For residents of private houses or for owners of suburban areas, the question often becomes relevant: how to make a screw wood splitter with your own hands and where to get instructions, drawings, photos for this? After all, in a private house you often have to prepare firewood. With a small number of them, you can handle it with an axe. If there are a lot of them, the ax will no longer help - it will take a lot of effort and time. In this situation, a wood splitter will come to the rescue; you can make it yourself.

To make a wood splitter, components from other equipment are used. Self-made units, based on the type of their working body, are divided into two categories: with a cleaver and with a cone. The main part of the cleaver is a vertical sharp plate. The wood is fed to it by a pusher. A wood splitter of this category is called a rack splitter. For devices of the second type, the main element is a cone with a screw thread. This type of wood splitter is called a cone splitter. Its second name is screw. In terms of its design, it is simpler than rack and pinion.

Operating principle, advantages and design of a screw wood splitter

The cone of the wood splitter rotates using an electric motor. It enters the log and, due to a gradual increase in diameter, tears it apart along the fibers. Firewood is supplied to the propeller manually. A homemade screw wood splitter has the following advantages:

- Simplicity of design.

- Low cost of nodes.

- Easy accessibility of units (almost all, except for the cone, they are available in everyday life).

- High productivity (up to 12 m3 of firewood about 60 cm long).

- Easy to use.

This device also has disadvantages. Firstly, it does not cut wood with interwoven fibers well. Secondly, the logs are not completely separated into logs - you have to complete this process manually. And this requires some effort.

Thirdly, to make the cone you will need a lathe. Although, you can make the screw yourself - there is a lot of information on this matter on the Internet. In addition, this part can be purchased ready-made.

The cone shaft must be mounted on a strong, stable platform. The recommended cone rotation speed range is from 300 to 500 rpm. In this scheme, the electric motor rotates the propeller via a belt drive.

The advantage of this scheme is that any engines can be used here. And the required propeller rotation speed is achieved through a belt or chain drive. A pulley of a smaller diameter is installed on the electric motor shaft, and a larger one on the propeller shaft.

To simplify the design of the unit, it is recommended to use an electric motor with a gearbox. This decision will not affect performance in any way.

There is an option in which the electric motor is connected to the cone directly. The maximum engine speed in this case should be 500 rpm, the minimum power should be 3 kW.

The option in which the engine is located under the tabletop is more preferable. In this case, the length of the tabletop will be shorter. In addition, this will protect the motor from splinters. In this scheme, a single-phase electric motor is suitable, which will help reduce the cost of manufacturing the device.

The log splitter must also meet the following requirements:

- permissible electric motor power – 2-4 kW;

- the presence of an on and off button, as well as a device designed for protective shutdown in case of emergency situations;

- the propeller shaft must be on bearing supports;

- there must be a persistent thread on the cone;

- the height of the unit should be about 800 mm;

- It is advisable to use V-shaped belts, and double-strand pulleys;

- the workpieces must be fed vertically (if the workpieces are fed differently, the screw may jam).

Stage three

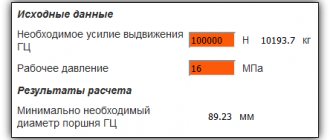

We select an electric motor of the required power so that the oil pump can develop a working pressure in the system of 16 mPa. Let's move on to the third part of the hydraulics calculator.

In the “Estimated rotation speed...” , set the value to 1500 . The most optimal speed for the NSh oil pump. In the “Required feed…” we set the value 38.9 . In the “Pump volumetric efficiency...” set the value to 0.9 . In the “Working pressure” we set the value 16 .

We get the theoretical result: 28.8 cc. Minimum required volume of the oil pump to ensure the rod extension speed in 5 seconds. The minimum electric motor power for this pump is 12.2 kW.

Design elements

To work you will need:

- Sheet of metal 4-5 mm thick.

- Cone (the best material for the main part of the entire mechanism is tool steel).

- Shaft.

- Pulleys (for transmission using a belt) or sprockets (for transmission using a chain).

- Belt or chain.

- Bearings having a housing.

- Electric motor.

- Wires.

- Button to turn the unit on and off (alternatively, you can use a magnetic starter).

- Angles for making a frame (steel pipes are also quite suitable for this purpose).

