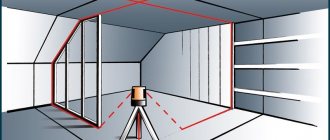

One of the popular tools when carrying out construction and finishing work is a laser level. It's no secret that such levels are used to obtain markings on the surface of walls, ceilings, and floors. Constant use of the device may cause damage. To fix a breakdown or malfunction, you will need to repair the laser level. We will find out how to do this further.

The procedure for handing over the level for repair

1. Transfer of the device and paperwork Transfer to us the level to be repaired in a way convenient for you. Upon receipt, an acceptance certificate will be drawn up. For repairs under warranty, you also need a warranty card. 2. Coordination of timing and cost Our specialists will conduct diagnostics and inform you of the timing of the repair and its full cost.

3. Payment You can pay for repairs in two ways:

- Cash in our office.

- Cashless payment.

4. Receiving the device after repair To receive the level after repair, you will need a completed acceptance certificate. Legal entities who paid by bank transfer will also need a seal or power of attorney from the organization.

This is interesting: How to use a level - instructions for use

How to repair a laser level yourself or how much does repair cost?

In construction it is simply impossible to do without measuring tools. To level the horizontal and vertical, laser levels are used, or they are also called levels. Their advantages include practicality, accuracy and high speed of measurement work. The measuring device is an expensive one and tends to break, so everyone who has encountered a problem will have to figure out how to repair a laser level.

Design of a laser level

The laser type level belongs to the category of optical measuring instruments that require an appropriate approach to use and storage. Failure to comply with storage and operating conditions leads to damage to the level. Before repairing a laser level, you should understand its structure.

The instrument in question appears to have a simple design, but some of its individual parts have a complex structure, which causes difficulties in self-repair at home. However, knowledge of the design of this measuring device will help simplify repair work.

The main element of the level is the light source, along which the corresponding constructions of horizontal and vertical planes are made. LEDs are used as a light emitter, the illumination of which is enhanced through the use of a lens system. An LED can fail only due to a malfunction of the electronic chip. The lenses can only break, in which case they will need to be replaced.

Outside the device there is a housing, which usually has a high degree of protection from moisture and dust. The housing is usually made of impact-resistant plastic. The housing design has a connector where replaceable batteries are installed or batteries are stored. To carry out precise measuring work, the device has a special installation system. This system allows you to position the level evenly and make the appropriate measurements.

Levels come in different varieties, which depends not only on the manufacturers. They are classified into simple or household and professional:

- Household device models are only capable of creating a beam that is directed parallel to the body

- Professional - they are capable of projecting laser beams in different planes and around the entire circle at 360 degrees. Such devices additionally use an electric drive that rotates the laser LED in a circle.

The more complex the design of the instrument, the more difficult it is to repair the level. To repair the device yourself, you should find out the main types of breakdowns that occur at laser levels.

This is interesting! Various breakdowns occur on levels, which can be classified as artificial, those arising due to improper operation or storage, as well as production ones - these are defects of the laser level during its manufacture.

Defects in laser levels and how to fix them yourself

When purchasing a measuring instrument, the question arises about which device to choose for repair. After all, in order to prevent level breakdowns, it is necessary to decide at the purchase stage which tool is suitable for performing certain jobs. If you buy a level for indoor work and use it outdoors, it will not last long. In addition, you should not choose cheap models if you have high hopes for the device. If Chinese cheap fakes are used frequently, they will quickly fail.

However, not only cheap levels break, but also expensive ones that require appropriate repairs. When you need to repair a level yourself, we will find out in detail:

- When, when the device is turned on, the laser beam is not rectilinear, but curved in the shape of an arc

- If the LED that creates vertical and horizontal projections does not light up

- If the control buttons are faulty

- In case of defects on the body caused by mechanical impact

- If the electric drive does not rotate when starting

- The laser beam becomes dim and barely noticeable

If the device has been dropped on the ground or damaged by heavy tools or building materials, even if it shows no signs of malfunction, it should still be diagnosed. The position adjustment system, and especially the self-adjusting mechanism, can also fail.

Level verification: what is it and why is it necessary?

Often device failures are hidden, that is, the level projects planes correctly, but at the same time they are distorted and inaccurate. Such a malfunction is not detected immediately, and you can perform a large amount of work, and only then discover that the laser level is “lying.” To prevent these types of malfunctions, verification should be performed regularly. In this case, you will not need to take the tool to a workshop or service center for verification, since you can complete the task yourself.

How to check a laser level yourself? First you need to turn it on, and then perform a number of the following simple manipulations:

- Place the level closer to the wall in the room and project the beam onto the opposite side

- Unfold the device and make a mark on the wall near which the level is located

- Move the device closer to the opposite wall and align the laser beam with the mark

- Once the laser beam is aligned with the mark on the nearest wall, you should turn it and check whether the projected line coincides with the marking on the opposite wall

The device is considered accurate if the beam falls exactly on the mark. A slight deviation is allowed, which may indicate an instrument error. The error depends not only on the cost of the level, but also on the range of measurements taken. The further the device is from the surface on which the beam is projected, the greater the inaccuracy value.

This is interesting! If verification shows that the device has a large error, then operation cannot be continued. First, the level must be adjusted, which you can do yourself if you have adjusting screws. Otherwise, you will need to take the device to a specialized center.

