Steel rope GOST 2688 80 (6*19+OC), 6-strand rope, type LK-R with organic core

| 9,75 | 995 | ||

| 4,8 | 84,4 | 12,8 | 1306 |

| 5,1 | 95,5 | 14,6 | 1490 |

| 5,6 | 116 | 17,8 | 1816 |

| 6,2 | 141 | 21,1 | 2153 |

| 7,6 | 211 | 32,3 | 3296 |

| 8,3 | 256 | 38,1 | 3888 |

| 9,1 | 305 | 45,4 | 4633 |

| 9,6 | 358 | 53,4 | 5449 |

| 11 | 461 | 68,8 | 7020 |

| 12 | 527 | 78,5 | 8010 |

| 13 | 596 | 89 | 9082 |

| 14 | 728 | 108 | 11020 |

| 15 | 844 | 125 | 12755 |

| 16,5 | 1025 | 152 | 15510 |

| 18 | 1220 | 181 | 18469 |

| 19,5 | 1405 | 209 | 21327 |

| 21 | 1635 | 243 | 24796 |

| 22,5 | 1850 | 275 | 28061 |

| 24 | 2110 | 314 | 32041 |

| 25,5 | 2390 | 356 | 36327 |

| 27 | 2685 | 399 | 40714 |

| 28 | 2910 | 434 | 44286 |

| 30,5 | 3490 | 520 | 53061 |

| 32 | 3845 | 573 | 58469 |

Check availability of our products with managers, contact numbers

Steel rope GOST 7668-80 (6x36+OS), double lay, type LK-RO with organic core

| Rope diameter | Weight of lubricated rope | Marking groups, N/mm2 (kgf/mm2) | |

| 1770 (180) | |||

| mm | kg/1000m | Breaking force of the rope as a whole, kN, not less | Breaking force of the rope as a whole, KG, not less |

| 11,5 | 513 | 75,1 | 7663 |

| 13,5 | 696 | 101 | 10306 |

| 15 | 812 | 116 | 11837 |

| 16,5 | 1 045 | 150 | 15306 |

| 18 | 1 245 | 175 | 17857 |

| 20 | 1 520 | 215 | 21939 |

| 22 | 1 830 | 258 | 26327 |

| 23,5 | 2 130 | 304 | 31020 |

| 27 | 2 800 | 396 | 40408 |

| 31 | 3 655 | 517 | 52755 |

| 33 | 4 155 | 588 | 60000 |

| 36,5 | 4 965 | 703 | 71735 |

Check availability of our products with managers, contact numbers

Steel rope GOST 7669-80, 6x36 (1+7+7/7+14)+7x7(1+6), double lay, LK-RO type, with a metal core

| Rope diameter | Weight of lubricated rope | Marking group, N/mm2 (kgf/mm2) | |

| 1770 (180) | |||

| mm | kg/1000m | Breaking force of the rope as a whole, kN, not less | Breaking force of the rope as a whole, KG, not less |

| 16 | 1 145 | 165 | 16837 |

| 28 | 3 395 | 506 | 51633 |

| 36,5 | 5 895 | 877 | 89490 |

Check availability of our products with managers, contact numbers

Cargo rope, elevator GOST 3077-80 (6*19+OS), double lay, type LK-O with organic core

| Rope diameter | Weight of lubricated rope | Marking group, N/mm2 (kgf/mm2) | |

| 1770 (180) | |||

| mm | kg/1000m | Breaking force of the rope as a whole, kN, not less | Breaking force of the rope as a whole, KG, not less |

| 8,8 | 293 | 42,3 | 4316 |

| 10,5 | 387 | 55,9 | 5704 |

| 12 | 530 | 76,5 | 7806 |

Check availability of our products with managers, contact numbers

Galvanized steel rope (cable), DIN 3055 (6×7+FC), DIN 3060 (6×19+FC), DIN 3066 (6×37+FC)

Diameter designation:

the first number is the diameter of the cable, the second number includes the braid

