Composite reinforcement is one of the modern materials designed to replace expensive rolled metal and provide greater resistance to the negative influence of external factors. After this type of polymer rod began to be produced in Russia in 2012, interest in it from builders began to increase every year.

The use of fiberglass materials for the reinforcement of monolithic concrete structures is especially important in cases of possible exposure to moisture, since polymers are not susceptible to corrosion.

Plastic rods are used at individual development sites, during the construction of large buildings and structures, for coastal fortifications and highways. In private construction, it is used to make reinforcing frames for strip and slab foundations, and also to reinforce masonry made of foam concrete blocks.

The material from which plastic fittings are made is a polymer mixture of longitudinal fiberglass of increased strength and thermally resistant resin. Standard diameters of produced rods range from 4 to 32 mm. Maximum operating temperature 60˚C. Tensile strength 150 MPa.

Preparation of materials for assembling the reinforcing frame

To increase the overall strength of a concrete monolith, it is reinforced with a structure made of fiberglass reinforcement in the form of a flat mesh or spatial frame, which is assembled from round rods of variable or constant cross-section. The individual elements of such structures are connected to each other using binding wire, fixing clamps or a special gun.

Therefore, to knit a reinforcing frame you need to purchase:

- plastic fittings of designed diameters;

- tie wire or tie clamps.

Unlike traditional metal rods, fiberglass reinforcement is supplied in the form of a coiled coil.

Therefore, before starting to assemble the frame, it must be unwound and cut into pieces of the required length. Cutting is done with a hacksaw or other tool that does not allow the material to heat up. Marking cut locations on the surface can be easily done using an ordinary marker.

The binding wire must be round in cross-section and have a diameter of at least 1 mm to ensure the necessary strength of the connection and not burst when twisted. To quickly obtain pieces of wire of the length required for knitting, the entire rolled coil must be cut into 3 or 4 parts with a grinder.

To make the binding wire softer, it can be burned in a flame using a blowtorch or in a fire. Unburnt wire bends worse and does not always provide a tight grip on the joint. In addition, unprepared metal has less ductility and is more likely to break during operation.

Knitting with clamps.

General knitting pattern.

Advantages and disadvantages of fiberglass reinforcement

Reinforcement frames made not from traditional metal, but from fiberglass elements, have the following advantages.

- Unlike metal ones, they are lightweight structures that do not create a significant load on the foundation of the building, which allows you to extend its service life.

- Fiberglass elements of reinforcing frames, unlike their metal counterparts, better tolerate tensile loads, which makes it possible to use them in strengthening the most critical concrete structures. Fiberglass reinforcement frames are characterized by an optimal ratio of their light weight and high strength, which allows them to be classified as a separate group of building materials that are gaining more and more popularity every year.

- Unlike metal reinforcement, which is subject to oxidation processes and over time reduces the strength of foundation structures, frames made of fiberglass elements are not influenced by such negative environmental factors.

- Parts of reinforcement systems made of fiberglass are dielectric and do not conduct electric current, which also affects their durability. Metal reinforcement structures used as grounding elements oxidize much faster under the influence of electric current, which cannot be said about rods made of composite materials. Naturally, fiberglass reinforcement cannot be used as a grounding element, but this only has the most positive effect on its durability.

- The wear resistance of fiberglass reinforcement structures, like steel ones, is also at a fairly high level.

- The coefficient of thermal expansion of a reinforcement frame made of fiberglass elements has a very similar value to that of concrete structures, which significantly reduces the risk of cracks forming in them when using such a material.

The ratio of the diameters of the rods when installing the reinforcing frame of the foundation

Judging by the reviews, we can highlight the following disadvantages of fiberglass reinforcement.

- Compared to metal products, fiberglass reinforcement has a significantly higher modulus of elasticity, approximately 4 times higher than that of steel products. This fact means that fiberglass elements, compared to metal ones, will bend much better under the influence of mechanical loads. When using these elements to reinforce the roadway and foundation, this characteristic is not critical, but to strengthen floor slabs it is better to use metal structures or make additional calculations.

- Reinforcing elements made of fiberglass tend to soften greatly and lose their elasticity when heated to a temperature of 600 degrees. Therefore, when using fiberglass parts, it is better to take care of reliable thermal insulation of the frame made from composite materials.

- Reinforcing bars made of fiberglass cannot be welded, unlike metal ones, so if there is a need for such an operation, it is better to use products in the inner part of which a steel tube is installed at the stage of their production.

