Pereosnastka.ru

Wood and metal processing

The development and improvement of methods for fire cutting and electric welding of metals with iodine and water have significantly expanded the possibilities of performing underwater technical work - ship repair, ship lifting, rescue, construction, etc.

Underwater work on fire cutting of metal is distinguished by many specific features and is often associated with exceptional difficulties and a significant danger for workers. The metal being cut is immersed in an aqueous environment that intensively cools it; this makes it very difficult to sufficiently heat the metal. The worker is constrained in his movements by heavy and uncomfortable diving equipment and has insufficient stability. Visibility during underwater work is usually very poor. In addition, there are additional difficulties created by the flow and disturbance of water, significant depths, contamination of the metal surface, etc. Most often, it is necessary to cut multilayer metal, and the layers of the package are often loosened by an explosion or impact during an accident, etc.

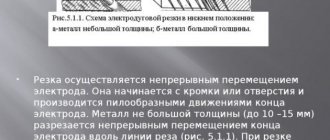

The simplest method is arc cutting, explored by the author of the book. Arc cutting under water is usually performed with a metal steel electrode with a diameter of 6-7 mm. For electrode rods, rolled wire is used, onto which a layer of coating is applied in an amount of about 30% of the weight of the rod, for example, with the following composition: 38% chalk; 56% iron scale; 6% Portland cement; 35 parts per 100 parts dry mixture of liquid glass (aqueous solution).

After drying and calcining the electrodes at a temperature of 250-300 ° C, the coating layer is impregnated with a waterproof compound by immersing it in varnish or other suitable solution. The coating layer must have sufficient mechanical strength and form a protruding visor at the end of the electrode when the arc burns, which significantly improves the cutting process. The molten metal flows out of the cut cavity under the influence of gravity, is blown out by a stream of gases and vapors created by the arc, and is removed by the movements of the electrode performed by the cutter, especially when cutting metal of significant thickness.

Arc cutting with a steel electrode has a number of undoubted advantages that give the method practical value: the comparative simplicity of the necessary equipment; ease of manufacture and availability of electrodes, for which any steel wire of suitable diameter available at hand is suitable; the relatively small diameter of the electrode is usually smaller than the width of the resulting cut, so the electrode can be inserted into the cutting cavity, which makes it possible to cut metal of significant thickness - up to 80 mm and, which is especially important for underwater work, to cut multilayer packages sequentially, layer by layer.

To carry out arc cutting underwater at acceptable speeds, a powerful current source is required to power the arc; Usually currents of 500-1000 are used. Work is carried out most often

Underwater cutters are built with a heating part for various flammable gases. Acetylene provides the greatest thermal effect, but the explosion hazard and possibility of spontaneous explosive decomposition of acetylene at pressures above 1.5-2 ati make it difficult to use in underwater work, since even at shallow river depths it is often necessary to exceed the permissible pressure limits for acetylene in order to overcome the back pressure of the column water.

Currently, acetylene is not used at all for underwater cutting; hydrogen is most often used. Hydrogen is non-explosive, so it allows you to work at depths of up to 30-40 m and produces a long preheating flame. As a heating gas, hydrogen also has major disadvantages, which include its low density. A cylinder containing 6 m3 of hydrogen contains only 0.54 kg by weight. Therefore, it is necessary to transport a significant number of hydrogen cylinders to support the work, which often encounters great difficulties.

A hydrogen-oxygen flame does not have a distinct core due to the absence of carbon particles in the flame, which makes flame control difficult. Hydrogen gives a lower calorific value of flame per 1 m3 compared to hydrocarbons; this increases its consumption and slows down the cutting process, increasing the warm-up time at the start of each cut.

Various gaseous hydrocarbons and their mixtures can serve as possible more economically advantageous substitutes for hydrogen. Due to the difficulty of providing underwater work with flammable gases, the question of using liquid combustibles, primarily gasoline, for these works has long arisen. The original underwater gas cutters, by analogy with conventional gas cutters for working in air, were designed with preliminary evaporation of gasoline and the supply of its vapor to the mixing chamber of the heating part of the gas cutter. Underwater gas cutters used electric heating of gasoline. These gas cutters turned out to be unsuitable for industrial use.

