Over time, the technical sphere does not stand still; on the contrary, it is constantly developing and providing its innovative developments in various fields and branches of science. Therefore, enterprises try to use the most highly productive, efficient and innovative inventions in production. A metal belt machine is one of these.

Multifunctional inventions include such a useful thing as a metal cutting machine. It is also called a mechanical saw. Many industrial organizations that work or are closely associated with metal, its processing and cutting are trying to acquire this device.

What is the machine for?

Before purchasing a metal strip cutting unit, you need to learn more about it: characteristics, purpose and types.

This device has very high power. Cuts metal, wood products, plastics. Works in both straight and figured cutting modes. Works with various sections and sizes of objects requiring detailed processing of each side.

An additional powerful unit processes objects made from the following alloys:

- steel and its alloys;

- non-ferrous metals and materials of increased hardness;

- titanium.

The main function of the band device lies on the saw, it looks like a strip made of steel with teeth.

The functional teeth are made of high-speed steel material. The movement proceeds without interruption in a given direction. Sawing is possible with the help of several supporting clamps, gradually building up pressure.

Due to the fact that the equipment is high-tech, the work is performed efficiently and quickly. The tape blade lasts for quite a long time, until the tool stops sawing due to dullness of the teeth.

Types of blades for band saws

And you definitely won’t have to replace the tool after a few months.

Machines for small and medium-sized businesses

The requirements for professional equipment are not limited only to the reliability of the mechanisms. Here, kilowatt motors and smooth adjustment of the saw feed speed (and without loss of power) are in demand.

Particular attention is paid to the weight of the equipment and the working dimensions of the saw frame. And such elements of the device as the hydraulic cylinder that controls the console stroke and the coolant supply system are implied by default.

The main feature of professional machines is that the equipment can be selected for specific tasks, be it cutting to size a profile pipe made of structural steel or sawing titanium ingots with a diameter of up to 400 mm.

Proma PPS-270THP – from RUB 390,000.

Stationary machine with control on a separate panel. The rotary stroke of the working console covers negative (from -45°) and positive (up to 60°) values of the radial scale. The saw blade feed speed is switched using a rotary switch.

Positive aspects include the presence of hydraulic unloading and the ability to turn off the hydraulic cylinder; indication of the tension force of the web on a mechanical strain gauge; double-sided coolant supply system.

Among the disadvantages: inconvenient adjustment of the coolant supply, and the bed is a rolled frame covered with sheet metal.

I recommend not neglecting the position settings of the guides - they allow you to correctly distribute the load over the surface of the saw blade.

Technical characteristics of Proma PPS-270THP

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.5 |

| Diameter of the workpiece (90°/60°/-45°), mm | 270/160/240 |

| Saw blade feed speed, m/min | 34,68 |

| Weight, kg | 360 |

Video review of Proma PPS-270THP:

LP-160 – from 75,000 rub.

Band saw machine on a stand made of rolled steel, with a coolant reservoir. The equipment is suitable for daily use, with mandatory cleaning at the end of work. Repairable, does not require special maintenance.

One of the advantages is smooth adjustment of the saw blade feed speed; hydraulic and manual method of lowering the working console; reinforced saw unit shaft bearings; limit switch.

One of the disadvantages is that coolant supply is implemented only on the outlet guide. There are no protective measures in the cutting area and at the entry of the saw blade into the console. Therefore, chips will fall under the casing.

I believe that independently modifying the line for two coolant nozzles and installing a holder for a small cord brush on the receiving guide will not take much time, but will increase the service life of the saw blade

Technical characteristics of the LP-160

| Characteristic | Meaning |

| Network / power consumption, V/kW | 220/750 |

| Diameter of the workpiece (90°), mm | 160 |

| Saw blade feed speed, m/min | 65-90 |

| Weight, kg | 250 |

Video review of LP-160:

Metal Master BSG 220 – from RUB 135,995.

Stationary model on a frame made of cast iron elements. The gear housing, saw frame and vice are also made of cast iron. This allows you to work with massive workpieces without noticeable vibrations.

