Internal or external

Surface devices are designed for wells and shallow wells. The distance to the water surface should not be more than 8-9 m. For wells with greater depth, submersible pumps are installed, which is why they are also called deep pumps.

Surface devices are placed outside the well. This makes them easy and convenient to maintain. They are often installed together with a storage tank to stabilize the pressure in the system. But because the surface pump operates outside the well, it makes a lot of noise and also takes up space. As a result, it is necessary to arrange an area for it and build a building to absorb sounds. Since the pump is out of the water, its motor is not cooled by it.

Layout of internal and external pump for a well

Submersible devices are divided into several types:

- vortex;

- screw;

- vibration;

- centrifugal.

Vortex pumps have one impeller. It draws water into the inner part and pushes it out into the outer part, due to which a vortex appears. As water passes through the wheel, its speed and pressure increase. The design of these pumps is simple, so they have a low price. But because of this, they have low efficiency and are unable to work with liquids that contain sand or other similar impurities, as this leads to rapid wear of the device.

Vortex pumps are recommended for use in wells with low flow rates or when a small water supply is required.

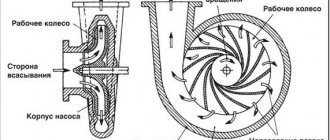

Vortex pump device

The main working element of a screw device is the screw (auger). Water, getting inside the pump, is gradually pumped by the auger, eventually pressure appears and the liquid is forced out. Just like the vortex device, the screw device has a simple design and low price. Recommended for use in wells with low flow rates. But compared to a vortex pump, a screw pump is more resistant to impurities in water.

Screw pump design diagram

Working principle of a screw pump

Water is pushed out of the well with special screws. They are located inside a housing with grooves and rotate during operation. The principle of operation is similar to a meat grinder, but water is “sucked” into the pump and supplied to the top.

This pump has its advantages and disadvantages. The advantages include the following factors:

- high water pressure at the outlet;

- there are no restrictions in its operation related to the depth of the water layer;

- no pressure drops;

- no noise;

- simplicity of design.

In addition to the positive, there are also negative points. They are also worth considering:

- screw pumps cannot boast of compact dimensions;

- there is no possibility of regulating the liquid pressure;

- Only submersible models can be used;

- the liquid is supplied with sand, if there is sand in the well.

In some cases, pushing water and sand to the surface can become a problem (causes frequent breakdowns).

Vibratory or centrifugal

The vibration device is capable of pumping water from wells up to 40 m deep. They have a simple design and a relatively low price. The vibration pump does not require constant maintenance, and is lightweight and small in size. But it is unable to work for a long time, and may also not produce enough pressure. The main drawback is that due to vibration, the walls of the well are destroyed, and it gradually fills up.

Vibration pump design diagram

A centrifugal pump, unlike a vibration pump, operates without damaging the walls of the well and does not make noise. There is also a large selection of devices of this type with different characteristics.

The impeller of a centrifugal pump consists of front and rear disks, and between them there are blades directed in the opposite direction of its movement. The height of the pressure depends on the number of these wheels; the more there are, the higher it is. Therefore, centrifugal pumps have different heights.

Note! Unlike all previous devices, centrifugal pumps are able to operate for a long time, and they are also more energy efficient.

Operating principle of a centrifugal pump

Which pump is best for a well?

Feed height

An important parameter when choosing is the height of the water supply. If the well is 100-150 meters deep, a centrifugal pump will be the best choice. The screw ones remain effective up to 50 meters.

It is worth paying attention to the length of the cable. It is better if it is enough for the entire depth of the well. Otherwise you will have to build it up, which is less convenient.

Water purification quality

Manufacturers of screw pumps allow the presence of sand in the pumped water to be no more than 50 g/m3. Screw ones are less capricious. This makes them a good choice for wells where the sand content in the water is high.

Budget

Screw models are comparatively cheaper than centrifugal ones. First of all, due to a simpler design. But it is worth remembering that savings can result in frequent pump breakdowns. Therefore, even when purchasing screw models, it is worth choosing more reliable, well-known manufacturers.