Rope construction:

the first number is the number of strands of the cable, the second is the number of wires in the strand

Core:

organic

Rope material:

steel

Coating:

galvanized

This rope is recommended for use in various fields, mainly for guy wires, suspensions, and fencing. They have different flexibility and elasticity.

| Rope diameter, mm | Structure / Lay of rope | Rope breaking force, kN, not less | Manufactured to standard | meters in bay | Approximate weight, kg/100m |

| 2 | 6×7+FC | 1,95 | DIN 3055 | 200 | 1,4 |

| 2,5 | 6×7+FC | 3,2 | DIN 3055 | 200 | 2,5 |

| 3 | 6×7+FC | 4,39 | DIN 3055 | 200 | 3,2 |

| 4 | 6×7+FC | 7,8 | DIN 3055 | 200 | 5,6 |

| 5 | 6×7+FC | 12,2 | DIN 3055 | 100 | 8,8 |

| 6 | 6×7+FC | 17,5 | DIN 3055 | 100 | 12,6 |

| 8 | 6×19+FC | 31,2 | DIN 3060 | 100 | 22,1 |

| 10 | 6×19+FC | 48,8 | DIN 3060 | 100 | 34,6 |

| 12 | 6×19+FC | 65 | DIN 3060 | 100 | 49,8 |

| 14 | 6×37+FC | 85 | Din 3066 | 100 | 67,8 |

| 16 | 6×37+FC | 117 | Din 3066 | 100 | 88,6 |

Check availability of our products with managers, contact numbers

Galvanized steel rope (cable) in PVC braid, DIN 3055 (6×7+FC), DIN 3060 (6×19+FC)

Diameter designation:

the first number is the diameter of the cable, the second number includes the braid

Rope construction:

the first number is the number of strands of the cable, the second is the number of wires in the strand

Rope material:

steel

Core:

organic

Coating:

galvanized + PVC braid

This rope is recommended for use in various fields, mainly for guy wires, suspensions, and fencing. Has a protective PVC coating. They have different flexibility and elasticity.

| Rope diameter, mm | Structure / Lay of rope | Rope breaking force, kN, not less | Manufactured to standard | meters in bay | Approximate weight, kg/100m |

| Galvanized rope. in PVC insulation 2/3mm | 6×7+FC | 1,95 | DIN 3055 | 200 | 2 |

| Galvanized rope. in PVC insulation 3/4mm | 6×7+FC | 4,39 | DIN 3055 | 200 | 4 |

| Galvanized rope. in PVC insulation 4/5mm | 6×7+FC | 7,8 | DIN 3055 | 100 | 6,7 |

| Galvanized rope. in PVC insulation 5/6mm | 6×7+FC | 11,3 | DIN 3055 | 100 | 10,1 |

| Galvanized rope. in PVC insulation 6/8mm | 6×19+FC | 16,2 | DIN 3060 | 100 | 15,8 |

| Galvanized rope. in PVC insulation 8/10mm | 6×19+FC | 28,9 | DIN 3060 | 100 | 26,4 |

| Galvanized rope. in PVC insulation 10/12mm | 6×19+FC | 42,5 | DIN 3060 | 100 | 40,1 |

| Galvanized rope. in PVC insulation 12/14mm | 6×19+FC | 65 | DIN 3060 | 100 | 55 |

Check availability of our products with managers, contact numbers

Our company offers steel cable, high quality rope. The products are widely used in construction (in the construction of structures for various purposes) and industry. It is distinguished by high quality, reliability, compliance with all requirements, and long service life. Each steel rope, the price of which is as affordable as possible, copes with all the functionality, allowing you to solve various problems. By choosing us, you can comply with all regulations and safety regulations. A steel cable, the price of which will pleasantly surprise even thrifty buyers, will not let you down even in difficult situations when solving difficult problems! We offer to order steel rope, buy products of the required size and type. Experienced specialists of the company will help you make your choice!

Above are the main GOST standards for ropes that are in major demand.

