The principle of installing an entrance door depends on the type of door frame and the material of the wall to which it will be mounted. Most often, the base is concrete, brick, or blocks. In accordance with the characteristics of the surface, a suitable anchor is determined that can provide a strong and durable fastening.

The door frames themselves can be of different materials (wood species), weight, dimensions. Entrance doors may have a hollow steel body. In this case, you will need an increased length anchor. In some cases, it will be appropriate to use anchors with a countersunk head. Since the head should not protrude from the body into the opening, it is important to select the correct size of the anchor.

Advantages of anchors over other elements

Anchors for installing metal doors are the most optimal fastening option. Other methods are significantly inferior. For example, when holes are drilled and reinforcement with an identical diameter is hammered into them, the end of which is welded to the mounting ear of the box. The rod fits in quite tightly and creates the feeling of a strong fixation, but when hammering in the hole in the masonry is slightly distributed. When the sash slams due to wind or careless handling, the fastening points become loose, and the weight of the structure presses on the foam and plaster in the cracks. The latter begin to crack and crumble.

Fastening with dowels with plastic caps also leads to loosening. Plastic seals holes well for stationary objects (shelves, hanging household appliances), and vibrations from the rebate quickly crush the soft material and the box begins to wobble. Anchors are superior to all fasteners due to their expansion capacity. The hole can be drilled 1 mm larger than the diameter of the rod. Placing the pin does not break the edges in the masonry. A screw or hammer mechanism releases the internal devices and firmly fixes the box.

Types of anchors

There are three types of anchors for fastening a metal door:

- Driven - has a jacket with thick walls and four slots, on which an external cut pattern is applied, which increases grip. The inside is threaded. After drilling in the concrete, the jacket is inserted into the hole and hammered to the end. A special bolt is screwed in and distributes the sleeve.

- Wedge-shaped - distinguished by a jacket and a rod part with a thread, at the end of which there is a cone. On the other side there is a support washer and a nut. In the relaxed position, the conical part does not press on the walls and the element passes freely into the hole. When twisted, the wedge tightens and expands the jacket, tightly fixing the end of the anchor.

- Rod - similar to the previous one, but has a longer leg. This is useful for attaching one part to another over a long distance, perhaps through a hollow layer.

What anchors to attach a metal door to?

Seeing the variety of such products, it is worth figuring out which anchors to attach a metal door to. One of the decisive factors is the width of the installation gap. If it turns out to be very dense, and the structure was able to be aligned evenly, then driven models with a length of 100 mm are suitable. The thickness of the mounting ears is 4-5 mm and the minimum gap between the box and the wall will allow the anchor to be deeply immersed.

In case of a gap of 10-20 mm, wedge-shaped models with a length of 150 mm will be required. Having passed through the box and the wide gap, the fastener will enter the wall more than 120 mm. If you are installing a door that is 50-60 mm smaller in size than the opening, and there is no possibility or need to completely lay out the extra distance (a corridor in an office building, rooms in a hospital), then long-length rod anchors are suitable. Fixing a light metal structure through the void into the masonry with these elements will reliably connect the box to the partition. The gap is sealed with foam and drywall panels.

The diameter of the anchor is selected 1 mm less than the hole for installation in the box. If a bolt or nut protrudes into the working part of the bowl, which is in contact with the canvas, then they need to be ground off. not only manufactures metal doors, but also professionally installs them using suitable anchors.

Installing doors is a complex process that requires knowledge of all the intricacies in order for the door to perform its function and look aesthetically pleasing in the room. In order to install doors, there are several methods that are chosen taking into account your own capabilities and interior features.

Shape and dimensions of the structure

The frame base must match the door parameters (width and height) in order to provide full coverage and support to the structure. An important nuance regarding the canvas is the purpose of the room for which it is intended. Because ventilation requirements will depend on this. In steam rooms and baths, doors must provide reliable thermal insulation, so the opening is sealed as tightly as possible.

The bathroom, on the contrary, needs to be well ventilated so that excess moisture does not accumulate and mold does not appear. Therefore, the gap between the frame and the door should be a little wider. Good ventilation is also required for rooms in which gas equipment is installed.

To ensure reliable protection against heat leakage, a rectangular frame is constructed from four bars, which will serve as a frame for the door. The vertical posts will become hinged and recessed elements, and the transverse ones will become the upper support and threshold.

For free movement of the door leaf, the gap between the door and the posts should be about 3 mm. In cases where air flow into the room is necessary, the box is assembled from three bars, and a gap of about 10–15 mm is made at the threshold site. A standard distance of 3 mm is left along the vertical posts and the lintel.

The box with the threshold assembly is slightly higher than without it. The difference is about 20 mm. It is important to take this nuance into account so that you do not have to shorten the door. Because it is possible to adjust the canvas only if it is made of wood.

