Applications of underwater welding

Welding under water is an integral part of any repair or installation work on metal structures and parts located below the waterline:

- oil pipelines that transport oil and gas to various countries and regions

- sea and river vessels that are subject to corrosion, various damage during storms and hostilities, etc.

- berths and port facilities, a significant part of which is below the waterline

- drilling rigs, platforms or dams

- special technical structures around wells on the seabed, etc.

In order to understand how it is possible to implement such complex tasks, it is necessary to have an understanding of the technological features and principles of underwater welding.

"League" - welding on water

Gas welding machines "League"

operate from a 220V network

using distilled water.

The electrochemical separation of water into a mixture of gases (hydrogen and oxygen) will forever relieve you of the difficulties associated with the acquisition of oxygen and acetylene. The flame temperature reaches 2600ºC, which ensures welding, soldering and cutting of ferrous and non-ferrous metals up to 4.5 mm thick.

Cost of gas welding when using electrolysis plants "Liga"

is reduced

by 45 times

compared to traditional gas welding using bulky gas cylinders.

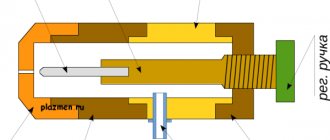

Rice. 1. Gas welding machine “Liga-02”

The principle of operation of the “League” is as follows: when electric current flows through water, hydrogen and oxygen gases are released. The hydrogen-oxygen gas mixture produced in the electrolyzer passes through a gas cooler-enricher, in which excess moisture is condensed.

The cooler-enricher allows you to dose the introduction of vapors of volatile hydrocarbons (benzene, gasoline, alcohol, etc.) into the gas mixture using a control wheel. The resulting gas mixture flows through hoses into a burner equipped with a built-in “dry” flame arrester. The amount of gas mixture produced, and therefore the strength of the flame, is regulated by the current regulator.

The maximum flame temperature achieved is 2600 ºС.

If the performance of the installation does not correspond to the diameter of the burner nozzle or the gas lines are clogged, then the pressure inside the electrolyzer increases. When the pressure exceeds 0.4 atm. an electronic pressure sensor is triggered, which turns off the current through the electrolyzer, gives a continuous sound signal, and the LED lights up.

To increase the efficiency of the electrolysis process, KOH alkali (150 g per 1.5 liters of distilled water) is added to the water once (before putting it into operation), which is not consumed in the process of producing the gas mixture (the electrolyte is changed once a year or after 200 hours of continuous operation ). During operation of the installation, the electrolyte level constantly decreases. When the minimum level is reached, the electronic level sensor is activated, which gives an intermittent sound and light signal.

Operating principles of underwater welding

Welding under water can be done in different ways, technologically significantly different from each other - dry and wet:

- Dry underwater welding involves the use of expensive additional equipment, which ensures the creation of conditions around the welding object under water under which it is possible to use conventional welding machines used on land. This could be an underwater chamber, an oxygen compartment, a box, etc. We will describe how this happens below.

- Wet underwater welding is carried out by a specialist welder directly in an aquatic environment using only the electrode brought into operation and his own skills and abilities. How does this happen?

In this case, the arc welding method is used, which is the most common. The welding arc, when working at depth, releases a lot of thermal energy and evaporates the water around it, which creates a gas-filled sphere that allows it to burn regardless of the layer of water around it. At the same time, combustion products raise suspensions around themselves, making it difficult for a specialist to see the welding seam. In turn, this type of welding is divided into subtypes:

- Semi-automatic. The welder manually adjusts the direction of the automatic wire feed. The advantages of this method include its duration and better visibility during the work process, since in this case much less combustion products are produced than with the manual method.

- Manual . The welder uses electrodes for underwater welding, can move freely and use welding equipment in hard-to-reach places.

Of course, to carry out work of such complexity, not standard equipment and consumables are used, but specialized ones, adapted for difficult conditions of use. We will consider below what requirements they must meet.

Equipment and consumables for welding at depth

The welding process takes place in cold water containing a large amount of hydrogen. In order to compensate for heat loss, an arc in an aquatic environment requires a higher voltage than on land, 30-35 V. Therefore, welding machines have a voltage of 70-110 V. Both alternating and direct current can be used for welding work. The most commonly used is direct current with a power of 180-220 A.

Electrodes for underwater welding have a special waterproof coating (film) impregnated with waterproof compounds: paraffin, nitro varnishes, etc. The weight of the film must be at least 150% of the weight of the electrode itself to ensure reliable and long-term protection of the rod when working in water. The diameter of the electrode is 4-6 mm.

The surface of the holders and cables for this type of work is sealed and has reliable electrical insulation to ensure uninterrupted operation of the welding circuit.