Also, our company has the ability to manufacture and supply ropes of such GOST standards as:

GOST 2172-80, GOST 2688-80, GOST 3062-80, GOST 3063-80, GOST 3064-80, GOST 3066-80, GOST 3067-80, GOST 3068-88, GOST 3069-80, GOST 3070-88, GOST 3071-88, GOST 3077-80, GOST 3079-80, GOST 3081-80, GOST 3083-80, GOST 3085-80 I1, GOST 3088-80, GOST 3089-80, GOST 7665-80, GOST 7667-80 , GOST 7668-80, GOST 7669-80, TU091, TU090, TU002, GOST 14954-80, GOST 16827-81, GOST 16828-81, GOST 16853-88, STO 71915393-TU 049-2007, TU 14-4- 163-2004, TU 14-4-273-2002, TU 14-4-625-2004

To clarify the availability of the required GOST or custom production, please contact our contacts, we will be happy to help!

Characteristics of manufactured ropes

| Coating | Galvanizing group | Purpose | Register | Conversion factor |

| Without cover | — | Cargo | No case | 1,000 |

| Without cover | — | Cargo | Maritime Register | 1,050 |

| Without cover | — | Cargo-human | No case | 1,150 |

| Without cover | — | Cargo-human | Maritime Register | 1,219 |

| Hot galvanizing | AND | Cargo | No case | 1,000 |

| Hot galvanizing | AND | Cargo | Maritime Register | 1,050 |

| Hot galvanizing | AND | Cargo-human | No case | 1,150 |

| Hot galvanizing | AND | Cargo-human | Maritime Register | 1,219 |

| Hot galvanizing | coolant | Cargo | No case | 1,200 |

| Hot galvanizing | coolant | Cargo | Maritime Register | 1,260 |

| Hot galvanizing | coolant | Cargo-human | No case | 1,380 |

| Hot galvanizing | coolant | Cargo-human | Maritime Register | 1,449 |

| Hot galvanizing | WITH | Cargo | No case | 0,926 |

| Hot galvanizing | WITH | Cargo | Maritime Register | 0,972 |

| Hot galvanizing | WITH | Cargo-human | No case | 1,065 |

| Hot galvanizing | WITH | Cargo-human | Maritime Register | 1,129 |

One of the most important and complex wire products is steel ropes. They come in various designs and types and differ from each other in the cross-sectional shape of both the rope elements and the rope itself as a whole, as well as in the physical and mechanical characteristics of the cores and wires.

Steel rope structures

All types of steel ropes are made from a huge number of individual wires, due to which they have low bending rigidity and increased strength. It is these qualities that determine their widespread use when carrying out loading and unloading operations using cranes.

Steel rope structures are standardized by a number of GOSTs, for example:

- GOST 3241-80 – regulates technical conditions for ropes made of round wires;

- GOST 18899-73 – closed load-bearing ropes.

In accordance with the requirements of GOST 3241-80, the following designs of steel ropes are distinguished:

- Single lay. They are made by twisting individual wires in a spiral to form one or several concentric layers;

- Double lay. In this case, concentric layers are formed not by individual wires, but by their strands;

- Triple lay. This type of steel ropes is made by laying double lay ropes.

When choosing steel ropes, you should keep in mind that products with one layer of strands have a greater tendency to torsion than double lay steel ropes, which have the opposite direction of lay of individual strands along concentric layers.

Application area

The use of steel rope can be found in various fields. This can be as a cable for mounting a tent and cable-stayed roof structures to suspension bridges and television and radio towers.

Different applications for wire ropes place different demands on strength, abrasion and corrosion resistance. To meet these requirements, the cable is made of materials such as:

- Stainless steel. Used where corrosion is a major factor.

- Galvanized carbon steel. It is used where strength comes first and corrosion resistance is less important.

The wire (one element) can have a cross-section of up to 3 mm. This is enough to withstand loads of up to 200 kgf/mm2. Steel cables and ropes differ in terms of lay, which can be single, double or triple. The arrangement of the wire in different layers has one of the following tangents:

- point (usually used for minor intermittent loads);

- linear (used in many areas);

- point-linear (used for additional strength).

