Principles and nature of the work performed

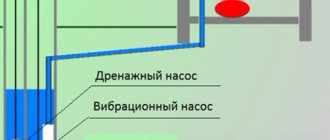

Depending on the principle of operation, water pumps can be vibrational or centrifugal, which include screw pumps.

In vibrating models, liquid is pumped due to a rapid and sharp pressure drop. Therefore, such devices are rarely used for water inflow from wells. Much more popular are auger pumps.

They are widely used in everyday life, in construction and production. They are often purchased for pumping liquid from various sources (wells, wells, open reservoirs, technical tanks). In addition to pumping, they can also be used in cleaning systems.

The main element of the pump is a screw - a rod with a continuous helical surface along the longitudinal axis. The principle of operation of the pump is that liquid enters the working chamber through the receiving holes. In the working chamber, a rotating auger on the rotor stimulates the movement of water. As a result, a pressure is created that forces the liquid out. The faster the screw rotation speed, the higher the productivity.

The advantage of auger systems is that they can be used for pumping water with a large number of abrasive particles. For example, in shallow wells, which often contain a lot of sand. The design of the auger prevents sand from getting clogged and blocking the work.

A screw pump, unlike other types of well pumps, has an almost constant outlet pressure, independent of the rotor speed. As the rotor speed increases, productivity increases and pressure remains stable.

Compared to vibration pumps, screw pumps operate more quietly and create almost no unnecessary movement.

Main features of screw pumps

In screw pumps, the working body is presented in the form of a screw, which by rotation creates a turbulent flow of water, which determines the operational features:

- High productivity and water pressure, and multi-stage modifications practically remove restrictions on the depth of intake and the height of water rise.

- Low operating noise and vibration, and the production of unit parts is more uniform, because the resulting forces act in different directions.

- High operational reliability, so unit breakdowns are extremely rare, and the repair itself is not difficult and so expensive.

- Screw pumps are capable of pumping liquid with some contamination with solid particles, and their performance does not decrease, and the pulsation of the water flow is minimal, which allows the units to be used in wells and wells with low flow rates.

Considering these factors, the problem of which pumps are better for a well, screw or centrifugal , may seem to have been solved, but screw pumps are somewhat larger in size, which must be taken into account when selecting a unit for a well with a certain diameter.

What to consider when choosing a pump

The choice of a specific model must be made taking into account its design features and characteristics, the parameters of the well (well) and the manufacturing company.

Pumps for wells or wells can be surface and submersible. The surface one is capable of operating at a depth of up to 10 m. The engine of this equipment is not protected from moisture and therefore requires installation under a roof. A submersible screw pump is much more powerful, has higher efficiency and allows water to be supplied from depths of tens and even hundreds of meters. Submersible models are sealed and remain below the water level during operation. They can function autonomously for a long time. The disadvantage of submersible products compared to surface ones is the difficulty of maintenance.

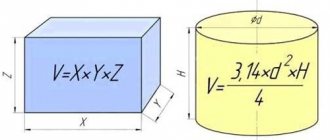

The main characteristics that are taken into account when selecting a model are: productivity, head height and lifting depth. The pressure in the water supply system and fluid flow depend on these characteristics.

Productivity is determined by the volume of liquid supplied to the discharge pipeline per second. It should provide peak consumption with a 10% margin. When calculating consumption, it is necessary to fully take into account all possible directions of consumption and their changes depending on the time of year and other conditions. If productivity is calculated based on average daily consumption, as is often suggested, rather than on peak consumption, then its value may be lower than necessary.

The pressure is measured in meters. To determine the required pressure, you need to add the height of the building and the depth of the source. Add 6 m and multiply the result by the pressure loss coefficient in the pipeline, which is 1.15. If the source is far from the house, it is necessary to add one additional meter of pressure for every 10 m of horizontal pipeline. The vertical distance is taken into account in a 1:1 ratio.

When calculating the required equipment characteristics, it is necessary to include a 10% margin. If the well depth is 90 m, then it is recommended to choose a product with a maximum depth of 100 m.

Important well parameters include diameter (the maximum diameter of the pump depends on it), production depth, and flow rate. These indicators are indicated in the well passport, which is issued by the organization that carried out the drilling. Or you can measure them yourself. It is almost impossible to accurately measure debit. It depends on the measurement technology, climatic conditions, time of year and conditions of use of the well.

The service life of the pump is affected by the quality of the build and the material from which it is made. This is usually stainless steel, occasionally aluminum, which is less durable.

Types of pumps

The following types of pumps are most often used in wells:

- Multistage (centrifugal);

- Screw or, as they are also called, auger;

- Vibrating.

Now let's look at the features of each type.

Pictured is a centrifugal pump

Centrifugal pumps

The purpose of this type of equipment is to lift drinking water from great depths. Centrifugal pumps are characterized by high performance and reliability. In addition, the maximum permissible amount of sand admixture is 180 grams per cubic meter, which is a very large indicator for a deep-well pump.