The machine is convenient in that the controls are located on a separate panel; a strain gauge is provided to control the belt tension; The cutting angle is set by turning the working console; its lock is located at the end of the bed; The coolant supply system has 2 nozzles with independent flow control.

Of the minuses, coolant is supplied directly to the cutting zone by a separate jet from the first nozzle, and the top of the bed is not wide enough (at maximum pressure, splashing is possible).

Please note that the machine “out of the box” requires precise adjustment.

And if during the check the motor does not turn off when the frame is completely lowered, most likely the position of the element that presses the limit switch is off. Technical characteristics of Metal Master BSG 220

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.1 |

| Diameter of the workpiece (90°/60°/-45°), mm | 225/90/155 |

| Saw blade feed speed, m/min | 40, 80 |

| Weight, kg | 185 |

Video review of Metal Master BSG 220:

PILOUS ARG 220 Plus – from RUB 241,199.

Stationary manual equipment with a pendulum stroke of the saw unit and hydraulic unloading. Drive – power electric motor-gearbox with worm gear, rotary table. It is possible to complete the machine with additional equipment. equipment (there are 19 items in the catalogue), for specific working conditions.

Available: cutting angle -45...+60, integrated coolant supply circuit, system that turns off the drive when the saw frame is completely lowered or the blade breaks, measuring stop.

The disadvantages of a machine with production potential should be the absence of a cord brush and adjustment of the saw blade tension without a control device.

Please note - due to the internal carbide plates of the guide units, only 27mm wide belts work stably.

Wider or re-sharpened blades with altered tooth alignment do not bring the expected effect. Technical characteristics of PILOUS ARG 220 Plus

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.0 |

| Diameter of the workpiece (90°/60°/-45°), mm | 200/105/150 |

| Saw blade feed speed, m/min | 40, 80 |

| Weight, kg | 250 |

Review of PILOUS ARG 220 Plus:

STALEX BS-315G – from RUB 317,537.

Band saw machine with gear motor and metal stand, for piece or batch processing of solid and profile metal workpieces in all its forms.

Available: adjustment of the cutting angle on a scale with gradations of 1°, switching the saw feed speed with one turn of the switch; control of the pendulum stroke of the saw console using a hydraulic cylinder with a bypass valve.

The frame design of the bed does not allow one to rely on the stability of the equipment during the processing of large-sized workpieces, even if additional supports and roller tables are used.

Due to the fact that the potential of the machine is many times greater than the capabilities limited by the weak support stand, the best solution would be to replace the base.

But due to the internal placement of the elements of the coolant supply system and the communications of the control system, it would be more expedient to simply strengthen the existing structure and ensure its reliable fixation to the floor. Technical characteristics of STALEX BS-315G

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.1 |

| Diameter of the workpiece (90°/60°/-45°), mm | 230/130/210 |

| Saw blade feed speed, m/min | 40,80 |

| Weight, kg | 350 |

Video review of STALEX BS-315G:

JET EHB 270DGSVIP – from RUB 530,000.

Semi-automatic machine for the needs of mass production, requiring processing accuracy of 0.1 mm. Changing the position of the saw unit is done manually; other manipulations can be carried out using the hydraulic system.

Loaded structural elements – cast iron; control of operating functions and coolant supply is located on the front panel; the result of adjusting the speed of the saw is reflected on the digital display; The limit switch can be adjusted to any position of the console.

There are no obvious shortcomings, the high price is a very controversial disadvantage (the more often the machine is used, the faster it will pay for itself).

In my opinion, Jet has no competitors within the existing range of professional bandsaw machines.

Technical characteristics of JET EHB 270 DGSVIP

| Characteristic | Meaning |

| Network / power consumption, V/kW | 380/1.5 |

| Diameter of the workpiece (90°/60°/-45°), mm | 270/140/240 |

| Saw blade feed speed, m/min | 20-85 |

| Weight, kg | 530 |

Video review of STALEX JET EHB 270 DGSVIP:

Features of the Band Cutting Machine

Due to its characteristics and efficiency, a metal cutting belt cutting machine is simply necessary for enterprises specializing in the metalworking of large parts and shaped products.