Classification of steel ropes

Depending on the type of laying of the strands, the following types of steel ropes are distinguished:

- The wires between the layers have a point contact - TK;

- Between the layers of wire there is a linear contact - LC;

- Linear contact and the same diameter of wires in each layer of the strand - LK-O;

- Linear contact and the presence of wires of different diameters in the outer layer - LK-R;

- Linear contact between filling wires and individual layers - LK-Z;

- Linear contact and the presence of strands with both wires of the same and different diameters - LK-RO;

- Combined point-linear contact of wires - TLC.

To work on drums and blocks with semicircular grooves, it is better to choose steel ropes with a linear touch. This is due to the fact that their service life is almost twice as long as that of TKL brand ropes.

Depending on the core material used, there are:

- Ropes with an organic core made from synthetic or natural materials – O.S. This type of core, thanks to its special impregnation, prevents rapid abrasion of the wires and protects the internal parts of the rope from corrosive processes;

- Ropes with a metal core – M.S. This type of steel rope is excellent for use in hot shops, as well as in cases where multi-layer winding on a drum is used.

According to the laying method, the following types of ropes are distinguished:

- Non-unwinding - N. In them, the strands retain their properties after the welding and dressing are removed from the end of the rope;

- Unwinding - R. In ropes of this type, after removing the welding or tying, the wires and strands change their position.

When making non-unwinding ropes, the wires are subjected to preliminary bending. Thanks to this, this type has greater durability, less tendency to form loops and knots, as well as torsion.

Depending on the direction of lay, steel ropes of left (L) and right (R) lay are distinguished.

There are various options for laying elements and the rope itself in triple and double lay products. In accordance with this, steel ropes are distinguished:

- One-way lay - O. They have the same direction of lay of the strands and lay of the rope itself along the outer wire.

- Cross lay. They are characterized by the opposite direction of laying of strands and strands and laying of the rope. For triple lay ropes, only this type of lay is used.

- Combined lay - K. The direction of lay of the strands alternates through one strand.

Products with cross lay are recommended for working ropes on blocks with wedge-shaped grooves or with an undercut, flat rims, as well as for cranes. In cases where the possibility of rope torsion is excluded, it is better to use ropes with one-sided lay.

Steel ropes also differ in degree of twist:

- MK - low-rotating. They are characterized by the presence of opposite direction of laying of individual elements in layers.

- Twisting - have the same direction of all strands in the strand.

Depending on the physical and mechanical characteristics of the wire, the following types of steel ropes are distinguished:

- Brand B. These ropes are used exclusively in particularly complex and critical cases.

- Grade I. Most often used as crane rope.

- Mark II.

Also, depending on the characteristics of the wire surface coating, steel ropes are classified into the following types:

- Without any coating;

- With zinc coating - coolant. Used to work in conditions with a particularly aggressive external environment;

- With zinc coating and designed for work in aggressive environments – F;

- With zinc coating for operation in medium aggressive environmental conditions – C;

- With coating of strands or the rope itself with artificial materials - P.

Steel ropes intended for cargo purposes are marked GL, and for cargo purposes - G.

According to manufacturing accuracy, ropes with increased T and normal H accuracy are distinguished.

Example of rope symbols

Surface Density of Zinc Steel Rope

| Nominal diameter, mm | Surface density of zinc, g/m2, not less, for wire groups | ||