Economical

Due to their higher efficiency, centrifugal models are more economical. At least from the point of view of power consumption. With the advent of automatic home water control systems, it has become easier to reduce energy costs. And here again the advantage lies with centrifugal models.

The best surface pumps

Marina CAM 80/PA

Technical characteristics of the surface pump:

- suction depth 8 m;

- head – 42 m;

- weight – 7.2 kg.

The Marina CAM 80/PA device operates silently and is additionally equipped with a water control sensor. Installation is carried out only in a horizontal position. The hole diameter is 1″.

The Marina CAM 80/PA pump produces stable pressure.

Note! Among users, it is often used to pump out initial water from a well with a high content of impurities.

Grundfos MQ3-35

The maximum head of the device is 33.8 m, the suction depth is no more than 8 m. The pump is installed horizontally and weighs about 13 kg. Equipped with a sensor that monitors the water level, protection against overheating, as well as an additional function for increasing pressure.

Most users are satisfied with this model, as it does not require maintenance for a long time and produces a constant and stable pressure.

The main disadvantages are the short cord, 2 m long, and the heavy weight. The device produces more noise than specified by the manufacturer. It is recommended for pumping only clean water, without impurities, otherwise the parts will wear out within one or two years, which leads to pump failure.

Gilex Jumbo

Model 70/50 Ch-24 is installed in a horizontal position. The maximum pressure is 45 m. The cord length is 1.5 m. The device is equipped with a 24 liter hydraulic tank and is fully automated. The body is made of cast iron and has small dimensions. Pressure adjustment possible. All parts and connections are made with high quality and without backlash.

The main disadvantage of the 70/50 Ch-24 Gilex Jumbo model is that the pump does not have protection against dry operation, and the cable is short.

Whirlwind PN-1100N

The centrifugal pump of this model is designed for installation in a horizontal position. The maximum pressure it produces is 50 m, the suction depth is 9 m. The engine runs quietly, the body is made of stainless steel and is light in weight. The pump is recommended for use with clean water only.

During operation of the pump, you need to ensure that it does not run dry, since the device is not equipped with a water control sensor.

Wilo PW-175EA

The maximum output pressure of this pump is 35 m with a suction depth of 8 m. Just like the previous model of the surface device, it is installed horizontally. The Wilo PW-175EA pump is equipped with overheating sensors and has compact dimensions. Power consumption 125 W. The device is assembled reliably and efficiently, and operates quietly.

The only drawback identified by users is that after a long period of inactivity, it may be necessary to push the impeller for the first start (with a screwdriver).

NeoClima GP 600/20 N

The pump can operate with a suction depth of up to 8 m. The maximum pressure it produces is 35 m. Power consumption is 600 W. The device is equipped with an overheating function. Equipped with a hydraulic tank with a volume of 20 liters. Recommended for pumping only clean water.

The pump body is made of stainless steel. The engine runs silently.

Note! Although the device is made in China, all parts are made and connected with high quality.

Judging by user reviews, the pressure switch may need to be adjusted, otherwise the pump will not turn off.

Vibration pump

The operation of the electric pump occurs due to the fact that a field is induced around the core with alternating current supplied to the turns of the coil, changing direction 50 times per second. Naturally, in one direction of the magnetic field the armature is attracted to the core, in the other it is repelled. Armature vibrations are generated and transmitted by the rod to the piston of the working chamber. It moves back and forth along the axis, while water is either drawn into the chamber through the receiving holes or pushed into the pressure line. The outlet of water from the working chamber through the inlet is blocked by check valves.

Advantages

- Unpretentious operation and maintenance due to the simplicity of the design;

- No need to worry about lubrication due to the absence of rotating and bearing parts;

- Less wear and tear, since parts do not heat up;

- They work in water containing mineral salts and alkalis;

- Work in water of any temperature;

- Low power consumption for operation;

- According to manufacturers, they have a long service life (users, naturally, differ in their opinions).

Flaws

The generation of vibrations in a water source when pumping is the main disadvantage. In addition to the unsuitability of the vibration pump for pumping wells, of course, there are other disadvantages:

- The vibration pump coil overheats even during short-term idle operation (5-30 seconds is enough). It is recommended to purchase vibration modifications with a thermal protection option. For example, the “Baby” modification turns off when the coil heats up and turns on after it cools down.