- Bolts and nuts.

Almost all of the parts listed can be recovered from old equipment. You can make the cone yourself. However, this will require certain equipment. The screw thread pitch should be 2:1. Therefore, it is advisable to purchase it so that the unit works without any problems.

You will also need the following tools for the job:

- electric drill with drills of different sizes;

- hammer;

- welding machine;

- Bulgarian;

- tape measure, keys;

- marker.

Manufacturing

First, cut the angles and pipes according to your measurements. From the sheet, cut out the table cover and the platform on which the motor will be installed. Connect the upper and lower frames, weld the legs. For mobile installation, axles will need to be welded to the frame. Install wheels on these axles.

After this, install the tabletop and shelf on which the engine will be mounted. Install the motor. Connect the motor shaft to the drive pulley. Assemble the cone shaft assembly. To do this, you will need to place the bearings in the housings, install the pulleys and shaft. Now drill holes in the frame and secure the assembled unit to it. To do this you will need bolts and nuts. Check the rotation of the shaft - there should be no resistance.

Installing the motor and main shaft

After this, you can install the belts. Having done this, check the trajectory of their movement - it should be straight. If this is not the case, drill new holes in the tabletop and install the shaft there. After this, check the trajectory again. Do this procedure until you get the desired result. The belts must move without beating, otherwise they may fly off.

Place the cone on the shaft and secure it with screws. The cone must be installed firmly, without play. Make flats on the shaft. They can come in handy if the cone gets stuck in a log. You will have to remove it using a pipe wrench. The flats will ensure the key adheres to the shaft. After this, install the divider (an old hammer may be useful for making it).

Cone installation

After this, proceed to connecting electrical equipment. That's it - the wood splitter is ready! You can clean its surfaces, prime them and apply paint. Now you can test the device.

The dimensions of the unit can be arbitrary. The main thing is that it is convenient to use. To do this, the dimensions of the machine must correspond to human height. Recommended sizes:

- length – 850 mm;

- width – 450 mm;

- height – 650 mm.

Video: do-it-yourself screw wood splitter.

Hand cleaver

The simplest device driven by muscle force. There are many original designs for such devices. All of them require some physical effort, although they facilitate the process thanks to some features of the device. This is the easiest way to make a cleaver with your own hands.

Manual devices have a lot of design options, differing in design features. There are three main types:

Safety precautions

You need to put the wood on the cone without gloves. Otherwise, they may become caught on the screw, which may result in injury. Only feed the workpieces in a vertical position. This will protect the working part of the unit from jamming and failure. Don't forget to ground the engine.

So, making a screw log splitter is a process that does not present any particular problems. This may only take one day. But in the future you will save a lot of time and effort when preparing large quantities of firewood. Just follow safety precautions when working.

A homemade screw splitter will help you chop a large amount of firewood without spending a lot of effort. This device uses the principle of splitting wood when screwing in a massive screw, which is a symbiosis of a screw and a regular wedge. The manufactured cone, thanks to the cut thread, easily tears the wood along the grain due to the large diameter of the screw.

Option two: custom cones for the wood splitter

Since extremely high precision must be maintained when making threads, it should be understood that even in skillful hands, a grinder can hardly replace a high-quality cutter and lathe. Therefore, you should try to perform this part on a machine or entrust the work to an experienced craftsman.

When ordering a conical screw for a wood splitter, the turner should provide as detailed diagrams of the required part as possible and indicate the parameters. The following are usually used: taper - 1:2, double-start thread, with a pitch of 5-6 mm. The thread should have the same tooth profile as a self-tapping screw intended for wood.

When working with a wood splitter, it is necessary to carry out all actions as carefully as possible. Due to the speed of the spinning cone, you should not try to hold the log while wearing gloves. Feeding logs should be done only with bare hands. Gloves or mittens can get caught in the threads and pulled off the hand, which can seriously injure your fingers or hand.

Main types of screw wood splitters

Based on the design of the drive, you can make several types of homemade wood splitters. Some craftsmen place a screw on the working shaft of an electric motor. In this case, very stringent requirements are put forward for the electric motor. It must only be low-speed and quite powerful.