| WITH | AND | coolant | |

| 0.20 to 0.24 | 15 | 20 | 30 |

| >0.24 to 0.32 | 20 | 25 | 45 |

| >0.32 to 0.38 | 20 | 25 | 60 |

| >0.38 to 0.45 | 30 | 40 | 75 |

| >0.45 to 0.55 | 35 | 40 | 90 |

| >0.55 to 0.65 | 40 | 50 | 110 |

| >0.65 to 0.75 | 40 | 60 | 120 |

| >0.75 to 0.95 | 50 | 70 | 130 |

| >0.95 to 1.15 | 60 | 80 | 150 |

| >1.15 to 1.40 | 60 | 90 | 165 |

| >1.40 to 1.80 | 70 | 100 | 180 |

| >1.80 to 2.40 | 80 | 110 | 205 |

| >2.40 to 3.00 | 90 | 125 | 230 |

| >3.00 to 3.80 | 100 | 135 | 230 |

| >3.80 to 4.40 | 110 | 150 | 245 |

| >4.40 to 5.10 | 110 | 165 | 245 |

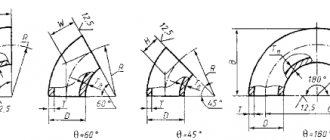

Direction and combination of lay directions of steel rope:

When installing ropes, the main requirement is to prevent them from unwinding. To do this you need the following:

- The drum with the rope should be placed on the unwinding device so that its axis is strictly horizontal.

- The winding end should be located at the top or bottom of the drum.

- The drum should slow down slightly during the winding process.

- The distance between two drums must be greater than three hundred diameters of the steel rope.

During installation, rope kinks, especially alternating ones, should be avoided.

How to measure rope diameter

“Nominal Diameter” defines the design diameter of the rope. In order to measure the actual diameter, you must use a caliper, the length of the jaws of which must be more than ¾ of the diameter of the rope being measured.

Measurements should be taken in two cross sections located at a distance of at least one meter from each other. At each of these points, measurements are taken in two planes perpendicular to each other. After receiving all four results, their arithmetic mean is calculated. For a new rope, the resulting figure should be located within the tolerance field of the “nominal” diameter.

Unwinding rope from a coil

The coil should be placed on the ground and the rope should begin to unwind strictly in a straight line, while trying to prevent contamination of its surface with moisture, metal chips, soil or any other harmful substances.

The coil can also be installed on a rotary unwinder. After this, the coil is rotated by pulling the outer end of the rope.

It is impossible to unwind ropes from fixed coils, as this leads to the formation of loops and twisting of the ropes, and this in turn significantly reduces their performance.

Picture 1.

Never unwind a rope from a fixed coil, as this may cause the rope to twist and form loops, which will significantly reduce the performance of the rope (Fig. 2).

Figure 2.

Wrong.

Note the formation of loops.

Tensile strength parameters of steel cables

To establish what load a steel cable can withstand, it is important to take into account that its choice is determined by two main parameters - breaking and working strength.

Tensile strength

Breaking strength refers to the minimum force on a rope at which it will break. If it is necessary to determine this value of a steel cable, the tensile characteristics are taken from GOST or determined using the formula:

R=Kd2, where

- K – safety factor;

- d – diameter, mm.

The coefficient K when calculating the breaking load of cables is unchanged and is selected depending on the type of specific product. So, if you need to find out the value of a single-strand type product, use the figure 70. For a rope with one organic core, take the number 40, with several cores - 34.

Steel rope GOST 7668-80 (6x36+OS), double lay, type LK-RO with organic core

| Rope diameter | Weight of lubricated rope | Marking groups, N/mm2 (kgf/mm2) | Price including VAT rub. / meter | ||

| 1770 (180) | |||||

| mm | kg. / 1000m | Breaking force of the rope as a whole, kN, not less | Breaking force of the rope as a whole, KG, not less | Black in grease | Galvanized |

| 11,5 | 513 | 75,1 | 7663 | 93,15 | 113,85 |

| 13,5 | 696 | 101 | 10306 | 112,02 | 141,01 |

| 15 | 812 | 116 | 11837 | 126,17 | 158,83 |

| 16,5 | 1 045 | 150 | 15306 | 150,85 | 195,57 |

| 18 | 1 245 | 175 | 17857 | 177,03 | 229,47 |

| 20 | 1 520 | 215 | 21939 | 207,83 | 269,44 |

| 22 | 1 830 | 258 | 26327 | 235,09 | 304,68 |

| 23,5 | 2 130 | 304 | 31020 | 272,30 | 353,00 |

| 27 | 2 800 | 396 | 40408 | 350,37 | 453,86 |

| 31 | 3 655 | 517 | 52755 | 449,73 | 582,68 |

| 33 | 4 155 | 588 | 60000 | 510,73 | 662,14 |

| 36,5 | 4 965 | 703 | 71735 | 605,39 | 784,88 |

| Check the availability of our products with managers, contact numbers: (495) 221-76-96, (495) 255-24-68 | |||||

