Rules for soldering copper parts

The soldering iron is used only for connecting small parts, and the soldering process itself is carried out at a temperature of +350 ℃. Large workpieces, due to their increased thermal conductivity, need to be soldered only with torches.

As for baths and stoves, there are two positions that differ from each other in filler. It could be solder or salt. It should be noted that salts perform two functions: a heating element as a source of temperature, and a flux.

That is, in technologies that use salt furnaces or baths, fluxes are not used.

In principle, regardless of the metal of the workpieces, the joining process itself is the same for all materials. And it is divided into six stages:

cleaning copper blanks mechanically to remove the oxide film;- degreasing;

- introducing flux into the soldering zone;

- heating zone.

- adding solder;

- cleaning the joint from flux and solder material.

Bronze soldering is also carried out. The main difference is the required brand of solder and flux. Since bronzes are an alloy of copper, tin and some other elements, choosing a solder is not difficult .

Bronzes also include alloys of copper and cadmium, copper and beryllium, alloys with lead and aluminum. It is necessary to pay attention to the composition of bronze, depending on which the properties of the material change.

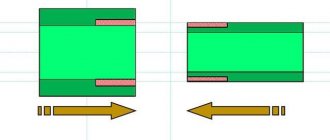

Types of connections

Low temperature soldering of parts

This technology for soldering bronze pipes is used for the installation of utility networks for heating, water supply and other similar systems where the temperature of the transported liquid does not exceed + 130 degrees Celsius. The flame from the gas burner in this case heats the product no higher than + 450 degrees Celsius, and the size of the part is 6-108 mm (read also the article 'Fittings for polypropylene pipes: types and their technical description').

Various soft metals are used as solder in low-temperature soldering: lead, tin, and even then. It is from this that this method took the name “soft soldering”. The width of the seam, depending on the size of the fittings, can be 7-50 mm.

The connection in question is very common when installing various plumbing systems.

This is due to the following factors:

- during low-temperature soldering, copper is not annealed (which affects the strength of the pipeline),

- the work process is less labor-intensive and more reliable,

- used only for the manufacture of water transport systems,

- cannot be used to connect gas pipelines.

High temperature soldering of parts

In this case, soldering of bronze tubes is carried out at a flame temperature exceeding + 450 degrees Celsius.

Along with this, solder based on the following metals is used:

- copper,

- silver,

- other alloys harder than tin.

The use of this technology makes it possible to purchase a permanent connection that has increased strength and can withstand a much higher temperature of the transported medium.

Another name for the connection is “hard solder”.

Soldering bronze pipes with hard solder is used in the following cases:

- connection of parts larger than 28 mm,

- joining of parts intended for transporting liquids whose temperature exceeds 130 degrees Celsius,

- production of heating systems (this connection method allows you to make a branch from an existing utility network without deteriorating the latter’s characteristics).

- The use of hard soldering is provided for in the installation instructions for gas pipeline systems.

Note! During high-temperature soldering, copper is annealed, as a result of which the pipe loses its strength. To minimize this phenomenon, it is necessary that the seam cools naturally, and that heating during soldering is as low as possible.

Cold connection of parts

There is also a connection of bronze pipes without soldering. For this purpose, special crimp couplings are used, the design of which is similar to similar products used when working with polymer parts.

From the outside, the cold joint coupling looks similar to a solder fitting. But, the first one is additionally equipped with rubber seals made of special polymers.

In addition, there is also a detachable connection for bronze pipelines. A collet fitting is used for this.

They are divided into two types:

- for joining hard and medium-hard parts,

- for joining soft and semi-hard products.

Selection of solder and flux

When soldering copper alloys at low temperatures, tin-lead and lead-silver solders are used.

Either rosin dissolved in alcohol or zinc chloride is added to the soldering zone. These are fluxes. Unfortunately, tin and lead additives are highly brittle compounds, which are formed due to the so-called intermetallic compounds. At low soldering temperatures, cracks form in them.

Therefore, to connect copper, solder materials are used that contain no more than 15% tin. The lead component increases the impact strength of the joint.

And if the material contains silver, then the copper compound becomes cold and heat resistant. But it is also necessary to take into account the fact that silver reduces the strength of the connection.

In diffusion soldering, solder for copper is made up of several metals: tin, lead, indium and gallium. If a low temperature process is carried out, high joint strength cannot be guaranteed. It is not higher than 70 MPa.

