Metal parts are susceptible to rust. If corrosion has covered most of the surface of the workpiece, it must be cleaned of plaque in order to maintain the integrity of the part and restore its original appearance. For fast, efficient processing, a sandblasting chamber is used. This is a closed type design that allows you to clean metal workpieces from rust and decorative coatings.

Sandblasting chamber

Main types of compressors for sandblasting machines>

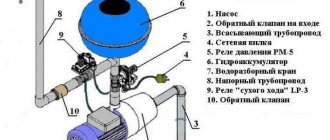

There are mainly 2 types of compressors used in sandblasting machines:

- screw;

- piston

In most cases, when manufacturing independently, preference is given to piston options. These compressors are characterized by high performance, but the air is supplied into the main line in certain bursts. To eliminate this problem, an additional receiver is installed.

Screw and piston compressors are used in sandblasting devices.

Some users also note that piston devices sometimes have problems with oil supply. This leads to the appearance of moisture-oil condensation. The consequence of this nuance is the formation of lumps in the abrasive material, which can lead to tool failure.

The operating principle of a sandblasting machine with a screw compressor is somewhat different. Here, the device is based on 2 worm-type gears, rotating in different directions. The main advantage is the absence of noise and unnecessary vibrations. It is for these reasons that if you plan to assemble a mini sandblasting machine for home use, it is better to choose a screw compressor.

Based on the type of power supply, compressors are divided into diesel and electric. Each option has its own advantages and disadvantages. If you plan to assemble a small mobile device, it is better to give preference to the diesel option, the main advantage of which is that it is not connected to a 220 V network.

Accordingly, the device will be convenient to carry around the site, for example, to remove paint from a fence or gate. Another advantage of a diesel compressor is the ability to automatically control engine speed. This makes it possible to regulate and save fuel consumption.

When making sandblasting yourself, preference is given to piston compressors.

The advantage of an electric compressor is lower fuel costs, but there is always a connection to the presence of a power outlet. It can be used at any temperature, while to operate a diesel appliance in frosty conditions, you will have to additionally purchase a cold start and preheating unit. Diesel engines really don't like low temperatures.

If you want to save as much as possible, you can make the device yourself using available components. In particular, ready-made compressor heads, which are removed from the pneumatic brake equipment of such cars as ZIL and MAZ, are suitable for work. They can often be found at old salvage yards, flea markets or on classifieds websites. For normal operation of the head, you will need to equip it with a receiver, as well as a frame for convenient fastening of other structural elements.

Using sandblasters

A sandblaster is a tool that will remove old paint, rust, debris and other surface imperfections before powder coating and painting.

To use a sandblaster correctly and get the desired effect, you need to know the basic principles of using this device. Here are some of them:

Step #1: All sandblaster valves must be closed, including the bottom mixing valve.

Step No. 2: fill the reservoir with the selected media.

Step #3: You should wear protective clothing, including a respirator, blasting caps, welding gloves and long shirts to avoid possible problems.

Step #4: you need to get rid of moisture and connect the air supply. Increase pressure and adjust it.

Step #5: Now the nozzle valve opens and the mixing valve closes. The main air valve then opens, which regulates the air flow into the tank. The pressure inside the tank should be increased.

Step #6: The mixing valve opens halfway. As soon as the pressure in the tank is increased, the other valves close. The nozzle is directed in the desired direction. At this time, the mixing valve opens slowly so that the sandblasting is distributed over the desired area.

Sandblasting is a technology for cleaning surfaces with abrasives.

The use of sandblasting surfaces has been popular for a long time and does not lose its relevance. When deep cleaning metal structures or facades, oil stains, rust, burnt marks, mold, soot and scale disappear. This technology allows you to remove all excess from the surface and prepare it for further processing. The equipment is also used for complete degreasing of a given area.

Cleaning technology involves using compressed air combined with abrasive particles. Using special equipment, high-pressure air is supplied, acting on the surface and removing unnecessary particles from it. With low pressure and gentle types of abrasive, you can gently clean modern composite materials that require careful handling, for example, the surface of an airplane, car, boat, helicopter, and others.

