What is riveting

The mechanical connection of parts using a series of rivets is called riveting, and the connection itself is called a riveted seam. It is used where it is inconvenient to weld parts or where non-weldable materials are joined. Not only metals are riveted, but also parts in clothing, accessories, etc. are connected in this way. But there it is more of a finishing touch than a loaded connection. So next we will talk about riveting in construction or home improvement. In principle, you can use a screw connection instead of riveting, but bolts and nuts are more expensive, and their installation takes longer.

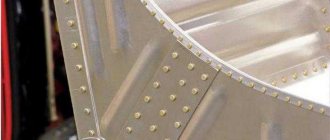

This is what a rivet joint looks like

If we talk about installing fences made of corrugated sheets, rivets are more reliable, since they can only be removed by drilling out the fasteners. When installing screws or self-tapping screws, they can be unscrewed and both metal and hardware can be removed. In some cases, riveting is more convenient when installing a roof made of corrugated sheets or metal tiles. On the roof, installing screw connections is problematic and time consuming. But rivets, and with a good tool, can be done in an hour or even less.

Most common use in private households

How are parts connected using rivets? The rivet is installed in the prepared through hole. It has a head that rests on the material and the rod. During the riveting process, the end of the rod is flattened, changing shape under the influence of force. Therefore, ductile metals are used for these hardware.

A little history

Not only nails can be considered one of the oldest representatives of construction fasteners, but also rivets, which were mentioned in 3 thousand years BC. Connecting elements using rivets was used in ancient Egypt, in the Gallo-Roman era, and at the dawn of the Viking era.

The principle, then and now, is simple: the fastener is inserted into the hole and then “flattened” out the other side. The connection is held and does not diverge due to two heads that clasp structural elements that are larger in diameter than the hole itself. Under the influence of force on the fastening site, the material of the connecting rod practically penetrates into the material of the walls of the working structure, filling all possible space. Hence the strength of the connection.

The most famous structure, the elements of which are connected by means of rivets, is the Eiffel Tower. In St. Petersburg, a similar miracle of construction of its time is the Bolsheokhtinsky Bridge. Famed shipbuilders, the Vikings, also used commercial fastenings to firmly secure the hulls on their ships for the rigors of sea voyages.

In the era of shipbuilding development to this day, rivets are also widely used and have a number of advantages over welded structures.

Since the 1950s, this fastener has become most widespread due to improvements in the installation process.

Types of rivet seams

If we talk about the method of joining sheets, then riveted seams can be overlapped (one sheet overlaps another) and end-to-end. Joint seams can have one or two overlays. With overlays they are more reliable and are used in critical and loaded places.

Types of rivet seams: overlapped and butted with overlays

According to the location of the rivets:

- single row;

- double row;

- multi-row.

They can be located opposite each other or in a checkerboard pattern. Seams can be strong, tight (sealed) or durable-tight. Dense ones are made using elastic gaskets placed between the parts to be connected. Durable and dense ones are used mainly in boilers. Now they are more often replaced by welding.

Classification of blind rivets

Depending on their technical characteristics, fasteners of this type are usually classified according to the material of manufacture, the strength of the rivet and its compatibility with the base material. In the manufacture of the sleeve and rod, aluminum is often combined with steel or stainless steel; one-component products made from the listed types of metal are less commonly produced. If we arrange the modifications of blind rivets according to the degree of strength of the material used to manufacture sleeves and stilettos, starting with the highest, then the row will be as follows: stainless steel, a combination of stainless steel with aluminum, and in the last positions, steel fasteners due to the high degree of susceptibility of such a connection to corrosive effects.

Types of rivets

What is a rivet? It is a cylindrical rod of ductile metal (may or may not be hollow) with a shaped head at one end. This head is called a mortgage. During the installation process, due to the flattening of the metal of the rod on the second side, a second head is formed. It is called closing (closing).

Types of rivets

There may be composite rivets (such as the popular blind or screw rivets), which consist of a body and a shank. But this does not change the essence: the embedded head rests on the material, and at the other end, due to the plasticity of the metal, a second head is formed. It is simply formed due to the fact that the rod is extended and the expanded part crushes the second part.

Types of cores and embedded heads

Rivets differ in the shape of the head and the shank. According to the type of rod they are:

- with a solid rod (high load capacity, but difficult to install);

- semi-hollow (part of the rod near the embedded head is solid, part is hollow);

- hollow (the head and rod have a cylindrical solid hole, they are easily riveted, but cannot withstand high loads).

