Engraving technology

The technological process of applying an image to an object with a laser beam occurs by changing the color of the treated areas or removing the surface layer of the material in the right places. Process parameters such as radiation power, focused beam diameter, wavelength, exposure time, frequency and energy of radiation pulses are selected individually for each of the wide range of processed materials. The features of engraving technology are discussed in more detail in the article at the link “Laser engraving on metal”.

Design of engraving machines

Laser engravers belong to the category of high-tech equipment. In addition to laser technology, their operation is ensured by optical devices, control programs and automation of control of performed actions. The following structural elements are common to all laser engraving devices.

- Ensuring precise positioning of the laser beam relative to the object being processed is guaranteed by the coordinate table. It is a frame on which guides are installed. The accuracy and smooth movement of the moving elements of the engraver depend on the quality of execution of this unit.

- The machine drive includes microstepping motors or servos that provide movement to the moving parts. Their peculiarity is that, depending on the nature of the current signal, they can change the speed of movement, direction of rotation, and number of revolutions. The force from the motors is transmitted to the moving mechanisms using belt drives or a ball screw.

- The work table acts as a base device for engraved objects. Most of them are carried out by lifting (manual or automated) in order to achieve a better technological position between the part and the laser head. Depending on the shape and properties of the materials of the objects being processed, the tables have design features (aluminum slats, honeycomb elements, in the form of thin pointed rods, and others).

- The optical system ensures the desired direction and focusing of the beam. Using a system of mirrors made of a special material that prevents scattering, the beam is delivered to the focusing lens. It compresses the entire energy of the beam into a diameter of several tens of millimeters.

- Actually the emitter itself, which, for example, in a gas laser consists of a lamp and a pump unit. A laser lamp consists of three cavities located in glass, metal or ceramic housings. The internal and external cavities are filled with carbon dioxide or its mixture with nitrogen and inert gas. The middle cavity is used for cooling with water or other special liquid. High voltage is applied to the electrodes located inside the internal gas cavity, allowing the tube to generate laser radiation.

- The pumping unit helps set the voltage and current required to form the laser beam.

- The engraving area must be cleaned of combustion products (traces). They should not settle on the surface of the lens. This function is performed by an air compressor, which is an integral part of the laser engraver.

Interesting: Cost of laser cutting

Laser machine for engraving and marking MiniMarker 2-20A4.

- Some materials produce large amounts of smoke when engraved. To eliminate it, the device is equipped with an exhaust fan with corrugated sleeves.

- While the engraver is operating, the lamp heats up. Overheating can quickly cause it to fail. A container with distilled water with a water pump immersed in it is an integral attribute of a laser engraver.

- The machine control system is an electronic unit that sends commands to drive motors, a laser emitter, air cleaning and cooling systems, and others. Teams are formed by software designed to perform a specific type of engraving work.

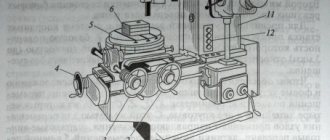

- For engraving on rotating surfaces, the machine is optionally equipped with a special rotary device, similar to that found on a lathe. It consists of a cylindrical clamping device and a stop - a centralizer, moving on the slide of the engraving machine.

Purpose of a laser engraver

Laser engravers make it possible to apply almost any graphic information, even very small ones, onto a wide range of different materials. Easy adjustment of the installation to any operating mode further increases the versatility in the use of laser systems - from cutting metal to the full depth to removing a small layer of the surface of an object.

Engraving text and image on metal

Software developments make it possible to obtain three-dimensional images in glass and other transparent materials. The ability to accurately dose radiation power makes it possible to develop the technology of applying images to coated objects. For example, removing varnish from the surface of non-precious jewelry can be done without disturbing the surface of the base material. Next, the opening areas are covered with galvanic coating to obtain a contrasting graphic image.

Laser engravers can easily create images on wood, chipboard, paper, marble and other types of stones, leather, plexiglass, and acrylic. However, metals are the most commonly engraved.

Engraving images and text on wood

Advantages of laser engravers

We offer the opportunity to buy modern and practical equipment for laser engraving at competitive prices. The range includes equipment from well-known domestic and foreign manufacturers, which has received a huge number of positive reviews from experts from around the world. Most of the devices presented in our catalog are universal.

In addition to reliability and reasonable prices, the machines have many other advantages:

- maximum durability of the resulting images;

- high clarity of text and pictures;

- the ability to quickly make changes to the program;

- high performance;

- minimum energy consumption.

Some models allow marking of finished products.