Cleaning technology is constantly being improved, and manufacturers are releasing new abrasives for various surfaces.

Required Parts

If you have a desire to make sandblasting with your own hands from a gas cylinder, it should be noted that it is no more difficult than sandblasting from an ordinary plastic bottle.

- ball valves in the amount of two pieces.

- gas cylinder.

- pipe, it will be used to fill the reservoir with consumables.

- tee in the amount of two pieces.

- sleeve 15 millimeters in the amount of two pieces.

- clamps.

- tape required for sealing at joints.

Types of structures

Types of sandblasting units vary depending on the task at hand. If you need to decoratively process glass, it is advisable to use a sandblasting chamber. To clean parts, an open type device is used. An open type sandblasting machine (depending on how the abrasive is supplied) is divided into several types:

- pressure;

- injection.

The pressure apparatus supplies air inside the unit, as well as into the dispenser of the sand container. The air flow will move, and then the compressed gas will enter the hose with a nozzle. The nozzle will determine the shape, as well as the pressure of the jet. This type of machine is usually used to process large surfaces and can be used for many hours.

The injection apparatus differs in that sand and air will move through different hoses. As a result, a small pressure will be created, which is suitable for short-term work.

Selection principle

When choosing a chamber for a sandblasting unit, you need to pay attention to a number of factors:

- The size of the device depends on the dimensions of the workpieces being processed.

- The compressor power depends on the type of material being cleaned.

- The performance of the equipment depends on the abrasive feed rate.

An inexpensive sandblasting chamber is suitable for your home. This will be enough to clean machine parts, metal structures, channels, pipes, sheets.

Device size

Overview of species

Today, manufacturers produce two types of sandblasting chambers - inhabited and uninhabited. The most popular are the first machines, which are characterized by the following operating features.

- The inhabited sandblasting chamber is a separate room with a high degree of sealing. There is an operator inside the room who processes incoming products. This is mainly industrial equipment.

- Inside the sandblasting chamber, the walls are covered with shock absorbers that can withstand and dampen the ricochet of abrasive.

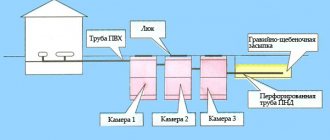

- After the abrasive material hits the surface being treated, the destroyed particles of dirt and abrasive fall onto the floor grate, from where they subsequently enter the collection and return chamber.

- The accumulated mass is sent to a separator operating on a cyclonic principle. It separates waste and abrasive, which can be reused.

As a result, upon completion of the work, dust and waste go into a storage tank, which is located outside the chamber, and high-quality abrasive goes into a hopper, where it will await subsequent procedures.

The difference between uninhabited automatic chambers for processing materials is their small area. If you look at it externally, such machines are not a room, but a table-top rectangular box with holes provided for the operator’s hands.

Features of sandblasting

The main feature of sandblasting is the wide range of tasks where it can be used. Today, using the device, you can clean almost any surface by choosing the right abrasive and method of exposure. In addition, after processing the material, its service life is automatically extended up to six times. This allows you to save on repairs - both current and major.

The sandblasting cleaning method allows you to degrease the surface for further processing, clean glass for decoration, and create roughness, thus “aging” the material. The advantage of this processing method is high speed, long-lasting effect, gentle effect and quick achievement of results.

Making a sandblasting chamber

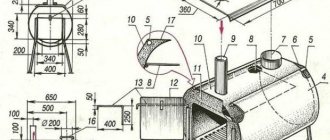

Before proceeding directly to the assembly, it is necessary to take into account a number of factors: draw up a competent drawing and description (one of the options will be presented below), select all the necessary components and decide on the location.

You always want your own sandblasting chamber to be as large as possible, but this will entail a number of consequences: you need a more powerful hood, as well as more durable materials for the body.

The sandblasting chamber is a metal box containing:

- holes for gloves;

- observation window;

- holes for supplying a hose for a gun;

- ventilation holes;

- viewing window;

- bottom grid on which the workpiece will lie;

- hopper for collecting waste abrasive and debris.