The device has wheels surrounded by a rim. They allow other elements of the machine to move. Wheels are one of the main transmission elements; they are called pulleys.

The circular motion of the pulley occurs due to the operation of an electric motor. It is additionally responsible for the efficiency and accuracy of the metal band saw.

When choosing and purchasing a tool, you need to look at the characteristics and parameters of the electric motor, its power and the country that produces its parts.

Engine characteristics

The main advantages of a metal cutting machine should be highlighted:

- durability;

- made from high-quality and durable materials;

- simple and safe use;

- refers to high-tech equipment.

When the saw moves, there is a strong pressure from it on the object. It goes towards the workpiece being processed, with which contact occurs. This device has a lot of advantages.

Among all the equipment, even the small and therefore convenient size wins. Therefore, if necessary, it is easy to work in a narrow space without problems. If you plan to use the tool in everyday life, you should safely take models made for workshops. They look smaller than regular saws, but their mass is small.

This is quite convenient, since it does not require the use of special equipment for transportation and subsequent installation of such a machine. When the belt with the canvas moves, the work occurs quietly, these elements are built in taking into account the current vibrations. This factor is the main advantage of the equipment.

Design features of band machines

Band saws come in several types. They differ in design, location of the cutting part, and the presence of additional functions.

Band saw machine design

Console type units

The second name is pendulum equipment. The working part (frame) is fixed on a special hinge. It is used to move the console up and down. Outwardly, they resemble large miter saws. They are used in enterprises for cutting metal pipes, channels, and profiles. Can be equipped with a movable work table. On some models of console saws, an adjustment mechanism is installed. It is used to change the position of the cutting blade relative to the workpiece being processed.

Gantry equipment machines with one or two racks

Two-post and gantry machines are structures with two guides, which are located on both sides of the workbench. Single-column machines are equipped with one rack, a horizontal frame, which moves along guides. The saw frame is located on a movable portal.

Horizontal machines

They consist of a saw frame and two holding axles. The working part of the machine with the cutting blade is attached to them. It is possible to change the position of the desktop.

Vertical machines

Vertical band saws are easy to maintain. They are common and have affordable prices. They can be compact, industrial.

An installation in which a saw blade is mounted vertically on the work table. In most cases, its position does not change. Workpieces must be fed manually, which reduces the accuracy of the cuts. Most often, such band saws are used for cutting strains, molds, and sawing wood.

Vertical Band Saw Machine

Unit operation

A metal band cutting machine has its own operating principles and individual structure.

Structure of a band cutting machine

Despite the fact that there are many species, they all have common features. The characteristics are indicated in the technical documentation of the unit and are subject to careful study before purchase.

The machine consists of the following structures:

- main body;

- saw unit;

- electromechanical and hydraulic equipment;

- block for supplying objects;

- drive mechanisms.

The capabilities of the machine are great, because the belt is tensioned on the flywheels, the design smooths out all the sharp corners. The unit operates in the drive mechanism, and the activity is performed as follows:

- first the machine must be turned on;

- the belt automatically starts moving;

- The object is being prepared and the cutting process is taking place.

The cuts are accurate, this happens with the help of uniform pressure during operation.

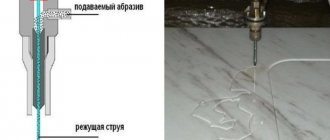

Specialists can also operate the device at an angle. In such a position, a metal cutting belt cutting machine will make processing easier. To prevent overheating, you need to use a liquid that will perform two functions at once: lubrication and cooling.

To perform this procedure, you must use ordinary water or a special liquid. It must be applied to the blade for washing to occur. This not only cleans the device, but also helps protect against failure or breakdown.

The equipment is cleaned with brushes provided by the manufacturer. They eliminate small particles, dust, debris, wood or small metal shavings. Thanks to this, the work is carried out smoothly.

