Welding of metals is used in cases where it is necessary to obtain the most durable, tight and reliable permanent connections. Welding technologies provided the impetus for the rapid development of technological progress.

Many designs simply could not be created without their use. There are various welding technologies based on the use of electric or gas welding processes, as well as types of welding joints, the classification of which is quite simple.

Welding types

Almost the entire variety of welding technologies used can be classified into one of the following types:

- electric arc welding;

- electric contact welding;

- gas welding.

Electric arc welding involves applying a voltage between the workpiece to be joined and the welding electrode, causing the ignition of an electric arc.

The high temperature that occurs when the arc burns leads to the melting of areas of the parts being connected that are directly adjacent to the place of future mating.

At the site of the future seam, a so-called weld pool is formed, that is, molten metal, after crystallization of which a reliable and durable weld is formed.

According to the level of use of process automation, electric arc welding can be manual, using a piece replaceable welding electrode, semi-automatic, with an endless, continuously supplied wire electrode, and automatic, carried out without the participation of a welder.

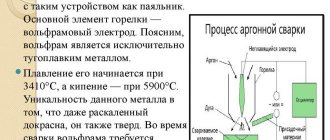

In addition to the above, the electric arc welding process can be atmospheric or in an environment of protective gases, which prevent the oxidation of the molten metal and contribute to the formation of a higher-quality weld.

In the case of electric resistance welding, the elements being connected are compressed with great force, and a significant electric current is passed through the contact point.

As a result, the metal parts being connected are heated to a plastic state, and under the influence of compressive force they are welded together.

The gas welding process occurs due to the melting of the metals being joined, as well as the filler material when burning gas using special gas-flame equipment.

Specifications

The use of OZL-6 is associated with their technical characteristics:

| Characteristic name | Data or description |

| Arc burning | Sustainable |

| Metal spatter level | Small |

| Formation of the resulting seam | good |

| Separability of slag crust | Satisfactory |

| Deposition coefficient (in the lower position of the seam) | 10.0 – 13.0 g/Ah |

| Deposition performance (for 4.0 mm diameter) | 1.1-1.7 kg/h |

| Consumption per 1 kg of deposited metal | 1.6 kg |

| The tendency of the weld metal to form pores | Prone to poor preparation of the joint and lengthening of the welding arc |

Recommended reading: Using SSSI electrodes

Size range

The most popular types of welding consumables of this brand are sold on the market:

- for operation with current from 60 to 130 A, diameter 3 mm and length 350 mm – 30 pcs. in 1 kg;

- for operation with current from 100 to 2100 A, with a diameter of 4 mm and a length of 450 mm - 15 pcs. in 1 kg;

- for work with current from 150 to 280 A, with a diameter of 5 mm and a length of 450 mm - 10 pieces per 1 kg.

Electrodes diameter 4.0.

Chemical composition of OZL-6 electrodes

The properties of consumables are ensured by the chemical composition of the coating, consisting of the following components:

- Carbon in an amount of 0.09%, which binds free metal molecules and gives it strength. Due to the precisely adjusted percentage, a solid connection is obtained that eliminates brittleness.

- Manganese – 1.9%. It plays a similar role, and also promotes the removal of sulfur and phosphorus. The resulting seam is smoother and more uniform, resistant to mechanical stress.

- Silicon – 0.38%, which is a deoxidizing agent. It removes free oxygen from steel, helping to reduce chemical segregation and improve mechanical properties, increasing ductility and strength.

- Nickel – 12.8% for oxidation resistance and increased heat resistance of the joint. Physical properties are maintained in corrosive environments.

- Chromium – 24.9%. It becomes an alloying component and reduces abrasive wear, the tendency to rust and improves the quality of the joint after thermal loads.

- Sulfur (0.011%) and phosphorus (0.022%) entering the main layer from the charge and alloys during manufacturing. Their number was minimized and the number of cracks during welding was reduced.

Properties of the resulting seam

The metal connection obtained by welding with OZL-6 electrodes has the following mechanical characteristics:

- temporary resistance 560 MPa;

- relative elongation by 25%;

- impact strength 90 J/cm²;

- ferrite phase 6.1%.

We recommend reading: What electrodes are used on stainless steel?

Weld.

Features of surfacing

A negative feature of these consumables was the high consumption during welding. Creating a fixed length seam will require 60% more electrodes compared to other brands.

Therefore, to increase efficiency, it is necessary to prevent sticking or boiling of the rod and splashing of metal around the workplace.

To do this you need to do the following:

- calcinate the electrodes before starting to join metals for 1 hour at a temperature of +180-200°C;

- do not work in a vertical plane;

- clean the tip of the rod;

- carefully sand the surfaces to be welded;

- conduct an arc spark along the top of the seam at an angle of 80° and at a distance from the joined edges of no more than 3 mm;

- follow the welding mode, focusing on the instructions printed on the packaging;

- after replacing the electrode, you need to clean the joint and continue welding from a point located slightly higher from the stopping point;

- Do not allow the seam to cool suddenly.

Metal stripping.