Assembly order

The sandblasting chamber assembly procedure includes several stages

It is important to follow their sequence, otherwise it may create some inconvenience and delay assembly. The material you will need is a corner with a shelf of 25-32 mm, galvanized steel 0.5 mm thick, impact-resistant plastic, rivets

The manufacturing procedure is as follows:

- We cut the corners according to the previously prepared drawing.

- Using welding, we assemble a frame from them.

- We attach a reinforced mesh as a bottom, on which the workpiece will be located. The mesh must be strong to support heavy products.

- We light from the two upper corners so that there are no shadows. This will allow you to work with greater comfort. The lighting should be bright enough, as there will be a lot of dust inside. It is worth remembering a little trick: if you choose white light, for example, neon lamps, with this spectrum the view will significantly deteriorate. It is better to use yellow, for example, incandescent lamps, or LED lamps with a suitable spectrum. The principle is the same as in fog lights, thanks to which you can distinguish something in bad weather.

- We place pre-cut sheets of metal on the sealant. It is necessary that one of the walls can be opened for inserting and removing parts and servicing the chamber from the inside.

- Additionally, we fasten the metal to the corners with rivets.

- Using scissors, we cut out the necessary hole in the metal for the ventilation mittens.

- For safety reasons, it is better to make the viewing glass from impact-resistant plastic rather than glass, since it is possible that abrasives (not only sand, but also metal balls) will be used in the chamber.

- The chamber must be equipped with a powerful hood (the more powerful, the better, at least 1500 liters per minute).

Safety precautions

Using a sandblasting chamber, like sandblasting without it, requires compliance with the same safety measures

It is important to wear safety glasses, and in the case of a sandblasting chamber, only a respirator is sufficient. A fully covered suit and closed shoes are required.

It is also important to remember the safety of others. It is advisable that the camera be installed in a separate room where no one will be present.

We saw that making sandblasting with your own hands is not so difficult. It is enough to have certain skills and a great desire. Thanks to such efforts, you can save a lot of money and make a worthy analogue of the factory options.

A sandblasting chamber will be an excellent assistant and addition to your device, since thanks to it, performing assigned tasks will become less harmful to health, more comfortable and, accordingly, productive.

Safety precautions

Whatever one may say, abrasive processing is a risk to human health. The master inhales dust and particles of material poured inside. Therefore, the main safety measures remain the protection of eyes, skin, hearing and breathing. When working with sandblasting, the particles have a speed of 650 km per hour. Improper use may result in serious personal injury to the employee.

The surface cleaning process itself is very noisy and dirty. Therefore, it is necessary to ensure that the master has a special suit and shoes for work, puts on gloves made of leather, and also does not remove the sandblasting helmet, into which purified air is supplied. The use of respiratory protection is mandatory.

How to do it yourself?

To begin with, it should be noted that you will not be able to make habitable type sandblasting yourself. This is only possible in a factory environment, and it is necessary to carefully approach the design of such a room. In addition, the cost of such installations reaches 1.5 million rubles, which is unprofitable for those who want to use a sandblasting chamber on the farm.

You can make an uninhabited camera with your own hands. It is noteworthy that with the right approach, the equipment will work no worse than the purchased version. You can achieve the desired result by preparing the necessary tools and quality materials.

The advantage of a stationary camera is its small size. It will not take up much space, and if necessary, it can be transported. In simple terms, a homemade sandblasting chamber is a metal box that can be assembled using drawings and drawings from the Internet.

Safety precautions

Before you begin assembling the sandblasting barrel, you need to take care of safety precautions. Work should be carried out in protective clothing and gloves to prevent damage to delicate areas of the skin from damage.

Work zone

It is usually understood as the space inside the chamber, which is tightly closed during surface cleaning.

It is important to provide a special mesh or grate on the floor of the working area so that sand or other abrasive does not linger in the chamber during the process, but falls inside

Also, the device should be equipped with a viewing window so that the operator can monitor the process and evaluate the result of the work done. Lighting is installed in the upper part of the working chamber to prevent the occurrence of dark areas. This is necessary to ensure that the material is cleaned at a high level. In this case, the lamps must be closed so that the abrasive does not damage their surface.

