The use of reinforcing mesh based on fiberglass load-bearing elements began in the 60s of the last century. In addition, a fairly large number of buildings and technological structures made of stone and concrete have been built and are in operation, in the foundations and walls of which fiberglass-based reinforcement is used. Feedback on the condition of buildings with elements of steel and fiberglass reinforcement and many years of operating experience will give more than all the theoretical calculations of “experts” combined.

Almost everyone who makes videos or posts their opinion about the shortcomings of fiberglass reinforcement is either sales managers of competing steel products, or amateurs who confuse the causes and consequences of the basic principles of strength and rigidity of structures. For the most part, such discussions about the disadvantages of fiberglass reinforcement are accompanied by formulas and data on the strength of steel and composites. But there are no clear reasons or processes why fiberglass reinforcement cannot be used. If a person who undertakes to comment on the advantages and disadvantages of fiberglass reinforcement has not demonstrated in practice a fragment of destroyed concrete or a piece of foundation with fiberglass reinforcement, all his reasoning remains fantasies on an arbitrary topic.

Fiberglass reinforcement has been used in construction, mechanical engineering, and special projects for more than 40 years. If this issue is of fundamental importance to you, refer to old Soviet textbooks from the 70s of the last century, magazines on construction topics; these sources reveal the physics and mechanics of foundation destruction processes and provide numerous examples of errors.

Possessing high specific strength, fiberglass reinforcement can work perfectly in the most difficult conditions, but at the same time it has a number of disadvantages that limit its use in construction:

- The fiberglass nature of composite reinforcement has almost zero ductility of the material. In human terms, a frame for a highly loaded foundation or walls made of such a rod will not be able to plastically adapt to the redistribution of load in a loaded concrete stone. As a result, in some places the building’s foundation will experience overload, which can cause cracks to appear;

- The fiberglass base takes tensile axial loads very well, but compressive loads much worse, and tolerates shear forces catastrophically poorly. This means that any transverse shearing force, of which there are many in “fresh” foundations due to sedimentary processes, will lead to destruction of the integrity of the reinforcement;

- Unfortunately, during the time that the concrete of the foundation gains strength, the fiberglass frame behaves somewhat differently, and precisely at this stage, therefore, each specific case in the arrangement of reinforcement requires a very careful and careful analysis.

Therefore, in those units where it is permissible to replace metal with a composite material, instead of a traditional eight-millimeter rod, a six-millimeter fiberglass reinforcement strand can be used. Few people know, but today building slabs from stressed concrete with fiberglass reinforcement are already being produced. But in production such material is much more expensive, so almost 90% of the range, including for foundations, are custom-made products.

Reviews from developers from forums

Flooded the basement. GWL is high. Additive to betok against leaks. Fiberglass reinforcement with two layers of grating. The floor slab is the same. 3/4 meter. Everything is fine. Now the car is on top. Knitted. Knitting wire using a screwdriver. Concrete from a household concrete mixer. KolotunAga, forumhouse.ru

I poured a foundation with plastic reinforcement for a summer house 9.5 by 6 meters. I poured in the spring 30 cm thick concrete height a meter and knitted the reinforcement in four rows, two pieces per row.

so far everything is fine, what will happen next x.z.))) 8mm plastic reinforcement replaces 12mm metal. and 10 times lighter than metal. Our price is 10 rubles cheaper per meter. ANDREY098, forums.drom.ru

An excellent material if used correctly, of course, fiberglass is not a replacement for iron reinforcement. There are structures where its use is more appropriate, for example, floors on the ground, mzlf foundations for small lightweight structures, platforms for cars, any unloaded structures

toropiga, forumhouse. ru

My house is on a slight slope of about 7 to 9 degrees.

The house has two floors, 9.5 x 8.5 + 4.5 x 7.5 garage, all connected by one strip shallow foundation into which composite reinforcement 10 mm is laid. It has been standing since 2013, made of aerated concrete, ceiling made of: wooden beams, roof: metal tiles, foundation depth on the high side is 1.8 m, on the low side - 0.6 m. Today there are no cracks anywhere. Warm, dry and good. forum.yourdom.ru

Reviews from experts, advantages and disadvantages of composite thread

If you wish, you can find the most complex calculations and quite simple primitive arguments about why glass and plastic fittings are good or bad. As a rule, serious research and reviews from specialists in most cases do not give specific recommendations, in fact, the “hot” problem of the foundation; in many ways, the possibilities of glass-plastic-based reinforcement must be assessed at your own peril and risk.

Among the numerous reviews of specialists, there are practically no real professional experts in the field of structural mechanics of composite materials. Their opinions and reviews, as a rule, are reflected in estimates and custom calculations for specific construction projects, cost a lot of money and are not presented to the public.