- Vibration mechanisms respond very negatively to changes in mains voltage: performance drops by 50% when the voltage drops by 10%. Naturally, voltage surges cause an increase in load on the mechanical parts and components of the device. Therefore, a voltage stabilizer is needed when the device is connected to the network. According to the passport, to avoid overheating: after an hour of work, you need to rest for 20-30 minutes. When installing a stabilizer, the operating time can be increased.

- Naturally, constant vibration during pumping leads to loosening of the threads in the joints of the parts. You have to check them from time to time.

- Rubber parts wear out quickly when the vibration pump operates with contaminated water. It is advisable to protect the suction pipe with a mesh filter.

- The presence of steel bolts in the body that quickly rust in water.

What are they used for?

Due to the characteristics of vibration pumps and the underground structure of the water source, vibration pumps are not used to equip borehole sources. The fact is that the well is equipped with a casing pipe, at the bottom of which there is a mesh filter, which leaves solid particles contained in underground water “overboard”. Naturally, during pumping, a sand cone is formed around the filter from particles of different fractions that have not passed through the filter cells. This cone becomes an additional natural filter for groundwater.

When vibration equipment is used to pump out a well source, solid particles are separated into fractions in a multi-fraction cone. Small particles fall down to the filter mesh, large particles rise up. Naturally, grains of sand with sizes close to the size of the filter mesh holes clog them, and the rate of entry into the casing and the volume of pumped liquid decrease as a result. If the grains of sand are smaller than the filter cells, they end up in the pumped water, and then events develop in two directions:

- The well is “sandy” - the source water supplied by the vibration mechanism becomes cloudy;

- The well silts up - small particles gradually clog the lower internal space of the pipe and the vibration pump located in it.

The second situation is serious - silting of the pipe. There are also two options here:

- The device can be removed from the pipe (you can, of course, disassemble it into parts and clean it yourself, but to clean the pipe, contact specialized specialists);

- The mechanism will get stuck when removing the source from the casing, after which, of course, you will have to fork out money for a new well (the worst case scenario).

In addition to these problems, another one very often occurs - vibration pumps become the culprits in the process of ground movements and destruction around the pipe. The casing collapses. Naturally, if the house is located next to it, the foundation sags.

From the above it is clear that the vibration pump is not used as a downhole pump. For well pumping, vibration-type equipment is suitable. Even if the water level drops and it enters the intake pipe with silt and sand rising from the bottom, it is enough to turn off the mechanism and wait until the well is filled and the suspended matter settles.

The vibrations generated by the vibrating pump come to the rescue when you need to pump a new well or increase the flow rate of a water source. In this case, they are used to obtain the desired result.

Naturally, in addition to pumping from a well, vibration modifications are used to supply liquid from various containers, for example, tanks, ponds, and flooded rooms.

Choosing a vibration pump

The main choice is technical

The main parameters of any type of pumping apparatus are:

- Q – volumetric fluid supply,

- N – power consumption,

- p – pressure,

- N – pressure,

- h – efficiency.

Naturally, the main function also determines the technical characteristics by which the modification of the working mechanism is selected. The technical parameters are primarily:

1. Height of water rise - pressure (H). This modification characteristic is specified upon purchase. The required pressure is calculated by adding the distance from the top of the well to the water surface of the source, the immersion depth of the mechanism, the length of the main pipes (x0.1), of course, multiplying the resulting sum by a factor of 1.2, which takes into account losses. Modifications with pressure ranging from minimum - 40 m to high - 90 m are sold. Of course, the closer the source is to the house, the higher the actual water pressure in the house will be. If the pressure is insufficient, there will be no moisture at the analysis points. (The “Baby” modification creates a pressure of 56.6 m, the pressure of the Chinese modification “Patriot NP” is up to 80 m, the pressure of the borehole “Vodojet” is up to 110 m).

2. Of course, the performance of the electric pump (Q) is the main indicator. Naturally, it must correspond to the planned load and not exceed the flow rate of the water source. There are three categories of pumping devices based on performance: [p]

3. Optimal immersion depth (h is the same for all manufacturers - 7 m).

4. Power (N) is the energy consumption of the pump to create pressure and flow (flow is the volume of liquid pumped by the pump per unit time). In most cases it does not exceed 300 W.