- It is better not to bend reinforcement made of composite materials on the construction site: this can cause damage. This operation, based on the drawings of the reinforcement cage, is best performed at the production site.

- The complexity and unusual installation technology for modern builders is another drawback of reinforcing elements made from fiberglass. Meanwhile, such a disadvantage cannot be considered too significant, given the reliability and durability of fiberglass structures.

Fastening fiberglass reinforcement using clamps and clamps

Wire tying tool

Using pliers for knitting is not very convenient. They do not provide the required connection coverage density and require a lot of effort. Therefore, steel wire is twisted onto reinforcing bars using special hooks or a knitting gun. Tool stores offer for sale two types of hooks designed for tying reinforcement:

- simple manual ones, which must be rotated all the time during operation;

- semi-automatic screw type, with a hook that rotates when you press the handle;

- plastic fasteners in the form of rings and vertical posts that fit onto the reinforcement.

Instead of buying a simple hook, you can make it yourself (read more about how to do this here), bending it from thick steel wire and sharpening the tip. In this case, you will have something to knit a project design from rods without purchasing a tool.

Precautionary measures

Before working with fiberglass reinforcement, be sure to wear gloves. Gloves with latex or PVC coating on the palm are suitable for this; this will prevent “glass splinters” from getting under the skin. Wear safety glasses and clothing that covers all areas of the body to prevent exposure to fiberglass particles. In addition, there is a need to protect the respiratory system from dust that can be generated when cutting reinforcement. For these purposes, a respirator that fits tightly to the face is used. Coils of reinforcement are unwound vertically. Large coils are unwound with the participation of at least 2 people and exclusively on the territory where construction work is carried out.

Preparation for installation

To begin with, calculations are made. It is necessary to determine the required amount of material, as well as the place where the outer end of the rod will be located and remove the packaging, without allowing the rods to fall apart. There are two most convenient methods for unwinding coils to the required length that have been identified in practice.

The first is to remove the reinforcement rings sideways from the bay. The second is to roll out the coils with a wheel, while cutting off the required length of the rod. In this case, it is extremely important to prevent spontaneous unwinding; holding all the rings of the rod close to its other end will help with this.

Rebar cutting

The choice of cutting tool is dictated by its thickness. If the diameter of the rods is no more than 8 mm, then they can be cut with a bolt cutter or metal scissors. If the diameter is larger, in this case you can use a grinder or a hacksaw. The “grinder” will provide quick and convenient cutting, and a fairly large volume of material.

Knitting reinforcement

The reinforcement frame is knitted with a nylon clamp or special wire. They need to be tightened as tightly as possible to ensure adequate strength for the future foundation. Light weight ensures that there is no need for special tools when knitting mesh and does not require much space.

The bottom layer of the transverse bars of the reinforcement frame is connected with special fasteners for tying composite reinforcement (clamps). Often the distance between horizontal and vertical grid lines ranges from 15-35 cm, but does not exceed 60 cm.

To knit rods at the corners, you should use ready-made elements, since it cannot be bent, much less exposed to heat.

Installation of reinforcement cage

When installed at the concreting site, the frame is stretched and fixed with clamps using ties driven into the corners of the site that will be concreted.

Technology of manual wire knitting of fiberglass reinforcement

In order for the reinforcement frame or mesh to take on the required spatial shape and not change it when concrete is poured, all individual elements must be securely connected to each other. The most common way to do this is to use tie wire. Knitting is a simple and quick joining method that does not require high qualifications. In addition, fiberglass reinforcement simply cannot be connected by welding, and therefore this type of fastening is most suitable in this case.

The entire process of how to knit fiberglass reinforcement for a foundation can be divided into the following step-by-step steps:

- the reinforcement rolled into a coil is unwound and cut into pieces of the designed length;

- plastic clamps are put on the transverse rods of the lower reinforcing layer;

- longitudinal rods are laid on the spaced transverse elements at a specified distance from each other;

- at all intersections of the reinforcement, connections are made by twisting loops of knitting wire folded in half;

- after assembling the bottom row, vertical reinforcing elements are tied to the intersections of the outer cells;

- transverse sections are tied to the upper ends or to the middle of the vertical posts, depending on the design number of rows;

- the next row of longitudinal reinforcement is laid and knitted;

- the assembled frame is transferred and installed inside the formwork for the strip foundation.

The work can be greatly simplified if you combine fiberglass reinforcement with metal. You can prepare rectangular frames from steel rods in advance and then you will not need to perform separate knitting of vertical sections.

