Reasons for installing a drainage system

If the pipes are placed along the perimeter of the land plot, then a reliable drainage system can be built. It is known that ground and flood waters, as well as precipitation that falls in quantities exceeding the monthly norm, pose a serious danger to the foundation of private housing.

Most often, the laying of drainage pipes is carried out before the construction of the house begins. But it happens that after the completion of construction work, serious reasons arise for waterproofing the foundation. Then, under special conditions, you can start preparing the drainage.

Let's consider the situation when pipes are installed at the beginning of construction, but for specific reasons:

- high groundwater level - less than one and a half meters to the ground surface;

- gentle slope of the area, promoting regular accumulation of moisture;

- the presence of clay and loamy soil with low drainage characteristics;

- The building is located in an area where, according to statistics, the level of monthly precipitation is exceeded.

The depth of construction of other structures in the local area also plays an important role. If there is a buried foundation next to the main building, then groundwater will not be able to drain freely and will constantly accumulate under the house, increasing the risk of flooding. Asphalt and concrete blind areas on the site act as a barrier to the natural circulation of wastewater. In this case, it would be correct to connect stormwater waste to the central system.

Installing a drainage pipe eliminates the damage caused to the foundation from the accumulation of moisture in the ground around the home and changes in the level of wastewater.

Plot

-10 votes

+

Vote for!

—

Vote against!

The most effective way to protect the foundation of a private house from the destructive effects of groundwater and storm water is a high-quality drainage system. This is especially important when water accumulates in the upper layers of the soil, as it can cause flooding of the basement or basement, wetting and deformation of walls, as well as the occurrence of fungal formations. This article will discuss how to lay drainage pipes.

Pipes for the drainage system, which are installed along the entire perimeter of the site, allow you to create high-quality drainage. After all, the danger of flooding is posed not only by groundwater, but also by flood water. Damage can also be caused by precipitation that exceeds permissible limits.

Drainage pipe photo

Unlike waterproofing the foundation, the drainage system can be installed after the house is built, if there are grounds for it. But under certain conditions, it is better to install it at the initial stage of construction. The following reasons are needed for this:

- flat location of the site, facilitating significant accumulation of water;

- clay and loamy soil, which have poor drainage characteristics;

- statistics of excess precipitation levels characteristic of the area in which the building is located;

- increased level of groundwater (less than 1.5 meters to the ground surface).

In addition, it is worth focusing on the depth of construction of other buildings on the site. The presence of a buried foundation next to the main building not only prevents the natural outflow of groundwater, but also contributes to its accumulation, thereby increasing the risk of flooding. The concrete blind areas and asphalt pavement installed on the site are also a barrier to the free circulation of water. In such a case, it is considered competent to connect storm drains to the main drainage system.

Laying a drainage pipe will help prevent the consequences of changes in groundwater levels and accumulation of moisture in the soil around the building.

Types of drainage systems

There are two main options for designing a drainage system:

- Open (surface) - used to remove excess moisture resulting from the accumulation of precipitation or melt water. The open drainage system is presented in the form of ditches and trenches.

- Closed (deep) - installation uses pipes with perforations, which are laid to a certain depth in a previously prepared trench. The main function is to drain groundwater and protect the foundation of the house.

Materials required for laying a closed drainage system

The process of installing a drainage system is quite labor-intensive and requires thorough preparation. From bulk building materials you will need:

- Sand . River sand is mainly used in drainage work. Its main function is to create a filtration cushion around the drainage pipe.

- Crushed stone . To set up the system you will need a medium and large fraction. The purpose of crushed stone is to form a stable layer to prevent the penetration of dirt and large parts of soil. In addition, crushed stone prevents excessive soil pressure on the corrugated pipe.

Basic materials:

- drainage pumps . They are used only in case of significant flooding of the area with groundwater. Promote mechanical drainage;

- drainage pipes . With their help, the main drainage system is formed. The quantity and diameter depend on the complexity of the laying pattern. Plastic pipes are most often used for drainage;

- geotextiles – protects the drainage pipe from soil contamination. As a rule, interlining or dornite is used. In addition to strength, both types of textiles have filtering ability;

- couplings - necessary for attaching drainage pipes to each other.

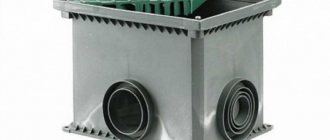

As a rule, the drainage system needs periodic cleaning; for this purpose, inspection wells are installed along its perimeter. A collector well is installed to collect water into the system.