The key feature of a laser engraver is minimal operating costs. In addition, the working parts of the installations practically do not wear out during the entire service life. In other words, regardless of the hours worked, engravers produce accurate and clear images.

Purchasing laser engraving equipment is a promising investment because this solution allows you to:

- significantly expand the range of manufactured products;

- minimize the cost of final products;

- increase the competitiveness of goods.

You can clarify the technical specifications and consult regarding the operating features of the equipment by contacting the managers by phone in St. Petersburg.

Types of machines

The main difference between engravers lies in the material of the active medium that forms the laser beam. According to this indicator, there are two types of equipment - gas and solid-state. In addition to the main technological differences, there are additional differences related to the conditions of its operation; work can be carried out in a production environment or in a private home business. Some types are discussed in more detail below.

Solid State

Such installations produce laser radiation with a wavelength that is well absorbed by metals. The active working fluid is a chemical crystal. Unlike gas ones, they can operate in pulse mode, which is necessary when applying certain types of images, for example, three-dimensional ones in the thickness of a transparent material.

Interesting: The best laser machines for cutting metal

Fiber

Here, the role of an active radiating body is performed by a fiber optic thread. In essence, this is the same solid-state laser, but it has a number of advantages. It is much less demanding on cooling conditions than solid-state with a crystalline working fluid or gas.

Laser fiber engraving machine for metal and plastics FMARK NS.

The design of the unit and pumping conditions are significantly simplified; the main working element is a semiconductor diode. The fiber laser engraver has ultra-precise focusing, which makes it the best among other types of similar equipment. More expensive, but also with increased functionality installation.

CNC

CNC laser machines, in addition to cutting blanks and cutting metal sheets, perform engraving work with the application of images of configurations of any complexity. Using the CNC system, programming and operational changeover from one type of image to another is carried out; it is enough just to replace the old file with a new one in the system.

Versatile, productive laser with the TruMark 5000 series compact head.

CNC laser machines for engraving are usually of a small size range; machines with a large work table, by their specific nature, are more suitable for cutting and cutting workpieces.

Tabletop

For people engraving at home, manufacturers produce desktop or mini laser machines. These are mainly small-sized devices for applying text inscriptions to materials used in everyday life (metal products, plastic products, small wooden objects). These machines are equipped with devices with the simplest possible controls. The work of a desktop engraver is presented in the following video.

Desktop laser engraver.

Manual

It is possible to obtain an image on a part using laser engraving only by mechanized means. However, laser marking (which differs from engraving only in the inability to obtain a relief surface) is possible with equipment that has a portable hand-held laser head. An example of the operation of such a laser marking system is shown in the following video. This is a non-classical option for manually adjusting the position of the laser beam on the workpiece, but part of the technology for performing the work with the installation indicated in the video is done with manual effort.

TOP 9 best laser engravers

Manufacturers of laser engravers can be divided into several groups. The first group includes high quality and expensive equipment from the USA, Europe, Taiwan and Japan. In the domestic market, the most popular of this group are Austrian laser engravers. The following models stand out from this company:

Speedy - 100R

Small-sized laser engravers "Speedy - 100R". Average price: 400,000 rub.

Speedy - 300

High-speed "Speedy - 300". Average price 900,000 rubles.

Rayjet - 300

Laser engraver "Rayjet - 300" with gas CO2 laser and protection against mechanical dust.

The second group includes cheaper laser engravers from China. They use lower quality components in their design in terms of operational reliability. However, many consumers are satisfied with the price-quality ratio and they are gaining their niche in the domestic market. Among the companies distinguished by stable product quality are the following:

Interesting: Artistic laser cutting of metal

Vassal 5065

Vassal 5065. Average price 17,000 rubles.

Feungsake PD271

Feungsake PD271. Average price 23,000 rubles.

NEJE 1000 MW

NEJE 1000 MW. Average price 6,500 rub.

KKMoon engraving machine

KKMoon engraving machine. Average price 7,500 rub.

Moski – MSQ Laser AS – 5

Moski – MSQ Laser AS – 5. Average price 25,000 rubles.

Gistroy

Gistroy desktop laser engraver.

Average price 40,000 rubles. The third group includes domestic manufacturers of laser engravers. They are trying to compete primarily with Chinese manufacturers. These include Laserny LLC, Scanner Plus LLC and others.

The highest ratings are usually from manufacturers who have their own scientific base. Based on fundamental research, new types of installations are created that exceed the technical parameters of previously produced equipment. They are usually located on the territory of developed countries. They set the tone in the development of laser technologies:

- in the USA - “Coherent”, “Newport”, “Rofin - Sinar”;

- in Europe - Trumpf (Germany), Trotec (Austria).