A new principle for designing underwater gas cutters was proposed and implemented during the Second World War. It turned out to be possible to abandon the preliminary evaporation of gasoline and replace evaporation with atomization, or atomization.

Gasoline is sprayed with oxygen, and the finest gasoline dust is supplied to the preheating flame zone, which has time to evaporate and burn completely. This invention sharply increased the performance of the underwater gas cutter and put gas-oxygen cutting, perhaps, in first place among the methods of underwater gas-oxygen cutting.

A modern underwater gas cutter has the following device. Gasoline under significant pressure enters the mixing chamber through several spiral channels of small cross-section and enters the chamber in separate thin streams. A stream of preheating oxygen approaches each gasoline outlet tangentially, spraying gasoline in the mixing chamber of a special device, where evaporation and ignition of the atomized gasoline occurs, burning out in the external torch of the preheating flame. Gasoline is supplied from a pressure tank, the required pressure in which is created by an inert non-flammable gas, usually nitrogen, supplied from a cylinder through a reducer. A normal installation, in addition to a gas cutter with hoses, includes a battery of 6-12 oxygen cylinders, a gasoline tank and a nitrogen cylinder. A petrol cutter consumes 30–60 m3 of oxygen and 10–12 kg of gasoline per 1 hour of continuous operation; Nitrogen consumption is insignificant and is used only to create pressure in the gasoline tank, so one cylinder is enough for several days of work.

The advantages of gasoline-oxygen cutting are the high thermal power of the preheating flame, reduced costs for transporting hydrogen cylinders, and the non-scarcity of fuel—gasoline. Gasoline-oxygen flames have a well-defined flame core for easy flame control.

Flame combustion products contain a lot of non-condensable gases CO and C02, which form a stable protective gas bubble, which makes the supply of additional protective air or oxygen unnecessary, simplifies and reduces the cost of installation and its operation.

Underwater oxy-fuel cutting provides high productivity. The installation required for cutting is transportable, not bulky, always ready for action and quite reliable in operation. Along with these advantages, underwater oxy-fuel cutting has serious disadvantages, which often force one to resort to other processes. These disadvantages include, for example, the rather noticeable reactive effect of the jet of gases flowing from the cutter, which interferes with the work of the diver-cutter. In addition, the dimensions of the mouthpiece of an oxygen gas cutter are so significant that it cannot be inserted into the cutting cavity, and therefore when cutting multi-layer loose bags to access the underlying element, it is necessary to cut and remove a fairly wide strip from the overlying element of the package, which is usually difficult and requires a lot of work. time. One of the serious disadvantages of underwater oxy-fuel cutting is the difficulty of igniting and regulating the preheat flame. The operation of igniting and regulating the flame under water is difficult and rarely used. Ignition and regulation of the flame above the water and the subsequent descent of the diver require a lot of time, especially at significant depths.

Great Encyclopedia of Oil and Gas

Underwater cutting - metal

Underwater cutting of metal is permitted only after the structure to be cut is securely fastened and the fall of the cut parts is prevented. It is prohibited to weld or cut structures under load or pressure. [2]

Underwater cutting of metal is permitted only after the structure to be cut is securely fastened and the fall of the cut parts is prevented. It is prohibited to weld or cut structures under load or pressure. [3]

Underwater cutting of metals is necessary for the repair of ships, the underwater part of metal structures of port hydraulic engineering and other structures. While underwater, the worker-cutter is constrained in his movements, since in addition to the resistance of the water and the state of weightlessness, he is wearing special diving equipment. Visibility is limited, especially during cutting, when a significant amount of iron oxide is released, forming a brown solution in water, interfering with the cutter's orientation and view of the structure being cut. [4]

Underwater cutting of metal is permitted only after the structure to be cut is securely fastened and the fall of the cut parts is prevented. It is prohibited to weld or cut structures under load or pressure. [5]

There are three types of underwater metal cutting: flame, arc and oxygen-arc. With any method, cutting is performed in a gas environment, which is created artificially or occurs naturally during the cutting process. Heating of metal when cutting under water is ensured by the creation of a gas bubble, which pushes water away from both the flame and the heated area of the metal being cut. [6]