Selection of drainage pipes

Before installing a drainage system, special attention should be paid to the selection of pipes for work. The first thing to consider is the use of perforated pipes in the arrangement of the drainage system. The second is the diameter and the presence of holes for moisture outflow and air exchange. And no less important is the material from which the pipes are made.

Currently, the following types of pipes are presented on the building materials market:

- asbestos-cement;

- ceramic;

- from polymer materials.

The most popular in arranging a drainage system are polymer drainage pipes. Their advantage over other types is as follows.

- Long period of operation - up to 70 years.

- High strength indicators.

- Resistance to corrosion processes and aggressive environments.

- Reduced weight, which simplifies the process of transportation and installation.

- Self-cleaning ability due to smooth surface.

- Resistance to siltation.

- Value for money.

- Easy to maintain. Thanks to the geotextile filter, the system does not need to be flushed.

Diameter of drainage pipes:

- up to 150 mm – for a drainage system that drains a small amount of water;

- up to 300 mm – for systems with high loads.

For a branched drainage system, you will need pipes of both small (for branches) and large diameter (for the main branch of the system).

Plastic drainage pipes

Polymer pipes, which are usually used for laying drainage systems, are made of PVC, polypropylene or polyethylene and are available in the following types:

- single-layer or double-layer . The choice of the number of layers depends on the density of the soil;

- flexible and rigid . Rigid pipes are suitable for simple drainage schemes, while flexible pipes allow you to create complex branching throughout the area;

- pipes with or without filter casing . As a rule, drainage pipes already have holes along their entire length. But if the purchased material does not have special holes, you can make them yourself using a drill and a thin drill bit;

- corrugated or smooth.

As for covering with geofabric, as a rule, samples already covered with filter textile are presented on the building materials market. When purchasing uncoated pipes, you can wrap their surface yourself by securing the material with rope or thin wire around the perimeter of the pipe.

Design of drainage pipe installation

Before starting work on installing a drainage system, it is worth first drawing up a plan for its location on the site.

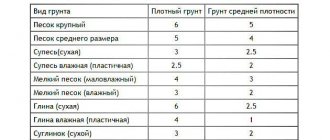

- This requires taking into account the type of soil and the height of groundwater. The most often used is a branched scheme, at the joints of which inspection wells are installed.

- The distance between the branches directly depends on the type of soil. For clay soil it is 10 meters, for loamy soil - 20 meters, for sandy soil - 45 meters.

Laying drainage pipes with your own hands

First you need to determine the location of the drainage system. There are only two placement options:

- “wall” drainage - passes only near the foundation of the house and prevents moisture from entering directly into the building itself;

- a drainage system located along the entire perimeter of the site protects not only the base of the building, but also other outbuildings and plantings located on the territory.

Stages of work

- The first step will be to mark the area for placement of drainage ditches. To facilitate the process, you can use a special laser rangefinder. Particular attention should be paid to places where moisture accumulates after rain - this means that water exchange in this area is difficult due to the density of the soil or the presence of obstacles.

- Trench. The recess under the drainage trench must be made taking into account differences in height. The main task of the prepared ditch system is the rapid and unhindered outflow of water.

Tip: during work, you can use a watering hose, running a certain volume of water - make sure that water does not accumulate in certain parts of the trench.

- Before installing drainage pipes, the bottom of the trench must be thoroughly compacted. Then any filter material is laid, and its ends should extend beyond the trench. Next, river sand and crushed stone are poured, first coarse, then medium fraction, to a thickness of no more than 20 cm.

- Drainage pipes are cut according to the dimensions of the diagram using a jigsaw or a special device - a pipe cutter. Next, you should begin laying the pipes, connecting the joints using fittings. In order for the joint to be strong, it is necessary to join the parts after pre-heating the joining sections.

- The pipes must be carefully wrapped with geotextile, securing the joints with rope or thin wire. The choice of such material is not accidental, since it must allow water to pass through the perforation. In addition to throughput, the functions of geotextiles include protecting the perforations of the pipe from clogging.

- Pipe laying must be done at a slope, connecting the ends to inspection wells. The system can use two types of wells: sealed, which allows the collected water to be used for technical purposes, and absorbent - the water will go back into the soil. The slope of the drainage pipes depends on its diameter; the larger it is, the less slope is required.

- The next step in installing drainage pipes will be filling the surface with crushed stone and sand. After which the structure is wrapped with sheets of filter material located on the surface and covered with a layer of soil.