The most common are screw splitters of another type, in which any electric motors can be used. Reducing the speed in them is achieved due to the use of various gearboxes or belt drives. A small diameter sprocket is placed on the working shaft of the electric motor, and a large pulley is installed on the cone of the wood splitter. Their dimensions must be selected in such a way as to reduce the engine speed to 500 rpm. It happens that when using high-speed electric motors it is difficult to achieve the required speed values. In this case, it is worth installing an intermediate shaft and a special stepped transmission.

All components of the device must be securely fastened to a durable frame. For more comfortable work, it can be equipped with a small folding table.

Advantages and disadvantages of cone splitters

The main advantages of cone splitters are:

- simplicity of design;

- the ability to assemble it yourself;

- good performance of the device;

- low installation price;

- Any person can work on such a device.

At the same time, the very simple and reliable design of homemade wood splitters has a number of disadvantages.

- One of them can be considered that wood with highly intertwined fibers is a big problem for its screw. This is why tree roots and logs with knots should be chopped by hand.

- The next drawback is the poor separation of large lumps into parts.

- It is also worth noting that making a cone yourself is almost impossible without the help of a qualified turner.

At the moment, on the Internet you can find high-quality drawings of a screw wood splitter for making yourself or offers for selling the finished product.

Making a wood splitter-screw yourself

The simplicity of the design and impressive performance are strong arguments for making such a machine yourself.

The most important part - a screw cone for a wood splitter - can be purchased at a specialized tool store or ordered from a turning shop. The cost of screws depends on the diameter (80-100 mm) and ranges from 1500 to 5000 rubles.

If you don’t want to search for pulleys and make a shaft yourself, then buy a ready-made wood splitter unit. It consists of a screw cone (carrot), a shaft with bearings and a double-groove pulley with a diameter of 200 mm. The approximate price of such a kit ranges from 3200 to 5600 rubles.

Main requirements for an electric splitter

A homemade electric splitter must be very reliable, safe to operate and have high performance. That is why, when choosing the type of device and assembling it, it is necessary to follow the rules for complying with the requirements for devices of this type.

The basic requirements for wood splitters are:

- the maximum power of the electric motor should not exceed 4 kW;

- to reduce the speed, you should use a belt drive or gearbox;

- the maximum rotation speed of the wood splitter shaft should not exceed 500 rpm;

- the device must be equipped with a convenient control button, a reliable differential automatic machine and a magnetic starter;

- the working shaft of the cone is secured with bearings;

- the cone of the device must be equipped with a special thrust thread;

- when using a belt drive, it is worth using V-belts and double-ribbed pulleys;

- The lumps must be fed in a vertical position, otherwise the screw may jam and damage the machine.

Dimensions of the log splitting machine

There is no separate diagram for the location of parts and components, and there are no restrictions. The assembly process can be based on the dimensions corresponding to a person’s height:

- bed height - 650 mm;

- table length - 850 mm;

- tabletop width - 450 mm.

Experienced users recommend placing the motor under a tabletop that can protect the unit from chips and sawdust. To ensure safety, all moving parts must be covered with a casing.

A machine with a hydraulic drive is also suitable for a home workshop; a hydraulic pump that drives the splitting ax will help you split round timber. A sharp plate is lowered onto the log with great force, tearing the wood fibers , separating small fragments.

To make a plate for a carrot wood splitter, it is recommended to use 1 mm sheet steel and a 4.0x4.0 cm corner.

In addition to the above options, chopping firewood can be done with a mechanical device , which can be set in motion by the power of one person. The equipment is controlled by a handle attached to the gearbox shaft. A mechanical wood splitter can be quickly converted into an electric unit if you use a belt drive adapted for a walk-behind tractor.

Swinging an ax over a huge pile of firewood, you can’t help but think about how to make this hard labor easier.

A chainsaw is not an assistant here, since it is designed for cross-cutting wood. Only in a hopeless situation can it be used to loosen a board or timber. A thick wedge and a heavy hammer will help split a particularly hard and thick log, but this work cannot be called productive.

A screw firewood splitter - a simple and reliable device - will help you combine high speed wood chopping with minimal physical effort. Its operating principle is based on the ingeniously simple combination of a screw and a wedge.

An ordinary screw can be easily screwed into wood, but can only slightly push its fibers apart. But when a double-start persistent thread is applied to a steel cone, the desired result is achieved.