Only persons who have reached the age of 18, who have passed a medical examination, who know diving, who are specially trained, who are well acquainted with the structure and operating rules of cutting equipment, as well as with the techniques and features of underwater cutting, and who have special certificates for the right to carry out these works. [7]

When using thin electrode wire and high current densities in carbon dioxide, underwater metal cutting can be effectively carried out. [8]

By using thin electrode wire and high current densities in carbon dioxide, underwater cutting of metal can be carried out effectively. [9]

For work in air, electric-oxygen cutting has not found serious industrial application; as for underwater work, significant improvements in electric-oxygen cutting have put it in first place among existing methods of underwater metal cutting. [eleven]

Cutting with a metal electrode is carried out without oxygen supply. For underwater cutting of metal with a thickness of no more than 20 mm, electrodes with a diameter of 5 or 6 mm are used with a coating of the same composition as for welding impregnated with paraffin. [12]

Underwater cutting is used for ship repair, ship lifting, rescue, restoration and salvage operations. There are three types of underwater metal cutting: gas flame, electric arc and oxygen arc. The most widespread in the gas-flame process are cutters operating on liquid fuel, since it is not necessary to create a shell of compressed air around the mouthpiece. [14]

After graduating from a vocational school and obtaining a qualification as a manual arc welder, working at a building materials factory or in construction, the welder will have to perform a variety of work on manual arc welding of building structure elements - columns, trusses, tanks, supports, vessels, reinforced concrete reinforcement and many other structures made of steel, non-ferrous metals and their alloys. The welder must know the physical essence of certain types of welding, the technology and technique of their implementation in order to form welded joints of the required quality. He must also know the equipment and technology of plasma and air-arc and underwater cutting of metals and be able to apply it in practice after passing the appropriate tests. Therefore, the welder training program provides, in addition to practical classes, which take up most of the training time, also a course of theoretical classes on the basics of welding. [15]

Underwater cutting, and even more so welding, if you think about it, is a completely unique phenomenon and a labor inaccessible to human understanding. For each of us, this process is associated with ultra-high temperatures and flames. It's not hard to imagine them outdoors. Moreover, all of us - even those who have nothing to do with welding work - have been able to observe them more than once on the streets and in courtyards. But how to ensure the same conditions at depth: where water not only cools, but also simply blocks the access of oxygen?

However, in reality, a method for cutting metal underwater was found a very long time ago: back in the 19th century. This was done using a carbon electrode. True, not in industrial conditions, but in laboratory conditions.

This was not enough for industrial use. However, thanks to those experiments, the very possibility of welding in a liquid environment was proven. By the way, not only in water: we could talk, for example, about oil. The fact is that during the burning of the arc around it - due to the decomposition and evaporation of the surrounding liquid - a gas bubble is formed. It is he who, figuratively speaking, does not allow the arc to “choke”. And she, in turn, constantly feeds the bubble with the generated heat. Based on this effect, the Russian scientist K. Khrenov was able to put the idea into practice in the early 30s of the last century. So it makes sense to quote here from his book “Welding, cutting and soldering of metals”, dedicated to this issue - also in order to pay tribute to the memory of the inventor. “For the first time in the world, electric arc welding under water was carried out and studied in the Soviet Union by the author of this book in 1932. Initial experiments were carried out in a small tank with running water, where the welder immersed his hands in long rubber gloves. Experiments have shown that it is possible to obtain stable combustion under water of a metal welding arc fed by current from a normal welding unit, subject to certain conditions. The most important of these conditions is that a sufficiently thick, completely waterproof layer of coating must be applied to the electrode rod, which should not become damp even if the electrode remains in water for a long time. The waterproofness of the coating layer is achieved after thorough drying by impregnating it with various varnishes and similar compounds. Good results, for example, are obtained by a solution of 80 g of celluloid per 1 liter of acetone,” wrote K. Khrenov.

Thanks to his experiments, the scientist was able to draw several conclusions that were fundamentally important for the development and implementation of this technology.

Firstly, it turned out that the arc melts metal under water almost as intensely as under standard conditions. Accordingly, such active melting of metal by an underwater arc makes it possible to successfully perform welding under water.

Secondly, K. Khrenov proved: metal melted under water and in air has a similar composition and mechanical properties.

Finally, thirdly, practice has shown: a specialist is able to perform all the main forms of welded joints under water - both in a normal and vertical position and in the ceiling position.

