil to pour into the screw compressor.

The easiest and most reliable way to determine what oil to pour into a screw compressor is to look in the operating manual. The manufacturer always indicates a list of compressor oils with optimal characteristics that will ensure the best functioning of the equipment. True, the fluids recommended by the manufacturer are suitable for ideal operating conditions. If the equipment operates in dusty conditions, outdoors and with sudden temperature changes, you will have to select which oil to pour into the screw compressor individually, taking into account the operating conditions.

The most significant characteristics of compressor oils are as follows:

- viscosity (and its dependence on temperature);

- cleaning properties (help remove dust and other debris);

- wetting properties (indicate the ability of the oil to envelop parts - and, therefore, effectively remove heat);

- resistance to high pressure;

- oxidative stability.

What kind of oil to pour into a screw compressor - synthetic or mineral?

There is no universal answer to the question of what oil to fill in a screw compressor. The use of synthetics, semi-synthetics, and mineral technical fluids is allowed. If the equipment is used in conditions close to ideal, i.e. in a room with clean and dry air, without sudden changes in temperature, then you can save money and take a mineral one. It costs less and has a short service life - usually 2 thousand hours.

For all difficult cases, the only solution to which oil to pour into a screw compressor is synthetic. It costs more than mineral, but surpasses it in all performance characteristics. For example, the replacement interval in engine hours for synthetics is about 8 thousand, i.e. You will have to change the oil four times less often. In addition, it can withstand a larger temperature range (from -40 − -30 degrees to +200).

Therefore, if finances allow, then it is worth filling the screw compressor with synthetic compressor oil.

What characteristics should the oil have?

High-quality oil for a screw compressor should have the following properties:

- Viscosity-temperature properties. Thanks to them, oil is supplied in sufficient quantities to the compressor, fills the gaps between the rotor and the housing, and lubricates the bearings well

- Wetting properties. Provide heat removal and cooling of interacting parts

- Detergent and dispersing properties. Allow the compressor to operate smoothly, keep the rotors clean, and reduce the risk of clogging and cold sludge deposits

- Resistant to wear and high pressure. The active substances contained in oils form a wear-resistant film that can withstand high pressures. Thanks to this, the equipment lasts much longer

- High oxidative stability. The oil should not oxidize quickly when exposed to oxygen and high temperatures. Otherwise, carbon deposits will form, which will negatively affect equipment performance.

Thus, to service screw compressors, you should use oils that have the properties described above. If at least one of these characteristics does not satisfy the requirements of the equipment or its operating conditions, then such liquid is not recommended for use.

How to choose?

When choosing oil for screw compressors, you should remember that an important function of the working fluid is to ensure tightness of the gaps. Therefore, its viscosity must be at least 7 mm2/s. The operating temperature range also plays an important role. It is desirable that it be at least +90 °C. If these specifications are not met, then the oil will have to be changed much more often.

Attention should also be paid to the labeling of the liquid. Usually standard options are indicated: SAE 20, SAE 40, SAE 60, etc. In some cases, the following markings are found: SAE 20W, SAE 30W. The letter “W” means that this is winter oil, i.e. it can be used at low temperatures.

In addition, it is important to consider the type of compressor: oil-free, oil-injected and oil-injected. Each of these types of equipment has its own fluids that meet the requirements of a specific modification.

Remember that motor vehicle oils cannot be used in compressors. They increase wear and do not protect surfaces from damage.

Synthetic or mineral?

There is no consensus on which is better: mineral water or synthetic water. Both types are popular and perform their functions quite well.

Mineral oils are cheaper than synthetic oils. They are usually used in cases where the compressor is used infrequently. They also have a temperature limit - it should not exceed +90 °C. Otherwise, the oil may ignite or detonate. In addition, mineral liquids do not have a long service life - only 2-3 thousand hours. This indicator depends on the manufacturer and brand.

Synthetic oils are more versatile. Due to their high viscosity, they can be used in any screw compressors. These liquids do not degrade and do not lose their properties when heated to +180...+200 °C. In addition, they do not cause detonation.

Synthetics also have very high low-temperature properties, so such oils can be used outdoors even in winter. The service life of such fluids is up to 8000 hours. This is 2-4 times more than mineral oil.

Perhaps the only disadvantage of synthetics is its high price. It is several times higher than the cost of mineral liquids. Therefore, such materials are used mainly in cases where the compressor is used actively and frequently.

How and when to change the oil in the compressor?

Information on how often to change the oil in the compressor and how to check its level is contained in the service book.

When equipment operates under heavy duty conditions, the frequency of lubricant changes is reduced. The oil should be changed unscheduled when it becomes cloudy or changes color (turns white due to water, darkens due to severe overheating).

When refueling the compressor, you must strictly follow the instructions - no air, moisture, or dust should enter the oil system.

Before changing the oil in the compressor, you need to remove the old lubricant, pour flushing liquid into it and turn it on for 10-15 minutes.

A lubricator (an oil sprayer that supplies it in the form of an oil mist) helps to lubricate friction pairs more effectively.

To better understand how to change the oil in a compressor, you can watch the following video instructions.

Changing the oil in a piston compressor

It is necessary to change the oil in an air piston compressor after the first 500 hours of operation, then depending on the load mode and the quality of the intake air, but at least once a year.

After every 4000 hours of operation, not only the oil should be changed, but also the oil filter, separator filter, and, if necessary, the drive belt.

The lubricant is replaced while constantly monitoring the filling level (should be between the central and upper mark of the compressor inspection window).

Changing the oil in a screw compressor

The first lubricant change in a screw compressor is carried out after 500 hours of operation, then at intervals of up to 8000 hours (the exact interval depends on the brand of the device and operating conditions).

You need to add as much fresh oil as the old one was drained. The need for topping up is determined after briefly turning on the equipment.

Oil change recommendations

When changing compressor oil, use only materials that are suitable for the equipment. Do not mix different brands of fluids or unsuitable products, such as motor oil.

When changing the oil, you must first disconnect the compressor from the network and bleed all the air from the receiver. Next, you need to prepare a container to collect the waste liquid and unscrew the drain plug. As soon as the oil has drained, tighten the drain hole.

Next, you need to pour new oil into the compressor crankcase. The level should be near the control mark in the inspection window. Then we close the filler hole and check the operation of the equipment. This is necessary so that fresh liquid is distributed inside the compressor.