- Chinese.

Top best engravers

If you look at products from China, Europe or the USA, you can find a lot of models. It is difficult to understand the nuances, so it is better to refer to the ratings.

Best in terms of price-quality ratio

KKmoon brand models are characterized by low cost and good performance. For example, models K4 and K5 are equipped with built-in fans. The working area is large - you don’t have to worry about your hands.

You may consider purchasing the VG-L7 Laser Engraver. Works with soft materials and does not require firmware. Compact.

A standalone controller eliminates the need to connect a computer

Universal laser engravers

Here it is worth highlighting the following models:

- NEJE DK-8-KZ - good speed and accuracy, can be used together with a smartphone.

- WOLIKE Mini 3000mW - air-cooled, compact.

- FEUNGSAKE 6550 - durable, variable focus, adjustable power.

Mini engravers

The top includes devices:

- NEJE DK-8-KZ - compact, runs on a mobile power source, supports bmp and jpeg formats.

- TwoWin 3W - high accuracy of drawing, durable body, good speed.

Professional laser machines

The best rating is presented:

- HCZ 6090 - can cut parts, high speed, continuous process.

- HCZ 30w - software in Russian, accuracy, durability.

How to choose equipment

All the variety of designs of laser engravers can be identified by the following main selection criteria.

- It is important to determine the nature and type of work performed. When carrying out both cutting workpieces and applying images, you should select equipment with balanced indicators of radiation power and the speed of movement of the laser head. Engraving does not require high power equipment.

- The model of the laser emitter of the machine depends on the materials on which the images will be applied. The wavelength of gas lasers is well perceived by non-metallic objects. Solid-state (fiber) emitters are equipped with machines that work with metals - finer focusing and energy intensity contribute to this.

- The dimensions of the workpieces being processed directly affect the dimensions of the laser engraver's work table. In production conditions where large workpieces must be processed, it is important to have large-sized machines. If you engrave souvenirs, for example, in a private business, it is better to get by with a small desktop machine.

- The choice of machine is influenced by indirect reasons: the reputation of the manufacturer, which in a certain way guarantees the quality of the assembly. Organization of service by the manufacturer and the possibility of inexpensive replacement of components will have a significant impact on the reliable operation of the machine.

You should wisely approach the acquisition of additional features that are usually offered by the manufacturer. A rotary rotator, autofocus, systems for feeding material into the work area, an additional chiller for cooling and many others will increase the purchase budget. However, without some, the technological process simply will not be able to function normally. Budget optimization should be carried out taking into account the reliable operation of the laser engraver.

Kinds

Before choosing a laser engraver, you need to decide on its type. This will help save money. In addition, with the right choice, you can find equipment that will be ideal for performing the assigned tasks.

Important! It is not necessary to consider only European or American brands. Among the Chinese there are also many worthy brands.

By source type

There are two varieties:

- Electrical. Just plug the device into a power outlet and it will start working. However, it can be difficult to move it to another location due to the length of the cable.

- Rechargeable. Portable models that are easy to move. However, they work for a limited time, after which the device will have to be charged.

There are also two types of engravers:

- Gas. Inside the device there is a tube containing a gaseous substance. Suitable for applying designs to leather, wood, plastic, glass, etc. Does not work with metals.

- Solid state. Solids are used as the active medium. Works with most materials. They are more expensive than gas ones, but are more suitable for industrial work.

By working surface area

Desktop engravers are suitable for home use. They do not take up much space and allow you to work with small batches of materials. However, they do not always provide a good view of the work surface.

Desktop engraver fits easily on a regular desk

Medium-sized devices offer great capabilities. They can handle a good amount of work, but they will need space. For example, in a garage or separate room.

Industrial machines with an area of 1.5 m are suitable for large-scale production. Special workshops are used for their installation. In addition, working behind them will require special qualifications.

By power

Choosing an engraver for your home is not such an easy task. The higher its power, the better the performance, but at the same time energy consumption increases. At the same time, there is one more nuance: the thicker the material, the stronger the device should be.

Therefore, before choosing a laser engraver, you should decide on the prospects. So, to work with materials up to 5 mm thick, a 15-20 W model is sufficient. Only the speed of this model is low and the work area is small. If you increase the power, the engraver can handle a 10 mm sheet.

A device of 80-100 W is enough to work with metal, plywood and other materials. This will give you good speed and working area. There are engravers with a power of 100-200 W - this is typical for industrial work.

For reference! For powerful devices, sometimes a conventional 220 V outlet is not enough. When choosing, you must pay attention to this.