Thus, underwater welding as a technology took place.

Of course, at first the situations in which it was used were quite rare. However, with the development of technology, the situation has changed radically. Marine technology has stepped far forward and began to solve fundamentally new problems. For example, oil production platforms, as well as underwater pipelines, have become widespread.

It is quite obvious: work at such facilities requires special treatment. Including the highest quality and reliability of welding. In accordance with modern requirements, it (as predicted by K. Khrenov) should not be inferior in its key characteristics to work performed in air. This is the only way to not only preserve and recoup the multi-billion dollar investments in the creation of such facilities, but also ensure safety for operating personnel and the environment.

Underwater welding and cutting technologies have also improved. In addition to arc welding, welding with metal electrodes, exothermic method and others appeared.

It is worth noting that domestic scientists are still actively working in this area. Thanks to them, new underwater welding techniques are emerging that can improve both its quality and labor productivity. And in such jobs this is especially important: after all, we are talking about people who have to perform work under water, often in completely extreme, dangerous conditions. For example, not so long ago, scientists from the E.O. Paton Institute of Electric Welding developed a method for cutting and welding metals with flux-cored wire. It creates a unique opportunity for diving specialists to work without replacing electrodes, i.e. continuously.

Thanks to this, a welder working at depth does not have to worry about the supply of electrodes he has. The wire in the submersible unit is enough for 2.5 hours of continuous operation. Even the speed of its feeding is controlled by the operator located at the control panel on the surface. And most importantly, previously the welder had to stop to change the electrode. Accordingly, a “crater” formed in the seam, which then had to be welded additionally. The same thing happened when cutting. There are no stops when using cored wire. Consequently, the seam is continuous and even. And that means high quality. And it requires a specialist much less time.

Of course, the new method requires the use of special equipment. Such equipment was created by the Electric Welding Institute. And its use opens up wide opportunities for automating the process of underwater welding and cutting. This allows, on the one hand, to minimize the presence of people at sites where work is associated with extreme conditions and high risk. On the other hand, such a solution provides the opportunity to carry out welding operations where previously they were simply impossible: for example, at a depth inaccessible to the welder.

Until now we have only talked about electric welding and cutting. However, gas technologies “on the underwater front” are also presented. Moreover, like electric welding, they are being improved.

This mostly applies to cutting. As practice shows, cutting is one of the most common types of underwater work.

For decades, relevant problems have been solved primarily by “electrical” methods: for example, using arc welding. However, now, with the development of technology, the above-mentioned exothermic method is becoming increasingly widespread.

It is based on a scientific fact known to many experts: metal can burn in an oxygen environment. It is enough just to supply oxygen and “ignite” using an electric arc, and the electrode in the oxygen stream ignites.

Of course, special electrodes are required for such cutting. Thus, special tubular electrodes are used, consisting of an internal heat-generating element, which is made in the form of low-carbon steel rods installed in a copper tube coated with an insulating material.

After “ignition,” the electrode not only begins to burn on its own, but also reaches a temperature of 5500 degrees Celsius. And as long as oxygen is supplied, the process does not stop.

The most important advantage of the method is the high temperature. It allows you to cut not only ferrous metals, but also many other materials. Including various non-ferrous metals, concrete, stone and even composite materials. So “gas technologies” for underwater cutting do not lose their importance.

Share on social networks:

Similar materials

Ceramic backing pad for roller

Reverse roller of root seam

Accessories for good welding

Rules for cutting metals underwater

Our additional

services and sites:

| e-mail: | [email protected] [email protected] |

| icq: | 613603564 |

| skype: | matrixplus2012 |

| telephone | +79173107414 +79173107418 |

S Aratov

project support:

Place our button on your page! And we will place your button or link on our page. Send your application by e-mail

our button code:

Underwater electric arc cutting of metals

When cutting underwater, special rules due to the presence of an aquatic environment must be observed. First of all, the entire current supply up to the electrode must be reliably insulated in order to reduce useless current leakage to a minimum. This should be especially observed when working in sea water, which has high electrical conductivity. In Fig. Figure 73 shows one of the designs of an electrode holder for metal electrodes. The simple cylindrical shape of the holder makes it easy to isolate metal parts, and the screw clamp of the electrode ensures reliable contact.