Drainage pipes video

Drainage system maintenance

When arranging a site with a drainage system, it is important not only its thoughtful and high-quality installation, but also compliance with operating rules. This will allow the system to operate for as long as possible.

Approximately once every four years, it is mandatory to inspect the condition of pipes and wells as a preventative measure. In addition, once every two years it is worth measuring the water level in the wells; a significant change in it may indicate the following factors:

- damage to the integrity of the pipe;

- formation of dense blockage;

- accumulation of silt deposits on the entire surface of the pipe;

- partial settlement of the pipeline due to soil movement.

In order to avoid such problems, it is necessary to promptly inspect the drainage system and clean it from various types of contaminants.

Errors in laying drainage pipes

The efficiency of drainage directly depends on the quality of the installation. Any disturbances during operation will lead to system failure. In the best case, you can repair the damaged area, in the worst case, you will have to completely reinstall the drainage system.

The most common mistakes include:

- selection of a pipeline system without taking into account soil quality. For example: on loamy soil it is not recommended to use pipes without a filtration system;

- violations associated with a change or absence of the angle of inclination of the drainage system;

- initially there is no option for draining water from the well;

- the technology for arranging drainage pipes is not followed - the installation was carried out without filter filling of crushed stone and sand;

- absence of geotextiles and filter material;

- poor-quality pipe soldering;

- no perforation.

When choosing the type of drainage system, you should base it on the location of the site and the quality of the soil. To independently arrange a drainage system, it is necessary to plan the drainage layout in advance. When choosing materials, preference should be given to the most practical and durable. These include plastic corrugated pipes with perforations. By following all the stages of laying the drainage system, you can obtain a high-quality drainage system. In addition, drainage guarantees protection of the basement or basement of the house from the harmful effects of groundwater.

Varieties of drainage schemes

The following options for their preparation are known:

- open (superficial);

- closed (deep).

The first type - open - is necessary for draining excess liquid that has accumulated in the ground from precipitation. This drainage system is represented by trenches and ditches.

The second is designed to remove groundwater and protect the foundation of the building from destruction. For this purpose, a drainage pipe is laid in a ditch of a specific depth. Moreover, the tubular product must be perforated.

What is drainage and why is it necessary?

The new owner of a country plot often has to work hard before he can fully enjoy his vacation in the lap of nature. Most land plots suffer from waterlogging.

Having built a house on such a site, you may encounter the problem of destruction of the foundation and difficulties in arranging a personal plot. To remove excess moisture, drainage is installed - an artificially constructed watercourse in the soil. It is a special system of underground channels or pipelines. The water that gets into them is collected in special storage tanks or discharged outside the site.

Drainage allows you to protect the foundation from destruction and create comfortable conditions for growing plants

Practice shows that the first warning signs that make you think about installing drainage are:

- a large number of moisture-loving plants on the site;

- the presence or periodic appearance of groundwater in basements and cellars of nearby buildings;

- the appearance after rain of a large number of poorly drying puddles.

However, the absence of these signs does not mean that problems with waterlogging will not arise. It is best to invite a specialist to accurately determine the level of moisture in the area and, if necessary, begin to arrange drainage.

Arrangement of a closed system

Before you begin this labor-intensive procedure, you need to prepare and purchase bulk building materials:

- Crushed stone of medium/large fraction, which is needed to obtain a stable layer that prevents dirt and bulky soil fragments from entering the system. This material also protects the corrugated pipe from the increased pressure of the earth layer.

- River sand creating a filtration cushion.

In addition to bulk substances, the following will be useful:

- Drainage pipes that form the drainage system itself. Depending on the intricacy of the project, the diameter and number of pipe products are selected. Recently, PVC products have become relevant.

- Drainage pumps providing mechanical drainage. They are used when the site has suffered serious damage due to flooding by underground runoff.

Installation instructions for perforated pipes

Before proceeding directly with installation, it is necessary to perform calculations and select the appropriate material. For design work, you will need a site layout and special data, which is best requested from your local land resources office:

- seasonal groundwater level;

- soil characteristics and soil structure;

- the volume of moisture falling in the form of precipitation and flood waters.

Using this data, specialists will carry out the necessary calculations and determine the required trench depth and pipe diameter.

The most affordable solution for arranging the system are plastic parts. An extremely simple design of a drainage pipe involves the presence of two layers of polyvinyl chloride or polyethylene, which allows them to serve for at least 50 years at a fairly significant depth.