How realistic is it to repair a laser level?

When a grinder or drill breaks down, the first thing the master does is rush to disassemble the tool himself and repair it. Few people think about taking such levels to specialized service centers. As soon as a level breaks, few people think about repairing it themselves. This is due to the fact that the device has a complex design (at first glance). If you understand the structure of the tool, then no problems with repairs will arise.

Most experts do not recommend repairing devices yourself. However, there is nothing wrong with trying to find the cause of the problem and fix it. In addition, most breakdowns can be eliminated even without disassembling the tool.

- The batteries or battery are low. If the level does not turn on, then the first thing you should do is make sure that the power supplies are working. If these are batteries, then they need to be replaced, and if they are a battery, then put them on charge

- Malfunction of contacts or their oxidation - if you do not use the device for a long time, and at the same time leave the batteries in it for a long time, they may “leak”. As a result, the design of the device will suffer. To prevent this kind of breakdown, it is necessary to remove the batteries from the instrument during storage. If these are lithium-ion batteries, then they must be stored exclusively in charged form.

- Failure of the charger - if the level is powered by a built-in battery, then the charging unit may fail. You can find out about such a breakdown by the absence of a charge indication when the plug is plugged into the socket.

- Horizontal or vertical projection does not work - in this case, it is necessary to disassemble the device body and perform diagnostics. Failures in the electrical circuit can only be determined by knowledgeable and experienced specialists. In addition, specialized equipment will be needed for testing. However, often the cause of projection inoperability is a loose wiring. Having a soldering iron, you should solder the wires in place in order to eventually restore the functionality of the laser projection meter

- Blurred or poorly visible laser projection - in this case, it is necessary to disassemble the housing and check the cleanliness of the glass. The glass usually gets clogged, so it needs to be cleaned. If the cause is not glass, then you need to change the LEDs or check the microcircuit

- The buttons do not work - if it jams, sticks or does not turn on at all, it must be replaced. To replace the button, there is also no need to take the device to a specialist. You should disassemble it, diagnose the breakdown, and, if possible, fix it.

- Malfunction of the pointer - the cause is a violation of the integrity of the weight. To fix the damage, you need to disassemble the tool and adjust the pointer

This is interesting! If the level is still under warranty, then in this case it is better to take it to the store and have it repaired. Such repairs will be free, and you will not need to interfere with the structure yourself.

From the above, we can say that you can repair the level yourself, without the help of specialists. The main thing here is accuracy and caution. If after disassembly it is not possible to identify the cause of the breakdown, then you should assemble the level and take it for repair. There are specialized centers for this.

Where to repair a laser level

Having understood the question of whether it is possible to repair the level yourself, we can conclude that if it is not possible to restore the functionality of the instrument, then there is no need to rush to buy a new one. A failed laser level can be restored by contacting specialized centers. Such centers are located not only in large cities of Russia, but also in smaller ones. There are specialized centers for repairing laser levels in the following Russian cities:

- Moscow

- Ekaterinburg

- Novosibirsk

- Rostov

- Nizhny Novgorod

- Ufa

- Samara

- Krasnodar

- Chelyabinsk

- Falcon

- Voronezh

- Irkutsk

- Krasnoyarsk

No matter what big city you live in, in order to repair a laser level, you must first try to find the breakdown yourself, and only then look for the addresses of service centers. These centers perform not only repairs, but also adjustment and verification of the measuring device. How much repairs cost at a service center depends on many factors:

- Location - the remoteness of the settlement from the city indicates the need for costs for shipping parts and components, which is an additional expense

- Laser level model - repairing cheap models is correspondingly inexpensive, but to repair levels from brands such as Bosch, DeWalt, Hitachi and others, you will need the appropriate components

- Type of fault - if it is a minor breakdown, then the cost of such repairs will be insignificant

To avoid being deceived, you should choose only specialized service centers and workshops. It’s not difficult to find out about these, since there are many reviews about these or other workshops on the Internet. If you know the addresses of good level repair shops in Russia, Ukraine and Belarus, then you can share the addresses directly on the site.

Instructions on how to repair a laser level with a step-by-step description

If you are faced with a situation where the laser level has stopped working, then you need to immediately begin repairing it. First, we assess the extent of the breakdown, and only if it turns out that the cause is internal, then we proceed to disassemble the case. All levels are dismountable, for which you need to unscrew a certain number of screws to remove the cover. If the projection stops working at the level, the repair will look like this:

- To repair a laser level you need to remove the housing

- Now you can diagnose the problem. If one of the projections does not work, then you need to look at the serviceability of the contacts. In the example, a malfunction of one contact was detected, due to which one plane does not work

- You can fix the damage by soldering the wires in their place. If it breaks off, then you need to find a similar wire (without insulation) and with the appropriate cross-section, and solder it in place of the damaged one

- In the end, all that remains is to assemble the tool and check its functionality. When assembling, you need to be careful not to snag the wires and again not break their integrity.

After assembly, it is necessary to install the power supplies in place and check the functionality of the tool.

The tool works properly. As you can see, the repair does not take much time, effort, and does not require special knowledge. If the laser level breaks down, then you must first identify the cause of the breakdown, and only then restore the functionality of the device. Only in exceptional cases is it recommended to seek the help of specialists, and in 60% of cases you can repair it yourself. Below is a detailed video description of the process of repairing a laser level with your own hands.