How the parts are connected

The technology for the production of welding joints, including their types, dimensions of the main elements and their symbols in the drawings, is established by GOST 5264-80. To correctly read a drawing intended for welding a structure, you need to familiarize yourself with this standard.

In accordance with GOST, when performing welding work, the following types of connections can be used:

- butt;

- corner;

- T-bars;

- overlap

It is worth talking about each of them separately, since the choice of welding joint and preparation of the edges of the workpieces directly affect the quality of the seam.

Butt

This welding joint is characterized by the adjacency of the side surfaces of the parts being welded, located in the same plane.

There are varieties of this welding operation. The work can be performed without preparing the surfaces to be joined. When welding relatively thin sheet material, its edges can be pre-flanged, that is, bent at an angle of 90 °C.

For thicker workpieces, to ensure complete penetration of the material through thickness, bevel the edges on one or both sides. The bevel shape of the edges can be straight or curved.

To hold the weld pool in the seam area, a flat lining is sometimes placed under the sheet blanks being welded, which is removed after the work is completed.

The seam itself when making a butt joint can be one-sided or two-sided.

Corner

This connection is applied to parts that are not in the same plane, the edges of which are located at a certain angle relative to each other. Such connections are also made with or without preliminary surface preparation.

Preparation consists of beveling the edges to be joined in different ways; one of the planes can be beaded. Welds, depending on design requirements, are single-sided or double-sided.

T-bar

With a T-joint, the edge of one of the parts being welded is attached to the surface of another part at an angle of 90°. Thus, the cross-section of the connection is shaped like the letter “T”.

To improve the quality of the connection, one-sided or two-sided bevels of the edges of the attached element are used. Those parts are processed whose ends are welded to the planes of other parts.

For better welding of the metal, when fastening parts, usually ensure that there is a small gap between them. The gap size is 2 – 3 mm.

In general, for each specific procedure, a flow chart of the operation must be drawn up, taking into account all the requirements of the design of the assembled structure.

overlap

Parts connected with an overlap are superimposed on one another, while being in parallel planes. Seams are made on one or both sides.

In this case, it makes no sense to bevel the edges, since the end sections and planes of the parts to be joined form a concave angle that holds the weld pool well and makes it possible to make a strong seam.

general information

In the manufacture of the rod, alloyed wire SV07X25N13 is used. Therefore, during welding, it is preferable to use DC machines with reverse polarity.

Reliable protection of the weld pool is guaranteed by the base coating.

Another advantage was the ability to obtain a high-quality seam in any spatial position.

Explanation of markings

Electrodes of this brand were developed in, and the marking gives the following information:

- OZL – ash main coating type;

- 6 – purpose of the manufactured seam.

Electrodes OZL-6.

Classification and GOST

Russian enterprises producing such products operate in accordance with GOST 10052-75 “Coated metal electrodes for manual arc welding of high-alloy steels with special properties.”

Generally accepted product qualifications:

- welding electrodes OZL-6-2;

- OZL-6-2.5;

- OZL-6-3;

- OZL-6-4;

- OZL-6-5.

Where are OZL-6 used?

Due to their characteristics, such consumables are used when it is necessary to make seams and connections of low-carbon steels, metals with a low content of alloying additives, heat-resistant alloys, cast and rolled structures installed in places with an aggressive environment. Performance characteristics are maintained at temperatures up to + 1000 °C.

Welding modes

The method of working with electrodes is presented in the table:

| Electrode diameter | Current strength when welding in the lower position, A | Current strength when welding in a vertical position, A | Current strength when welding in the ceiling position, A |

| 2 | 40-55 | 30-40 | No |

| 2,5 | 50-70 | 40-60 | No |

| 3 | 60-80 | 50-70 | No |

| 4 | 120-140 | 100-120 | 100-110 |

| 5 | 140-160 | 120-140 | No |

Other classifications

Depending on the length of the seam, welding joints can be intermittent (stitches) or continuous. The latter are used to obtain a sealed structure (pipes, various containers).

By changing the arc length, welding speed, and groove depth, you can obtain convex and concave welding joints. There is also a normal option, when the connection is almost flat, and the seam does not protrude above the surface, but we also do not form a recess.

Welding seams are obtained at different positions of the workpiece. Depending on this, they can be bottom (the simplest connection), horizontal, vertical and ceiling (the most complex version of welding work).

Calculations

When designing various structures, all technical parameters, including the use of a certain type of welding, as well as the choice of method for connecting parts, are carried out on the basis of preliminary calculations. First of all, the structure is calculated for strength .

The initial data for this is the modeling of the loads to which the structure will be subjected during operation. Based on this, the material and method of connecting individual elements are selected. Calculation methods for each type of welded joint are standardized and unified.

When carrying out calculations for the strength of welds, the nature, directions and magnitudes of loads on the joint areas are determined. The obtained values are compared with the maximum permissible values for the materials used.

Based on their comparison, a conclusion is made about the safety margin of the structure. This calculation is made many times, separately for each connection option, type of welding used and structural material. Only with correct calculation can a reliable connection be obtained.