Capillary soldering can also be carried out with these solders. But with one condition - the gap between the workpieces should not exceed 0.5 mm, and the soldering temperature should not exceed +900 ℃.

For soldering tin bronze, silver, tin-lead and copper-zinc solders are used. When the tin content in the alloy is high, copper-zinc material is undesirable. During the soldering process, bronze should be heated gradually and the metal should be thoroughly fluxed.

Some useful tips

Soldering iron tip temperature controller circuits.

Now the reader needs to be given some useful tips that will definitely help him in the process of soldering bronze.

- Use only high-quality gas burners, as this tool is very dangerous to use. You need to make sure in advance that it is really working. Otherwise, some problems may occur in operation. In recent years, instead of burners, many people use hair dryers. This option is considered safer. If a person has such a tool, then it is precisely this that should be used. This will not only make the work safer, but will also allow you to easily regulate the temperature, which is important in this process.

- In your work you need to use only the correct proportions. If it is necessary to prepare more flux or solder, then it is imperative that the proportional ratios be observed, otherwise you may end up with a poor-quality connection that will be destroyed in the shortest possible time.

- Uniform distribution of the mixture on the elements being connected. In the process of preparing for soldering, be sure to ensure that the solder lies evenly on the parts to be joined. This is very important to get an even load on all areas.

If you do not follow these nuances during the work process, you can pay with early breakdown of parts and failure of the entire mechanism.

Some types of solders

Cadmium solders when soldering copper and steel require certain skills to work with them. Because the manufacturability of these materials is lower than that of previous ones.

It should be noted that such a connection is heat-resistant (up to +350 ℃), but not cold-resistant. In addition, a cadmium alloy joint will not be very strong.

Zinc solder materials are rarely used for soldering copper because the metal itself quickly dissolves into the solder material. This weakens the joint, hence the low tensile strength - up to 15 MPa.

Zinc solders alloyed with silver or copper also have low fluidity. Although these materials are doped with cadmium or tin, they have good fluidity, but the strength of the compound itself decreases greatly.

Copper-phosphorus grades with the addition of silver are a good option for soldering. The connection can withstand high loads, up to 300 MPa, and temperatures up to +800 ℃. But solder metal bonded to copper is not ductile. This means that it has low bending strength.

Silver solder materials have proven themselves well in high-temperature copper soldering conditions. True, they show their qualities if soldering is carried out with acetylene or in special furnaces where corrosive fluxes are used.

Solders with a high silver content are used in the process of joining copper blanks in a vacuum or when heated with argon. If the process is carried out under pressure, then either foil (silver) or silver coating is used for the connection.

Solder materials with a high copper content and a low silver content are used rarely and in exceptional cases. Because it is a refractory alloy that requires high heating temperature.

As for pure lead solders, the connections made with them are not strong enough, but they have high ductility. For example, such joints after soldering can be bent up to an angle of 130°, and in tension they can withstand up to 140 MPa.