Galvanized steel rope (cable) in PVC braid, DIN 3055 (6×7+FC), DIN 3060 (6×19+FC)

Diameter designation:

the first number is the diameter of the cable, the second number includes the braid

Rope construction:

the first number is the number of strands of the cable, the second is the number of wires in the strand

Rope material:

steel

Core:

organic

Coating:

galvanized + PVC braid

This rope is recommended for use in various fields. Steel cable is used mainly for guy wires, suspensions, and fences. The steel cable has a protective PVC coating. They have different flexibility and elasticity.

| Rope diameter, mm | Structure / Lay of rope | Rope breaking force, kN, not less | Manufactured to standard | meters in bay | Approximate weight, kg/100m | Price including VAT rub./meter |

| Galvanized rope. in PVC insulation 2/3mm | 6×7+FC | 1,95 | DIN 3055 | 200 | 2 | 9,0 |

| Galvanized rope. in PVC insulation 3/4mm | 6×7+FC | 4,39 | DIN 3055 | 200 | 4 | 14,0 |

| Galvanized rope. in PVC insulation 4/5mm | 6×7+FC | 7,8 | DIN 3055 | 100 | 6,7 | 19,0 |

| Galvanized rope. in PVC insulation 5/6mm | 6×7+FC | 11,3 | DIN 3055 | 100 | 10,1 | 29,0 |

| Galvanized rope. in PVC insulation 6/8mm | 6×19+FC | 16,2 | DIN 3060 | 100 | 15,8 | 39,0 |

| Galvanized rope. in PVC insulation 8/10mm | 6×19+FC | 28,9 | DIN 3060 | 100 | 26,4 | 57,0 |

| Galvanized rope. in PVC insulation 10/12mm | 6×19+FC | 42,5 | DIN 3060 | 100 | 40,1 | 81,0 |

| Galvanized rope. in PVC insulation 12/14mm | 6×19+FC | 65 | DIN 3060 | 100 | 55 | 110,0 |

| Check the availability of our products with managers, contact numbers: (495) 221-76-96, (495) 255-24-68 | ||||||

LLC "PO KANPRO" offers steel cable and high quality rope. Our products are widely used in construction (in the construction of structures for various purposes) and industry. The steel cable is of high quality, reliability, compliance with all requirements, and long service life. Each steel rope, the price of which is as affordable as possible, copes with all the functionality, allowing you to solve various problems. By choosing a steel cable “PO KANPRO”, you can comply with all standards and safety regulations. A steel cable, the price of which will pleasantly surprise even thrifty buyers, will not let you down even in difficult situations when solving difficult problems! We offer to order steel rope in Moscow, buy products of the required size and type. Experienced specialists at KANPRO will help you make your choice and select a steel cable that best suits your needs and tasks. Delivery is possible not only in cities such as Moscow, but throughout Russia.

Above are the main GOST standards for ropes that are in major demand.

Also, our company has the ability to manufacture and offers to buy versions of ropes of such GOST standards as:

GOST 2172-80, GOST 2688-80, GOST 3062-80, GOST 3063-80, GOST 3064-80, GOST 3066-80, GOST 3067-80, GOST 3068-88, GOST 3069-80, GOST 3070-88, GOST 3071-88, GOST 3077-80, GOST 3079-80, GOST 3081-80, GOST 3083-80, GOST 3085-80 I1, GOST 3088-80, GOST 3089-80, GOST 7665-80, GOST 7667-80 , GOST 7668-80, GOST 7669-80, TU091, TU090, TU002, GOST 14954-80, GOST 16827-81, GOST 16828-81, GOST 16853-88, STO 71915393-TU 049-2007, TU 14-4- 163-2004, TU 14-4-273-2002, TU 14-4-625-2004

To clarify the availability of the required GOST or custom production, please contact our contacts, we will be happy to help!

