Currently, an alternative to a conventional electric welding machine has become an inverter for plasma welding and cutting.

Previously, this device was actively used only in industry, but every day it is increasingly being used in the domestic sphere.

This fact determined the relevance of this article, which will consider inverter welding machines as a type, characterize their main types , and also analyze the advantages and disadvantages of this multifunctional device.

general information

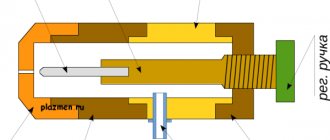

Plasma is an ionized gas, also the fourth state of matter. Modern plasma welding machines are capable of producing temperatures from 5 to 10 thousand degrees Celsius. A device for plasma cutting and welding is often called a plasma torch. The plasma torch can form three types of arc: indirect, mixed or direct.

Before welding, the arc is “twisted” in a special way, since it is prone to decay. After “twisting”, a thin, stable arc is formed, since the gas is ionized very quickly. The end result is a very powerful arc, capable of generating energy at one point. It is at this point that the base metal melts.

A plasma arc can heat almost any metal, regardless of its thickness and composition. Heating to the melting point and even to the boiling point is possible. The only condition is that it is necessary to provide a sufficiently powerful arc.

Additionally, the welding zone is protected with another gas, inert. This can be nitrogen, argon or organic acetone vapor. The torch of the plasma torch is designed in such a way that it can supply shielding gas and plasma simultaneously. So the weld pool is protected while work is being carried out. The metal does not oxidize and the seams are of very high quality.

Where are they used?

The plasma welding machine is multifunctional, which is why it has found its application in many fields of activity. It is used:

- During the heat treatment of steel and other metals.

- When connecting (welding and soldering) or cutting ferrous and non-ferrous metals.

- In the bluing .

- For cutting tiles, glass, concrete and other materials.

Interesting: "Plazar" - a device for plasma cutting, welding, soldering

Video

Here, for example, cutting ceramic tiles with Multiplaz 3500:

Unfortunately, due to the high cost of this device, not every enterprise can afford to purchase it.