As a result, it should be noted that a good specialist in a service center is not one who has exorbitant prices for repairs. A good technician will handle the repair quickly, and his services will not cost as much as a new level.

[Total votes: 0 Average: 0/5]

moiinstrumentu.ru

Repair: practical recommendations

You should know that it is not only the displacement of the tendril that can cause the stated problem and repair. The cause may be a failure in the load settings. And you can solve it by following these steps:

Diagram of an optical level device.

- Remove the sticker from the surface of the case. Opening the device will void the warranty in any case.

- Below you will find a plastic screw. When you open it, you will see a screw called “A”. This is the load. Carefully inspect the platform. You will immediately notice deviations.

- Rotate screw “A” to find the desired position. This can be achieved by hanging a plumb line on the wall.

- Check the position of the horizontal and vertical beams. They should be fine.

- Check frontal roll.

- Finally, to adjust the platform, you need to slightly loosen the screw located in the middle, and tighten those on the edges. This is to move it lower and tilt it forward. If you want to raise the platform, do the opposite. Loosen the outer screws, and tighten the one in the center. The process requires the utmost care.

If the glass of the laser level breaks, you can replace it yourself.

To do this, purchase material. Then make a mark on its surface that will correspond to the shape of the damaged one. Glass should be purchased with a width of about 2.5 mm. Replace when finished.

Level verification: what is it and why is it necessary?

Often device failures are hidden, that is, the level projects planes correctly, but at the same time they are distorted and inaccurate. Such a malfunction is not detected immediately, and you can perform a large amount of work, and only then discover that the laser level is “lying.” To prevent these types of malfunctions, verification should be performed regularly. In this case, you will not need to take the tool to a workshop or service center for verification, since you can complete the task yourself.

How to check a laser level yourself? First you need to turn it on, and then perform a number of the following simple manipulations:

- Place the level closer to the wall in the room and project the beam onto the opposite side

- Unfold the device and make a mark on the wall near which the level is located

- Move the device closer to the opposite wall and align the laser beam with the mark

- Once the laser beam is aligned with the mark on the nearest wall, you should turn it and check whether the projected line coincides with the marking on the opposite wall

The device is considered accurate if the beam falls exactly on the mark. A slight deviation is allowed, which may indicate an instrument error. The error depends not only on the cost of the level, but also on the range of measurements taken. The further the device is from the surface on which the beam is projected, the greater the inaccuracy value.

Why is a laser level inaccurate?

Schemes for the arrangement of axes when checking the level: A-B – diagrams for the arrangement of the axes when checking the level; G – level positions during the third verification.

The reason for repairs may be violation of storage conditions, shaking during transportation. To check the operating condition of the device, the readings taken are evaluated using several values:

- vertical line (referred to as y);

- horizontal line (called x);

- the plane is tilted.

You can check the horizontal beam in a simple way. This will require a room with a large area. Each wall should be about 20 m. Place the device against one wall, then turn it on. A projection will appear on the wall bordering the level. Put a mark on it. It will mark the starting point.

Then, turning the device 180°, perform similar actions on the opposite side. This will be a continuation of the beam.

Important! Do not move the tool during operation. You should move it so that all the points that you marked before coincide with the central one.

The final mark should be on the third wall. It is placed according to the same principle as the second one. The repair procedure should be repeated 2 times. This way you can eliminate errors and further problems with the tool.

Diagram of a laser level device.

Note the difference between the readings. If it is within the normal range, then the device is working properly. Otherwise, repairs will be required. Carefully disassemble the structure. Inside you will find a small tendril. He is responsible for the tilt of the head. If there is a displacement during the fall, the level will show inaccurate data. Therefore it should be corrected. Some craftsmen advise removing it, arguing that the laser level can be used in any plane.

In a similar way, you can check along a vertical line. The only difference is the position of the device. By rotating it 90°, you get a projection in a different plane.

If the data obtained indicates the presence of a deviation, you will need to take the measures indicated above.

How to check the level

Malfunctions are detected when checking the laser level. To do this you need to do the following:

- install it in any corner of the room;

- Direct the laser horizontally to the opposite corner (diagonally);

- along the line issued by the device, make 6 marks along the entire length;

- move the level to the corner where the beam was directed;

- align the laser line with the marked points - it should rush to the opposite corner.

Reception and delivery

Bring the device to our service center and pick it up yourself when ready. Call a courier who will pick up the device at the specified address and deliver it upon completion of the repair.

- Cost within the city - 500.- *

- Cost outside the city - from 500.- *

* Reception of goods by courier and delivery are paid separately.

By region:

Send the device by any transport company to the legal address of our service center.