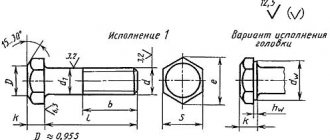

Rope GOST 2688-80

Steel ropes, manufactured according to state standard 2688-80, are intended and completed for drum winches, cranes and hoists, lifting devices of mine installations, hoists, ship cranes, for equipping ladders, earth-moving and mining machines, bridge cranes, for drilling machines, for hydraulic elevators , excavators, overhead roads and cable cranes, for skip hoists of blast furnaces, metallurgical cranes and standing rigging.

Double lay rope type LK-R, design 6x19 (1 6 6/6) 1 o.s. Wire diameter: central (36 pcs.) - 0.3 mm; first layer (36 pcs.) - 0.28 mm; second layer (36 pieces each) - 0.22 and 0.3 mm. The cross-sectional area of all wires of the GOST 2688-80 steel rope is 6.55 mm2.

| Rope diameter, mm. | Weight of 1000 m of lubricated rope, kg. | Total breaking force, N |

| 3,6 | 48,8 | 8 780 |

| 3,8 | 55,1 | 9 930 |

| 4,1 | 64,1 | 11 550 |

| 4,5 | 73,9 | 13 300 |

| 4,8 | 84,4 | 15 200 |

| 5,1 | 95,5 | 17 200 |

| 5,6 | 116,5 | 20 950 |

| 6,2 | 141,6 | 25 500 |

| 6,9 | 176,6 | 31 800 |

| 7,6 | 211,0 | 38 000 |

| 8,3 | 256,0 | 46 100 |

| 9,1 | 305,0 | 55 000 |

| 9,6 | 358,0 | 64 650 |

| 11,0 | 461,0 | 83 200 |

| 12,0 | 527,0 | 95 000 |

| 13,0 | 596,6 | 107 500 |

| 14,0 | 728,0 | 131 000 |

| 15,0 | 844,0 | 152 000 |

| 16,5 | 1 025,0 | 184 500 |

| 18,0 | 1 220,0 | 220 000 |

| 19,5 | 1 405,0 | 253 000 |

| 21,0 | 1 635,0 | 294 500 |

| 22,5 | 1 850,0 | 333 000 |

| 24,0 | 2 110,0 | 380 000 |

| 25,5 | 2 390,0 | 430 000 |

| 27,0 | 2 685,0 | 483 500 |

| 28,0 | 2 910,0 | 525 000 |

| 30,5 | 3 490,0 | 629 000 |

| 32,0 | 3 845,0 | 654 500 |

| 33,5 | 4 220,0 | 718 000 |

| 37,0 | 5 015,0 | 854 000 |

| 39,5 | 5 740,0 | 977 000 |

| 42,0 | 6 535,0 | 1 110 000 |

| 44,5 | 7 385,0 | 1 225 000 |

| 47,5 | 8 430,0 | 1 435 000 |

| 51,0 | 9 545,0 | 1 625 000 |

| 56,0 | 11 650,0 | 1 980 000 |

Galvanized steel rope (cable), DIN 3055 (6×7+FC), DIN 3060 (6×19+FC), DIN 3066 (6×37+FC)

Diameter designation:

the first number is the diameter of the cable, the second number includes the braid

Rope construction:

the first number is the number of strands of the cable, the second is the number of wires in the strand

Core:

organic

Rope material:

steel

Coating:

galvanized

This rope is recommended for use in various fields. Steel cable is used mainly for guy wires, suspensions, and fences. They have different flexibility and elasticity.