5. The maximum pressure (p) created by vibration pumps is 0.4 mPa.

Subtleties of choice

Following is noteworthy:

- Is there an adapter that allows you to attach a hose/pipe with a diameter of 19 or 25 mm to the vibration pump;

- How convenient is the threaded connection?

- Is the vibration pump cable long enough to avoid splicing it in the cavity of the source casing pipe (the length should be enough to reach the nearest power supply);

- What kind of insulation does the cable have (naturally, the best insulation is rubber, with which the mechanism can be confidently used at any outdoor temperature in any season).

Water intake from above or below is fundamental

Some vibration modifications have an inlet pipe in the upper part of the housing, some - in the lower part.

If you choose a submersible vibration pump with a top position, you will not have to worry about dirt or sand getting in the water supplied. A device of this modification is placed above the bottom of a water source with a minimum height margin of 30 cm.

To pump out liquid from a well being constructed, increase the flow rate of wells, or pump new ones, vibrating pumps are used that take water from below. In this case, you need to ensure a minimum height reserve under the vibration pump of 90-100 cm, and you need to provide the vibration pump with thermal protection in case it may overheat if left without water (this is necessary, and it does not matter where the suction valve is located).

Housing material

Naturally, to the previous vibration mechanisms with aluminum casings, modifications with plastic casings that are not subject to corrosion have been added. It's hard to recommend anything here. Therefore, the choice of “which is better” depends on the buyer’s decision.

Recommendations for selection

When choosing a pump, you should give preference to devices with a steel or cast iron body, as they are more durable. To prevent the device from breaking due to voltage surges in the electrical network, it is recommended to install surge protection. To prevent working elements from wearing out too quickly, filters should be installed.

To protect the pump from overheating and dry operation, it is better to install sensors if it is not equipped with them in advance. When calculating power, you should choose a device that is 20% more powerful so that it does not constantly work at maximum loads, as this will quickly lead to its breakdown.

Well pump: which model to choose

Here are a few examples of the most popular pumps in ascending price.

- VORTEX CH-100V (1100 W). This model is a representative of vortex borehole pumps. The immersion depth declared by the manufacturer is 35 m. Case diameter is 102 mm. Thanks to its sufficiently high power, it can pump up to 2400 liters per hour. However, with a head of 60 m, the volume decreases to approximately 1600 liters. Buyers note the reliability of the pump, which would be quite rare in this price category. Like all vortex pumps, there is a relatively high noise level. Such a well pump costs 6,500 rubles.

- Well pump BELAMOS TF3-60 (800 W). Popular model from a well-known manufacturer. Has a check valve. The declared productivity is 3000 liters per hour. The owners note that even with a fairly deep immersion (maximum - up to 40 m) it retains power. Head - 60 m. Case diameter - 75 mm, all elements are made of stainless materials. Cost - from 8000 rubles.

- Aquarius BCPE 0.5 - 63U (1270 W). More expensive model. We were unable to find a purchase option cheaper than 10,000 rubles. The maximum pressure is 90 m, which is quite a lot for this price segment. The declared productivity is 2900 l/hour. Stainless steel materials and food-grade plastic were used in production. Copes well with voltage surges. The downside is that there is no check valve.

- BELAMOS TF3-80 can be found on sale for 11,000 rubles. And this is a good price for such a device. The body is made of stainless steel, the impeller is made of food-grade plastic. Diameter - 75 mm. Immersion depth - up to 80 m. Productivity - up to 2700 l/hour. Includes 50 meter power cord. The owners note that such a pump can fully satisfy the needs of a large family.

- QUATTRO ELEMENTI Deep 1500. Sold for 14,000 rubles. In return, the consumer receives a centrifugal pump capable of providing a lifting height of up to 115 m. It has a low noise level and high productivity - up to 5500 liters per hour. Among the features are the immersion depth of 2 m, the length of the power cable - 1.5 m. These points need to be paid attention to.

Which pump do you prefer? Tell us about your decision in the comments!