Features of using composite reinforcement

Reinforcement, which is made of composite materials, is mainly used to strengthen strip or slab foundations in low-rise construction. This is explained by the fact that this reinforcement, due to its relatively recent appearance on the domestic construction market, has not yet been studied much and has not been tested by long-term practice of its use.

Before proceeding with the installation of the reinforcement cage, it is necessary to prepare the formwork for pouring the future foundation. This procedure is carried out according to the standard scheme, as in the case of using metal reinforcement. To reinforce strip foundations of small buildings, composite rods with a diameter of 8 mm are mainly used, which corresponds to 12 mm metal products. First of all, meshes are knitted from such rods, from which a reinforcing frame is then mounted.

Fastening the reinforcing mesh using tie wire

When using rods made of composite materials, it is important to know how to knit fiberglass reinforcement so that it forms a reliable frame that effectively strengthens the concrete structure. Elements that will allow you to reliably and correctly tie such a structure can be plastic clamps or ordinary knitting wire. The choice of one option or another depends only on personal preferences and the availability of certain devices at hand.

The nuances of knitting structures for pouring a slab foundation

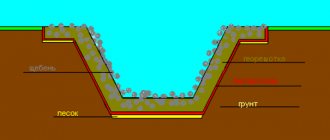

Reinforcement of monolithic slab-type support bases is carried out in the form of one or two rows of meshes, depending on the design solution. Therefore, in this design, reinforcing bars are not considered as longitudinal and transverse. To raise the lower mesh above the waterproofing layer, plastic clamps are placed on the reinforcement every one and a half to two meters. This allows you to install the reinforcement cage strictly in a horizontal plane at a given height.

An important feature of assembling reinforcement for a slab foundation is that it is produced locally. This is necessary due to the large size of the structure and the impossibility of subsequent movement. Therefore, during knitting, you must be extremely careful not to step on the laid reinforcing bars and damage the structure.

In the Swedish and Finnish insulated slab (more about it in this article), it is necessary to provide for the intersection of the slab rods with the reinforcing frame of the side support strip. To do this, the rods are cut longer, placed on vertical side reinforcement frames and tied with wire.

Machines for the production of fittings

PLPSA-20 line allows you to produce 2 bars of reinforcement simultaneously. The produced reinforcement has a constant cross-section with one or two stiffening ribs, due to which the adhesion of the reinforcement to concrete is increased.

Our production line is designed for the production of composite reinforcement with a diameter from 4 to 24 mm.

| Diameter of fiberglass reinforcement | Capacity m/min. | ||

| One stream | Two streams | Three streams | |

| ASP Ø 4 | 6,7 | 13,5 | 20,2 |

| ASP Ø 6 | 6 | 12 | 18 |

| ASP Ø 8 | 5,3 | 10,5 | 15,8 |

| ASP Ø 10 | 4,3 | 8,7 | 13 |

| ASP Ø 12 | 3,4 | 6,7 | 10,1 |

| ASP Ø 14 | 2,7 | 5,4 | 8,1 |

| ASP Ø 16 | 1,5 | 3 | 4,5 |

Requirements for the premises where equipment for the production of fiberglass reinforcement will be installed.

- Recommended room length: from 22 m;

- Recommended ceiling height in the room: from 2.5 m;

- Height difference at the technological site: no more than 50 mm;

- Ventilation: local outflow with a capacity of at least 250 l/min;

- Air temperature in the room is not lower than 16°C

Raw materials for the production of fiberglass composite reinforcement.

- glass roving

- Group of epoxy resins

- IsoMTHFA

- Reaction accelerators

Let's imagine that the production line is busy for 24 hours.

What benefits can you get from this?

DiameterCost of production 1 linear meter Average market price 1 linear meter

| ASP Ø4 | RUR 2.01 | 5-6 r. |

| ASP Ø6 | 4.1 r | 8-9 r. |

| ASP Ø8 | 7.6 RUR | 13-14 r. |

| ASP Ø10 | 11.7 RUR | 20-22 r. |

| ASP Ø12 | 17.6 RUR | 27-30 rub. |

| ASP Ø14 | 25 rub. | 39 - 44 rub. |

Let's take the average, most common diameter of the F8 fittings, with a machine productivity of 7 meters per minute, the average profit from production per day will be (13 rubles - 7.6 rubles) * 7 m/min * 60 min * 24 hours = 54432 rubles .!!!

Main characteristics of the line for the production of fiberglass reinforcement.