Expert advice! It is important to pay attention to the type of thread: a persistent two-start thread is required; if you use a single-start thread, you will have to forcefully push the log onto the carrot cone. Ask your sellers for a two-start thrust thread. Otherwise, when using a single-start thread, you will have to force the logs onto the screw cone with great effort!

Only the two-way cone is easily screwed into the log and, due to its wedge-shaped shape and persistent thread, splits it into two parts.

Read also: How does a foam container work?

There are two main design schemes for cone splitters. In the first, the screw cone is installed directly on the shaft of a low-speed electric motor with a power of 3-5 kW (speed no more than 500).

Another option is implemented through the use of double-strand pulleys of different diameters and flexible drive belts. A small pulley is placed on the shaft of the electric motor, and a large pulley is placed on the shaft of the wood splitter screw.

The ratio of their diameters is selected so as to reduce the propeller speed compared to the engine speed by 2.5 - 4 times to 300-400 rpm.

The rotation speed of the cone screw can be reduced using a gear motor - a single unit in which the electric motor is structurally connected to a reduction gear. However, such models are not widely used in the market of screw axes.

Those who want to make such a machine with their own hands should remember that the high speed of rotation of the screw cone (more than 500 rpm) increases the risk of injury, since in this case it is difficult to hold the log in your hands.

In order to reduce the risk of injury to the machine, a stationary steel wedge is placed under the screw cone, which protects the log from jumping off.

Materials and tools for assembly

Assembling the machine with your own hands does not require the use of expensive parts. Many blanks can be taken from an old washing machine or a faulty walk-behind tractor, and you should ask an experienced turner for a drawing of a cone for a wood splitter.

To make a homemade device you will need the following materials:

- special cone;

- hub or shaft;

- set of sprockets and pulleys;

- a chain from a car or any drive belt;

- automobile housings with bearings;

- metal corners or pipes;

- thick steel sheet for the working surface;

- electric motor;

- copper wires;

- starter or special button;

- differential machine;

- a set of various fastening materials.

Many units will fit from an old washing machine or car. You should not make your own screw. There are a lot of materials on the Internet in which craftsmen advise cutting out this part using an ordinary grinder. Experts say that this idea will just turn out to be a carrot, not a cone screw.

To assemble the electric splitter, you will need the following tools:

- welding machine;

- drill and drill bits;

- electric grinder;

- small hammer;

- spanners;

- pencil and tape measure.

To protect the surface of the machine from corrosion, you can use any type of enamel. However, it is worthwhile to properly prepare the metal for painting. This can be done using a special brush and chemical rust converters.

About homemade products

When familiarizing yourself with factory products, some might have a completely logical thought: “Why not save money and do something similar yourself?” With the right hands and a clear head, anything is possible. We invite you to familiarize yourself with the most interesting wood splitter designs that you can actually make with your own hands.

Spring log splitter

It is an evolutionary step in the development of classic cleavers. Using a spring log splitter requires the use of muscular strength, but to a lesser extent due to the spring mechanism, large arm and additional load. In the diagram it looks like this.

The design of such a homemade product includes a metal pipe or profile (this will be our shoulder, increasing the gain in strength, with a blade at the end), a metal support and a hinge connection between them. The return mechanism is spring type, you can use an old shock absorber. The video below shows an example of working with such a mechanism.

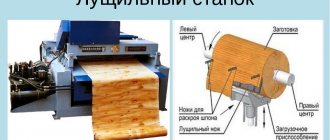

"Carrot"

A mechanism with such a simple name also does not require the use of high-tech parts. To manufacture it, you need a drive, a simple gearbox with a belt drive, a pair of bearings, a shaft, a threaded cone and a table-frame. A drive with a power of more than 2 kW, at least from an old washing machine, is not a problem to find. Paradoxically, the most complex part of the system is the cone. You need to either buy it ready-made or order it from an experienced milling machine friend. The diagram of a screw splitter is shown in the figure below.

The splitting of the chocks is carried out by screwing in the cone, due to which the wood fibers are literally torn. The main thing is not to make money feeding logs - this is a rather unsafe design, and a carrot can just as easily screw on the sleeve of your clothes. How it works is in the next video.