With their help, you can provide good pressure of water extracted from a depth of up to 120 meters. Therefore, they are used not only in wells, but also in artesian wells. In addition, another advantage of such devices is that they are able to work without interruption for a long time.

As for the design features, inside the device there is an impeller with blades attached to it. An electric motor drives this wheel, resulting in reduced pressure in the middle of the impeller and increased pressure in the area of the blades. Due to this pressure difference, water is first sucked into the center of the wheel and then pushed out into the pipeline.

As a rule, such pumps are equipped with thermal protection, which turns off the device in case of emergency situations. In addition, they are equipped with floats and electronics to protect against exposure to air.

Scheme of operation of a centrifugal pump

The centrifugal pump housing can be made of stainless steel or plastic. As a rule, cheaper models are equipped with plastic cases, costing about $100. The price of expensive models can reach $700.

Italian submersible pumps for wells ZDS and Pedrollo have proven themselves well; in addition, good devices of this type are produced by Denmark (Grundfos), Germany (Wilo), Russia (Vodomet). However, it should be borne in mind that the same manufacturer can produce both cheap and expensive models, the quality of which will vary greatly.

- Submersible centrifugal pump for well

Vibration pumps

The main difference between vibration pumps and other types of devices is that they have no rotating parts. Inside the housing there is a core with a winding to which electricity is supplied. As a result, an electromagnetic field is formed, as a result of which a rod with a piston at the end is attracted to the core.

Vibration pump design diagram

At this moment, water is drawn in, but after a split second the electromagnetic field disappears and the piston returns to its original position, while the check valve closes and water is pushed into the chamber. When the piston and rod are again attracted to the core, water is pushed into the pipeline.

It is not recommended to install such equipment close to the bottom of the well, since as a result of vibration, small sand particles may rise from the bottom. This will lead to rapid failure of the water filter.

Note! It is not recommended to install a vibrating submersible pump in a well that is located on quicksand, as the equipment can negatively affect fragile soil.

Vibration pump "Rucheek"

Vibration pumps belong to the cheap category of equipment, so they are often used by summer residents.

The most common models are domestically produced:

- "Stream";

- "Baby";

- "Summer resident";

- "Aquarius".

The average cost of such devices is about $50. In addition to the low price, another advantage is reliability, since the design does not contain parts that can overheat. However, for a house where a family lives permanently, the best choice is still a centrifugal pump.

Screw pump cross-section

Screw pumps

The main feature of such a pump is that it can pump contaminated water, so it can be used not only for a well, but also, for example, for a reservoir with industrial water to supply an irrigation system with it. In addition, these pumps can work with different types of liquids, so they are actively used in the chemical industry, housing and communal services, etc.

Screw-type submersible pumps for wells are also characterized by very high wear resistance and reliability thanks to a simple mechanism based on a worm screw. As the screw rotates, it creates a cavity that fills with water and moves toward the pipeline. To make it easier to understand this principle, imagine a regular meat grinder in which a screw ensures the movement of pieces of food to the knives.

The only disadvantage of such a pump is that it cannot extract water from great depths. Therefore, if the well is deeper than 15 meters, then you will have to pay attention to other types of devices.

Autonomous water supply scheme

Manufacturing companies

The list of companies, as well as the range they offer, is quite large. The Russian market presents mainly products from domestic, European and Chinese manufacturers. Screw pumps come in different brands.

Highest price segment:

- Grundfos. Excellent quality at a high price, very wide range. Large, world famous manufacturer.

- Gardena. European manufacturer. Prices are above average. The number of models for wells is small.

Middle price segment:

- Speroni. European manufacturer. Quite high quality and reliability.

- Pedrollo. Wide range of models. International company. High level of product reliability.

- Aquario. A large number of models, there are options for narrow wells. Relatively high reliability.

Lower price segment:

- Aquarius. Several dozen models for wells. Well-known Ukrainian manufacturer. Insufficient reliability of pumps.

- Gilex. Products are manufactured in Russia. Popular brand. Conflicting reviews about product quality.

- Belamos. Production is located in China. Reliability is in class.

Generalization and simplification of pump selection for a well

To choose the right pump, you need to consider several parameters:

- Well characteristics: water purity, well depth and flow rate, well bore diameter. The choice of pump depends on the combination of characteristics, because with low contamination, relatively shallow depths and sufficient flow rate, it is advisable to select centrifugal pumps, because their dimensions and electrical power are somewhat lower, which simplifies installation and saves money during operation.

- It is advisable to supply problem wells that have an unstable flow rate, a very low level of water intake, or an increased content of solid particles in the liquid with screw pumping units, because they are less problematic to operate and more reliable under harsh conditions.

Scope of application

Initially, the screw pump was conceived as equipment for pumping liquids characterized by high viscosity. Such units are used in various industries, including not only food and textile, but also chemical.

They are also used in construction. Well, for the installation of autonomous water supply on the site, household-grade screw pumps are usually used. Their services are especially often used if the water contains a lot of sand. In such conditions, the answer to the question of which is better, a screw pump or a centrifugal one, will definitely be in favor of the screw pump, since its “rival” will quickly wear out due to sand.