Where to repair a laser level

Having understood the question of whether it is possible to repair the level yourself, we can conclude that if it is not possible to restore the functionality of the instrument, then there is no need to rush to buy a new one. A failed laser level can be restored by contacting specialized centers. Such centers are located not only in large cities of Russia, but also in smaller ones. There are specialized centers for repairing laser levels in the following Russian cities:

- Moscow

- Ekaterinburg

- Novosibirsk

- Rostov

- Nizhny Novgorod

- Ufa

- Samara

- Krasnodar

- Chelyabinsk

- Falcon

- Voronezh

- Irkutsk

- Krasnoyarsk

No matter what big city you live in, in order to repair a laser level, you must first try to find the breakdown yourself, and only then look for the addresses of service centers. These centers perform not only repairs, but also adjustment and verification of the measuring device. How much repairs cost at a service center depends on many factors:

- Location - the remoteness of the settlement from the city indicates the need for costs for shipping parts and components, which is an additional expense

- Laser level model - repairing cheap models is correspondingly inexpensive, but to repair levels from brands such as Bosch, DeWalt, Hitachi and others, you will need the appropriate components

- Type of fault - if it is a minor breakdown, then the cost of such repairs will be insignificant

To avoid being deceived, you should choose only specialized service centers and workshops. It’s not difficult to find out about these, since there are many reviews about these or other workshops on the Internet. If you know the addresses of good level repair shops in Russia, Ukraine and Belarus, then you can share the addresses directly on the site.

Basic faults

Let's see: how to repair a laser level, what can be done at home.

Without special education and tools, it is quite possible to cope with malfunctions that arise as a result of careless handling, mechanical shaking during transportation or damage to the case, as well as carry out maintenance and repair of fasteners and tripods.

If you find an inaccuracy in the level readings, you can try to correct it, for which you need to disassemble the case. Inside you can find a small “antenna” that allows you to adjust the laser head, guided by the classic bubble levels or a plumb line, try adjusting the beams in space.

In addition to the displacement of the antenna, the accuracy of the readings can be affected by changes in the setting of the special weight. Having opened the case, inspect: there should be a special plastic bolt at the bottom, open it, find the screw with the abbreviation “A” - this is the load.

By carefully examining the platform, you can find deviations in the load settings. Adjust and check the accuracy of the work, for which use plumb lines or classic levels.

At home, among other things, you can repair the level housing if it is damaged, and also replace the glass covering the optical system. New glass can be purchased ready-made or made yourself.

Another common malfunction is the unclear operation or failure of the control buttons. The cause of this breakdown may be construction dust or excessive pressure on the buttons themselves during operation.

To repair, open the case; if you find that the button contacts have come loose or have fallen off as a result of corrosion, solder them with an electric soldering iron in compliance with all soldering rules.

If the buttons are out of order, which can be determined using a multimeter in ohmmeter mode, and they are not hidden, replace them by selecting similar new ones or suitable ones, but of a different type.

Important! It doesn’t matter whether you are repairing Bosch levels - the most famous and most popular, or another, little-known company, after opening the case you automatically lose the warranty!

It is impossible to create universal instructions for repairing a level; the range of faults can be very wide. However, we note that if the laser itself has failed on your level or the optical system has broken down, you are unlikely to be able to make repairs yourself; in this case, you will have to contact a workshop.

Remember, careful handling, timely cleaning and maintenance will make the service life of your level very long, and therefore...

Wisdom is not the ability to find a way out of difficult situations, but the ability to avoid getting into them.

This is interesting: Vibrating rammer for soil compaction: types and technical characteristics

Defects in laser levels and how to fix them yourself

When purchasing a measuring instrument, the question arises about which device to choose for repair. After all, in order to prevent level breakdowns, it is necessary to decide at the purchase stage which tool is suitable for performing certain jobs. If you buy a level for indoor work and use it outdoors, it will not last long. In addition, you should not choose cheap models if you have high hopes for the device. If Chinese cheap fakes are used frequently, they will quickly fail.

However, not only cheap levels break, but also expensive ones that require appropriate repairs. When you need to repair a level yourself, we will find out in detail:

- When, when the device is turned on, the laser beam is not rectilinear, but curved in the shape of an arc

- If the LED that creates vertical and horizontal projections does not light up

- If the control buttons are faulty

- In case of defects on the body caused by mechanical impact

- If the electric drive does not rotate when starting

- The laser beam becomes dim and barely noticeable

If the device has been dropped on the ground or damaged by heavy tools or building materials, even if it shows no signs of malfunction, it should still be diagnosed. The position adjustment system, and especially the self-adjusting mechanism, can also fail.

Price list

| Adjustment | from 1000 rub. |

| Adjustment and metrological examination | from 1500 rub. |

| Compensator repair | |

| Correction of undercompensation | 1300 rub. |

| Re-stretching the torsion threads of the compensator | from 1500 rub. |

| Replacing the torsion threads of the compensator (excluding the cost of spare parts) | from 1500 rub. |

| Replacing the compensator (excluding the cost of spare parts) | from 1300 rub. |

| Replacing the compensator limiter | from 500 rub. |

| Tribrach repair | |

| Removing the tribrach shank | from 500 rub. |

| Bushing repair | from 1500 rub. |

| Leveling the tribrach pad | from 300 rub. |

| Replacing gaskets | from 300 rub. |

| Replacing the screws on the tribrach | from 500 rub. |

| Replacement of the tribrach (excluding the cost of spare parts) | from 500 rub. |

| Optics repair | |

| Cleaning optics | from 500 rub. |

| Replacing the eyepiece/reticle (excluding the cost of spare parts) | from 1000 rub. |

| Focus repair | from 800 rub. |

| Repair of racks | from 300 rub. |

| Replacing the guide screw | from 1500 rub. |

| Replacing the ratchet | from 900 rub. |

| Repair of the guide screw | from 1000 rub. |

Adjust vertical and horizontal separately

Let's consider the option when, when checking the laser level, a failure of only one vertical or horizontal line is detected. In this case, you should not touch the general compensator adjustment screws (green arrow in the photo), as this will not give the desired result.