Bottom

Most often performed conical

In this case, it is important that the bottom has large dimensions, otherwise it will not be possible to organize the free placement of spent abrasive and waste from the processed material. Additionally, when arranging the bottom, it is worth providing unobstructed access to it, so that it is convenient to subsequently pour abrasive and dust into a bucket or other container

Hood

Designed to provide air discharge and remove dust from the chamber. It is an important design element, so it is necessary to take this point into account when assembling the camera. It is recommended to use an electric motor as a hood, the power of which does not exceed 0.75 kW. It would be enough. When choosing an engine, you should give preference to models with a bladed propeller.

Sandblasting machine

It is the basis of the system and is a special installation through which it is possible to organize the processing of surfaces of various materials. Injection guns are considered the most popular. They first pump air into the chamber, and then release sand, which moves by gravity through a hose from a separate container.

Using an injection gun you can remove:

- slight dirt;

- matte layer;

- thick layer of paint;

- layer of rust.

The second most popular are pressure-type sandblasting machines. In them, the air line is divided into two parts. The first leads to a container with abrasive, the second leads to the exit from this container. Such models will speed up the processing process.

General building

With its help, it is possible to connect hinged parts and ensure effective control of the device by connecting electrics. It is necessary to provide openings in the housing for hands, which should be located at a height convenient for the operator. The optimal diameter of the holes is 12 cm. When choosing gloves, you should take this point into account.

Lighting

The camera of the device must be equipped with high-quality lighting

It is important that the working area is completely visible and there is no dark area inside. To protect the lamps from damage from abrasive material, it is recommended to cover them with a plastic casing

On average, two lamps are enough to illuminate a small camera.

For information on the features of sandblasting chambers and their production, watch the video below.

Kinds

Chambers for sandblasting metal parts are divided according to various factors. By design, two types of models can be distinguished:

- Manned vehicles. These are large-sized structures used for cleaning large parts, objects, and machines. These are closed metal boxes, inside of which there is a movable sandblasting nozzle. The operator controls the technological processes while inside the chamber. The advantage of habitable structures is the ability to process workpieces of any size.

- Uninhabited units. These are small-sized boxes that do not exceed the height of the operator. They consist of metal walls, a sight glass, a hole for a sandblasting nozzle, and two rubber gloves fixed inside the chamber. The operator is located outside and controls all processes using attached gloves.

Inhabited structures have a serious drawback. Due to the operator being inside a metal box, the risk of harm to health increases significantly. Before operation, the camera must be checked for the presence of an effective ventilation system, and the operator must wear a respirator, protective gloves, goggles, and overalls made of thick fabric.

There are three types of uninhabited chambers:

- Ejector models are small-sized structures that allow you to process small workpieces made of glass, plastic, and metal.

- Pressure models are models with increased power. They are used when working with metal surfaces due to their ability to clean off thick deposits.

- Automatic models are equipment that is operated using a control panel. For the operator, this is the safest sandblasting option.

How to choose a sandblasting chamber?

The initial data for selection are:

- A waste separation system is mandatory (it is present in pressure-type chambers with an air exchange of more than 8000...9000 m3/h).

- Power of ventilation units (calculated from the condition that sandblasting performance should be 4...4.5 times less than the performance of fans).

- The presence of a cyclone for collecting particularly fine fractions of abrasive or sand.

- Is there a unit for automatic cleaning of pipelines in the design (by the way, they should not be made of plastic: this material can change its characteristics depending on temperature, which negatively affects the values of pneumatic resistance and the actual performance of the installation).

- Materials adopted for wall cladding (the higher their elastic characteristics, the more effective the cleaning is).

- Availability of useful additional options (trolley, rail track, etc.).

The price of the basic configuration of a pressure-type sandblasting chamber should also take into account the presence of several sets of gloves for the sandblasting chamber, protective masks, helmets, overalls and shoes for operators.

Buy or make a homemade sandblasting chamber - which is better?