An approach can be called professional if reviews from certain experts evaluate a specific situation of use, for example, a glass plastic rod in the foundation of a house, using practical results and analyzing the reasons. Otherwise, such expert reviews can be called, at best, advertising or anti-advertising.

Reviews disadvantages

I would say that all the advantages of composite reinforcement are best realized when it is used to reinforce foundations, floor screeds and similar structures lying on an elastic foundation. But the use of composite reinforcement in floors requires serious calculations; here it cannot be used “by eye” according to equal-strength replacement tables. forum.derev-grad.ru

Composite reinforcement has been used since the 70s of the last century. Nowadays, it is gaining popularity in low-rise construction (read personal construction). In terms of its properties, it really differs from iron quite well. Certification for use in low-rise construction was successful, they can be used safely. Now for the pros and cons. Pros: this is, of course, the price of the reinforcement itself, plus the price for delivery, it is much lighter than iron, which simplifies installation, it does not rot or rust, it is resistant to the aggressive environment of concrete, there is a whole list of why it is better, but these are already deeply technical details. Now the disadvantages: it is really not recommended to use it in vertical structures, for example in piles and columns, this is due to the fact that its compression coefficient is much lower than that of iron, well, I think it’s obvious to everyone why this is so))) Everything else is fairy tales from manufacturers and sellers of iron fittings. A lot of houses have already been built, none of them have fallen apart yet, I personally have been in a house that has stood for almost 10 years. UnDiE, chevy-clan.ru

Why did fiberglass reinforcement appear on the construction market?

Composite materials, including fiberglass reinforcement, are manufactured using a relatively simple technological principle of impregnating glass or basalt fibers with an epoxy or polyester matrix resin. Next, the bundle is formed on a machine into a rod of composite reinforcement calibrated in diameter, and baked at a low temperature in a special drying oven. Typically, the length of one piece of reinforcement does not exceed 100 m.

Fiberglass reinforcement does not require the operation of complex and expensive equipment, so the production costs themselves are relatively low, most of the cost is the price of the resin for the matrix and the fiberglass tow. And yet, if you compare the cost of fiberglass and steel rods of the same diameter, metal reinforcement has a warehouse price that is 10-20% less, and this is a very big difference for such an area as construction.

Nevertheless, fiberglass material has quite strongly replaced rolled metal products, not least because of a number of specific properties, but the main factors were slightly different reasons:

- Fiberglass reinforcement has increasingly begun to be used in private low-rise construction. It is more accessible to use, it is easier and much cheaper to transport, store, and cut. It does not need to be straightened and leveled before use, as is the case with the steel version. The material can be bought in a whole bay and cut into pieces of the most non-standard length. Whereas a standard 11-meter steel rod would require a lot of waste if your foundation, for example, has reinforcement 8 m long;

- The availability of equipment for the production of reinforcing strands has allowed many small enterprises - manufacturers of building materials - to establish in-line production of fiberglass reinforcement in a wide variety of rod surface designs. A huge number of offers, a competent sales policy and hidden advertising allow you to diversify the market;

- The desire of contractors to save money in construction work by using a more profitable material for reinforcement, for which a formal, “blind” recalculation of the strength equivalent of composite materials and steel reinforcement is often used.

Which reinforcement is better for a foundation: composite or metal?

I believe that fiberglass reinforcement is much better than steel rod.

I think it's an excellent frame material. Of course, there is a drawback - the inability to bend the composite at an angle of 90 degrees. In such areas of the foundation you have to cut it and knit it. remontiks.com We made a foundation for a fence, it’s been standing rooted to the spot for three years now :), we actually knitted it with wire, so I think it’s quite suitable for the foundation of a house. PS Metrostroy switched from steel reinforcement to fiberglass quite a long time ago. Tikhonov Sergey, otvet.mail.ru

Composite reinforcement is often criticized by those who have never used it. Based on my own experience, I recommend using it for the foundations of light, small buildings. It is not afraid of dampness, does not rust, and is easy to cut and install. When laying concrete, you don’t have to worry about correct pouring and forming a concrete pad remontiks.com

Application options for glass reinforcement

An undeniable advantage of steel reinforcement is the very well predictable behavior of the metal under the most difficult loading conditions. All existing skyscrapers and high-rise buildings are built only on steel reinforcement; moreover, most of these “wonders of the world” have an internal metal frame.

Glass reinforcement is not suitable for high-rise buildings or heavily loaded foundations. The structural mechanics of foundations is, in general, a whole science, primarily due to the complex interaction of individual parts of the foundation with the soil, with the walls of the entire structure.

In the existing foundation model, the most problematic areas are the corner zones, where the reinforcement experiences tensile, bending and shear loads. In these places, not every steel reinforcement is able to provide a rigid connection of corner blocks. The metal reinforcement in the foundation block achieves this only due to a combination of high ductility and elasticity. Fiberglass reinforcement cannot be used in these foundation units. Despite its high longitudinal strength, it will not be able to withstand twisting and cutting at the corner contact point of the foundation.