Of course, you can use them to level the vertical, but then the horizon will be lost.

This requires adjustment of a specific module with an emitter; in the ADA 2D Basic Level it is secured with three small hexagon socket bolts, so small keys will be needed for repairs.

To begin with, we release the red bolt, since it secures the module in the pendulum socket, then with two yellow bolts we adjust the position of the emitter depending on the projection of the plane relative to the desired one.

When we have found the desired position, fix it with a red bolt and clamp the yellow ones.

ATTENTION! You need to twist the yellow pins VERY carefully and over a tiny distance, since any minimal movement immediately affects the error!

Principle of operation

The basic element of any device whose name includes the word “laser” is an emitter of highly targeted monochromatic (one-color) radiation. The phenomenon is based on forced radiation, which, depending on the power, is perceived differently.

Low-power laser emitters based on red, red-orange, yellow-orange and green diodes make it possible to produce a point or beam of light.

At a high level of pumped energy, a laser beam can turn into a weapon - it can set fire to materials that absorb radiation well.

Devices used in everyday life and construction and repair work operate on laser diodes of the red, yellow-orange and green spectrum; blue and violet ones are much less common (such models are much more expensive). To concentrate light radiation, biconvex lenses are used, as well as other optical devices that allow the beam to be converted into a plane.

Household appliances have a standard circuit shown in the illustration. Design variations are related to the power of the emitter and additional accessories.

Laser-based level and level design

Laser levels and levels use the principle of directly indicating a target - a point or line on a surface. They can be tracked directly (in relatively low light) or through the eyepiece of the device.

- In addition to a point or line (the trace of the intersection of a light plane with a solid opaque surface), levels and levels allow you to obtain a cross-shaped pointer, as well as simultaneously use two or more emitters.

Due to the scattering of the laser beam into a plane, such devices are often called “laser plane builders”. In general, the set of functions of the device depends on the number of emitters and optical devices for concentrating or scattering the beam.

Substitutes for professional equipment

In homemade devices, a special laser emitter is replaced with a conventional laser pointer.

With sufficient power and quality, as well as the presence of two or more attachments that allow you to transform the laser beam, such a pointer is quite suitable for making a laser level with your own hands.

You just need to take care of sufficiently strong and convenient fastening and installation of the pointer in a strictly defined position with the possibility of displacement.

As can be seen in the illustration, a telescopic tripod with a convenient mount that allows the holder to be rotated is used to mount the professional device.

Since such tripods are often found in the households of amateur photographers, they can be easily adapted to make a tripod for a laser level with your own hands.

If you don’t have a tripod, you can make a simple stand based on a stick or timber with a support at the bottom, use a container of water or a hanging mechanism. These options will be discussed in detail below.

If you have a tripod and a construction bubble (“spirit level”) level, creating a device comes down to installing a tripod and attaching a level to it with a laser pointer fixed on it. The illustration shows a level with an existing groove for the pointer, but in fact the fastening is simply done using clamps, wire or even tape.

The most difficult part is the correct orientation of the laser beam. To do this, it is advisable to insert a piece of hard rubber or foam between the pointer and the surface of the level, securing it with clamps or elastic bands, as shown in the diagram.

Here 1 is a pointer, 2 is a piece of dense and moderately elastic material, 3 is clamps or elastic bands. After setting the bubble level strictly horizontally (this can be done on any flat surface), the laser pointer turns on.

By cutting the insert and tightening the clamps tighter or looser, we carry out a kind of adjustment of the level (of the future).

Once parallelism between the horizontal plane and the laser beam has been achieved, you can mount the resulting device on a tripod in any convenient way.

Support in the form of a rod, float device or suspension

As already mentioned, in the absence of a tripod, we use improvised means - a barbell made from a broom handle, a shovel or just a piece of timber, or a container of water.

The structure of the rod is very simple: a beam or stick is attached to a piece of board or OSB board (plywood) strictly vertically and so that the structure is stable.

You can check the angle between the support and the rod with a building square, but it is better to use a regular building level. Spacers can be used as support, as shown in the diagram below.

A block the size of a bubble level with an attached pointer is mounted to the top of the rod - and the device is ready.

If you place a large container on the floor, filled almost to the brim with water, and place a level with a laser pointer on a flat piece of foam, you will also get a quite suitable support for a homemade level. In addition, in a container with water, the device can rotate freely, “drawing” a plane along all the walls of the room.

Interestingly, for such a “float” level you don’t even need a bubble level. With an even piece of foam plastic on which the pointer is rigidly and strictly horizontally fixed, the laser beam will move only horizontally - due to the impeccable evenness and horizontality of the water surface.

Simple steps for making such a laser level with your own hands and its operation are shown in the video.

The suspension is even easier to install. A beam is attached to a chandelier hook or other similar mount on the ceiling of the room using a rope or thin wire.

A laser pointer is fixed on the beam so that the light beam is directed toward the floor (if floor markings are needed) or toward the walls. Next, by rotating the resulting level from the pointer, we obtain a light point or line on the desired surface.

Main types of defects

It is possible to repair a laser level in some cases, but first you should make sure that the warranty period for the device has expired. Warranty cases include:

- If, during the operation of the tool, irregularities appear on the laser line when projecting horizontal marks.