| Rope diameter, mm | Structure / Lay of rope | Rope breaking force, kN, not less | Manufactured to standard | meters in bay | Approximate weight, kg/100m | Price including VAT rub./meter |

| 2 | 6×7+FC | 1,95 | DIN 3055 | 200 | 1,4 | 6,0 |

| 2,5 | 6×7+FC | 3,2 | DIN 3055 | 200 | 2,5 | 8,0 |

| 3 | 6×7+FC | 4,39 | DIN 3055 | 200 | 3,2 | 10,0 |

| 4 | 6×7+FC | 7,8 | DIN 3055 | 200 | 5,6 | 16,0 |

| 5 | 6×7+FC | 12,2 | DIN 3055 | 100 | 8,8 | 19,0 |

| 6 | 6×7+FC | 17,5 | DIN 3055 | 100 | 12,6 | 27,0 |

| 8 | 6×19+FC | 31,2 | DIN 3060 | 100 | 22,1 | 45,0 |

| 10 | 6×19+FC | 48,8 | DIN 3060 | 100 | 34,6 | 60,0 |

| 12 | 6×19+FC | 65 | DIN 3060 | 100 | 49,8 | 87,0 |

| 14 | 6×37+FC | 85 | Din 3066 | 100 | 67,8 | 110,0 |

| 16 | 6×37+FC | 117 | Din 3066 | 100 | 88,6 | 144,0 |

| Check the availability of our products with managers, contact numbers: (495) 221-76-96, (495) 255-24-68 | ||||||

Marking groups, dimensions and weight

The last digit in the rope designation is a marking group that indicates the strength characteristics of the rope. The higher the number, the stronger the cable and the greater the load it can withstand during operation.

According to GOST 2688-80, ropes are produced with a cross-sectional diameter from 3.6 to 56 mm with strength characteristics from 1370 to 1860 N/mm 2 (140-190 kgf/mm 2). The standard tables indicate the diameters of the ropes, all wire layers of strands, strength characteristics and the approximate weight of 1 thousand meters of cable. The weight of a steel rope GOST 2688–80 can be determined by multiplying the weight value of 1 thousand meters of cable taken from the table by the length of the rope and dividing the resulting value by 1000.

1 thousand meters of rope with a diameter of 12 mm weighs approximately 520 kg; with a diameter of 21 mm - 1630 kg. The weight of one meter of a product with a thickness of 37 mm will be approximately 5 kg, and one meter with a thickness of 56 mm will be 11.6 kg.

Transportation and storage

5.1. Ropes are transported by all types of transport in covered and open vehicles in accordance with the rules for the transportation of goods in force for this type of transport. The placement and securing of cargo during rail transportation is carried out in accordance with the Rules for Loading and Securing Cargo, which are in force in accordance with the established procedure. Transportation of ropes by rail is carried out by carload, low-tonnage or small shipments. 5.2. Storage of ropes - according to the conditions of 5 GOST 15150. When storing the user of a rope wound on a drum, the axis of the drum must be parallel to the floor on which the drum is installed. Ropes received for storage are subject to immediate inspection and lubrication of rope sections exposed during transportation and loading and unloading operations with rope lubricant. During long-term storage, ropes must be periodically inspected at least every 6 months on the outer layer and lubricated with rope lubricant.

Delivery within the Russian Federation:

Moscow, St. Petersburg, Arkhangelsk, Astrakhan, Barnaul, Belgorod, Bryansk, Vladimir, Volgograd, Vologda, Voronezh, Ekaterinburg, Ivanovo, Izhevsk, Yoshkar-Ola, Kazan, Kaluga, Kirov, Kostroma, Krasnodar, Kurgan, Kursk, Lipetsk, Omsk, Orel, Orenburg, Penza, Perv, Pskov, Rostov-on-Don, Ryazan, Samara, Saransk, Saratov, Sevastopol, Simferopol, Smolensk, Stavropol, Tambov, Tver, Tomsk, Tula, Tyumen, Ulyanovsk, Ufa, Chelyabinsk, Yaroslavl and others.