Types of rivets by type of rod and head

Rivets have the following types of heads (pictured above):

- Semicircular (high and low). Sometimes also called spherical. The most reliable, create a strong seam.

- Cylindrical and conical (flat). Used if the connection is in an aggressive environment.

- Secret and semi-secret. Installed when fasteners should not protrude above the surface. The most unreliable connection, used only when necessary.

Different rivets can be installed side by side.

Each type of rivet head is found with each type of shank. They are selected depending on the planned load. For maximum loads, hardware with a solid rod and a semicircular head is needed. Hollow seams can also be used for seams that are not too loaded, but they do not provide tightness. If such a characteristic is important, then semi-hollow ones are installed.

Types of rivets

Despite the fact that welding has become accessible even to a layman, riveting does not lose popularity. After all, not all metals can be welded, and the welded seam is susceptible to corrosion. Therefore, new varieties of rivets are constantly appearing, so there is definitely no complete list. Let's look at the main and more popular ones.

- Classic or ordinary. Universal, used for all types of seams. They can be distinguished externally - they resemble fungi.

- Semi-tubular (the rod is half hollow). They require less effort during installation, but their strength is low. Used in connections with low mechanical load.

Classic and threaded rivets - Embedded, pull-out, tear-off or traction. Composite (two-part) hardware. They are good because when installing they do not need to be held on the other side of the seam. They are used to install fences or install roofing materials.

- Piston. They are used for connections with low loads, made mainly from soft metals (aluminum and alloys, copper).

Nut and rivet rivets - Threaded (nut). For connecting parts with thin walls (up to 0.3 mm). They differ in that the inner part has a cut thread, the outer part has a vertical notch that prevents rotation around its axis. The screw is screwed inward, pulling the free part of the housing to the connection point. This is exactly how it turns out - due to creasing - the closing head.

These are the main types of rivets that are used in construction, mechanical engineering and other fields. Each species has its own subspecies that differ in nuances.

Blind rivets

Let's say a few words separately about blind rivets. They are used for fastening corrugated sheets and metal tiles. These are the ones you most often encounter when arranging a site. The blind rivet consists of a tubular body and a solid rod inserted inside. They are called composite because they have two independent parts. Also, this fastener is reinforced - after installation, part of the rod remains inside, which increases the strength of the connection.

How does a blind rivet work?

The length of the blind rivet body must be greater than the thickness of the parts being connected. It is inserted into a hole made in advance, after which the riveter grabs the rod and pulls it through the hollow body. At the far end of the rod there is a ball that forms the closing head from the flared edge of the body. The excess rod is removed with a tool, but some of it remains inside, which makes this connection quite strong.

As is clear from the description, it is important to choose the correct rivet size. Too short will not allow a normal bead to form, which will weaken the connection. A body that is too long will give a lot of play, which is also not good. So when selecting this type of fastener, carefully look at the recommended thickness. Ideally, your connection is in the middle of the range.

Rivets for joining loose and soft materials

The hardware listed above is not suitable for joining soft and plastic materials - plastic, chipboard. There is another type of similar fastener for them. It is not as large in size and less durable. But, during installation, less force is created so as not to destroy the materials.

There are the following types of rivets for joining plastic or soft materials:

- Petalaceae. When installed, the rivet body opens into several petals. The large contact area of such a closing head allows the load to be redistributed.

Such rivets can be placed on plastic, fiberboard and other “non-metals” - Spacer. This is an exhaust subspecies, but with cuts along the body. When installed, they fold, also forming a kind of petals, but double. In this case, the head of the hardware remains on the surface of the part without going deeper into the material.

There are also plastic rivets. They are usually made for furniture, sometimes for fixing decorative panels. These rivets are more like screw rivets. The lower part is cut into several petals; inside there is a thread through which the rod is screwed. As it twists, the rod pushes the body apart, which is held in place by friction.

Properties of different types of rivets

The first and one of the most important things is that rivets create a reliable connection, unlike screws and screws, and do not damage the material. Also, rivets take up very little space and do not have complex installation specifics.

Such fasteners have low cost and the highest practicality and efficiency. Due to this, rivets are most often used in installation and reconstruction work.

In addition to all of the above, rivets have the following advantages:

- highest resistance to vibration;

It is worth noting that the threaded connection weakens under prolonged vibration. Construction staples do not have this problem. They are tightly attached to the object due to which vibration will not separate them.