The strength and ductility of fiberglass reinforcement will be sufficient to build the foundation and basement of a one or two-story house. But provided that in the corner joints of the foundation, special couplings will be used to splice the reinforcement at right angles. Moreover, fiberglass is easy and simple to use for a simple strip foundation 70-90 cm deep.

The use of fiberglass reinforcement in combination with special grades of concrete for the foundation is considered successful. Often, when special additives are used in the foundation to enhance frost resistance or water resistance, steel reinforcement begins to corrode intensively. Especially in foundations on soils with a high salt content or in close proximity to transformer substations.

In the walls of low-rise buildings, especially those made of aerated concrete block, arbolite stone and any other building material with low rigidity and contact strength, the use of fiberglass reinforcement is even encouraged. It is much simpler and easier to work with than a steel bar.

In addition, composite reinforcement is simply ideal for attaching external insulation or laying facing bricks, where either galvanization or stainless steel is required. And, even more so, it is worth using a thin glass thread for working on the base blocks of the foundation.

Reviews from builders, engineers and specialists

Good afternoon, you can even knit with plastic clamps. They knit only so that the structure does not move during pouring! Composite reinforcement works great; we have thousands of photos of work with composite reinforcement over 6 years of work. The main thing is to buy normal fittings from GOST, and not COUNTERFEIT!!!!!!!!!!! It is now from 80 to 95% on the market! And add basalt fiber to concrete at the rate of 3 kg of fiber per 1 m3 of concrete. Something like this………… forum.vashdom.ru

Plastic (in particular fiberglass) reinforcement has a tensile strength 3 times greater than metal (1.5 times stronger than special high-strength alloy) so compare the price of D12 metal and fiberglass D4!!! The thermal expansion of fiberglass is the same as that of concrete, but that of metal is slightly different! There are also disadvantages: it bends poorly, low shear strength. It is advisable to knit a mesh made of composite reinforcement more often, using thinner reinforcement, because adhesion to concrete is weak. The most important drawback is QUALITY!!! For many manufacturers it is, to put it mildly, not very good. srbu.ru

They also build bridges with composite reinforcement, in Belgium they restore cathedrals, etc. Don’t be lazy and follow the link and see what the Canadians (thimbles) are doing https://aslanfrp.com/Aslan100/index.html No one argues that composite reinforcement can be used everywhere instead of metal. There are a number of structures where this cannot be done! Or it must be combined with metal. Tests of imported analogues in various institutes can be seen at the link. https://aslanfrp.com/Aslan100/aslan100_papersr.html For a snack video https://youtu.be/xQDXnISGXhw stroimdom.com.ua

The main disadvantages of metal fittings

The reinforcing frame, which is present in each foundation, eliminates the risk of destruction of the concrete structure, which can occur when it is exposed to bending and compressive loads. In the presence of such a frame, which was previously made only of metal reinforcing elements, the foundation can easily withstand serious loads that arise due to frost heaving of the soil. In such a reinforced concrete structure, cracks, delaminations and other defects that affect its reliability and durability practically do not occur.

Meanwhile, metal reinforcing elements also have disadvantages, the main one of which is that the metal does not withstand the effects of high humidity and aggressive environments (salt sea water, concrete slurry, etc.). As a result of such interaction, corrosion processes arise and develop in metal structures.

Corrosion affects the integrity of the concrete structure

The use of metal reinforcing structures is not recommended for strengthening concrete structures of those buildings whose premises are subject to requirements for radio transparency and magnetic inertness. We are talking about premises in which complex electronic equipment is installed (various research centers, laboratories, medical institutions). To strengthen the foundations and walls of such buildings and premises, only dielectric fiberglass reinforcement can be used, which appeared on the construction market relatively recently.

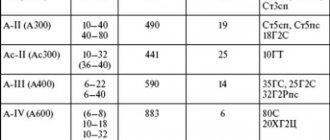

Comparative characteristics of steel and fiberglass reinforcement

Horizontal reinforcement

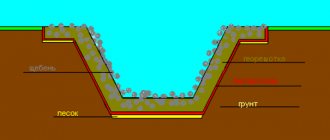

This method of using composite reinforcement in construction is used for the installation of slab foundations. Their main difference from strip-type bases is the absence of corners and adjacent areas. In fact, the entire structure is made in the form of two large grids, located one above the other. All assembly work is carried out at the installation site, since moving an assembled element of such a large size is quite problematic.

Therefore, the required number of longitudinal rods is initially laid. Transverse ones are placed on them and a mesh is knitted using wire or clamps. The second one is knitted directly on it. After this, the lower mesh must be raised onto stands above the bottom of the pit. Next, the upper mesh can be placed on vertical posts installed at the intersections of the reinforcement.