Methods of using hydrogen welding machine

The hydrogen welding machine can operate both from a three-phase electrical network and from a household one. Also used in manual and automatic modes. During operation, a mixture of oxygen and hydrogen is supplied to the burner; the flame temperature is 600-2500°C.

It is worth noting that atomic-hydrogen welding with such a device is easy to use. Typically, the desired operating mode is set in a matter of minutes, which depends on the required gas flow and the temperature at the place where the process is performed. When welding with hydrogen, unlike acetylene, the environment is not polluted with harmful substances. This is due to the fact that devices that use hydrocarbons as fuel emit only pure steam. The device works thanks to hydrogen, which is produced in the device itself. It is formed due to the fact that water (which is poured by hand) is split into oxygen and hydrogen atoms, resulting in the formation of a gas mixture with high energy, which is necessary for welding. To operate such a device effectively, you need 1.5 liters of distilled water and electricity.

Although the hydrogen welding machine is safe, you should wear protective clothing and goggles during operation.

Using such devices, you can perform such procedures as: soldering, welding, powder coating, surfacing, oxygen cutting. Based on which operating mode you choose, you can perform a variety of complex jobs: from connecting parts of small thickness to cutting thick and durable steel sheets. In addition to their main purpose, such devices are actively used by dentists, jewelers, refrigerator repairmen, as well as during body work, during maintenance and repair of radiators, etc.

High safety of welding work is ensured due to the fact that the device includes an automatic shutdown system, which turns off the device if the operating pressure exceeds the norm.

Organization of the welding process under water

It was already mentioned earlier that underwater welding is divided into two main types: dry and wet, the principle of organizing the work process of which is significantly different from each other:

- Dry welding under water. This type of work is used infrequently, since it requires large financial costs, time, training and specialized additional equipment (cranes, ships, control and measuring instruments, etc.). Subtypes of dry welding at depth:

- Welding in a dry deep-sea chamber or mobile box. This type of work is used infrequently, since it requires large financial costs and specialized additional equipment (cranes, ships, etc.). With this method, a deep-sea sealed chamber (“caisson”) is immersed or constructed under water, which is also hermetically sealed around the working surface. The welder works inside this structure, which is maintained at atmospheric pressure by filling it with gas and displacing water. The quality of seams and working conditions for this type of welding are in no way inferior to those carried out on land.

- Hyperbaric welding. The welding process is carried out in chambers where a gaseous environment is maintained, displacing water. The welding specialist himself is located outside this box; welding is performed using an electrode wire. The most important condition that must be met with this type of welding is a very tight fit of the welding elements at the joint.

- Wet welding under water. With this type of welding, both the diver and the work object are in an aquatic environment. No specialized additional equipment (besides welding) is required for this method. This significantly saves time, gives the welder freedom of movement and does not require additional costs. The quality of the seams, unfortunately, due to the peculiarities of welding carried out directly in water, is inferior to dry underwater welding.

The difference between a plasma cutter and a welding machine

The difference between the Gorynych plasma machine and a standard welding inverter lies in several parameters:

- Weight. The weight of the plasma generator (burner) does not exceed 700 grams, and the control unit - 4 kg. The use of a plasma generator does not require additional compressors and transformers, gas cylinders, wire, or electrodes.

- When changing the welding material, it is enough to switch the operating mode on the control unit.

- The plasma generator filling fluid is ordinary water (if cutting metal products) or a solution of 45% ethyl alcohol. Therefore, if you buy Gorynych, welding will be carried out using basic consumables - water. For one hour of operation, the device requires 200 grams of liquid.

- The device consumes several times less electricity than welding inverters, so its cost pays off quickly enough with active use. Therefore, if you buy Gorynych, welding conventional metal structures will cost several times less than inverters.

- The device operates from a standard 220 V network. The amount of electricity consumed is 2.5 kW/hour. If necessary, the vehicle voltage supplied through a converter can be used as a current source.

- The device has unlimited functionality - it is capable of cutting any non-flammable material. Therefore, if complex and diverse plasma welding is required, buying Gorynych will be the optimal solution.

- With the help of Gorynych, you can weld metal sheets with an accuracy of several millimeters and a seam thickness of 0.3 mm.

- The plasma generator does not harm the environment and does not emit harmful waste.

Requirements for underwater welders

This profession is fraught with many difficulties and risks; it requires specialists to strictly adhere to safety precautions and certain knowledge and skills.

To become an underwater welder, you must have a welding degree and a technical diver certification. Only with these specializations in hand will you be able to enroll in an underwater welding school, where you will be taught all the necessary nuances and skills for further work in this specialty. If you have questions related to this topic, or perhaps you work in this specialty, please leave a comment or share your personal experience.