Rice. 73. Electrode holder for underwater arc cutting, 1 - insulation; 2 — clamping cap; 3 - current-carrying rod; 4 - handle

Underwater cutting is performed with coated metal consumable electrodes, carbon or graphite electrodes. The most widespread is cutting with a metal consumable electrode, as it gives a narrower cut with high productivity. Electrodes are made from low-carbon rods with a diameter of 6-7 mm, a length of 350-400 mm, onto which a coating 2 mm thick is applied. The coating must be protected from water by impregnation with paraffin, celluloid varnish or other moisture-resistant materials. To make cutting easier in poor visibility, you can use a wooden ruler placed along the cutting line. Due to the fact that cutting occurs with intensive cooling of the base metal and electrode, the current should be 10-20% greater than when cutting in air. Below are approximate modes of underwater electric arc cutting of steel with a consumable metal electrode at a depth of up to 10 m.

Underwater electric arc cutting is performed using direct current of straight polarity. Cutting is carried out using the method of supporting the electrode. The length of the arc is determined by the height of the cover sleeve.

Uninteresting in our opinion: a1 a2 a3 a4 a5 a6 a7 a8

for railway transport, certified by VNIIZhT - “Favorit K” and “Favorit Shch”

, internal and external washing of cars.

Posting articles How and with what to wash the sides of boats and yachts Buy car shampoos Buy liquid silicone Buy chemicals for washing cars

Welding modes

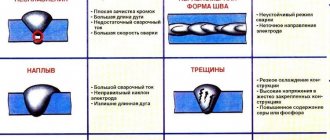

The first type of underwater welding described is most often used. It is the cheapest and allows you to get high-quality connections. For this, the correct modes are important. Underwater, it is better to carry out welding work with direct current, so the arc burns more stably. The current strength is set higher than on land due to the rapid cooling of the metal by the coating liquid. The optimal parameters for working with electrodes with a diameter of 4-5 mm are 200-250 A, with a deposition rate of about 6 g/A x H.

The voltage during underwater welding should not exceed 35 V. This is important for the safety of the worker. There is no metal burning defect due to the constant cooling of the product with water.

Underwater cutting of metals

Cutting metals under water is of great importance when performing ship repair, ship lifting and rescue work.

Cutting metals underwater has many specific features. The metal being cut is in water and is intensively cooled, which makes it difficult to cut through it sufficiently. A carver working underwater is constrained in his movements, as he is wearing special diving equipment. Visibility when cutting underwater is also limited.

There are three types of underwater metal cutting:

- gas-flame;

- arc;

- oxygen-arc.

With any method, cutting is performed in a gas environment, which is created artificially or occurs naturally during the cutting process. Heating of metal when cutting under water is ensured by the creation of a gas bubble, which pushes water away from both the flame and the heated area of the metal being cut.

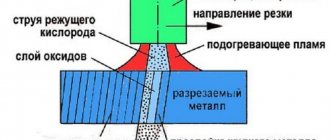

For underwater oxy-fuel cutting, special cutters are used that operate on gaseous hydrogen or liquid flammable gasoline. Under water, metal cools more intensely than in air, so heating it requires a flame 10-15 times more powerful than for similar work in air.

Underwater torches have devices to create and maintain a gas bubble that pushes water away from the flame. To form a protective gas bubble, carbon dioxide, carbon monoxide and additionally blown air are used.

The head of the hydrogen-oxygen cutter consists of a cap 3 and mouthpieces 1 and 2. Cutting oxygen 4 flows through the central channel of mouthpiece 1, and a hydrogen-oxygen mixture 5 flows through the annular channel between mouthpieces 1 and 2, forming a heating flame 7. Outside the mouthpiece 2 there is cap 3, through which compressed air 6 enters, which serves to form a bubble 9 around the flame. The flame of the cutter is ignited above the water, after which compressed air 6 is supplied to the mouthpiece and the cutter is lowered under water 10 (8 - a stream of cutting oxygen). If the flame goes out under water, then raise the cutter, light and regulate the heating flame, and perform a secondary immersion. When working at great depths, underwater ignition of the torch flame is used. For this purpose, a “fire board” and a rechargeable battery are used.