Ignition, spontaneous combustion and smoldering temperatures of some materials

Consumers completely in vain ignore such parameters as the temperatures of ignition (ignition), spontaneous combustion (spontaneous combustion) and smoldering of modern materials during the construction and renovation of premises. Ignoring them can result in great disaster: accidents and loss of property. After all, most of us only carefully study the wear resistance, strength, and specific heat capacity of building materials.

In this article we will try to fill this gap and present the auto-ignition temperatures - or more precisely, “the minimum temperatures required for the ignition of paper, gasoline, many materials, as well as gas or steam in air without the presence of a spark or flame” (all in degrees Celsius) according to foreign sources, part in the table - the rest in the text:

The lowest auto-ignition temperatures are for white phosphorus - 34 and transparent -49 (but for amorphous - 260 degrees), carbon disulfide - 90, diethyl ether - 160, acetaldehyde - 175 degrees (in degrees Celsius). Next comes a group of materials that require higher, but not prohibitive, temperatures to ignite.

Acetylene will ignite at 305, acetone and propanone at 465, bituminous coal and anthracite will glow at 464 and 600 degrees, respectively, benzene will spontaneously ignite at 560, gasoline will spontaneously ignite at 260-280 degrees (kerosene is lower at 210 o C), butadiene - 420 , butane - 405 (or 420 degrees), bitumen coal at 300, butyl acetate - 421, butyl alcohol - 345, butyl methyl ketone - 423, hydrogen -500, heptane - 204, hexane - 223, hexadecane, cetane -202, hydrogen - 500 , gas oil - 336, glycerin - 370.

Diesel fuel (foreign brand Jet A-1) ignites at 210 degrees, charcoal and coke coal - 349 and 700, respectively, dichloromethane - 600, diethylamine - 312, diisobutyl ketone - 396, diisopropyl ether - 443, dimethyl sulfoxide monoxide - 215, dodecane and dihexyl - 203, isobutane-462, isobutene-465, isobutyl alcohol-426, isooctane-447, isopentane-420, isoprene-395, isopropyl alcohol-399, isophorone-460, isohexane-264, isononane-227, isopropyl alcohol-399, light hydrocarbons - 650.

Lignite glows at 526 degrees, carbon spontaneously ignites - 609, coal oil - 580, kerosene - 295, fuel oil (depending on the brand) has a self-ignition temperature of 210-262 degrees, magnesium - 473, methane - 580, methanol, methyl alcohol - 470 (there is a brand with t=375), nitroglycerin will ignite at 254 degrees, nylons at 289-377, sulfur - 243, styrene - 490, propylene, propene - 458, polyethylene will ignite depending on the chlorine content at temperatures - 415-420 degrees, polystyrene - 226, polyvinyl alcohol - 405, propane - 455, industrial gas - 750, carbon - 700, carbon monoxide - 609, semi-anthracite coal - 400, cotton fabric - 267, cyclohexane - 245, ethylcellulose - 188 degrees Celsius.

Jet fuel A1 ignites at a temperature of 210 degrees Celsius. Popular materials now are products made of polycarbonate and polypropylene. Polycarbonate ignites at a fairly high temperature - 478, but polypropylene will ignite before paper at a temperature of 201 degrees Celsius.

People often forget to mention the ignition temperatures of rubber and rubber products. Rubber, butadiene will ignite at a low temperature of 155, and rubber, butyl at 185 degrees. The self-ignition temperature of low-purity natural rubber is 191, and high-purity rubber is 331, vulcanized rubber is 412, with the addition of butadiene-styrene, depending on the additives, 182 degrees (with 24% additive filling) and 280 degrees (with 85% additive).

READ ALSO: 15 renovation houses have been commissioned in Moscow since the beginning of the year

Many people are interested in the temperature of ignition or ignition of roofing felt or roofing felt. Of course, the composition and characteristics of these materials may differ significantly. At the same time, the following ignition temperatures of roofing felt are called: 365 ° C. When stacking, thermal spontaneous combustion is easily possible, and fresh roofing material is especially at risk of spontaneous combustion.