Vibrating pumps are also not used in such conditions, because vibrations will affect the bottom of the source, and because of this, the amount of impurities will only increase. This means that screw pumps will be the best option.

Equipment classification

All screw pumps for wells are divided into models for standard and deep purpose:

- Standard - used in wells and small wells where the water is saturated with fine sand fractions. They have lower productivity and are designed to work at depths of up to 25 meters.

- The deep-well pump has more power due to the elongated housing and auger. This makes it possible to use it in artesian wells at a depth of several hundred meters. Such products are more expensive.

When choosing a suitable product, you should take into account the features of the entire structure, namely:

- water depth;

- required volume of water consumed;

- its feed speed.

The connection diagram of the screw pump will depend on this. The average electricity consumption of both types is approximately 1.5 kW/hour, when connected to a standard 220 V network. Manufacturers often recommend using a separate power source with additional automatic protection.

Features of maintenance and operation of submersible screw pumps

The design of the device is shown in the photo.

Main parts and components of a submersible screw pump

The operating principle of such units is based on an “Archimedean screw” or a screw shaft, which creates a vacuum at the suction end that occurs as a result of pushing the volume of liquid in the direction of the discharge pipe. Submersible pumps have gained great popularity and wide application due to their several important features:

- Convenient design. Screw pumps are quite easy to operate, which does not require specialized knowledge, and most repair work can be carried out even in the field. For example, it is not difficult to replace the bearing on the drive shaft, and to replace the shaft seal there is no need to dismantle the pump.

- Ease of repair work. In addition to the fairly simple replacement of bearings, oil seals and mechanical seals, ease of dismantling is ensured by the use of standardized self-clamping couplings.

- Careful design development. The suction housing is manufactured to ensure that there is no deposits around it. In addition to the streamlined body shape, the suction pipe can be rotated by 90°.

- No vibration. Even the high number of revolutions of the working bodies and the high production power that electric screw pumps have create almost no vibration. This is explained by the use of rotors in designs made by drawing parts or casting.

- The absence of pump vibration increases their service life.

How best to use

When purchasing a screw pump for an equipped source, you will have to take into account certain operating rules. By following simple recommendations, the homeowner will be able to significantly extend the life of the device. To operate a screw pump in a well, it is advisable to select a pump that can be well mounted on the wall of the shaft. It is advisable to install the device at an optimal depth so that the likelihood of the water level dropping to a critical level is minimal. This will prevent the device from running dry.

It is advisable to maintain a distance of at least 1 meter from the bottom so that liquid mixed with sand is not pumped through the water supply. When purchasing a screw unit, you don’t have to worry about the reliability of the operation of such equipment. The design of the product and the basic principle of operation were specially developed in such a way that the water intake hole was located above the engine itself. The working unit, thanks to this design, can be cooled naturally. The probability of fire in this case is practically zero.

Features of water intake are decisive in the selection of functional characteristics of equipment. Before selecting a suitable pump, be sure to take into account all the required control parameters.

You may also like

Operating principle of vibration pumps for wells

Choosing a deep pump for an artesian well

Types of screw pumping equipment

Since screw devices are used in many fields of application, they differ from each other in their design features. According to their design, the units are divided into the following types:

- Screw pumps - these units are designed for pumping large volumes of aggressive chemicals and abrasives. The screw device works effectively in both vertical and horizontal positions. Often such equipment is used for water from wells and deep wells. Screw units have a simple design and relatively low cost;

- Rod pumps - these types of devices are used for highly viscous media in oil production and refining enterprises. The rod pump design includes a wellhead gland, a rotary column and a surface drive. Units of this type are characterized by high productivity and fairly high cost;

- Vacuum pumps - these units are equipped with two screw rotors rotating in opposite directions. Thanks to this design of the vacuum pump, the liquid first enters the area between the screw chambers and the cylinder, and then enters the exhaust port.

A screw pump for viscous liquids shows high performance, but the efficiency of the device largely depends on the correct use of it. In this regard, before purchasing a device for domestic or industrial purposes, you need to make sure that it is suitable for the chosen area of application.

Vortex or centrifugal pump – which one to choose?

Manufacturers sell many models of both screw and centrifugal and vortex pumps. The models differ in their technical characteristics and ability to provide water. The choice of units of any type is wide.

How advisable it is to purchase one or another can be judged by several criteria:

- Dimensions . Must be suitable taking into account the specific well and its diameter.

- Power is a characteristic that determines the depth of liquid intake, and when choosing which, you need to take into account the characteristics of a particular water supply.

- Formed water head . All household appliances that are connected to the mains (including washing machines, boilers, dishwashers) can operate at a certain pressure in the water supply system.

- The number of water “consumers” and their need for water resources.

- Technical support unit in a populated area - the speed of repairs and the qualifications of the craftsmen depend on this possibility.

Choosing a pump for a well is not the easiest task, and to solve it, you need to consult with a specialist.

Otherwise, there is a high risk that the purchase will not be successful, and the money invested in the pump will not justify itself.