It is unrealistic to make an inhabited chamber yourself - this is only possible in a factory after careful design. The total cost of such installations starts from 1–1.5 million rubles; they include a housing made of steel or sandwich panels, a gateway with swing gates, grated flooring, complex ventilation, lighting, control systems, etc.

It is quite possible to make an uninhabited camera yourself, and it will work no worse than a purchased one. The feasibility depends on the availability of tools, materials, and accessories: if everything has to be purchased separately, it is easier to buy a ready-made camera in a specialized store.

How to make a camera with your own hands

A small stationary camera will not take up much space; it can be stored and used in a garage or shed. Essentially, it is a box made of metal or other material, lined with metal more than 1 mm thick. It is best to place the finished camera on a table or other stand - this way it will be comfortable to work with it.

Work zone

The working area is the inner part of the chamber, closed during cleaning, into which the product is placed. There must be a mesh or grate on the floor of this area so that sand does not linger inside and fall through the bottom. The device must be equipped with a viewing window through which the operator can observe the process and evaluate the results.

Good lighting is planned at the top of the working area so that there are no dark areas left. The lamps must be closed, otherwise dust and sand will quickly damage all contacts. Inside the housing there are gloves attached with a clamp on the flange, as well as a sandblasting sleeve with a nozzle (in the pressure chamber) or a gun (in the injection chamber).

Cone bottom

The bottom must be large, otherwise the workings with abrasive will not be able to fit and will begin to layer and accumulate in slides. To easily remove waste, you need to provide unobstructed access to the bottom (it is most convenient to pour abrasive and dust into a regular bucket). If the chamber assumes the possibility of returning the mass, and its collection is carried out automatically, the bottom walls should be sloping.

Hood

The hood creates a vacuum of air and removes dust from the sandblasting chamber. It must be equipped, because part of the sand or other abrasive material, after hitting the surface of the product, is destroyed and turns into flying dust. To equip the hood, it is recommended to use an electric motor with a power of 0.3–0.75 kW with a bladed propeller.

Sandblasting machine

The basis of the entire system is the sandblasting unit itself, which processes various surfaces. The most common are injection guns that operate on a simple principle: compressed air is supplied separately from sand, and the latter flows by gravity from a separate container through its own hose. Typically, such devices are used to treat delicate surfaces - removing small dirt, frosting glass. The injection device will also remove a thick layer of paint and rust, but 3-4 times slower than a pressure device.

Pressure-type sandblasting machines have an air line divided into two parts: one goes into the container with abrasive, the second goes to the exit from it. After the sand is released under pressure, it is connected to a stream of compressed gas, and the acceleration of the particles will be maximum. With this processing, the speed of action is an order of magnitude higher.

General building

This section of the sandblasting installation connects the attachment parts, device control, and electrics. The holes for the arms should be located at a height convenient for the operator, and the distance between them should also be optimal. The most comfortable hole diameter is considered to be 10–12 cm, and this is the size of gloves that should be selected.

Sandblasting gloves must be strong and dense, because they will protect your hands from ricochet. To fasten them, it is better to choose flanges, which, after putting on gloves, are clamped with clamps. At the top of the common body there is an air damper through which clean air will flow.

Lighting

The lamps should illuminate the work area evenly so that all areas of the workpiece are clearly visible to the operator. To protect the lamps from impacts and dust, they are covered with a plastic casing on top, and to maintain transparency, a fine-mesh mesh is placed on the outside (the same device should be attached to the viewing window). Usually, two light bulbs are enough for high-quality lighting for an average-sized camera.

Specifications

For glass processing, it is recommended to use special abrasive or polishing compounds. It could be:

- garnet or quartz sand;

- corundum;

- Cooper slag;

- other compositions.

The performance of the chamber when processing glass will depend on the time of exposure to the surface, the size and other characteristics of the abrasive particles, and the pressure under which the abrasive is applied to the surface. To ensure efficient operation, the device must be connected to a 380 volt power supply.

What is it - design and types of devices

Historically, there are several types of abrasive treatments that are performed using different technologies. Thus, devices on the market may differ in their design, operating principle and characteristics. However, most sandblasters are based on the same design principle.