In addition, the double-layer design promotes self-cleaning, preventing blockages. To prevent clogging of the holes in the pipe body with soil particles and small debris, they are wrapped in coconut fiber cloth or geotextile before installation.

The order of work is as follows:

- Installation of the drainage system begins with marking the territory, which is carried out according to a pre-drawn diagram. Trenches are dug along the designated lines, the depth of which is determined by preliminary calculations. To determine the width of the structure, add 40 cm to the outer diameter of the prepared parts. When carrying out work, you need to remember the required slope of the drainage pipe, which is usually at least 3°.

- A crushed stone-sand cushion is installed at the bottom of the prepared trench. To do this, first fill in a layer of sand 10 cm thick. The material is well compacted. Then a layer of crushed stone 20 cm wide is laid on top of it.

- Geotextile-wrapped pipes are laid on the prepared base. You can cut the part to the required length with a regular mounting knife. Special couplings are used to connect the elements. In order to prevent freezing of the system, it is recommended to lay drainage pipes deeper than the freezing level of the soil.

- After laying the pipes, their slope is checked again. To do this, you can use a regular cord stretched along the pipeline.

- In places where trenches turn and in areas where the angle of slope changes, special inspection wells must be installed. They are equipped with lids to prevent littering of the structure. These structures are necessary for monitoring and periodically cleaning the drainage system.

- At the last stage, backfilling is carried out, that is, all actions are performed in reverse order. A layer of crushed stone is poured over the pipe, followed by sand, and the last layer is the soil that was removed when digging the trench. You can lay turf on top.

The system is discharged into an open reservoir or rainwater drainage system. In any case, a check valve is installed at the end of the outlet pipe. If it is impossible to organize such a withdrawal, a so-called prefabricated well is installed. As it fills, it is necessary to pump out water.

Perforated drainage pipes are laid on a sand-crushed stone bed.

During installation, you should try to avoid common mistakes that lead to disruption of the functionality of the drainage. These include:

- Insufficient depth of trenches, which can lead to disruption of the water balance of the site.

- Using pipes that are not suitable for the type, which leads to rapid failure of the system.

- Incorrect drainage angle, which disrupts the functioning of the structure and can lead to serious problems with the water regime in the area.

Practice shows that laying drainage pipes with your own hands is a completely doable undertaking. The only thing that must be entrusted to specialists is calculating the system and drawing up a pipe laying diagram. Everything else is fairly simple work. When performing it, it is very important to follow the instructions, carefully monitoring key points: the slope of the system, the reliability of pipe connections, the organization of inspection wells, etc. A properly equipped drainage system will serve for many years, preventing excess moisture from damaging the foundation of the house and ruining the site.

Source: aqua-rmnt.com/kanalizaciya/drenazh/ukladka-drenazhnyx-trub-svoimi-rukami.html#i-2

Plastic drainage pipes

All polymer products that are used for the installation of drainage systems are made of polypropylene, polyvinyl chloride or polyethylene.

In addition, they are:

- One-/two-layer, the number of layers is introduced in proportion to the soil density.

- Flexible/rigid. The former have found application in complex branched schemes across the site, the latter in simple drainage projects.

- With/without filter casing. Most often, drainage pipes have a number of holes along their entire length. If they are not there, then using a drill and a thin drill, you can make holes yourself.

- Corrugated/smooth. On the building materials market you can purchase pipes with a filter coating on the surface - geofabric. If it is missing, then wrapping textiles around the perimeter of the pipe can be done independently, using the material at hand to secure it - thin wire or rope.

How to choose pipes?

The main element of the system is the pipeline. For this reason, special attention is paid to the choice of pipes or drains, as they are more often called. Experts recommend paying attention to the following technical parameters:

Material

Manufacturers offer products made from asbestos cement, polyethylene (with perforation) and polyvinyl chloride (you can do the perforation yourself). Asbestos cement is the cheapest material. However, serious doubts arise about its environmental safety. Therefore, an increasing number of buyers are choosing products made from durable plastic. Ready-made drains with perforation are sold wrapped in geofabric. Cheaper PVC pipes require additional processing - cuts are made in a checkerboard pattern up to 5 mm wide. Processing is carried out on both sides. The distance between cuts is 50 centimeters. Additionally, you will need to purchase geofabric to wrap the pipe before laying it in the ground. The fabric serves as a filter and prevents liquid dirt from clogging the perforated pipes.

Diameter

The diameter is selected depending on the amount of groundwater and precipitation. Typically this value is from 5 to 8 centimeters.