- In case of violations in the suspension system of prisms, which leads to the disappearance of sections of light lines.

- When violations of vertical rays occur, which leads to a difference between the level readings and the true readings.

- If during operation any element of the control board fails. Violation of any element of the board will certainly lead to a malfunction of the entire device.

- If a phenomenon such as sticking of buttons and switches occurs. This makes it impossible to turn the device on or off, or to switch between different functions.

- If a luminous beam does not appear when the level is turned on.

While the tool is new, it is handled with care, but over time, during active use, the device may fall or various types of aggressive substances may come into contact with it.

How to check a laser level yourself?

Checking a laser level may be necessary when doubts arise about its correct readings. To check the device, you need to place it in any corner of any room. Using a marker, you should put mark No. 1 in the corner with the device, then you need to direct a horizontal beam to the opposite wall diagonally from the device, and put mark No. 2 there. As soon as this procedure is completed, the device must be moved to the opposite corner and installed there.

Now you need to combine the beam with the nearest mark No. 2, and direct it to mark No. 1. If the beam coincides with it, then the device can be considered serviceable, but if not, then it will need to be repaired or adjusted.

Is it possible to fix it?

It is almost impossible to repair laser levels yourself. The device is a complex mechanism consisting of not only mechanical but also electronic elements. To repair the laser level, it is recommended to contact specialized workshops.

Numerous experience of level owners shows that only such a unit as the sight can be repaired. In this case, you will need to disassemble the tool body. Inside, there is a tendril on the movable element, which should be moved into a special hole on a metal base. In other cases, it is recommended to entrust laser level repairs exclusively to specialists. After all, the device is a fairly expensive device, which is very easy to damage if you try to carry out repairs yourself.

It is impossible to avoid breakdowns of the level, like any other instrument, but you can extend its service life by careful handling and proper care of it. Features of instrument care are described in the instructions that come with each product.

DIY laser level repair

No matter what brand is on the instrument - “Made in the USSR” or “Made in China”, no matter how sad it may sound, they still do not last forever. Our assistants are breaking down, passing the baton of everyday work to a new generation, ready to constantly bring order to the chaos of construction. However, the motley composition of loyal allies experience the hardships of construction in different ways. The life of a simple hard-working hammer drill is spent in constant clashes with bricks, concrete and his other eternal enemies. He is unpretentious, constantly ready for a fight and pays little attention to the careless attitude towards his person. But the laser level is not like that - like an emo boy, a slight slap on the head causes him unbearable mental torment. But if the existence of the latter does not bring any benefit, then the laser level sets guidelines for construction work. It’s also not cheap and is instantly addictive. His failure, in addition to ruining his mood, takes a toll on his wallet. Therefore, today we will talk about the most common malfunctions of laser levels and how to fix them.

1. LARGE MEASUREMENT ERROR

Why do we love laser levels? Marking with it is done quickly, conveniently and, most importantly, accurately. If the first two statements do not cause any complaints, then the last paragraph, like a footnote in fine print in a loan agreement, is fraught with not very pleasant surprises. The insidiousness of such a laser level indicator as “accuracy” is that it is impossible to immediately, “by eye”, determine a 1mm error there for 5 meters, or all 5mm. And most people don’t even check the device before buying. And it is necessary to check, because... Level accuracy is a man-made indicator, and these hands are not always straight. The long and winding route to the shelves also often contributes.

And, of course, first of all, a careless attitude. Fell, hit - without subsequent recovery procedures, the career level as a measuring instrument can be given up.

In any case, this problem is solved by adjustment. To put it simply, to adjust the accuracy, the screws securing the emitter to the pendulum structure are used. I have seen many videos on YouTube where it is proposed to reduce the error using counterweight screws. This method has significant limitations both in terms of level models and in situations in which it can be used, so there is no point in considering it.

So, the order of manipulations with the fastening screws depends on the design of the laser level. It can be used:

1) diodes in a metal case; 2) laser diode tube. As you might guess, they are configured differently.

But if in ordinary buckets the arrangement of screws for fastening the emitter is the same, regardless of the model and brand, then in 3D levels there are several such configurations. In the last picture, the best combination of them in terms of adjustment is when there are 4 adjustment elements and they are paired. For comparison, there are 3 of them in the Fukuda 3D laser level, they are placed on the sides and adjusting this level is a real punishment.

2. RADIator DOESN'T WORK

Another common failure of a laser level is the refusal of the emitter to fulfill its direct duties - to build lines. There are several reasons for this disobedience:

1) one or more thin copper wires running from the circuit on the pendulum to the control board are broken.

First you need to find a break. He is not always visible, because... The wire may be in its place, but poorly/not soldered to the control board. Therefore, you need to take tweezers and carefully pull each of the wires. When a weak link is discovered, we replace it with a new one. The diameter of the replacement wire should preferably be no more than 0.08-0.1 mm;

2) the laser diode has burned out. This is not a pleasant experience. There is nothing to repair here, the only cure is replacement. The situation is further aggravated by the almost complete lack of spare parts from official dealers - manufacturers are not interested in repairing their products, much less with their own hands. They can understand, but it doesn’t make it any easier. We'll have to look for donors. For some models, it would be a good idea to try your luck in finding spare parts at a famous Chinese flea market.