Electricity consumption: at start 11.25 kW, during operation from 2.8 to 5.5 kW;

Line length: 16m excluding finished product output;

Line width: 1m;

High-strength and durable fiberglass reinforcement successfully replaces rods and wire made of rolled steel, which are prone to corrosion. To be able to offer fiberglass reinforcement at competitive prices, it is necessary to optimize production costs without compromising quality. This is facilitated by the installation of a reliable and efficient line for the production of fiberglass reinforcement PLPSA-20.

The costs of installing high-quality equipment are significantly lower compared to the purchase of imported and many domestic machines, which allows you to quickly recoup investments in production equipment.

Basic line elements

A machine for the production of fiberglass reinforcement is a set of devices that perform various functions, in particular:

- creel (feeds roving threads);

- tensioning device in combination with a heating unit and an impregnation bath;

- winding mechanism;

- tunnel oven;

- water cooling unit;

- pulling device;

- automated reinforcing bar cutter;

- automated thread twisting;

- coil winder (receiving device).

Production technology of composite reinforcement

Glass roving threads are fed in a certain order from a special device (creel) to the tensioning mechanism. During the production of composite reinforcement:

- The threads are sprayed with hot air, as a result of which they dry and warm up a little.

- The heated threads are dipped into containers with an impregnation solution.

- Then the threads are pulled through a spinneret, the size of the holes of which determines the diameter of the produced reinforcement.

- At the next stage, the rods are wrapped with a roving thread; the thickness of the winding layer depends on the diameter of the manufactured reinforcement.

- The rods wrapped with roving pass through a tunnel oven - heating to high temperatures is necessary to accelerate the polymerization of the resins.

- After the furnace, the rods are cooled in running water.

- The cooled rods are cut using an automatic device into rods of a given length.

- Finished products are stored by diameter.

The production technology is quite simple, thanks to which, after installing the equipment, it is possible to quickly launch the production of composite reinforcement.

Workshop setup

The equipment is installed in any room that meets the requirements for the length and height of ceilings; it is important to provide effective forced ventilation, since the production of composite reinforcement involves the use of a tunnel oven and chemical compounds.

The equipment is a complex of components and devices that are mounted in one line. It is possible to choose a single-flow, double-flow or three-flow line; in the second and third cases, the productivity is much higher. Using a machine from you, you can start producing products that are in demand in the modern construction market.

Source: https://plastosnova.ru/dlya-proizvodstva-armatury/

The nuances of knitting fiberglass frames for strip foundations

Features of the assembly of reinforcement for strip foundations include the presence of lateral junctions, intersections and corners.

In places where the tapes meet under the internal walls, the connection of the perpendicular frame with the external one is made using bent U-shaped elements.

In the corners, the reinforcement is bent at a right angle or prepared L-shaped elements are tied. The overlap length of the connected rods must be at least 30 cm and at least 2 knits are performed in this area.

Fiberglass reinforcement should be bent very carefully, without using heat treatment. The elastic properties of plastic make the bending procedure quite difficult. Therefore, to assemble corners and junctions, it is recommended to buy prefabricated bent elements.

The intersections of fiberglass reinforcement under the strip foundation can be connected by straight sections or one of the intersecting structures can be assembled at the installation site.

Advantages of fiberglass reinforcement

This type of building material is significantly different from the usual steel and has many advantages over it:

- Resistant to corrosion. Fiberglass reinforcement is not at all afraid of alkaline and acidic environments.

- Low weight with high strength. Its weight is 10 times less than that of steel.

- Low thermal conductivity, which protects walls and foundations from freezing, which is especially important in the northern regions.

- Non-conductive current and no interference.

- Price. For the same price as steel reinforcement of small diameter, you can purchase fiberglass reinforcement of larger diameter.

- High tensile strength of the material. This figure is 3 times greater than that of steel reinforcement.

- No seams. Before transportation, metal rods are cut to the specifications of the vehicle in which they are transported. Subsequently, the reinforced mesh has many connections, which are the weakest points in the foundation and walls. Since fiberglass reinforcement is supplied in coils up to 150 m, there is no need to cut it, which leads to a minimum number of seams. Transportation can even be carried out in the trunk of a car.

- No overpayment for the amount of material. Metal reinforcement is sold in the same length of 12 m, you can’t buy less of it, and you can buy fiberglass in the amount that is needed for construction.

- There is no need to purchase additional tools when installing fiberglass reinforcement, for example, a welding machine.

- The same coefficient of expansion under thermal influence as concrete guarantees the absence of cracks in the finished structure.