Soil type

Soil type is one of the most important parameters when choosing pipes:

- In soils with a high content of crushed stone, products with perforation are installed, but without a geofabric filter.

- In sandstones, geotextile-wrapped and perforated pipes are used. Additionally, it is recommended to make a coating of crushed stone to prevent pipeline deformation.

- Perforated products with a coconut fiber filter are installed in clay soil. A cheaper option is to use geofabric. A backfill of crushed stone must be made, covering the pipeline by 15-20 centimeters.

- For loam, perforated pipes wrapped in geotextile are used.

In any soil, you can also use ordinary PVC pipes with homemade perforations and geofabric wrapping. This will significantly reduce the cost of the drainage system.

Self-installation

Laying drainage pipes with your own hands begins with specifying the installation location.

Placement can be done in two options:

- “Wall” drainage system, which is installed around the perimeter of the foundation of a private building and protects it from moisture getting inside.

- Drainage along the perimeter of the entire local area, allowing to protect the basement of the building, all utility structures, and green spaces.

Sequence of installation work:

- Mark the area where the drainage ditches will be located. With the help of a laser rangefinder, starting actions can be significantly simplified. In this case, it is necessary to pay attention to the accumulated excess water after rain, which clearly demonstrates the difficulties of water exchange due to the increased density of the soil or existing obstacles.

Methods for arranging a drainage structure

When thinking about how to lay a drainage pipe, you need to understand that there are several ways to install drainage structures:

Trenches with crushed stone and sand. Closed drainage, which consists of grooves dug in the ground, filled with a layer of crushed stone, on top of which sand is laid. For better effect, they can be made in the shape of a “herringbone”, while the central trench, to which the secondary trenches approach, should be made with a slope directed towards the water discharge point. The distance between drains is selected depending on the composition of the soil. On clayey soils it should not exceed 10, loamy - 20 and sandy - 50 m.

Open drainage. The simplest and cheapest option. It consists of grooves, half a meter wide and about 70 cm deep, dug along the perimeter of the site. The sides in the drains are made beveled, at an angle of about 30°. Water is discharged from the system into a common drainage ditch. The main drawback of the design is its unaesthetic appearance, which somewhat spoils the landscape of the site.

Design using perforated pipeline. The most common technology for laying drainage pipes. Deep drainage designed to drain high-lying groundwater. Ceramic or asbestos-cement pipes with holes drilled in them are laid in the ground. A more modern option is perforated plastic or ready-to-install drainage systems, which can be found on sale.

Drainage trays. This is a surface drainage that allows you to remove moisture from the site that has fallen on it in the form of precipitation. To equip the structure, special trays are used, which can be made of modified concrete or plastic. Trenches are led from water intakes to the discharge point, while a slight slope of about 2-3° must be observed. The parts are installed in small grooves, their sides should be at ground level. The top of the trays must be covered with decorative grilles.

If the area is located on a hill, open drainage ditches are dug across the slope. This way it will be possible to “intercept” the water flowing from above.

Source: aqua-rmnt.com/kanalizaciya/drenazh/ukladka-drenazhnyx-trub-svoimi-rukami.html#i-2

Operation of the drainage system

When arranging a drainage system, you need to think through everything down to the smallest detail, install it efficiently, and follow the basic rules of operation. Thus, the life of the drainage system will be significantly extended.

As a preventative measure, a mandatory inspection of the technical condition of drainage and wells will be required - approximately once every 4 years. The liquid level in inspection wells should be measured every 2 years.

Even a slight deviation of this parameter from the norm indicates:

- violation of the integrity of the tubular product;

- dense blockage;

- sludge deposits on the surface of products;

- partial deformation of the pipeline due to ground movement.

Such problems can be prevented if you promptly inspect the drainage system and clean it of various debris.

Recommendations for selection

The key guideline when choosing geotextiles is the material used in its production process. The presence of natural fibers in the composition indicates the unsuitability of the product for performing insulation work in soil drainage systems. Under the influence of water, such material quickly collapses, gets clogged into filters and holes, and completely “paralyzes” the work of drainage. The most practical and durable are those made from synthetic raw materials.

An equally important factor in choosing a material is production technology. According to this parameter, geotextiles are divided into two types:

- Heat-fixed - during the manufacturing process, subjected to heating at certain temperatures. During this procedure, synthetic fibers are fused, and the finished product receives a dense, uniform structure. The strength of this material is quite high. The main area of application of thermofixed geofabric is the insulation of foundation structures of buildings. To achieve maximum drainage effect, experts recommend constructing filter layers from crushed stone of a larger fraction.