The gap between the door frame and the opening must be at least 10 mm on each side so that the structure can be easily installed and fixed.

Option No. 1 Installing the door with anchors and screws

Installation of a door block involves fastening its elements using self-tapping screws that pass through special holes for installation. Typically 4 anchors or screws are used on each vertical side. It is also allowed to attach racks with 3 fasteners on each side. In this case, it is necessary to evaluate the degree of filling of the remaining gaps between the anchors. The smaller the distance between them, the less likely it is that the stand will not deform when blown with foam.

This option is considered the most reliable, as it involves a strong connection to the doorway of all parts of the door frame. At maximum density with the opening, the door block will be stable, durable and invulnerable. Even over time, it does not deform or become beveled, which is an excellent condition for the long-term operation of the door.

Along with impeccable practical and operational advantages, there is one drawback. It consists of violating the integrity of the door elements and thereby leaving marks from the screws. The visible parts of the fastening elements, even if they are the same color as the racks, sometimes look unaesthetic. The solution is to use decorative plugs, although they also do not blend perfectly with the overall background of the door frame.

Peculiarities

The door block serves as a remarkable interior detail. Additional accessories are added to it.

Pen

The handle is part of the necessary functionality. It emphasizes the finished look of the entrance block. It is selected in accordance with the appearance and material of the canvas.

Door handles are classified by type:

- Push - control the lock latch. They consist of two parts, fixed on both sides of the canvas. Push-type ones also include rotary rounded ones.

- Stationary (staples) - not functionally connected to the lock.

- On the bar - the most universal and common in modern door blocks.

The handles are secured to the door leaf with screws and self-tapping screws. To ensure secure fastening, screw the self-tapping screw into ⅔ of the door material.

How to correctly position a horseshoe over the canvas?

Decorative plastic and other horseshoes are fiction because they are not charged with energy. Inside the home, amulets are placed with their horns facing up, which symbolizes a full cup accumulating good luck. On the outside, the horseshoe is secured with its horns facing down, as a talisman against evil spirits.

In modern homes, such talismans are attached to decorative strips above a metal door or at the top of the door leaf.

The accessory is secured using self-tapping screws into pre-drilled holes or with special glue.

Mirror

A mirror is an important element of the hallway interior. At first, the idea of placing life-size mirrors on the front door was due to the lack of free space in the corridor. Now it has turned into an original design solution.

Advantages of a mirror panel on a door:

- Visually lightens the massive structure.

- Visually increases the space of a corridor or hallway.

- Reflects light, increasing the level of illumination.

- Brings an element of originality into the interior.

Disadvantages of mirrors on entrance doors:

- Weighting of the door panel, not designed for the strength limits of the awnings.

- The fragility of a large-area mirror plate.

- The quality of conventional mirror coating on glass is not designed for vibration loads.

- Increased level of contamination of the mirror surface.

When attaching mirrors to the front door, the following factors are taken into account:

- When hanging a life-size mirror of large thickness, it is necessary to replace the canopies with reinforced ones due to the significant weighting of the door leaf.

- Vibration loads on the mirror when opening and closing the door.

- Reserving space for fittings, etc. - 20 cm from the end of the door.

Special requirements for mirror fabric:

- the mirror is made of impact-resistant tempered glass;

- the thickness of the mirror is selected optimally to prevent an increase in the weight of the sash;

- a thin mirror sheet should not distort the reflection.

Methods for attaching a mirror plate to a door:

- Mechanical. Fastening is performed:

- brackets;

- staples;

- profiles;

- self-tapping screws with silicone inserts.

- Glue. Used when the mirror surface area is no more than ¼ sq. m. with help:

- double-sided tape;

- construction adhesive “Liquid nails”;

- glue for mirrors "Soudal";

- using a combined method (glue and double-sided tape).

When attaching a mirror to a metal door, use a gasket that compensates for vibration loads:

Mechanical fastening is carried out using self-tapping screws into pre-drilled holes.

Additions to the iron base

Additions are designed to bring the doorway to the required size when the thickness of the door block does not match the doorway.

Additional panels are produced by:

- Plain , finished with edge tape. Selected strictly according to size.

- Telescopic , having tongue-and-groove connections. The width is adjustable.

What to attach the extensions to depends on the size of the mismatch of the door block. Additional strips are fixed:

- On foam - the simplest method with fastening with polyurethane foam after installation and wedging.

- For nails - with preliminary drilling of holes, securing the finishing nails in them with the points outward. Extras are driven into them.

- Self-tapping screws are the best way to attach to a metal door.

- With expansion - if there is a large expansion of the doorway. It involves installing an additional block before installing the door block itself.

