Criterias of choice

Choosing a milling machine begins with an analysis of the material it will have to work with: metal or wood.

Then technological operations and the scope of work are analyzed. When choosing a spindle, pay attention to its main characteristics:

- rotation frequency;

- power;

- design;

- speed adjustment;

- method of attaching the tool;

- work performed;

- type of cooling.

It is worth paying attention to the current connected to the equipment

Power

The choice of spindle power is determined by the hardness of the material being processed. For wood and boards made from its waste - chipboard, MDF, a power of up to 3 kW is sufficient. The equipment can process plastic, plywood, and do engraving.

Non-ferrous metals and their alloys are relatively soft, but have a high viscosity coefficient. A clean cut is obtained only with a power of up to 6 kW and a rotation speed of 18,000 rpm. Machining steel and cast iron requires a spindle with a power of more than 6 kW and a rotation speed of up to 22,000 rpm. Depending on the hardness and viscosity of the material, the modes are selected by a combination of rotation speed and feed rate.

Milling method

Milling is done in a counter and reverse manner. The rotation of the tool is directed against the movement of the part or coincides with it.

There are processing modes:

- power;

- express

In the power mode, processing occurs with a large feed, at low speeds, due to the power of the spindle. The cutting edge captures a thick layer of material every time. The high-speed mode assumes the ability of the tool to rotate at high speed. The table service is small. The mode is suitable for non-ferrous metals and wood and guarantees high cleanliness of the treated surface.

Important! Cast iron can be processed well at low speeds and low feed rates. He doesn't like high speeds.

Cooling

Milling spindles have 2 types of cooling:

- air;

- water

For cooling by air flows, special slots are made in the unit body. When the shaft rotates, turbulence occurs and cold air is drawn in from outside. The water cooling system is complex in design. It must be sealed. Air-cooled spindles installed on home equipment last longer.

On industrial equipment, bearings reduce friction and heating of the spindle. Enough air flow. The gearbox is lubricated and cooled with oil. The engine has its own cooling system - an impeller on a shaft.

Workpiece material

Cutting modes and sharpening angle of the cutting edge are selected according to the characteristics of the workpiece material.

Tree

A clean cut is obtained when processing wood with a rapidly rotating tool. Feed and cutting depth are small. The spindle is suitable for high-speed, with a power of up to 1.5 kW.

Important! When processing wood in a power mode, chips and cracks between the fibers form on the part, and the surface becomes rough.

Metal

Cutting metal requires a lot of power and high strength of the unit. During machining of a part, in addition to the torque, resistance acts on the spindle. Its force is directed perpendicular to the axis of rotation.

Metal spindles have a durable, massive body, mostly cast iron. The shaft is equipped with thrust and radial bearings. The rotation speed of the tool should be adjusted between 20–18,000 rpm.

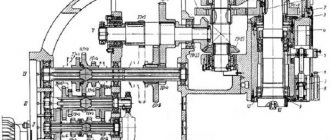

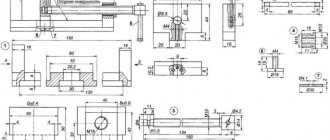

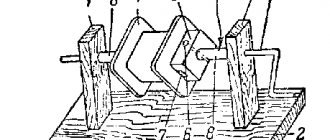

Caliper structure

Creating a CNC milling machine for metal with your own hands

The support of a lathe is a unit that ensures the fixation of the cutting tool, as well as its movement in the inclined, longitudinal and transverse directions. It is on the support that the tool holder is located, moving with it due to a manual or mechanical drive.

Support with carriage for machine Optimum D140x250

The movement of this unit is ensured by its structure, which is characteristic of all lathes.

- The longitudinal movement, for which the lead screw is responsible, is performed by the caliper carriage, while it moves along the longitudinal guides of the frame.

- Transverse movement is performed by the upper - rotating - part of the support, on which the tool holder is installed (such movement, due to which the depth of processing can be adjusted, is carried out along the transverse guides of the support itself, which are shaped like a dovetail).

Quick-change tool holder MULTIFIX cartridge type

The tool holder, also called the cutting head, is installed on the top of the support. The latter can be fixed at different angles using special nuts. Depending on the need, single or multiple tool holders can be installed on lathes. The body of a typical cutting head has a cylindrical shape, and the tool is inserted into a special side slot in it and secured with bolts. There is a protrusion on the bottom of the cutting head that fits into a corresponding slot on the support. This is the most typical tool holder mounting scheme, used primarily on machines designed to perform simple turning work.

Service

Both a homemade CNC and an industrial milling machine require proper care:

- Warming up is required before starting work. To do this, start the engine and leave it running for 10 minutes at minimum speed.

- Moving elements must be cleaned of dirt and lubricated with machine oil.

- If the equipment has a water cooling system, it is important to use a special cutting fluid.

You also need to periodically change the rotor bearings. Before turning on the equipment for the first time, it is necessary to check the fastening elements to prevent damage to the integrity of the structure during operation.

The spindle for a CNC milling machine is the main part that makes the cutter move. If you wish, you can make homemade equipment so as not to buy industrial equipment. However, to do this, you need to choose the right components, find a drawing in advance and assemble the machine without your own changes.

Classification

Technical characteristics, diagrams and operation of the 6р12 milling machine

Given the variety of milling machines and spindles, it is easier to classify them according to their technical characteristics:

- Rotary type milling spindle. Often made independently.

- Vertical rotary mechanisms.