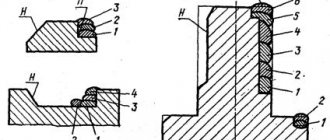

Rack design

For all its effectiveness, a rack-and-pinion wood splitter is a controversial decision. And first of all, this concerns safety. It is necessary to carefully calculate the rotation speed of the gear, the force from which is transmitted to the rack. As a rule, splitting with such a wood splitter is carried out very quickly. By pressing the rack against the gear by pressing the handle, the operator sets it in motion. By releasing the handle, the contact with the gear is reduced due to the spring, the return mechanism is activated and the rack returns to its original position. The rail must be placed on a carriage that will move along the frame. Actually, it is necessary to fix the pusher plate on it. Schematically it looks like this.

It turns out that maximum attention should be paid to the frame, i.e. its stability, as well as the quality of the slats - it will not be possible to turn one without special skills. For the rest, at least some experience in welding and the use of electric drives will help. The end result may look like this craftsman in the video.

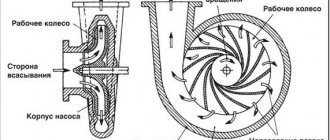

Hydraulic cleaver

In our opinion, this is the most technically complex solution, but it is also the safest. Armed with Pascal's law, a hydraulic cylinder, a drive, a pump and an oil tank, with the help of an experienced hydraulic engineer you can create a system that develops a force of 5 tons and above. Schematically, the structure of such a product looks like this.

The man in the video did it, maybe you can do it too?

DIY cone splitter

At the initial stage of assembling an electric cleaver, it is worth making a good sketch, which will indicate the location of the parts and mechanisms of the device, as well as its dimensions. You will need an electrical wiring diagram that any electrician can create. These steps will help you assemble the machine efficiently and prevent many mistakes. It is also necessary to take a responsible approach to the manufacture of a special wedge, since it is the most vulnerable part of the mechanism.

The most suitable material for a wedge is considered to be expensive tool steel, but it is very difficult to process even for an experienced turner. Most often, ordinary steel is used for this, which is then strengthened by carburization or hardening. Long and high-quality operation of the screw cone will be ensured only if it is well manufactured. A simple metric thread is not suitable for these purposes, as it wears out quite quickly and does not fit into the wood well. Experts advise making a double-start thread with a pitch of 5 mm.

Making a wood splitter yourself

The cost of a factory-made screw cleaver, depending on the configuration, ranges from 16 to hundreds of thousands of rubles. The main working element is a cone for a wood splitter, which can be ordered from a turning workshop. To make a screw wood splitter work with your own hands, drawings for craftsmen are offered.

It will not be possible to make a thread with a grinder, since the persistent thread on the “carrot” must be maintained precisely. In addition, when making a cone, the turner must know the ratio of the length and cross-section of the base - 2:1, the thread is double-start with a pitch of 5-6 mm, the tooth profile is like that of a chisel.

Depending on the size of the part, it will cost up to 5,000 rubles. Completely finished working unit:

- screw cone;

- shaft with bearing unit;

- transmission pulley for belt drive.

The entire set will cost no more than 6 thousand, but the unit is safer when manufactured for the design load.

The manufactured machine must meet the following requirements:

- engine power not less than 2 kW;

- at high speeds, the thread pitch must be kept smaller to reduce the load on the drive;

- the fit on the gearbox shaft must be tight to prevent rotation;

- the cone is made of tool steel;

- the tip of the screw is sharpened, it should enter the wood softly, without effort;

- height of the working platform - 80 cm.

The schematic diagram of the device looks as shown in the diagram.

As can be seen from the diagram, the device is simple, but requires precise alignment of the units, selection of pulleys with the required gear ratio and V-belts that match the profile.

To help the craftsman, there is a video on how to make a cone wood splitter with your own hands:

There is another scheme that does not require a belt drive and gearbox. The low speed motor shaft can be directly connected to the screw wedge. Shaft speed less than 500 rpm is not dangerous for the drive of a screw wood splitter.

Chunks that are knotty or deformed with a bend must be pricked with extreme caution. The log can bounce along an unpredictable trajectory, spinning a block in your hands. The wedge may get stuck in hard wood. Therefore, if possible, the machine should be equipped with reverse.