When installing the entrance block, serious installation measures are carried out. Anchor connections eliminate the need for welding. They make it easier to dismantle the door frame without disturbing the integrity of the structure to replace or correct the geometry of the door section. Fastening the fittings is facilitated by the presence of modern hardware.

Option No. 2 Hidden installation

As in the previous method of installing doors, self-tapping screws and anchors are used to hold each door frame post in the doorway. What is distinctive is that for their location it is not the mounting holes that are selected, but the places where the door hinges and the locking part will be located. This option is technically complex and requires accurate calculations. The DoorExpo company recommends calling a competent installer who has a professional view of the work and can quickly complete the installation.

If there is the slightest inaccuracy after the doors are hung on the hinges, it will not be possible to adjust the correct position of the door frame. To do this, it will be necessary to dismantle the door, unscrew the anchors and begin installing the door again. The risk of installing a door yourself using this method also lies in the possible deformation of the doors. Due to the large distance between the anchors or screws, when using polyurethane foam in the gaps, the racks can give in and deform under pressure. To prevent this from happening, you should install wooden door frame spacers when using polyurethane foam. You need to keep the spacers until the foam in the gaps has completely dried.

Required Tools

You can install a door frame with your own hands using various tools; many owners have some of them, but what is missing will have to be rented or purchased.

- Miter box. A device that allows you to cut timber at different angles.

- Pencil, tape measure, construction tape.

- Acrylic paint on wood.

- Polyurethane foam for sealing the box.

- Chisel for making cuts for hinges.

- Hammer, drill, screwdriver.

- Nail puller, crowbar, hammer. For dismantling work.

- Miter saw, hacksaw and utility knife.

- Building level.

Option No. 3 Installing the door on foam

The easiest way to install a door is to attach it to polyurethane foam. Modern door blocks are not intended for this installation option, since their design features do not correspond to the conditions under which the door can be supported by foam.

In order to install a door on foam, the door frame is first assembled. Assembly takes place directly in the doorway. After all its elements are fastened together, it is necessary to adjust their position so that they are parallel, exactly vertical and horizontal. When the box is positioned perfectly, you can blow out the space between the wall and the beams with foam.

The main point is not to ignore the installation of spacers. When drying, polyurethane foam tends to increase in size. Therefore, it can disrupt the parameters that have been aligned and established for so long when preparing the door frame. When blowing with foam, it is important not to damage the surface of the box itself. Film, tape or other improvised materials that adhere well to the surface without damaging its texture will help protect it.

In our online store you can purchase door blocks, components, and installation kits. If you have no experience in installing doors, you can order the installation of the door by our craftsmen.

In the store you can find several hundred different types of fasteners that are used in various fields. One of them is a frame anchor. It was created for attaching doors and window frames to a brick or concrete base, which is how it got its name “frame”. Today, this type of anchor is used for installing door frames and metal-plastic windows.

A few words about measurements

The first step is to measure the width and height of the opening. You need to measure not from the box, but from the concrete (or brick) base. Only after this can you go to the store. There are two options:

- Order a door according to the dimensions of the opening.

- Buy a ready-made model with similar parameters.

In the first case, the purchase will cost much more, but you will not have to waste effort on expanding (narrowing) the opening. If the current canvas is a new sample, then you will be able to choose a model that is ideally sized. In "Khrushchev" and other standard houses built in the USSR, as a rule, openings of non-standard sizes. Therefore, the installation technology involves expansion. This operation will require a lot of physical strength.

Before placing an order, decide which direction the closing will take place. If your apartment is located against the wall and there is a distribution box (with machines and meters) hanging on it, then it is best for the handle to be located on the other side. In this case, the canvas will not hit the box.

Application areas of the anchor

The anchor, which is also called a frame dowel, is used when fastening wooden and plastic window frames, for installing doors and for other work when it is necessary to conceal the installation of a door frame or other element.

Most often, this type of fastening is used when installing windows.

The metal frame anchor consists

of a cut steel sleeve, a pin screw and a horse nut. It involves only through installation. In the manufacture of these anchors, only high-quality metals are used that can withstand heavy loads.

How to choose the right anchor?

Once you have selected the required fasteners, you can begin selecting a frame anchor. It is important to remember three important parameters:

:

- the material from which the anchor is made

. It can be ordinary or stainless steel, galvanized material, or brass. The choice depends on the specific environment in which the fastener is used. - the quality of the spacer sleeve

- the main part of the anchor. Pay special attention to its thickness: it should be more than 0.8 mm; if the readings are smaller, the anchor is considered to be of poor quality. - hairpin length

. The choice of fastener for this parameter depends on the tasks it needs to perform.

The diameter and length of the bolt have several parameters

: 8x72 mm (72 is the length of the stud, and 8 is the diameter of the sleeve). Maximum dimensions: 8x172 mm.

When choosing an anchor material, it is important to pay attention to the material of the working area

. It will effectively hold elements on structures made of solid brick and concrete; for loose materials it is better to choose other types of fastening.