Soldering bronze

| Photo | Brand | Melting temperature | Price |

| Solder PMFOTSr 6-4-0.03 | 640-680°C | from 1560.00 rub. | |

| Solder PMC-54 | 876-880°C | from 1775.00 rub. | |

| Solder POIN 52 | 120°C | from RUB 14,000.00 | |

| Solder POS-10 | 268-299°C | from 536.71 rub. | |

| Solder POS-18 | 243-277°C | from 603.49 rub. | |

| Solder POS-25 | 260°C | from 746.94 rub. | |

| Solder POS-30 | 183-238°C | from 850.54 rub. | |

| Solder POS-35 | 256°C | from 945.89 rub. | |

| Solder POS-4 | 266°C | from 437.30 rub. | |

| Solder POS-40 | 183-238°C | from 1055.72 rub. | |

| Solder POS-50 | 222°C | from 1266.90 rub. | |

| Solder POS-60 | 190°C | from 1466.12 rub. | |

| Solder POS-61 | 183-190°C | from 1466.12 rub. | |

| Solder POS-63 | 183°C | from RUB 1,515.43 | |

| Solder POS-90 | 183-220°C | from 2087.70 rub. | |

| Solder POSK 50-18 | 142-145°C | from 1050.00 rub. | |

| Solder POSS 18-0.5 | 183-277°C | from 502.91 rub. | |

| Solder POSS 25-0.5 | 183-266°C | from 622.45 rub. | |

| Solder POSSu 25-2 | 185-260°C | from 622.53 rub. | |

| Solder POSS 30-0.5 | 183-245°C | from 708.78 rub. | |

| Solder POSS 40-0.5 | 183-235°C | from RUB 879.77 | |

| Solder POSS 50-0.5 | 183-216°C | from 1055.75 rub. | |

| Solder POSS 61-0.5 | 183-189°C | from 1221.77 rub. | |

| Solder POSSu-10-2 | 268-285°C | from 498.78 rub. | |

| Solder POSSu-15-05 | 184-275°C | from RUB 390.18 | |

| Solder POSSu-18-2 | 186-270°C | from 511.70 rub. | |

| Solder POSSu-30-2 | 185-250°C | from 717.93 rub. | |

| Solder POSSu-4-4 | 239-265°C | from 418.20 rub. | |

| Solder POSSu-4-6 | 244-270°C | from 418.78 rub. | |

| Solder POSSu-40-2 | 185-229°C | from 889.11 rub. | |

| Solder POSSu-5-1 | 275-308°C | from 425.20 rub. | |

| Solder POSSu-8-3 | 240-290°C | from 444.48 rub. | |

| Solder POSSu-95-5 | 234-240°C | from 1865.78 rub. | |

| Solder POSu 95-5 (lead-free) | 234-240°C | from 1880.93 rub. | |

| Solder POTs-10 | 220-225°C | from 2090.00 rub. | |

| Alloy Rose | 90-98°C | from 1500.00 rub. |

Before saying anything about the most convenient solders for soldering bronze , it is necessary to note several types of this alloy (tin, lead and other types of bronze), therefore different solders are used for their type, which will be discussed further.

1. Soldering of tin bronzes should be carried out using copper-zinc, silver or tin-lead solders. For this, any soldering method can be used: soldering iron, gas torch, HDTV heating, contact heating, salt baths, etc. Soldering can be carried out with tin-lead solders using fluxes made on the basis of zinc chloride with the addition of hydrochloric acid. For high-temperature soldering of bronze, silver and copper-zinc solders are used.

2. Soldering of lead bronzes is carried out with any flux solders that are used for soldering tin bronzes. At the same time, the soldering surface must be fluxed very carefully, because lead oxides will form in these places, preventing the solder from flowing into the required gaps.

3. Aluminum bronzes have much better mechanical characteristics than copper alloys, so they are actively used in the mechanical engineering sector. Such products must be treated in hydrofluoric or hydrofluoric acid before soldering. When working with tin-lead solders, it is necessary to use active fluxes with a high content of hydrochloric acid. High-temperature soldering of aluminum bronzes is carried out only using fluxes containing sodium silicofluoride.

4. Soldering of manganese bronzes should be carried out using phosphoric acid. In addition, in this case, it is best to purchase solder with the addition of nickel, which will increase the strength and ductility of the soldered joints.

Use of borax

Soldering brown copper has always been considered the easiest way to connect copper pipes. Essentially, borax is a high-temperature flux in the form of a paste.

When heated to 700-900 ℃, it begins to melt, turning into a glassy mass. With its help, not only copper blanks are connected, but also copper and iron, for which solders made of copper, silver, gold or brass are used, that is, medium-melting alloys.

The only thing you need to pay attention to is the salts that are formed during the process of soldering copper with borax.

High-quality borax-based flux can be made at home, which is what most craftsmen do.

To do this, they mix boric acid and borax in equal proportions. Add water to it, mix and evaporate. The result is boron flux. To increase quality, chloride or fluoride salts can be added to the mixture.

The technology for soldering copper tubes is practically no different from the standard process. But it also has its own nuances.

For example, borax is applied both on top of the tubes and on its internal surfaces. Then the two pipes are heated for 15 seconds, and only after that solder is added to the heating zone.

How to solder copper wire

At home, you often have to solder copper jewelry. Despite the apparent simplicity of the process, it is actually not simple. Firstly, you need to use a file to process the copper wire so that the connection of its two parts passes along a larger plane. It is imperative to secure the parts to be connected relative to each other so that mixing does not occur during the soldering process.

Liquid flux is added to the joint, after which the joint is heated with a burner. Next, solder is supplied to the heating zone. It is better if these are small pieces that are installed end-to-end with tweezers. You can lay them down before heating the copper wire.

Soldering of edible and non-edible copper is a standardized process based on two documents - GOST 1922249-73 and GOST 16038-80. That is, the norms and rules stipulate specifically how to carry out the work, with what and under what conditions.