Band saw metal cutting capabilities

The band saw method can be used to cut both thin-walled rolled products (pipe, channel, angle, beam, I-beam) and blanks with a solid cross-section - hexagons, circles and squares. The requirements for long and shaped steel that is subjected to such cutting are not strict.

The maximum diameter of the workpiece at which band saw cutting of metal is permissible varies depending on the type of device and for some machines can reach up to 1600 millimeters.

Cutting on a band saw surprises not only with its capabilities, but also with the variety of equipment. The operation can be performed:

- on console machines,

- single-column,

- two-post,

- portal.

Machines can be vertical or horizontal, and depending on human participation in the cutting process - manual, automatic or semi-automatic.

Despite its simplicity, band saw cutting allows you to achieve very high-quality results. A product with increased geometric accuracy and a smooth surface comes off the machine.

The cutting width is usually no more than one and a half millimeters, which means production waste is kept to a minimum. Metal cutting with a band saw can be carried out not only at a straight angle, but also at an acute angle: up to 60 degrees.

| Number of cuts | Diameter of long and pipe metal products | Price of one cut RUR/mm | |

| Regular metal | Ultra-strong alloys (titanium, armor, etc.) | ||

| up to 10 cuts | 10-50 | 1,6 | from 37.0 |

| from 10 cuts | 1,5 | from 36.0 | |

| up to 10 cuts | 52-100 | 1,8 | from 94.0 |

| from 10 cuts | 1,6 | from 80.0 | |

| up to 10 cuts | 105-150 | 2,6 | from 180.0 |

| from 10 cuts | 2,2 | from 171.0 | |

| up to 10 cuts | 155-200 | 3,1 | from 395.0 |

| from 10 cuts | 2,6 | from 390.0 | |

| up to 10 cuts | 205-250 | 4,2 | from 620.0 |

| from 10 cuts | 3,1 | from 600.0 | |

| up to 10 cuts | 255-300 | 4,7 | from 1265.0 |

| from 10 cuts | 3,3 | from 1200.0 | |

| up to 10 cuts | 305-350 | 6,5 | from 2340.0 |

| from 10 cuts | 4,8 | from 2250.0 | |

| up to 10 cuts | 355-400 | 7,8 | from 2475.0 |

| from 10 cuts | 6,9 | from 2400.0 | |

| up to 10 cuts | 405-450 | 9,0 | from 4050.0 |

| from 10 cuts | 7,1 | from 3950.0 | |

| up to 10 cuts | 455-500 | 10,0 | from 4780.0 |

| from 10 cuts | 7,9 | from 4600.0 | |

| up to 10 cuts | 505-700 | 11,0 | from 5790.0 |

| from 10 cuts | 10,0 | from 5610.0 | |

| up to 10 cuts | 700-900 | — | from 12300.0 |

| from 10 cuts | — | from 12100.0 | |

| up to 10 cuts | 1000-1100 | — | from 26200.0 |

| from 10 cuts | — | from 26000.0 | |

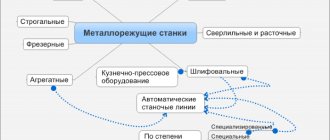

Varieties

Band cutting machines for metal come in different models and types, as well as the purpose of the unit in the production process.

A popular type of equipment for this type of equipment is the carbon band saw. This device is designed to work with unalloyed and alloyed steel.

Another type is bimetallic, its purpose is to cut heavy and hard objects.

Bimetal band saw

The carbide saw is designed for difficult-to-cut metals. These can be cast iron and titanium products. Diamond saws are used for abrasive materials.

Saws are also classified into groups. Pendulum or cantilever can move up and in the opposite direction, as well as make circular movements. Such devices are indispensable for all kinds of pipes. They also have a different control system.

A column or single-post saw has a horizontal position and moves along a vertical post. Two-post or two-column units move along two vertical posts, they are located on the sides.