A riveted seam will begin to lose its properties only if it is subjected to significant mechanical impact, notable for tearing and shearing. However, the rivet will only break and not come out of the joint.

- various types of rivets are extremely popular;

The demand is due to the fact that fasteners have a wide variety. Therefore, you will always choose the most suitable tool to solve your specific problems.

Cold paper clips are made using soft and ductile metals. Therefore, they are suitable for connecting oversized objects and performing simple reconstruction work.

“Hot” fasteners are made from hard steel grades. Their distinctive feature is that they do not deform without heating. They also provide an extremely reliable connection. However, they have limited specific applications. They can be used only if the high temperature conditions do not have a negative effect on the part.

Metal riveting

The process of riveting metals consists of two stages: preparatory and the actual installation of hardware. Preparation - drilling holes, countersinking for countersunk heads if necessary. Please note that countersunk heads can be on one (either) side or on both.

The riveting process itself is as follows:

- insert the rivet;

- tighten the parts to be connected;

- form a closing head using a tool;

- check and clean the connection.

This is how blind rivets are installed

With a good tool, work goes quickly. For private use and one-time work, manual riveters are usually used. And even with them, the process itself (without drilling holes) takes a matter of seconds. If we talk about installing corrugated sheets or metal tiles, it is recommended to coat each hole made with paint to prevent corrosion. It is these processes - drilling and painting - that take a lot of time.

In general, there are two ways to install rivets: cold and hot. When hot, the joint is preheated to a certain temperature (determined by the metal and the thickness of the parts). In practice, it is used when installing rivets of large diameter - 12 mm or more.

The rivets are placed in rows. The minimum distance between adjacent ones is 4 diameters; from the edge of the sheet to the center of the hardware is no less than 1.5 times the diameter of the rivet. When attaching a profiled sheet, place it in a recess, not in a wave.

INSTALLING BLEND RIVETS

- The rivet is installed in a pre-drilled hole.

- Using the installation tool, the core is pulled out, forming the closing head of the rivet.

- After the closing head of the rivet is formed, the resistance to pulling out the core increases sharply, and the core breaks at a thin place.

- Installed rivet.

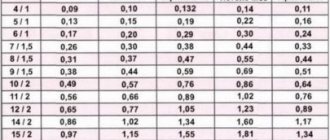

Selection of rivet sizes

Rivets are selected based on the thickness of the metals being connected. The following are important: the parameters of the embedded head and the diameter of the rod. The diameter of the rod determines the diameter of the drill, which is used to prepare a hole in the parts to be joined. You can approximately determine the diameter of the rivet by doubling the thickness of the parts being connected. The length of the rod is at least 2 times the diameter of the rivet, and the protruding part must be at least 1.25-1.5 times the diameter.

| Rivet diameter | 2.0 mm | 2.3 mm | 2.6 mm | 3.0 mm | 3.5 mm | 4.0 mm | 5.0 mm | 6.0 mm | 7.0 mm | 8.0 mm |

| Hole diameter for precision assembly | 2.1 mm | 2.4 mm | 2.7 mm | 3.1 mm | 3.6 mm | 4.1 mm | 5.2 mm | 6.2 mm | 7.2 mm | 8.2 mm |

| Rough hole diameter | 2.3 mm | 2.6 mm | 3.1 mm | 3.5 mm | 4.0 mm | 4.5 mm | 5.7 mm | 6.7 mm | 7.7 mm | 8.7 mm |

In general, the diameter of the rivet rod can be from 1 mm to 36 mm, and its length can be from 2 mm to 180 mm. Moreover, a larger diameter does not equate to greater joint strength. Here, both the material from which it is made and its type (hollow or solid) play a role. How to choose? According to the characteristics of the rivets. After all, you choose them to connect certain materials of a certain thickness. You also know approximately the load that will be applied to the connection. Therefore, when selecting, pay attention to what the manufacturer recommends.

How to select a rivet according to the thickness of the material being fastened? According to the manufacturer's instructions, but in general, the diameter of the rod should be at least twice the thickness of the materials

Must be indicated:

- Recommended diameter for connection. All you have to do is select a drill and make a smooth hole without burrs.

- Minimum and maximum thickness of the connected package. It is important that your connection is within the specified range.

- Shear force. This is the load applied perpendicular to the connection that the rivet can withstand without destruction.

- Breaking force. Under what load along the rivet will it fail?

It is the tensile and shear forces that determine the strength of the future seam. The higher these values, the greater the load it will withstand.