Along the way, it is useful to touch upon the ignition temperatures of some other roofing materials. For example, roofing tiles made of bituminous asphalt. Typical ingredients of imported asphalt roofing include: limestone, oxidized asphalt, mineral granules, fiberglass mat (fiberglass and urea, formaldehyde and formaldehyde binder) and a sand and talc backing. In a typical shingle, asphalt makes up about 20% of the shingle's mass, aggregate 43%, and the surface granules 25%. So, the ignition temperature of asphalt is 400 degrees Celsius, but the softening temperature is 54-173 ° C. From here you can estimate the ignition temperature of such a roof.

In general, asphalts that will be oxidized to produce asphalt roofing products must have a minimum flash point of 260 °C (500 °F).

Like most of its products, oil ignites at a fairly low temperature - 225 degrees Celsius; for obvious reasons, the combustion or ignition temperatures of paper are very close - 218-246 degrees, peat - 227, but dry oak wood is much higher - 482 degrees and pine forest - 427, just wood - 300 degrees, semi-anthracite coal - 400. Strictly speaking, the standardized value of the ignition (ignition) temperature of paper is 233 ° C or 451 ° F ", and this must be taken into account, since paper fire is frequent fires are caused by left behind cigarette butts or unextinguished matches.

Severe hydrocarbons are self-flammable at- 750, Toluol- 535, cotton- 221, cycloglixan-245, cyclohexanol-300, cycloglopsanon-420, cyclopropopan-498, acetic acid- 427, carbon-700, furfurol-316, epihlorgidrin- 416, ethan- ethane- 515, ethylene, ethene-450, ethyl acetate-430, ethyl alcohol, ethanol-365, ethylene oxide-570 gr. Celsius.

As a result, consumers can often become unwitting victims of an accident: fire, poisoning by combustion products and smoldering materials, or, as they say, get burns out of the blue.

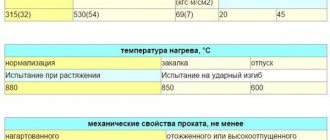

The following are the temperatures of ignition (ignition), spontaneous combustion (spontaneous combustion) and smoldering of some commonly used, as well as “exotic” materials that were not included in the reference material above according to domestic sources.

Note: the spontaneous combustion temperatures in the table are given for the substance in the molten state.

You also need to know about seemingly harmless spilled sugar, or rather about its dust. Any place that contains sugar dust and a lot of oxygen, such as a sugar silo, can quickly become a hazardous environment. According to fire protection studies, a room covered with at least 5 percent of its surface area in a thin layer of sugar dust (0.8 mm) poses an explosion hazard. Tiny sugar particles burn almost instantly due to the high surface area to volume ratio.

READ ALSO: Five ice palaces and two football fields will be built in Moscow

Table sugar or sucrose is highly flammable under the right conditions, just like wood.

True, at the beginning, when sugar is heated, it turns brown and caramelizes, losing moisture in it, turning almost into charcoal, and the sugar molecules line up in long chains. As the temperature rises, a flash occurs that blinds and an explosion occurs. These properties of sugar are considered by some to be a biofuel option, and more.

Well, somehow the flammability of mineral wool, which is considered and classified as non-flammable and safe, has been forgotten. But it has its “buts”... at least in relation to chimneys. Rock wool products are often used as insulation in chimney penetrations.

Mineral wool always contains an organic binder. Research has shown that smoldering of this organic material can occur in chimney insulation. Smoldering is a flameless combustion that propagates at a very low speed in a porous medium and is characterized by the release of heat. At the beginning of the smoldering process, oxidation of the environment predominates, which can occur if there is a sufficient amount of energy. In the case of chimney insulation with mineral wool, hot flue gases, which is very important, add energy to the wool. A stable process occurs if the porous material is of sufficient thickness and serves as a thermal insulator to prevent the reaction heat from being released into the environment.