What is the fixation used for?

The reliability of the entire structure depends on fixation to the load-bearing wall , which is why it is important to know how to secure a metal entrance door. Types of fastenings:

- One-piece:

- “grip” fastening;

reinforcing rod.

Anchors are used:

- Mechanical:

- wedge;

- mortgages;

- driving;

- spacer;

- frame;

- façade;

- hairpins;

- springs;

- ceiling;

- bolts with hook or ring.

- Chemical:

- For interior and exterior use;

- vibration-resistant;

- monolithic fastener;

- for thin-walled and loose bases;

- for long-term use.

- For foundation construction.

- Plastic.

- Height adjustable.

- Ground.

Installation

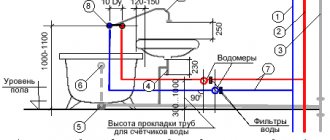

To carry out installation, you will need tools: a hammer drill, a Phillips screwdriver and a hammer. We'll tell you how to use a frame anchor using the example of installing a window frame. Installation is carried out in several stages

:

- Place the frame on spacers, align the window block relative to the vertical and horizontal planes, secure it on both sides with wedges, which need to be hammered in as tightly as possible.

- Select and mark mounting locations. Once the frame is securely secured, begin identifying locations for the frame anchors. Typically, fasteners are located 30 cm from the upper and lower corners of the block, but these are not mandatory conditions.

- Drill all the way through the wood frame, then insert a frame anchor into the hole and tighten it with a screwdriver. The fastener will expand on two sides: on one side – with a cap, on the other – with a cone-shaped nut. After this, the cracks are sealed with polyurethane foam.

I installed metal entrance doors 4 years ago using anchors that came in Installation of a metal door on anchors. The topic of the section “Windows, doors Contents