It would be useful to recall that the engine must have a moisture-proof housing and be grounded. The belt drive is covered with a protective casing. When feeding chocks to the cutting table, you cannot work in the tops. If you move awkwardly, it can get wrapped around the cone along with your hand. The machine must be equipped with an emergency braking stop.

Read also: Frost-resistant adhesive for rubber

As an example of folk ingenuity, one can cite a device for splitting a small number of short logs. A conical attachment with a cross-section of 30 mm on a low-speed hammer drill will allow you to split dry wood. But there are difficulties here. The drill tends to make a turn behind the screw; it should be held firmly, resisting, or the tool should be strengthened in the holder.

At a summer cottage or in a private rural house, collecting firewood requires time, effort and endurance. To avoid chopping wood with an ax, many property owners with stove heating buy a high-performance screw log splitter. A factory-assembled machine is expensive, but some craftsmen make the device with their own hands from scrap parts.

Screw cleaver - what is it?

The simple design of the cone log splitter is very effective if you need to chop several cubic meters of firewood

You can split wood without much effort using a screw splitting splitter. To understand how this device works, it is enough to remember how, in the process of unsuccessfully screwing a screw into a wooden strip or plank, these objects split at the point of physical impact. It’s easy to combat this phenomenon - just pre-drill a hole for the self-tapping screw, and it will go like clockwork. The principle of splitting wood when screwing in a screw was used by home craftsmen in the design in question. But a simple screw does not move the fibers apart enough, so it was modified by greatly increasing the taper and reducing the ratio of thread depth to tool diameter. The result is a screw, which is a symbiosis of a wedge and a self-tapping screw. The device is easily screwed into wood thanks to the threaded part and breaks it along the fibers due to the multiple increase in the diameter of the tool.

Screw log splitter diagram

Depending on the design of the drive, there are several types of screw splitters. In some, the screw is mounted directly on the shaft of the electric motor. In this case, the requirements for the power unit are quite stringent - the electric motor must be low-speed (no more than 500 rpm) and quite powerful (at least 3 kW).

The scheme in which the cone is installed directly on the electric motor shaft is suitable only for low-speed power plants

In other screw splitting schemes, electric motors of any type are used, and a reduction in rotation speed is achieved through the use of mechanical gearboxes, belt and chain drives. In this case, a pulley (sprocket) of small diameter is installed on the shaft of the power unit, and a large diameter is installed on the shaft of the wood splitter cone. The ratios of their sizes are selected so as to reduce the rotation speed of the electric motor to an acceptable 300 - 500 rpm . Sometimes, when using high-speed motors, it is impossible to achieve this without significantly increasing the diameter of the driven sprocket (pulley). In this case, an intermediate shaft and a double (stepped) transmission are installed.

About the design

The basic principle is copied from the effect of deformation of wood obtained when screwing wood screws into it to fix another object. When hardware enters the wood and begins to split its fibers, a crack forms in the part, leading to splitting.

Basic design of a cone log splitter

The machine consists of two main parts:

. It is made from a profile pipe and has the shape of a bedside table. Consists of four racks connected to each other by jumpers. The top is covered with a steel sheet to the size of the perimeter and a thickness of 10 mm. Two bearing mounts are installed on it. A similar plate is attached at the middle level. Holes are drilled in it to mount the electric motor. A table for feeding material is welded to the frame. It is made from two racks, using a profile pipe, connected by a jumper. The top is made of steel sheet. The dimensions correspond to the perimeter of the table. Metal thickness 10 mm. A knife is welded to the surface of the table to separate the log. It prevents a fragment from unexpectedly falling under the screw cone with its subsequent tightening and deformation of the shaft. It is welded strictly under the cone at a distance of 20 mm from the largest diameter of the cone included in the kit for this machine.

The base part is represented by a strong frame- The mechanical part is represented by a shaft , two bearings, a pulley that reduces the rotation speed, a cone with a screw thread, an electric motor, a small pulley for the engine and a rubberized belt.

How does it work?

The steel shaft is placed in bearings and installed in mounts on the frame. A pulley with a diameter of 400 mm is attached to its end. An electric motor with a small pulley with a diameter of 140 mm is installed on the middle platform. A belt drive is installed between them.