If you need to work at an angle, use a rotating table. There may be a stationary table, but the saw itself is in constant motion. These machines can have a permanent or maneuverable mode, auto or semi-automatic mode, depending on the functions they perform.

In some industries, specialized machines are found: with vertical manual stands, with a tilting frame, with a movable frame, with movement along and across the table, with a variable tilt.

General terms

For proper operation of any band saw you need:

- organize the supply of lubricating and cooling fluid (coolant) to the cutting area;

- prevent chips from getting inside the saw unit;

- evenly distribute the load on the working section of the web.

Violation of any point will lead to breakage of the canvas. If the required conditions are met, the operator is freed from manipulations associated with excessive physical exertion - in most cases, before starting work it is sufficient:

- pour coolant into the container provided for this purpose and open the supply (if there is no tank and line, supply it manually);

- control the position and condition of the cord brush, which removes technical dirt from the blade after cutting, before entering the cavity of the saw unit;

- do not overtighten the canvas and adjust the hydraulic unloading correctly (or do not put too much pressure on the spring-loaded console).

Main characteristics of metal bandsaw machines

| Criterion | Meaning | Peculiarity |

| Machine configuration | Vertical | Compact; options with a movable table are controlled manually, the saw unit of the model with hydraulic unloading moves onto the workpiece under its own weight; It’s inconvenient to change the canvas. |

| With pendulum console | Easy to maintain, cuts individually and in batches, most machines are equipped with a coolant supply system. | |

| With guide posts | Industrial equipment. Massive construction; Maintenance requires the use of lifting equipment. The movement of the saw frame of a 1- or 2-post machine is possible only in one plane, which determines the exceptional cutting accuracy. | |

| Permissible dimensions of the workpiece, mm | Up to 120 | Machine for home workshop. |

| Up to 400 | A machine for a small and medium-sized business processing shop. | |

| Over 400 | Industrial equipment. | |

| Saw blade rotation speed*, m/min | Up to 50 | At low speeds, standard saws process stainless steel, heat-resistant steel, and titanium alloys. |

| Over 50 | To process structural steel, aluminum, and copper alloys, a high blade feed speed is required. | |

| Saw feed speed adjustment unit | Mechanical block (shafts – belt). | Strictly specified positions (calculated ratio of pulley diameters). If I have to cut alloy or tool steel, I choose a position of up to 50 m/min; if the table is bronze or steel for cold stamping - over 50 m/min. |

| Electronic unit (frequency converter). | The larger the range of values, the more impressive the list of processed metal. The machine, with an adjustment from 16 to 120, will correctly cut both copper alloy and nickel steels. | |

| Method for adjusting cutting speed | Screw feed vice. | The workpiece, clamped in a vice, is fed to the saw blade. If you need an exact depth of cut, then this is the fastest and most convenient feeding option. |

| Spring (manually controlled machine). | The adjustable spring is convenient because it eliminates the need for the operator to constantly maintain the frame in the desired position. It is enough to lightly press the saw against the workpiece. | |

| Hydraulic unloading | The most convenient system for long-term work - a hydraulic piston lowers the saw frame at a given speed. | |

| Coolant supply line | Present | Forced (the cooling system has its own pump) supply of coolant to the cutting zone. |

| Absent | You will have to pick up an oil can with a supercharger and supply coolant to the saw yourself. | |

| Weight, kg | Up to 40 | Tabletop machines with flat base. |

| 40-100 | Models with a pair of transport wheels for comfortable movement of the machine around the garage or construction site | |

| From 100 | Stationary equipment with high processing accuracy. The greater the weight of the machine, the stronger the floor should be (down to the local foundation). |

*The dependence of the cutting speed on the characteristics of the metal being processed is very conditional.