Temperatures ranging from 400 to 750 °C have been measured in smoldering processes in the reaction zone. The smoldering combustion generates additional heat in the penetrating structure, which in turn increases the temperature of both the penetrating insulation and the surrounding floor and roof structures. The additional heat can have a significant impact on the chimney penetration temperature and create a potential fire hazard in surrounding structures. Organic material begins to evaporate when its temperature reaches 200 °C, and, in studies, all organic material burned when the temperature exceeded 500 °C. Similar fire retardant properties and pyrolysis of binders have been reported for stone wool.

The amount of additional heat generated by smoldering combustion depends on the amount of organic material and the maximum temperature of the insulation.

Not all materials literally burn up. There are those that, starting from a certain temperature, smolder or melt. The settled dust of coal melts at 149 degrees Celsius, organic glass at 125 degrees, aluminum at 320, even tea at 220 degrees.

In conclusion, we should provide material that can be no less useful in practice: what is the calorific value of individual types of fuel, as well as an alternative to oil and gas in terms of the high calorific value of metal filings.

Thermal properties of wood

The efficiency will directly depend on the thermal conductivity of the material. Any owner of a private house with a stone stove knows about this nuance. The quality of combustion also depends on another indicator – combustion temperature. By increasing the degrees, you can heat the water in pipes or brick walls much faster, thereby protecting your home from severe frosts.

If you put poplar in the firebox, you can observe a very high flame, but its temperature will not exceed 500 degrees, and this is not so much for heating the room. It is preferable to use ash, beech and hornbeam. They burn actively, but at the same time they emit a temperature of 1000 degrees. This indicator is ideal for heating a room.

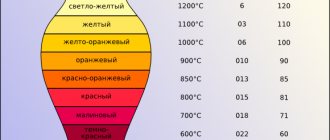

Combustion temperature measurement

It is very difficult to measure combustion temperature at home. A regular thermometer will not work here. Of course, “by eye” it will also not be possible to determine the correct combustion temperature of a certain material. To carry out such research, you need to purchase a special device called a pyrometer.

But you need to know that the high combustion temperature of wood in the stove will not mean that it will release the required amount of heat. Therefore, you should also take care of quality equipment. Good stoves have the ability to artificially reduce the supply of oxygen to the wood. Thus, it is possible to achieve an increase in combustion temperature and a decrease in heat transfer.

Since measuring the combustion temperature of different types of firewood at home is very difficult, expensive, and sometimes impossible, you can rely on official data. All indicators have long been calculated in laboratory conditions by specialists through comparative analysis. To obtain the necessary results, before testing, the firewood was thoroughly dried - brought to optimal condition for experiments with open fire.

Thermal conductivity of materials:

| Wood species | Calorific value in calories |

| Birch | 4968 |

| Pine | 4952 |

| Spruce | 4860 |

| Alder | 5050 |

| Aspen | 4950 |

The concept of “firewood combustion temperature” does not entirely correctly reflect the main characteristic. It is necessary to pay more attention to the ability to generate heat. The unit of measurement for this parameter, calories, is thermal energy that warms 1 gram of ordinary water by 1 degree.

Heat output

In practice, a person should be interested in the heat performance of the selected material. This is the temperature that can be reached when burning a certain type of wood.

Firewood heat output table:

| Breed | Heat output in percent | Temperature in Celsius |

| Beech and ash | 87 | 1044 |

| Hornbeam | 85 | 1020 |

| Winter oak | 75 | 900 |

| Larch | 72 | 865 |

| Summer oak wood | 70 | 840 |

| Birch | 68 | 816 |

| Fir | 63 | 756 |

| Acacia | 59 | 708 |

| Linden | 55 | 660 |

| Pine | 52 | 624 |

| Aspen | 51 | 612 |

| Alder | 46 | 552 |

| Poplar | 39 | 468 |