How did rubber come about?

The chronicle of the emergence of rubber in European rubber countries began when Columbus in 1493 brought strange treasures from the new continent. Among them was a surprisingly bouncy ball, which the local natives made from the milky sap of the Hevea tree. The Indians called this juice “cauchu” (from “kau” - tree, “chu” - tears, cry) and used it in ritual ceremonies. The name stuck at the Spanish royal court. However, in Europe the existence of the unusual material was forgotten until the 18th century.

General interest in rubber arose only after the French navigator C. Condamine in 1738 presented scientists from the Paris Academy of Sciences with a certain elastic material, samples of products made from it, its description and extraction methods. C. Condamine brought these things from an expedition to South America. There, the natives made various household items from the resin of special trees. This material is called “rubber”, from the Latin. resina - “resin”. It was from then on that the search for ways to use this substance began.

Vulcanization of rubbers. Rubber

Rubbers are the basis for the production of various rubber products (RTI).

RTI

is a large group of rubber, rubber-fabric and rubber-metal products: tires, conveyor belts, drive belts, balloons, inflatable boats, prefabricated structures, household and medical products, etc.

Characteristics of the most important industrial rubbers

Source - Chemical Encyclopedia ( 1) or Chemical Encyclopedia (2)

When manufacturing rubber goods, it is necessary to take into account that rubber, consisting of individual, unbound macromolecules (“raw” rubber), has

plasticity

from the Greek.

plastikós

- suitable for modeling, pliable, plastic.

to irreversibly change its shape

under the influence of mechanical loads . This property does not allow the direct use of “raw” rubber in rubber goods, but can be used in the preparation and molding of products. In addition, “raw” rubber is able to dissolve in non-polar organic solvents, for example, gasoline (the preparation of rubber glue is based on this).

To eliminate plastic deformation and solubility for practical use, rubber is converted into rubber

.

Rubber (from Latin resina

– resin) is an elastic material (vulcanizate) formed as a result of the vulcanization of natural and synthetic rubbers.

It is an insoluble network elastomer - a product of cross-linking of rubber molecules by chemical bonds. When receiving rubber products, rubber mixtures

, which, in addition to

rubber

, contain

a vulcanizing agent

(for example, sulfur),

filler

(carbon black or finely dispersed silicon dioxide, aluminum and calcium silicates) and other ingredients. The rubber mixture is molded into a product blank, which is then vulcanized.

The optimal rubber mixture is one in which plastic deformation predominates before vulcanization, and after vulcanization, in the finished product, elastic deformation should mainly develop with a minimum degree of plasticity.

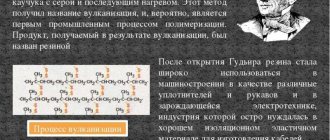

The essence of the vulcanization process is that when the rubber mixture is heated, macromolecules of rubber and sulfur form a three-dimensional mesh structure that has increased strength due to the elimination of plasticity.

Sulfur atoms join along the double bonds of macromolecules and create cross-linking sulfide bridges between them: Depending on the amount of cross-linking agent (sulfur), networks with different cross-linking frequencies can be obtained. Extremely cross-linked rubber - ebonite

- does not have elasticity and is a hard material.

Vulcanization of rubber underlies the production of a variety of rubber products. This is a large group of rubber, rubber-fabric and rubber-metal products: tires, conveyor belts, drive belts, oil seals, couplings, gaskets, shock absorbers, dielectric carpets, balloons, inflatable boats, pontoons, prefabricated structures, rubber shoes, household products and medical purposes, etc. An example is the tire manufacturing process shown in the video:

Tire production technology

In addition to being used in the production of rubber products, butadiene and styrene-butadiene rubbers

used to produce

impact-resistant structural materials

- ABS plastics.

Rubber value

Today, rubber is most widely used in the production of rubber. Modern industry produces various types of automobile, aircraft, and bicycle tires. It is used in the manufacture of all kinds of seals for detachable elements in hydraulic, pneumatic and vacuum devices.

The product obtained during the vulcanization of rubber with sulfur and other chemical elements is used for electrical insulation and in the production of medical and laboratory instruments and devices. In addition, various rubbers are used for the manufacture of conveyor belts operating under heavy loads, anti-corrosion coatings for boilers and pipes, various types of glue and thin-walled high-strength small products. The synthesis of artificial rubber has made it possible to create some types of solid rocket fuel, where this material plays the role of fuel.

What is rubber vulcanization and what does it do?

The technological process of vulcanization involves mixing rubber, sulfur and other substances in the required proportions. They are subjected to heat treatment. When rubber with a sulfur agent is heated, the molecules of this substance are held together by sulfur bonds. Some of their groups form a single three-dimensional spatial grid.

The composition of rubber includes a large amount of polyisoprene hydrocarbon (C5H8)n, proteins, amino acids, fatty acids, salts of certain metals and other impurities.