To accurately determine the possibility of working with any material, it is necessary to take into account the lowering speed of the saw unit, the technical characteristics of the band saw, and the properties of the material being processed. However, ignoring speed = ruining the workpiece and blade. Model summary table

| Model | Peculiarity | For what purpose |

| Industrial machines | ||

| 1. LPS 8535 | A simple and maintainable machine made from domestic components and parts. At the request of the customer, it can be assembled using imported components. There are manual and automatic modes. | For sawing ferrous and non-ferrous rolled steel, alloy and stainless steel, cast iron. The unit is capable of working in 2 shifts, in temperate and cold climates. |

| 2.Fmb OLIMPUS 3+VHZ | Semi-automatic, two-column machine; requires specialized maintenance; installation requires its own pedestal on a monolithic foundation. | Suitable for batch sawing of rolled products and long-term processing of large-sized workpieces made of steel of all grades; work with aluminum-bronze and titanium alloys is possible. |

| Entry-class equipment | ||

| 3. Encore Corvette 422 | Movable console with adjustable spring; rotary vice; collapsible frame-stand; transport wheels; coolant supply is not provided. | For one-time work in a small amateur workshop. |

| 4. Blacksmith S13.11 | The thin-walled stand ensures low weight; common saw blade size; power button on the handle, without fixation; convenient speed adjustment; rotary support of the working console; no coolant supply. | For cutting workpieces from different materials in extremely limited space (balcony, stall, etc.) |

| 5. TRIOD BSM-115/230 | It is possible to work with the saw unit in a vertical position; Belting; worm gearbox of the drive shaft. Manual sawing speed control, Without coolant. | For cost-effective cutting of materials in rooms with an area of 5 m2. |

| Machines for small and medium-sized businesses | ||

| 6. Proma PPS-270THP | Stationary; The rotating saw unit allows cutting at any angle up to 60°. The adjustable hydraulic cylinder and return spring are responsible for the speed of lowering the console. | Suitable for the production of metal structures to order, when frequent changes in the processing angle are expected. |

| 7. LP-160 | Stationary; manual or hydraulic control of the speed of the console is possible; a coolant collection zone is structurally provided. | The best option for long-term sawing of workpieces to size. |

| 8. Metal Master BSG | Mobile; there are no backlashes in critical components; it is possible to work both with diagonal lowering and in a vertical position of the saw unit; the working console lowers under its own weight, with insignificant spring resistance; The saw angle is adjusted by turning the table with a vice. | Meets the needs of a repair shop for machining structural and tool steel parts. |

| 9. PILOUS ARG 220 Plus | Stationary; controls on one panel; independent adjustment of coolant supply, console lowering speed is controlled by hydraulics. | Suitable for long-term work with high-alloy and automatic steels, bronze and copper alloys. |

| 10. STALEX BS-315G | Stationary; a solid table allows you to process small parts; the console rotates in a range of 105°. | For precision machining of structural steels for the needs of small-scale production. |

| 11. JET EHB-270DGSVIP | The body, table, pulleys of the saw unit are made of cast iron; all controls are on the remote control; belt rotation speed – with visualization on the display; console rotation accurate to 1°; control of web tension with a tensiometer. | Meets the needs of continuous production, when not only speed is important, but also processing accuracy up to 0.1 mm. |

Saws are divided into types and automation

Metal cutting machines are divided into certain automation classes.

they are:

- gravity or manual;

- automatic and semi-automatic.

In manual cantilever units, the frame is lowered due to human work, and in gravity units, due to the mass of the frame. With this operating mechanism, the feed speed is regulated by a special cylinder with a valve. This type of work is called hydraulic loading; it is used when you need to fix the frame at one point.

When working, the master independently installs and secures the object in a vice for cutting. The speed can be set manually or from the remote control.

But manual frames have a number of advantages over other types:

- bevel cutting;

- cheap repairs;

- loyal price.

The pricing policy allows you to purchase this product without large capital expenditures

The hand saw also has disadvantages:

- Vibration during cutting, which reduces the life of the device.

- It is difficult to control tension and clean, so the pulleys need to be adjusted periodically.

- It is difficult to control the pressure on the object.

A hand-held metal band saw is used in small companies for tools and stainless steel, as well as for profiles. In semi-automatic frames it moves up and down, the vice is clamped and unclenched mechanically through a drive, the object is installed manually.