You also need to keep in mind that replacing the laser diode automatically leads to subsequent adjustment of the laser level. You can read how to change the emitter in the following articles:

3. BEAM VIBRATIONS

Symptoms include the line not stopping. Her runs can range from a fraction to a couple of millimeters. In this case, the problem lies in the magnets located under the pendulum. The cause of this defect is:

1) a foreign object caught on the magnets; 2) one of the magnets has come unstuck.

In any case, you will have to completely disassemble the level, and it is often necessary to remove the pendulum structure. For some models (for example, this includes the entire line from the previously mentioned Fukuda), you will have to unsolder the wires.

4.BUTTONS STICKING

Although laser levels have an almost completely sealed housing that prevents dust and dirt from getting inside, this protection is not ideal. Therefore, over time, these unwanted guests still settle in the insides of the device, gradually increasing their presence until it becomes critical. This has the most detrimental effect not on the bearings (they are either closed or sealed with a special washer on top), but on the control panel. In many models of laser levels, regardless of shape, it is a plastic insert with rubber membranes in places that need to be pressed.

Dust gets clogged between the membrane and the button cover. If such a breakdown occurs, repairing a laser level involves disassembling the device, removing the control panel and cleaning it of dirt.

5. THE PENDULUM DOES NOT BLOCK WHEN THE LEVEL IS TURNED OFF

The pendulum, which is locked after the device is turned off, guarantees long and fruitful operation of the level for a long time. If, after deactivating the device, the pendulum does not lock, then soon the accuracy of the device will noticeably decrease. This small malfunction leads to serious consequences, so it must be corrected as soon as possible.

Most problems with this part of the structure are related to wedging, so it is necessary to determine and eliminate the cause of this phenomenon.

6.VERY WIDE LINE

The thickness of the line increases in proportion to the distance to the surface on which the beam falls. The standard reading for laser levels with red beams is 1.5mm at 2 meters, plus 0.5mm for every subsequent 5 meters. If initially the line thickness is >3mm, then this is extremely sad, because Laser focusing is disrupted. And even sadder is the realization that there is no cure for this. Therefore, actions in paragraph 2.2 are carried out with subsequent flow into paragraph 1. 7.LEVEL DOES NOT TURN ON

First, you need to make sure that the problem is in the device, and not in the exhausted power source(s). We replace the power supply element with a new one and look at the result of the replacement. Or we measure the voltage of the old one with a multimeter, the readings should be at least 1.1-1.2V. If the battery is fine, then the problem is in the level itself. Therefore, you need to try to find it. For this:

1) carefully inspect the electronic component of the device to ensure there are no breaks/damage to the wires; 2) check the serviceability of the capacitors - they should not be swollen; 3) examine the tracks of electrical boards; 4) use a multimeter and a tester to ring the main elements of the microcircuits.

Once a faulty element is detected, it will need to be replaced.

As can be seen from the list of faults described above, it is quite possible to repair a laser level yourself. It does not require any specific equipment or knowledge. It is enough to have a screwdriver, a hexagon, a soldering iron and know how to use them.

The most common laser level breakdowns and how to fix them

1. Error when measuring with a laser level.

Using a laser level, it is extremely easy to apply the necessary markings on a plane horizontally and vertically. Doing this is simple, quick and convenient, since the device produces points and lines with great accuracy. Of course, they have an error, and it is noted in the accompanying documents in millimeters per meter of distance of the mark from the device. For household options, up to 3-5 mm per ten meters is allowed, and for professional ones, 1-3 millimeters per the same ten meters. Most often, no one checks this figure before purchasing, although this should be done even if you take the same Leica and Makita, not to mention little-known companies or laser levels produced by hardworking Chinese. Of course, it is extremely rare that the error differs greatly from that indicated in the operating instructions, but it happens that it is discovered only after bringing the level home. This is a definite defect, and here you have to hand over the unit right away, without trying to find a replacement for it. But it also happens that an error appears after careless handling of the device: it was dropped, used outside the permissible temperatures, moisture, dust got in, and so on.

If you notice that your laser level has started to frankly mess up with the data, then adjustment will help to establish its flawless operation. Some models can be returned to service by using adjustments using various pendulum screws, this way you can significantly reduce the error in the operation of the device. There are quite a few videos on the Internet that show adjustment in detail using this simple method, but since it has significant limitations on its use, we will not consider it in detail in this case.

All work with screws will depend on how the laser level is designed. It can contain either diodes in a metal housing or a diode laser tube. It is clear that the way to configure one is completely unsuitable for configuring the other. In addition, if in conventional units the arrangement of screws is unchanged, then those that are commonly called 3D devices can have different options and configurations.

The most convenient way for adjustment is if the level has four adjustment elements and are placed in pairs. It is very inconvenient to adjust the device if it has three screws and they are located on the sides of the case.

2. The emitter has failed.

This is another common problem with all laser levels, and indeed with laser equipment in general. Without this, it is not possible to construct points and lines. The reasons can be completely different.

Very often, due to an impact, contacts come off the board or wires break - they are very thin, made of copper wire, and are damaged extremely easily and quickly.

In this case, you need to find the break point: for this, it is most convenient to carefully pry up each wire with tweezers, and this way you can quite easily find the one that has moved away from the board or is torn. The failed copper wire must be replaced with a similar one. The size of the replacement wiring must be at least 0.08 mm and no thicker than 0.1 mm.