Video: nuances of installing an entrance door Work order Preparing the opening Main stage of installation Completion of installation Video instructions for installing a metal door The key element of the security of our apartments and houses is the entrance doors. In addition, they are the first to be seen by others. It is important that the entrance doors meet such characteristics and requirements as: reliability, strength, aesthetic appearance, convenience, thermal insulation and sound insulation. And all these characteristics depend not only on the quality and type of the door leaf and door frame, but also on correct installation. No matter how good the door is, inept installation can completely destroy all its good aspects. Below we will look at detailed instructions on how to install a door with your own hands efficiently and reliably. At the same time, we will try to consider as widely as possible the options for installing various designs of entrance doors. Preparation for work, necessary tools Even when choosing a door, you should carefully take measurements. To order a door, it is important to correctly determine the dimensions of the doorway. The difficulty lies in the presence of a door frame (frame) and a thick layer of mortar around the entire perimeter. Determining the actual size is sometimes a problem, because there is no clear boundary of the end of the opening. As a result, it is taken into account that nothing should remain in the lower part down to the base of the floor. If there are thresholds or the boat is very raised, then at the time of dismantling all this will be removed. The upper part of the opening never widens, that is, does not rise. The sides can be expanded slightly if necessary, but the width of the support beam, which marks the top edge of the opening, should be taken into account. As a result, the door should be 20-25 mm narrower on each side. In other words, the door frame of the new door should be 40-50 mm less than the total width of the opening and the same amount lower. To carry out work on installing the front door, you will need the following tools: a hammer drill or impact drill with a drill and a shovel; level; roulette; hammer and sledgehammer; angle grinder (grinder); wooden board, ax and saw for forming pegs. The choice of necessary materials differs depending on what will be used to fill the gap between the door frame and the walls. This can be polyurethane foam or cement mortar. After all, an unsuccessful installation can reduce to a minimum all the advantages of the door. Metal anchors with a diameter of 10-12 mm and a length of 100-150 mm or metal To secure the front door, anchors or metal rods with a diameter of 10-12 mm are also required. Video: nuances of installing an entrance door Procedure of work Whatever the door is in design or material, the installation process will be similar, with only a few nuances in each individual case. If the new door is separated from the main frame, it should be removed before installation and set aside while the frame is secured. It is advisable to cover the entire perimeter of the frame and door with masking tape if there is no protective film on it. If a metal door is being installed, then even before installation it is necessary to fill the inside of the frame with cement mortar or polyurethane foam. Before the actual installation, the filling will have time to set or dry and the excess can be removed. Typical structure and configuration of an entrance door Preparing the opening When dismantling an old door, you should not be particularly careful, it is only important not to damage the walls, especially if they are made of foam concrete or it is an old brick building. The door leaf is removed from the hinges or the hinges are unscrewed from the hinges. Using a grinder or saw, several cuts are made around the perimeter of the door frame and, using a crowbar, it is removed from the opening. Using a hammer drill, the opening is cleared of excess mortar and plaster around the entire perimeter. Particular attention should be paid to the bottom of the opening. As a result, the door must be mounted flush with the floors in the hallway or corridor, and this parameter depends on whether the screed will still form or not. Moreover, in the vacated opening under the old door there may be a wooden beam or brickwork that has become unusable over time. All this must be cleaned and removed, and instead, if necessary, form a base of bricks or the same wooden beam of the required height. The main installation stage From this stage, the help of a second person will be required, especially if an iron door is being installed. You need to place the frame from the new front door in the opening and use a level to check whether it can be installed strictly vertically. It should be checked in all planes, preferably in several places. For example, place a level in a vertical rack from the inner end and on one of the adjacent sides, and place the level on the lower partition. As a result, the corresponding level indicators must show a strict level match. If any part of the doorway interferes with leveling, then it is necessary to scrape off the protrusion. I ask forum members for advice on installing wooden doors. attaching interior doors to anchors is overkill, a “frame dowel” is quite suitable, and then If everything is fine, then the position of the frame is fixed with wooden pegs. For this purpose, it is better to use two pads per place. One lining is made with an even thickness 5 mm less than the gap, and the second is in the form of a wedge, while the second part is much longer than the first and is made with a small bevel angle. This makes it easier to adjust the box to level. Advice: It is better to abandon the old-fashioned method and not fix the door with nails first. In this case, there is a very high probability that the door frame will move. Once the door is clearly level, you can begin securing it. There are several different options you can use for this. It all depends on the design of the door and a little on the material from which it is made. There should be three attachment points on the sides and two on the top and bottom. That's the minimum. Initially, the side on which the hinges for the door are located is fixed, starting from the top point. After each fastening, it is better to check with a level that the installation is correct. After this part is secured, you can hang the door leaf and adjust the position of the door frame, and also check that the frame is not deformed and there are no excessive tensions. After this, you can remove the door leaf again and begin securing the other side and both vertical jumpers of the door frame. Again, adjusting your actions, if necessary, maintaining the level in both planes. So, methods of fastening the door frame: Anchor or pin fastening to the eyes. This fastening is most often found on doors of any type. For metal ones, they are an integral part of the box design. Wooden and plastic doors are most often attached with screws. A hole 10-15 cm deep is made through the hole in the eye using a hammer drill with a drill. An anchor bolt or a pre-prepared pin is inserted into the hole. The pin is a piece of reinforcement with a diameter of 8-12 mm, one edge of which is slightly flattened with a hammer to form a head, and the second is sharpened. The fastener is driven all the way into the hole. The anchor bolt is tightened using a socket wrench. If a pin is used, it is welded to the eye. Anchor or pin fastening through the door frame. Actually, everything is repeated, as in the first option, only the holes for fastenings are made directly at the end of the door frame. At a wooden door, it is also necessary to prudently drill a recess with a large drill, where the head of the anchor bolt or the flattened edge of the pin will hide. Grip type fastening. This type of fastening is suitable for a metal door. In this case, the door frame is held by the outer edge to the doorway, and a hook is welded from the inside, which holds to the inside of the wall. This option is suitable for apartments and houses with monolithic walls and allows you to install an entrance door without drilling or drilling holes in the walls. Completing the installation When the door frame is secured, the door leaf is hung and its operation is finally checked. To do this, the door opens first by 45 degrees, and then by 90. In these positions, it should not move spontaneously. There should be no play when closed. If everything is fine, then it’s time to start sealing the gap between the door frame and the wall. Filling with foam will speed up and facilitate this process. But the strength of the polyurethane foam may not be enough, and this will affect the burglary resistance of the entire structure. It is best to use cement mortar with the addition of alabaster. The entire gap is tightly filled with the solution. This will be much more effective with your hands than with a trowel or spatula. The solution for filling the space is prepared so that it does not float. It is advisable to bring it to the state of a loose solution, similar to a curd mass. The operation of the locks must be checked and, if necessary, the mating parts located on the door frame are adjusted if this option is present in the design. A rubber sealing tape is carefully glued around the perimeter of the door. Every other day, you can remove the protective film and previously applied masking tape. All that remains is, if necessary, to hang the trim on the outside of the doorway. They are screwed onto a wooden door using self-tapping screws with a countersunk head. For reliability and safety, it is better to recess the heads of the screws into the wood of the trim and cover them with wood putty. In the case of a metal door, the platbands are reinforced with rivets or bolts. In fact, this is where the process of installing the front door ends. After this, it is necessary to build slopes with which to hide the door fastening points and give a normal aesthetic appearance to the inside of the doorway. Video instructions for installing a metal door

Installing steel doors will help secure your home from unauthorized persons, and will also perfectly protect the room from drafts. With minimal construction skills and the necessary set of tools, you can install doors yourself without involving professionals. Proper installation of metal entrance doors will contribute to a long service life of the product.