Setting up the band saw

It is clear that machines of different levels have different setup requirements. However, there are conditions that are common to all devices. In order for the equipment to work flawlessly, it is necessary to periodically lubricate the moving parts of the mechanism. A special paste is used for fittings, and machine oil is used for other components. When cutting with a band saw, it is important to monitor the condition of the bearings: to check whether they have moved away from the plane of the band blade. The older the equipment, the more attention must be paid to the functioning of the drive. If it is worn out, this will inevitably affect the evenness of the cut.

Features of units on the market

Popular models are semi-automatic, they are suitable for small organizations. They can be used to work from different angles. This manipulation simplifies working with shaped parts.

As soon as the machine is turned on, the object is clamped and cutting occurs. Pressure occurs using a frame and a hydraulic cylinder. Therefore, even stainless steel materials are sawn.

But in large enterprises and in industry, automatic belt machines are often used.

Automatic banding machine Alligator-500A

They are indispensable if you need to cut a whole series of different workpieces. Manipulation saves both the time and effort of the craftsmen. Because a person is only required to configure certain parameters and set the workpiece for cutting. After this, the entire process proceeds automatically, the force at each stage is set individually.

To avoid unforeseen situations related to the saw, the technician needs to slow down or stop feeding the frame while the pressure is increasing.

Automatic devices are better than their mechanical predecessors and are more efficient in operation. They cope with any task and can make any corner cuts, work in three modes, and cut long parts without a master.

Belt Cutting Parameters

What are the main advantages of cutting on metal cutting machines? First, we should consider the parameters of such equipment.

Machine parameters

Main characteristics:

- rotation degree of table angle, clamps and frame;

- blade speed;

- its size;

- pulley size;

- number of stages of supplying items in automatic mode;

- large pitch of the item in auto mode;

- specifications;

- parameters in the package;

- weight.

What shapes of objects can be in the maximum value of the blank (the size of the solid blank is 90, 45, 60 degrees):

- circles;

- rectangles;

- squares.

Square shape of metal product

Electrical equipment power:

- saw drive;

- engine for cleaning;

- hydraulic unit drive;

- chip conveyor motor;

- pump;

- general.

Types of Band Saw Teeth

The band saw blade is equipped with teeth ranging from 1 to 32 per linear inch. If the choice of band blade requires a variable tooth pitch, then their number is in the range from 0.75/1.25 to 10/14 per inch. The number of teeth that stays in the cutting zone at the same time depends on the density of the teeth. Optimal - 3-5.

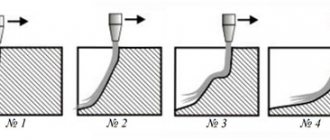

The teeth of the cutting edge are not located straight, but are deviated to the sides from the plane of the main belt. The type of this deviation is called saw setting. The teeth are alternately inclined to the right and left sides, which provides a wider cutting line than the thickness of the blade and prevents it from getting stuck in the material. There are three types of wiring most commonly used:

- right, straight tooth and left;

- right and left alternately;

- wavy setting with variable tooth angle.

Layout form

The first type is used when cutting packages of solid billets, pipes, and rolled profiles. Wave-shaped - for pipes, especially thin-walled ones, rolled products of small sizes with small wall thickness. The standard right/left is almost universal, but works best when cutting soft materials - copper, aluminum, non-ferrous alloys and plastic.

Machine in operation - advantages of processing

A metal cutting machine is used to produce parts for transport and mechanics. It is used for processing elements in the manufacture of vehicles and machines. But even with all its simplicity, the unit has its own nuances - large allowances. All this is due to the low accuracy of preparation.

There are several cutting methods:

- using circular saws;

- using incisors;

- hacksaw blades;

- diamond wheels;

- band saws.

It is easier to work on a band saw, since the master is able to complete the cutting faster and with greater accuracy, and the cut is smooth. Material is saved, specialists can work at an angle, and also cut various difficult-to-cut objects.