- Equipment with two spindles.

- Mechanisms used when working with end parts.

- Vertical rotating structures for manual processing.

If we talk about using spindles at home, we can highlight engravers. They are often installed on homemade milling machines. However, these machines have a serious drawback. Due to the weak torque, the metal is processed with great difficulty. Most often, wood or plastic is processed with such equipment.

Bormashinka

Often these devices are compared to engravers. The main difference is the preservation of torque regardless of changes in speed. The drills are also equipped with a cartridge clamp and are quieter than engravers.

DC motor

A special mechanism that is equipped with CNC. It works quietly and does not create vibrations. Thanks to the presence of CNC, it becomes possible to change the power during operation. The key disadvantage of a DC motor is a poor cooling system, and as a result, rapid overheating when working with hard materials. To avoid damaging metal workpieces and damaging the engine, additional cooling is required.

DC motor

Straight grinder

Often this equipment is used as a milling spindle. It can be used to process both wood and metal. The kit does not include a device for adjusting power, which reduces the functionality of the straight grinder. It also makes loud noises when working with metal.

Sparky milling cutter

Used as a rotary milling spindle. The advantages of this equipment are high power, high productivity and the ability to regulate speed. Sparky milling cutters also have good cooling, which prevents the processed materials from overheating. Used for working with wood and metal.

Kress milling cutter

Excellent price/quality ratio. Can be equipped with CNC systems. High performance, ability to regulate speed. It is possible to work with various materials.

Professional spindle

This is a mechanism that was developed specifically for milling machines. It is equipped with water cooling, which allows you to work for a long time without the risk of damaging the workpiece. The characteristic features of this equipment are high accuracy and reliability. Quiet during operation. The main disadvantage is the high cost.

Design and technical parameters

If we are talking about the device of a milling machine, then each of them will have a spindle. This element is present in any equipment, regardless of what materials it can process. The type of material changes, first of all, the engine power.

When the spindle rotates, the cutter begins to move, with the help of which the material is processed. Its operation directly depends on the condition and characteristics of this piece of equipment. The spindle design implies the presence of guides for its movement along with the cutter. It moves along the Z axis and within the desktop. Universal models are equipped with a speed switch. This additional element allows you to work with wood, metal, plastic, and stone. On modern machines, spindles are equipped with water or air cooling.

Cooling is a mandatory element in the serial production of metal products. It is advisable to choose an air system, as it saves space. If there is no cooling, the metal cutter will overheat and damage the metal surface.

What is a spindle for a lathe?

Review of the 675 milling machine: characteristics, design

The spindle for a lathe is a shaft with a hole in the middle. Blanks for future parts are inserted into it, into the hole. It is made of high-strength steel, since it is constantly under heavy load. Now a little more detail.

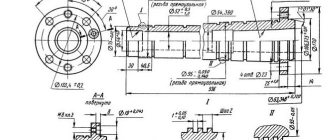

Drawing and design of the device

The design of the spindle depends on a large list of factors. For example, on what work will need to be completed, or on the speed at which the work will occur. You can also add types of machine to this list, since different types require different spindles.

Requirements for the spindle unit

In the past, the main support for this unit was the bearings on which the spindle rotates. The deviation on them reached about one micrometer. Now everything has changed: now the requirements for modern spindles have increased, and they are manufactured using either magnetic or air supports.

This allows you to achieve much better results than when using bearings: now deviations from the norm are only about two-tenths of a micrometer, which allows you to work with even the most complex parts without fear of producing defects.

However, two tenths of a micrometer is not a limit. Using a flywheel that accelerates the spindle, it is possible to reduce the error to three hundredths of a micrometer, which is much less than the previous result. True, such work must be performed after the flywheel is turned off. That is, work is performed due to inertia, with the help of which the spindle continues to move.

Here is a list of requirements that spindle units must meet:

- Accuracy. This requirement is checked based on the machine for which the spindle is needed and the application.

- Processing speed. Spindle units always rotate at different speeds (this depends on the type). To put it bluntly: the faster, the better. The speed determines the level of quality of the completed part.

- Rigidity. It's not the same with speed. That is, the lower, the better. It is calculated using the ratio of the spindle deflection and the level of radial runout. Having calculated the resulting number for two spindles, we can say which one is better.

- "Lifetime". This indicator means how long the spindle can last when performing the intended work. It depends on which bearing is used during operation. Naturally, the worse it is, the faster the spindle assembly will break.

- Vibration resistance. Naturally, during operation the machine vibrates a lot, which can lead to defects if the spindle does not meet this requirement. If the spindle assembly does not tolerate vibration well, then the level of accuracy during operation will be noticeably lower.

- Maximum heating level. This is one of the most important requirements. During operation, the spindle assembly gets very hot due to the friction force, and therefore sometimes it needs, so to speak, to “rest” from work. If it gets too hot, it may begin to change and break, so you need to choose the one that is most resistant to high temperatures.

- Maximum weight tolerated. Thanks to this requirement, it is possible to determine what weight the tools can be mounted on the spindle assembly. The size of the tool used also depends on this indicator.

Taking into account all these requirements for the spindle, you can choose the spindle unit that is best and most suitable for the job.

Purpose and principle of operation

The most important and, as a result, the main purpose of the spindle assembly is to attach a chuck to it, which in turn is intended for clamping the workpiece of the future part.

Reference! The workpiece is secured to the spindle using a special chuck, faceplate or collet clamp, which are attached to the end of the spindle.