What else is important to know?

Not every person will be able to install a door frame efficiently the first time. But don't despair. Because many flaws can be eliminated.

- If there is an unsightly seam, you can close the joint between the laminate and the door frame with a plinth or a special flexible threshold.

- If the box does not fit into the opening, then the posts and crossbars can be trimmed a little.

- Platbands allow you to beautifully seal the gap between the door frame and the wall. If their width is not enough, you will have to plaster and decorate the gap.

- To install an interior door frame in a concrete or brick wall, it is impossible to do without a hammer drill. If you are installing an MDF door frame first on slats, use a drill to make holes and only then use a hammer drill.

- Attaching a door frame to a wooden wall is much easier than to other materials. In this case, a hammer drill for drilling holes is not useful. You just need to screw the door frame to the wall using anchors. The main thing to consider is that over time, wooden buildings can shrink significantly.

- To facilitate the installation process, special installation systems for door frames were created. Thanks to them, the structure can be placed in walls made of any material without using wedges and spacers. This kit includes hidden mounting fasteners, detailed step-by-step instructions and diagrams. Using the system, even a beginner can insert a door frame.

source

Installing a metal entrance door with your own hands: preparation

Before you begin installing a new reliable iron door, you should dismantle the old one. First, it is removed from the hinges, and then the door frame is carefully removed. To do this, use a nail puller to pull out all the nails and pull out the frame, using a little force if necessary.

If the nails are firmly embedded in the door frame, then it should be sawed in several places so that it can be pryed off with a crowbar or a nail puller.

After removing the door frame, the doorway is thoroughly cleaned of any remaining plaster and protruding nails.

It should be remembered that ideally the opening should be slightly wider than the door block (15-25 millimeters). Therefore, you need to measure the height and width correctly.

What to do if the opening does not meet ideal parameters:

- The narrow opening should be widened using a hammer drill or grinder with a circle marked “stone/concrete”;

- A very wide opening is laid with bricks in one row;

- A slightly narrowed opening should be corrected with a solution made on a cement-sand base with the addition of plasticizers.

At the end, the opening is carefully cleaned and trimmed. The easiest way to prepare an opening is in a brick house.

Closing the gaps

The door opens and closes perfectly.

But what to do if for some reason the gap turns out to be too large? More than 20 mm.

Our advice: use cement-based mortar of the strongest brands to seal it. PC - 500 D0 is good.

- Under no circumstances use any type of putty or grout based on alabaster or gypsum, much less polyurethane foam. Such a fix can cost you dearly later.

- You can close the gap between the box and the wall. As mentioned above, if the gap is more than 20 mm, use a cement-based mortar to seal it. If less, you can get by with polyurethane foam.

How to install a metal entrance door to an apartment with your own hands

If there are special iron plates with holes on the sides of the door frame, then installing the doors will not pose any difficulties. But this installation method is possible if the door is adjacent to the wall on both sides, for example, in a narrow corridor.

Installation technology:

- The door block should be installed in the opening and leveled using tools: a level and a plumb line. The obtained result must be secured with wedges and re-checked for correct installation.

- Holes for fastenings are drilled in the wall, at least ten centimeters deep.

- We drive in the metal rods, riveting their upper part.

- Then you should check whether the door was warped during installation. To do this, it is opened and closed several times. You need to make sure that the locks and latches work well without jamming.

- The opening is sprayed with water and filled with foam.

- When the foam has completely hardened, it is necessary to trim it. This is usually done the next day, and until this point it is strictly not recommended to use the door to avoid distortions.

According to fire safety requirements, the door must come off from the outside so that residents of the apartment can freely leave the premises during a fire or smoke.

Content

- What will you need?

- Stages of installing a new door

- Video on the topic

Entrance door. This is what we see first. Without entering the house, we, of course, evaluate it not only from the aspect of aesthetic appearance. The main task of the front door is to ensure the safety of those who live behind it: after all, this is one of the basic human needs.

The installation of entrance doors must be approached as responsibly as possible: even small flaws can cause big troubles in the future. For example, if during the installation process you do not align the position of the door, then it will close itself under its own weight. And one fine day you will find yourself in front of a slammed door without keys. To avoid such troubles, we reviewed the step-by-step process of installing a metal door, taking into account all the important points.

How to use anchor bolts to secure metal doors

One of the most common fasteners used when installing a door frame are anchor bolts. They are made of durable steel grades and coated with a special anti-corrosion coating. These fasteners can withstand heavy loads for long periods of time, even in seismically unstable areas. Therefore, their use when installing doors is completely justified. A hardware store will tell you what kind of fastenings are needed.