The second reason for the breakdown of the light emitter is a failed LED. It cannot be repaired, of course - only a complete replacement with a similar one is possible. The problem here is that you simply won’t be able to find an original spare part for any more or less well-known brand. The fact is that manufacturers are extremely uninterested in the fact that their products are subject to repair - it is much more profitable if the user does not take it for repairs, but buys a new device. But, there are always options for replacing the LED, and you can easily find an analogue in workshops, junk shops or Chinese sites like “Ali”.

Replacing the diode itself is a simple process and a minimum skill is enough for everything to work out. Once your level is working, do not forget to completely configure it again, as if you had just purchased it.

3. Beam jitter

You can often see that the beam seems to blink or “run through” again after a few fractions of seconds. It interferes with work, and is just annoying, to be honest. The problem lies in the fact that such a malfunction is caused by magnets located under the pendulum. The normal functioning of the magnets can be interfered with by debris and dust that has fallen on them or the fact that one of them has come out of its nest and is not holding firmly.

To eliminate this drawback, you need to completely disassemble the level, remove the pendulum; some models will require not only complete disassembly, but also unsoldering the board with those thin wires that we talked about above.

3. Buttons on the control panel get stuck

The housing of modern laser levels is not only durable, but also quite sealed. Which, however, does not prevent the buttons from completely breaking; most often this happens because dust gets inside and settles on the board and disables the buttons. However, this happens with any devices that are used during construction or renovation.

The control board is hidden inside the case, and on the surface we see only a few buttons, which are surrounded by a rubber or plastic gasket. It could also just be a membrane made from a whole piece of PVC with small protrusions. Dust and small debris falling between the contacts of the board and the button become an obstacle to the passage of the signal and the control panel completely or partially fails. Most often, this becomes noticeable by the poor operation of the button, when you need to press it several times to get the desired result.

Device design

In appearance, the level is designed simply, but its individual parts are technically complex structures. Therefore, in most cases, it is not possible to repair a laser level on your own; this requires special equipment and professional knowledge.

Level device diagram

One of the main elements of the device is light sources. They have built-in laser LEDs. They are placed in a plastic case, which has a protective function. It has fastenings that fix the device in the right place and also allow you to adjust the direction.

The simplest versions of a laser level set the direction parallel to the body of the device, but before that you need to set it up using a regular bubble level built into the device. Professional models are capable of firing 2 or more beams at once. They are self-adjusting, the beams are mutually oriented.

Design of a laser level

The laser type level belongs to the category of optical measuring instruments that require an appropriate approach to use and storage. Failure to comply with storage and operating conditions leads to damage to the level. Before repairing a laser level, you should understand its structure.

The instrument in question appears to have a simple design, but some of its individual parts have a complex structure, which causes difficulties in self-repair at home. However, knowledge of the design of this measuring device will help simplify repair work.

The main element of the level is the light source, along which the corresponding constructions of horizontal and vertical planes are made. LEDs are used as a light emitter, the illumination of which is enhanced through the use of a lens system. An LED can fail only due to a malfunction of the electronic chip. The lenses can only break, in which case they will need to be replaced.

Outside the device there is a housing, which usually has a high degree of protection from moisture and dust. The housing is usually made of impact-resistant plastic. The housing design has a connector where replaceable batteries are installed or batteries are stored. To carry out precise measuring work, the device has a special installation system. This system allows you to position the level evenly and make the appropriate measurements.

Levels come in different varieties, which depends not only on the manufacturers. They are classified into simple or household and professional:

- Household device models are only capable of creating a beam that is directed parallel to the body

- Professional - they are capable of projecting laser beams in different planes and around the entire circle at 360 degrees. Such devices additionally use an electric drive that rotates the laser LED in a circle.

The more complex the design of the instrument, the more difficult it is to repair the level. To repair the device yourself, you should find out the main types of breakdowns that occur at laser levels.

How to deal with the problem of buttons sticking

Appearance of the level

One of the most common causes of laser level failure is faulty buttons. This happens when construction dust gets inside or they are pressed too hard during use.

Repairing a laser level in such a situation is simple: you need to disassemble the housing and solder the loose contacts in place. In this case, it is recommended to use special solder with flux - with it the connections will hold tighter.

If the buttons stop functioning, they can be replaced with new ones.

In case of other malfunctions, it is necessary to give the equipment into the hands of specialists, otherwise there is a risk of completely ruining it. To avoid breakdowns, you need to carefully carry out operation, transportation and storage. After opening the case yourself, the warranty on the level disappears.

Frequent breakdowns of the laser level

Sometimes it happens that the device does not work correctly or does not output a beam at all. Laser level repair is carried out in the following circumstances:

- when the device draws an arc instead of a horizontal line. Its ends can be either lowered or raised;

- when incorrectly displaying a vertical line that is noticeably different from the true vertical position;

- the output of laser beams is difficult due to a breakdown of the emitter suspension system;

- failure of the control board. It contains microcircuits and other complex elements and is connected to connectors. If one thing “burns out”, the device will stop working;

- refusal to operate or sticking of buttons;

- failure of the emitter when the light is not output or the luminous flux is too weak.

Repair is usually required after the device has been dropped - in almost every such case, the structure of the emitter system breaks down. This directly affects the accuracy of the level readings.