- Needle-punched - stitched with auxiliary threads. As a result of using this technology, manufacturers manage to create high-quality material, but in terms of strength it is still inferior to thermally bonded material. Geofabric made using the needle-punched method is suitable for drainage based on geocomposite mats.

Last but not least, the density of the material should be important when choosing. The ability of the fabric to retain water and strengthen the walls of the ditches depends on this parameter. Modern production technologies make it possible to create materials with different densities. It is this factor that has a predominant influence on the formation of the price of the product. Average densities range from 100-800 g/m².

Even specialists cannot clearly answer the question of choosing the most suitable fabric for insulating the drainage system. As a rule, when selecting material, they focus on a whole range of related factors. Of course, unconditional preference is always given to denser materials, the service life of which is much longer. However, its price will also be much more expensive.

But here it is important not to overdo it. For example, to install a drainage system, it is not at all necessary to purchase expensive geotextiles with a density of 800 g/m², traditionally used in the construction of runways at airfields. In a household setting, these are completely unjustified and unprofitable costs.

Cheap material with a density of 100 g/m² is also not suitable for drainage. Due to its low strength, the material will quickly collapse and the full functioning of the drainage system will be in great question. Most often, this type of geofabric is used in landscape design, where only its visual characteristics are primarily needed.

As practice shows, the most suitable material for constructing drainage systems is a fabric with a density of 200 g/m². Water passes through this material well, and small particles of debris are effectively retained. Sufficient strength ensures a long, trouble-free period of operation.

In unstable soils, where the risk of landslides is extremely high, it is better to use geofabric with a density of 300 g/m² for insulation and additional reinforcement. A material with such characteristics will provide reliable protection for any soil drainage system.

When choosing a material, ask the seller in which country it was manufactured. Today on the market you can find products of Russian, Czech, German and American origin. The final decision on the right choice will be helped by reviews from experts and customers, regularly published on thematic Internet sites.

Requirements for drainage pipes

Since the drainage main is one of the most significant elements of the system, the following requirements are imposed on drainage pipes:

- Regardless of the design and material of manufacture, drainage pipes must ensure the free passage of waste;

- have high mechanical strength;

- the inner surface of the pipes must have a minimum coefficient of friction;

- Main pipelines must have a wide range of operating temperatures.

In addition, the drainage should not sag under external influences, be it the mass of transported wastewater or soil pressure.

Possible errors when installing drainage

The quality of installation and the efficiency of the drainage system are interconnected. Any defects during operation can damage the system, which will lead to repair of the site or complete reinstallation of the drainage system. Therefore, we will add to the current topic: installation of a drainage pipe: how to lay it correctly.

The most common installation errors:

- the pipeline system was selected without taking into account soil conditions;

- the angle of inclination is changed or missing;

- at the initial stages there were no plans to drain water from wells;

- no geotextile or filter material;

- pipes are soldered in bad faith;

- the technical process for arranging the system was not followed - installation was carried out without filling sand/crushed stone;

- there is no perforation.

Knowing how to properly lay a drainage pipe, taking into account the location of the site and the condition of the soil; By preparing a laying plan and following the installation instructions step by step, you can achieve a high-quality drainage system. This means that the ground floor and basement of your building will be reliably protected from the negative effects of wastewater.

Source

Assortment of plastic drainage channels

Plastic corrugated channels are characterized by the highest level of ring rigidity. They can be equipped with a filter shell (geotextile or coconut fiber) or not. The range of outlet channels includes:

- Flexible single-layer corrugated HDPE drainage pipe with or without perforation: applicable for shallow depths, hardness class - SN4 (depth up to 3 meters) or SN2 (up to 2 m).

- Smooth on the inside and corrugated on the outside, a two-layer pipe made of HDPE or LDPE: ring stiffness SN6 (recommended depth up to 4 meters), convenient for transportation and installation.

- Corrugated flexible PVC pipe for deep installation: ring stiffness SN8 (depth up to 10 meters).

- Smooth on the inside and corrugated on the outside, a two-layer rigid HDPE pipe designed for a deep drainage system: hardness class SN8 (depth up to 8 meters), does not have a filter.

A double-layer drainage pipe is often used in systems with shallow burial depths, since its internal smoothness can ensure the most efficient drainage of water and long-term operation.

If the drainage system requires high-strength pipes, you need to purchase two-layer plastic products