A molecule of natural rubber can contain up to 40 thousand elementary units; it does not dissolve in water, but is easily broken down in organic solvents. However, if rubber can almost completely dissolve in gasoline, then the rubber in it will only swell.

Vulcanization of this material helps to reduce the plastic properties of rubber, optimizes the degree of its swelling and solubility in direct contact with organic solvents.

The process of rubber vulcanization provides the resulting material with more durable properties. Rubber made using this technology is able to maintain elasticity over a wide temperature range. At the same time, disturbances in the technological process in the form of an increase in the addition of sulfur lead to the appearance of hardness of the material and loss of elasticity. The result is a completely different substance, which is called ebonite. Before the advent of modern types of plastics, ebonite was considered one of the best insulating materials.

Hot vulcanization

The technology for such vulcanization is as follows. A certain amount of sulfur and special additives are added to the molded raw rubber. As a rule, the volume of sulfur should be in the range of 5 – 10%; the final figure is determined based on the purpose and hardness of the future part. In addition to sulfur, so-called horn rubber (hard rubber) containing 20–50% sulfur is added. At the next stage, blanks are formed from the resulting material and heated, i.e. curing.

Heating is carried out using various methods. The blanks are placed in metal molds or rolled into fabric. The resulting structures are placed in an oven heated to 130 - 140 degrees Celsius. In order to increase the efficiency of vulcanization, excess pressure can be created in the oven.

Alternative techniques

Nevertheless, science, as we know, does not stand still. Today other vulcanizing agents are known, but sulfur still remains the most important. To accelerate the vulcanization of rubber, 2-mercaptobenzthiazole and some of its derivatives are used. Alternative techniques include ionizing radiation using certain organic peroxides.

Typically, for any type of vulcanization, a mixture of rubber and various additives is used as the starting material, giving the rubber the required properties or improving its quality. Adding fillers, such as carbon black and chalk, helps reduce the cost of the resulting material.

As a result of the technological process, the rubber vulcanization product acquires high strength and good elasticity. That is why various types of natural and synthetic rubbers are used as raw materials for the production of rubber.

Material properties

The performance properties of the resulting vulcanized rubber and products made from it largely depend on the type of reagent used. Such characteristics include resistance to exposure to aggressive environments, rate of deformation during compression or increased temperature, and resistance to thermal-oxidative reactions.

The resulting bonds irreversibly limit the mobility of molecules under mechanical action, while simultaneously maintaining the high elasticity of the material with the ability to undergo plastic deformation. The structure and number of these bonds is determined by the rubber vulcanization method and the chemical agents used for it.

Read also: Removable sockets in the kitchen

The process does not proceed monotonously, and individual indicators of the vulcanized mixture in their changes reach their minimum and maximum at different times. The most suitable ratio of the physical and mechanical characteristics of the resulting elastomer is called the optimum.

The vulcanizing composition, in addition to rubber and chemical agents, includes a number of additional substances that contribute to the production of rubber with specified performance properties. According to their purpose, they are divided into accelerators (activators), fillers, softeners (plasticizers) and antioxidants (antioxidants). Accelerators (most often zinc oxide) facilitate the chemical interaction of all ingredients of the rubber mixture, help reduce the consumption of raw materials and time for its processing, and improve the properties of vulcanizers.

Fillers such as chalk, kaolin, carbon black increase the mechanical strength, wear resistance, abrasion resistance and other physical characteristics of the elastomer. By replenishing the volume of feedstock, they thereby reduce rubber consumption and reduce the cost of the resulting product. Softeners are added to improve the processability of rubber compounds, reduce their viscosity and increase the volume of fillers.

Plasticizers can also increase the dynamic endurance of elastomers and abrasion resistance. Antioxidants that stabilize the process are introduced into the mixture to prevent “aging” of the rubber. Various combinations of these substances are used in the development of special raw rubber formulations to predict and adjust the vulcanization process.

Prospects for further development

Thanks to the development of synthetic rubber production technologies, rubber production is no longer completely dependent on natural material. However, modern technology has not replaced the potential of the natural resource. Today, the share of natural rubber consumption for industrial purposes is about 30%.

The unique qualities of a natural resource ensure the indispensability of rubber. It is necessary in the production of large rubber products, for example, in the manufacture of tires for special equipment. The world's most famous tire manufacturers use mixtures of natural and synthetic rubbers in their technologies. That is why the largest percentage of the use of natural raw materials falls on the tire sector of the industry.

Cement for vulcanization

Cement for vulcanization is used for self-vulcanization operation, it can start from 18 degrees and for hot vulcanization up to 150 degrees. This cement does not contain hydrocarbons. There is also OTR type cement used for application to rough surfaces inside tires, as well as Type Top RAD and PN OTR series adhesives with extended drying time. The use of such cement makes it possible to achieve long service life for retreaded tires used on special construction equipment with high mileage.