The difference in pulley diameters makes it possible to reduce the rotation speed from the engine to the shaft with a cone by three times, but allows you to increase the power of the machine by 3 times.

The screw cone is made of steel grade 45 or 42X. It is turned on a lathe. The tapered thread is angled to engage the material.

The length of the cone is 250 mm, the diameter of the base for the shaft ranges from 40 mm to 100 mm.

A hole for the shaft is drilled in the base. The cone is secured to the shaft using screws or internal threads.

Types of drives for cone splitter

The drive for producing the work of a mechanical cleaver can be:

- Electric motors powered from a mains voltage of 220 V and 380 V. The choice depends on the required power of the machine.

- Internal combustion engines running on gasoline or diesel fuel.

- From a special device on a mechanical lawn mower or mini tractor. This is a temporary drive.

Operating principle of an electric cleaver

When the engine starts, torque is transmitted through a belt to a large pulley and the shaft rotates in bearings with a cone splitter mounted on it. The operator moves a block of wood along the receiving table towards the cone.

The material is in a vertical position. The principle of manual feeding is necessary for tactile control of the pressure on the block. The cone is screwed into the wood using a screw thread. The shape of the cleaver ensures gradual splitting of the tree into logs of the required size. All that remains is to put the resulting product in the woodpile.

Important! Particular attention must be paid to the safety of work on these machines. They have a large number of exposed rotating parts with high power. Electric current is used to operate. It is important to follow all safety regulations. Mandatory use of protective clothing and personal protective equipment, mittens, tarpaulin boots, glasses.

Requirements for a cone splitter

The design of the screw splitter should ensure not only high reliability and performance, but also safety during operation. Therefore, when choosing the design of the unit and its manufacture, it is important to adhere to the requirements for equipment of this type and the recommendations of the craftsmen who have tested the machine in action.

Flexible transmission is a simple and affordable way to change the speed of rotation of the propeller when using high-speed electric motors

- the electric motor power should be in the range from 2 to 4 kW;

- to reduce the number of revolutions, it is recommended to use a gearbox or flexible transmission;

- cone screw rotation speed - no more than 500 rpm;

- the machine must be equipped with an on/off button (magnetic starter) and a residual current device (RCD);

- the cone shaft is mounted on bearing supports;

- the cone must have a persistent thread;

- when driving with a belt, it is better to use double-ribbed pulleys and a pair of V-belts;

- During operation, the supply of logs must be carried out with their vertical orientation, otherwise the screw may jam and damage the installation.

You should not follow the lead of the “craftsmen” who offer the simplest design of a wood splitter, in which a shaft with a wedge-shaped screw is clamped into the chuck of a powerful electric drill or hammer drill. Such a device not only has low efficiency, but is also very dangerous, since it will not be easy to hold it in your hands with the increased resistance of the wood. If you still decide to use this scheme, then try to secure the tool on a solid base in order to use it in the traditional way.

To obtain a mobile design, an internal combustion engine is used to drive the machine

How to choose a hydraulic wood splitter

The main characteristics of modern wood splitters and their description are presented in a small plate below.

| Selection criterion | Types and capabilities of devices |

| Construction type | The most popular devices are hydraulic wood splitters, the force in which is created by a motor and a hydraulic piston, due to which the workpiece is pressed against the knife. Screw cleaver (carrot wood splitter) is another common solution due to the fact that you can do it yourself. The drive axis rotates the screw cone, which, when feeding the workpiece, literally screws into it and tears the layers of wood. A rack wood splitter is simple to use, but quite dangerous to use. In such a cleaver, the workpiece is pushed due to the force transmitted to the rack from the rotating gear. If all of the above options are equipped with a drive, then an inertial or spring wood splitter already requires some use of manual force. With its large arm and spring, it modernizes the approach to traditional tuning. |

| Drive unit | Devices based on electric motors (220 V/380 V) and gasoline engines are used. The choice is determined solely by convenience and working conditions. |

| Maximum splitting force | Determines the magnitude of the piston pressure on the workpiece - typical for hydraulic and rack-and-pinion wood splitters. In private use, it is enough to use models with a force of 4 to 6 tons. More powerful models are suitable for working with long logs and on an industrial scale. |