At the heart of every sandblaster there are several key elements:

- container for abrasive material (sand, steel shot, etc.);

- a hose made of friction-resistant material through which abrasive flows from the container;

- a nozzle on the hose that allows you to regulate the supply of sand;

- controls - instrument panel, power supply and automatic control.

The container for the sandblaster can be sealed or not sealed. In the first case, sand is supplied under pressure, which increases work efficiency. Such sandblasting machines are called pressure blasting machines. In the second case (unpressurized), sand or other abrasive is supplied under normal atmospheric pressure. Such devices are cheaper, but in terms of their efficiency they are significantly inferior to sealed ones.

Injection devices are also used in cases where the surface treated with sand may be damaged due to excess power. Containers differ in volume, material of manufacture, and shape.

There are two types of sandblasting hose: for supplying dry sand and for supplying wet sand. All sandblasting machines in Russia are designed to supply wet sand, since dry processing is prohibited by sanitary and epidemiological rules. The same ban exists in some other countries.

The ban is due to the fact that processing with dry sand is dangerous for the worker and the environment due to the fact that a large amount of silicate (dust) is released into the air, which enters the human lungs and settles on surrounding objects. Silica dust can cause respiratory diseases in humans.

The nozzle on the hose is a ceramic or steel structure that delivers sand directly into the gun (outlet). Ceramic materials are more resistant to friction, so their use is preferable.

On the other hand, some of the metal types of nozzles can significantly reduce the amount of abrasive spent on a particular type of work (up to 40%), which in certain conditions can save more money.

Each sandblaster has an instrument panel that allows the worker to operate it. Some of the devices are equipped with special automation, which can automatically control the power of the device or the supply of sand. This makes the sandblaster safer and easier to use.

What type of container is on your sandblasting machine?

SealedNot Sealed

Chamber

Usually, when we talk about sandblasters, we are talking about the design described above. However, chamber devices for sandblasting, which can be conditionally called hermetically sealed, also deserve special mention. This is stationary sandblasting equipment in the form of a metal chamber with a door. Objects that need to be processed can be placed inside the chamber.

Like conventional sandblasting machines, chamber-type equipment is equipped with an abrasive container. The difference from non-stationary devices is that during operation the device emits a minimal amount of dust and sand into the environment, which allows people without protective equipment to be free in the room.

Design and principle of operation

When choosing a sandblasting chamber, you need to pay attention not only to cost. The equipment must ensure high-quality cleaning of scale and rust from the surface of parts. The capabilities of the units depend on several technical characteristics:

- diameter of the nozzle and connecting hoses;

- compressor power;

- abrasive material feed rate;

- control system;

- camera dimensions.

During the processing process, metal products go through the following stages:

- First, the part is secured in the chamber using clamps.

- After this, special containers are filled with abrasive material.

- The operator starts the compressor, which allows you to regulate the air flow rate. For this purpose, a system of valves and shut-off valves is used. During the processing process, air is mixed with abrasive particles. The resulting mixture comes out through the nozzle.

Thanks to abrasive processing, you can evenly clean the product from plaque, rust and dirt. Before starting the equipment, it is necessary to check the condition of the connecting hoses and clamps.

Recommendations for making a sandblasting chamber

Before you start creating a camera with your own hands, you need to develop its design and draw up a drawing. This will allow you to clarify the dimensions, purchase and measure materials correctly. The internal parameters of the device should not be made too large to avoid the effect of strong rebound and additional impacts of the abrasive on the product. If the chamber is still large, it is worth lining its walls from the inside with soft material, for example, rubber. Other tips for creating a sandblasting booth include:

it is necessary to pay close attention to the quality of ventilation of the installation; to install the viewing window, it is advisable to purchase impact-resistant plastic, since simple glass will break quite quickly; It is recommended to lay a reinforced mesh at the bottom of the chamber, and place a strong chute under it for waste abrasive; To place any products in the chamber, including those with a non-standard shape, the sides should be covered with a tarpaulin and not made rigid.