Manufacturing materials

A wide variety of materials are used as raw materials for blind rivets. This allows the use of hardware in almost all types of repair and construction work. A number of materials are used to make rivets, each of which has its own strengths and weaknesses and determines the installation location of future products.

Aluminum

Its anodized or varnished version is often used. Aluminum rivets are lightweight and low in cost, but in terms of strength they are somewhat inferior to steel models. The products are used for fastening light metals and plastics and are widely used in electrical engineering.

Stainless steel

Also used in several modifications. Thus, grade A-2 is considered one of the most resistant to rust and is used for installing parts when performing external work. While A-4 has no equal in resistance to acidic environments and is widely used in the chemical industries.

What material should the rivet be made of?

Rivets are usually taken from the same material as the parts being connected - this avoids electrochemical corrosion. Pay attention to strength characteristics. But, as a rule, when connecting aluminum parts, the strength of aluminum hardware is sufficient.

In general, rivets are made from the following metals:

- steel: ordinary - grades St2, St3, St10;

- corrosion-resistant X18N9T;

- galvanized;

You can get confused)) - alloyed (stainless) - 9G2, 304, 316.

When connecting copper parts, it is permissible to install brass and copper. Aluminum is joined with aluminum alloys. Steel sheets - corresponding grades of steel rivets. There are also mixed hardware - from two different metals (chemically non-conflicting). The most common are aluminum-steel.

To install facade elements, slopes, ebbs, metal tiles and corrugated sheets, rivets made of galvanized painted steel are usually used. Painting - matching with details.

FEATURES OF BLEND RIVETS MATERIAL

| Aluminum (99.5%) | — light weight — high resistance to corrosion (sea water) — easily deformed — high electrical and thermal conductivity |

| Aluminum alloy (AlMg) | — hard and durable — easy to polish — with increasing magnesium content, the peel strength increases and the ability to deform decreases — resistant to sea water (AlMg5) and mild alkalis |

| Steel | — for fastening heavy structures — easily deformed — durable — easy to apply coating (for example, anti-corrosion) |

| Stainless steel | - very resistant to corrosion - for fastening heavy structures - durable - non-magnetic (A2 and A4) - A4 has higher acid resistance than A2 (mechanical characteristics are the same) |

| Copper | — high electrical and thermal conductivity — easily deformed — suitable for soldering |

Note! The rivet shaft forms the closing head and must be made of a material that is obviously superior in hardness and strength to the material of the rivet body. Typically a steel rod is used.

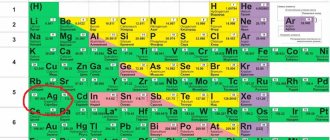

CONTACT CORROSION

Contact corrosion is the increase in corrosion of some metals when they come into contact with others. The rate of contact corrosion is determined by the polarization characteristics of the contacting metals, the ratio of their areas and the ohmic resistance of the system.

The table below shows how different metals can be combined

| Contact metals | ||||

| Rivet body material | Aluminum | Copper | Steel | Stainless steel |

| Aluminum | Great | Badly | Fine | Great |

| Copper | Badly | Great | Badly | Fine |

| Steel | Fine | Badly | Great | Great |

| Stainless steel | Great | Fine | Great | Great |

| Monel (Ni/Cu) | Badly | Fine | Great | Fine |

RIVET COATINGS

Corrosion can never decrease to 0%. The purpose of coatings is to reduce the destructive effect of corrosion on a rivet joint.

- COLORING. The rivet body is coated with paint based on organic binders. Painting is possible in various colors according to the RAL catalog.

- GALVANIZING. This anti-corrosion coating, obtained through electrolysis, is silver in color and is characterized by the formation of a high-strength film on the metal surface, which ensures the installation of a rivet or rod without scoring.

- ZINC-NICKEL CHROME PLATING. This is a coating obtained through electrolysis with an alloy of zinc and nickel. The resulting yellowish film guarantees corrosion resistance even after the rivet body is deformed during installation.

Operating principle

Blind rivets are installed using the through-mounting method. A hole 0.1-0.2 mm larger than the diameter of the rivet is pre-drilled in the sheets to be joined. The fastener is inserted into the hole, the gun is placed on the core - a few movements with the handles and you're done. Advice. If you need to do a “decent” amount of work - install a fence made of a metal profile, a canopy, walls, it is better not to buy the cheapest tool. As practice shows, it fails very quickly. You can buy blind rivets in bulk inexpensively in the Russian Federation from the Mashkrepezh company. The company has been in the hardware market for more than 20 years.