| Working position | Determines the position of the workpiece axis during operation. There are splitting axes with horizontal, vertical and combined positions. The first option is the most common when used privately and is used in most hydraulic and rack and pinion designs due to convenience and safety. |

| Log sizes | The length of logs when using hydraulic splitters is limited by the piston stroke and the maximum splitting force. Typically this value is limited to 0.52 m. The thickness of the workpieces can vary from 0.25 to 0.5 m depending on the model of the splitting splitter. In slatted solutions, the length of the log is determined by the dimensions of the slats and, again, by the force created. The use of screw wood splitters allows the use of larger diameter logs - up to 0.7 m, but this increases the labor intensity of the work. |

| Options | Height adjustment. This option has a positive effect on ease of use, but at the same time increases the cost of the product; its absence can be compensated for by a homemade stand. Availability of wheels, preferably large ones. Provide convenience during transportation. A security system , usually of a two-lever type, in which the operator must simultaneously use two hands on the remote control, is an integral part of all modern factory products. |

Of course, the speed of its work can also be considered as a parameter when choosing an assistant in the wood splitting business, but it is believed that even the minimum values are more than enough.

What is needed for making

Making an “iron lumberjack” does not require the use of scarce parts, so most components and blanks can be found at home or in the garages of friends and acquaintances. Here's what you'll need during the process:

- cone (you can grind the screw yourself or purchase it on the construction market);

- shaft (if you make your own threaded wedge, you can use a suitable hub from agricultural machinery);

- pulleys or sprockets;

- drive belt or chain from automobile or motorcycle equipment;

- bearings with housings (supports for car driveshafts are an excellent option);

- steel profile pipes or angles for the frame;

- metal sheet with a thickness of at least 4 mm for the desktop;

- electric motor;

- wiring;

- switch or magnetic starter;

- RCD;

- bolts and nuts M8 or M10.

Most parts can be used from old automobile or agricultural equipment . The only thing that may be difficult is making a cone screw. However, you should not even try to cut this part using a grinder, as some “authoritative” sources advise. The time spent is not worth the resulting misunderstanding, which can only indirectly be called a screw. Moreover, in operation this “carrot” will not even come one iota close to the efficiency that a cone made by turning will give.

Main components of a cone log splitter

If you plan to use the wood splitter as a mobile unit, then you should take care of durable metal wheels in advance. A truly mobile design is achieved using a gasoline or diesel engine as a power plant.

When making a machine, you will need tools that any “handy” owner will have:

- welding machine;

- electric drill with a set of drills;

- Bulgarian;

- hammer;

- set of wrenches;

- tape measure, marker.

Any enamel for exterior use is suitable for protection against corrosion. It is only important to thoroughly prepare the metal surface for painting, so if necessary, prepare a metal brush (manual, or in the form of an attachment for a drill or grinder), a primer and a rust converter.

Preparatory work: approximate dimensions and drawings

Before taking up the tool, it is important to draw up at least a simple sketch diagram with the location of the main components and parts of the machine and indicating its main dimensions. In addition, you will need an electrical connection diagram, which you can involve a familiar electrician in working on. The diagrams and drawings of finished structures presented to your attention will help you correctly configure the wood splitter and avoid mistakes in its manufacture.

Layout of a log splitting machine

The most important step in the process of creating a mechanical cleaver is making a wedge, so let’s look at this in more detail.

The best material for a cone is tool steel, but not every turner will undertake to make a part from it - the metal has increased hardness and requires special handling. Most likely, the screw will be made of the most popular grade of structural steel - St 45. In this case, it is better to strengthen its threaded part by any available method - hardening, nitriding or carburization.

148

What size should wood splitters be?

The components and parts of wood splitters can be arranged in any order without copying everything thoroughly from the diagrams. There are no strict restrictions. Only the basic principles of fastening parts are observed. At the same time, how convenient it is to operate the wood splitter is also important. This factor must be given special attention to avoid accidents. Therefore, you need to choose the appropriate height of the wood splitter according to the height of the person. Of course, you can make a wood splitter in the recommended parameters: 80-90 cm long, 40-50 cm wide and 60-70 cm high. However, it is best to assemble the wood splitter individually.