Installation using anchor bolts:

- The door is leveled in the opening and secured with wooden spacers;

- Opposite the special holes in the door frame, cavities for anchors are drilled;

- The anchors must be inserted into the holes and driven in, and caps painted to match the doors must be placed on top;

- The opening is filled with construction foam.

If there are no holes for the anchor, they should be drilled in the side posts (three pieces on each side). The fittings are driven into them and welded to the doors with a welding machine.

Remove protective films

Remove protective films from the door leaf after finishing finishing work if you are doing repairs. And after installing the slopes.

We described in detail how to install door slopes (extensions) in the article.

Once again, please note that installing an entrance door is a technically complex process. We recommend entrusting it to professionals. This way you will avoid problems with the operation of the front door.

If you damage the door during installation, repairing or purchasing a new door will be expensive. Torex's certified installation crews will install your door quickly and professionally.

If for some reason the door is damaged during the installation process, specialists from the Togech plant will repair or replace it free of charge. You can find out detailed information and the cost of installing a door in the “Customer Support” section by following the link.

has a wide partner network, including in cities such as Moscow, St. Petersburg, Novosibirsk, Voronezh, Saratov, Samara and another 120 cities in Russia and the CIS countries.

www.torex.ru is the official website of the Torex company. This website is for informational purposes only and under no circumstances constitutes a public offer as defined by the provisions of Article 437 of the Civil Code of the Russian Federation. To obtain information about the cost of Torex products, please contact official dealers.

Prices in showrooms may differ from prices on the website. For current information on the cost of Torex doors, check with official dealers in your city.

The manufacturer reserves the right to make changes to the list and specifications of products at any time. For valid product information, please contact authorized dealers.

* All fields are required

By clicking on the button, you consent to the processing of your personal data User Agreement

The opening must be initially prepared for the installation (assembly) of the door. This also affects the price of the installer’s work - the more work he has to do to clean the opening, the more money the company will take from you.

Basic points: removal of the old door and its frame; the second wooden door (if present) may also interfere, since it is necessary to take into account the extension of the handle from the door leaf into the opening, usually the length of the handle = 5-7 cm from the door leaf.

(in the photo below, installation in the old foundation with expansion along the perimeter - cutting of 3 sides)

Further. The opening should ideally be 2-2.5 cm larger than the size of the box. These are the necessary installation gaps; the door must not only be leveled and “balanced” in the opening, but also foam must be applied around the perimeter to ensure tightness. In addition, the walls in the house are also not always smooth, they may have a convexity or curvature (for example, the top is piled 2 cm outward), and then installing the door will require a certain offset or slight deviation from the level to compensate for the curved wall, and in order to do this, just and you need this very loose gap of 2-3cm on each side. Otherwise, the door can be “slammed into the opening” so much that later it will simply jam or blow mercilessly from places it shouldn’t come from if it were installed properly. This is why it is IMPORTANT TO CONTACT EXPERIENCED INSTALLATION PROFESSIONALS.

So here it is. If the opening is smaller than the size of the box + 2cm-3cm, then it definitely needs to be expanded. Also, do not forget that with current factory doors, the casing and the frame are a single whole; the overhang of the casing around the perimeter is usually +5-7 cm. This means that there should be a distance of 7-10 cm to the left and right of the opening so that the platband does not rest against a perpendicular wall or pipe if your apartment is corner. If there is no space, then the platband will be cut down for you locally. Usually they cut off with a grinder exactly as much of it as it gets in the way.

So. The opening is cleaned and prepared for the installation of the front door.

Installation of the entrance door for welding

One of the oldest installation methods. It has no particular advantages over other methods. But, since it sounds “impressive” - “WELDING” - this hypnotizes many customers, instilling the illusion of super reliability. But this is a normal installation method, nothing more.

How does this happen:

Pieces of reinforcement (more precisely, a rod) are cut off, 5-7 cm long, and inserted into the drilled hole in the opening. And since the fittings have neither a washer nor a cap, there is only one way to attach it to the door - “weld”. That's all “INSTALLATION FOR WELDING”. It sounds loud and impressive, but in fact it is a simple installation option.

Another disadvantage of this method is that the reinforcement at the end is smooth and cannot provide reliable adhesion between itself and the concrete in which it sits. Concrete is not wood; you can’t drive reinforcement into it like a nail into a board. This means that the hole in the opening will always be larger than the diameter of the reinforcement, which causes backlash if the door is heavy. And the play leads over time to loosening, distortion and jamming of the locks.

Note that this is not the most modern method and not so reliable. Otherwise, why are elevator equipment (which weighs many tons), 350 kg air conditioners (outdoor units of air conditioners and multi-systems weighing 120 kg and above), and other heavy suspended equipment not secured by “welding”, but EXCLUSIVELY BY ANCHOR BOLTS.

Installing doors on anchors (anchor bolts)

Modern and reliable installation method. And all over the world! Let's repeat. Heavy elevators in your own home, heavy outdoor air conditioner units, which weigh 100-200-300 kg or even more, are installed on anchor bolts. Because this is the modern and most reliable and durable way to install any suspended equipment and more.

The anchor has a STEEL DOCK at its end which, when tightened, BURES into the concrete. This ensures the HIGHEST CONTRACTION, eliminating play and loosening. It is also important that the anchor bolt allows you to pull it towards itself, since when tightened, a tension is created in the product, that is, the same entrance door is, as it were, attracted to the opening on each side, but by definition it is not possible to pull anything with a piece of reinforcement, so like the reinforcement is smooth and will simply fall out. And there’s nothing to pull her in.

So, if you need REALLY HIGH-QUALITY INSTALLATION OF AN ENTRANCE DOOR (INSTALLATION), then choose anchor bolts, as all civilized companies that are responsible for their work do.

Installation cost

On average, the price for installing an inexpensive door starts from 2,000 rubles. into the finished, cleaned opening. More expensive models, due to their size and weight (reinforced, heavy and three-circuit), usually cost 2,500 rubles. for standard installation. Some models - 2700-3000 rubles. for installation. Naturally, additional work to expand the opening, remove slopes (cutting gypsum board (plaster knocking down) around the perimeter from the apartment side) and other work are not included in this amount. The full turnkey cost can always be clarified with the manager or with the surveyor at the measurement.

Correct installation of the entrance door in a private wooden house

In the first year after the construction of a wooden house, doors are usually not installed, since the material shrinks and all openings become lower, sometimes even by 15 millimeters. Under such conditions, any door can become deformed and stop working properly. After the frame shrinks, you can safely install doors and windows.

Tools required for work:

- Level and plumb lines;

- Hand or electric drill;

- Chisel and hammer;

- Roulette;

- Hacksaw with wood blade;

- Planer (regular or electric).

First, the size of the frame is adjusted to the door frame. It is desirable that it fits end to end, but a gap of no more than one centimeter is allowed. Excess wood is trimmed with a plane, and its deficiency is compensated by stuffing wooden slats. If there was no opening initially, then it can be easily cut with a saw, having previously calculated the dimensions.

When installing the frame, you should remove the door from it to make it easier to level. Long wood screws are screwed into special holes, which will securely fix the door frame. Special plugs are installed on top of them.

Then the door is hung back and its adjustment is made. It should not sag or warp.

Wide gaps between the box and frame are filled with foam, and narrow gaps are sealed with insulation (tow).

There are beautiful platbands on the street and inside sides.

Additional strengthening of doors is necessary to protect them from burglary. No matter how impressive the door looks, there will always be professionals who can easily break it or knock it down along with the jamb.

Ways to strengthen entrance doors:

- It would be advisable to install additional hinges or replace existing ones with reinforced ones, which are sold in specialized stores.

- Locks must be installed at a considerable distance from each other, for example, one at the top of the door and the other in the middle.

- The more the door frame fastenings are recessed into the wall, the less chance it will be knocked out.

- Installing special anti-removals will prevent it from being pressed out using a crowbar.

- You can fasten iron squares around the perimeter of the doors and drive their edges into the wall.

- If you install a safe door, it will be almost impossible to break into it.

Sometimes door installers offer services to strengthen them and protect them from burglary. In this case, you should listen to the advice of professionals.

Removing an existing door frame

If you have a wooden door installed in a wooden frame, then dismantling does not require much physical effort. But if you want to reuse the box, for example, in a country house or in auxiliary buildings, you need to try to dismantle it carefully.

- Remove the door leaf from the hinges.

- Using a nail puller, remove any nails that secured the frame to the wood studs or sides of the opening.

- Using the back of a nail puller, pry the frame away from the walls on all sides and remove it entirely. If you cannot reach some fastenings, then the frame will have to be cut with a hacksaw and removed in parts.

Dismantling a metal door requires more time and effort.

Using a grinder, cut off the fastenings of the metal door frame. Where the circle cannot reach, use a chisel and hammer or hammer drill and expand access for the angle grinder to part of the wall. Sometimes you can remove an inconveniently located fastener with two cuts facing each other.

Please note that when cutting the fasteners, the door leaf is wide open and is fixed in this position by an assistant. He also insures the craftsman against the possibility of the box suddenly falling out of the wall.

If, after removing all the fasteners, the box does not want to be removed easily, you can use a nail puller or a bent crowbar - a crowbar.

Gradually moving the tool along the frame, remove the box from the wall. For safety, it is advisable to do this together.

Clean the walls from loose pieces of plaster, protruding nails and anything else that could weaken the installation site of the metal door. Seal gaps and cracks with putty or mortar. If the voids are too large, fill them with pieces of brick.