Features of operating a water pump

Instructions for assembly and use are included with each unit, but it is important to take into account all its points. This will ensure an error-free installation. The inner cavity has a built-in motor with a 2-voltage switch. Before starting, it is worth checking whether it is positioned correctly.

How to use the water pump:

- Remove the cover from the exhaust pipe.

- Pour oil into it. The level is checked through a special window. It should pour to the center. Afterwards, close the pipe with a lid.

- It is necessary to pump out the air. To do this, remove the cover along with a quarter of the fitting.

- The pump is started for 15 seconds, and the cap is placed on the thread.

For high-quality operation, the pump must have a sufficient oil level, which must be checked regularly. Fuel is added as needed, without exceeding the permissible level.

Fountain device

From the very beginning it may seem that making a small fountain is very difficult, but this is not entirely true. Of course, there are also complex hydraulic structures, but for the dacha they choose simple models that you don’t have to spend a lot on, since you can use improvised means for the work.

The main difficulty in manufacturing is its decoration.

All fountains have two types:

- Closed - in them water constantly circulates in a circle. The pump is installed in the main tank and supplies water from there to the pipeline system. The pressure in it is created only by pumping equipment.

- Open - water enters such a system from foreign sources. The source can be a natural reservoir or river, or the water supply system of a country house. The pressure in such a system can be created by the pressure drop in the system due to physical laws. We will talk about this in more detail below.

A garden fountain for a summer cottage is an oasis on the territory of a summer cottage.

In gardens, the first option is often built, since they are easy to maintain and simpler in structure. In this case, water must be periodically topped up (it evaporates and splashes) and cleaned (filtration equipment is installed). Sometimes they even perform a complete pumping out and replacement.

Open models require a water supply system and a water removal system. Good drainage and devices that control the filling level of the main tank are required.

Interesting to know! Water from a flowing fountain can be used to water plants, but it is not required around the clock, so such a fountain will have to be turned off at some intervals.

An example of an open option without a tank - water goes into the ground through the drainage system

Therefore, let’s continue to talk specifically about closed fountains, because they are preferred by the majority (read the article about the types of fountains for dachas).

Technical features and types of pumps

The pump ensures the movement of water, because the fountain is a closed system. The cycle goes like this: the fountain raises the water up, it goes into the prepared cup, the actions are repeated. Designer forms complement the ambiance of the dacha, not only with the murmur of water, but also with rare figures or special nozzles that regulate the pressure and direction of the stream, for example, a set fountain nozzle for a dynamic water cannon.

Spraying can be:

- cascade type;

- jet;

- resemble a bell.

Filtering functions are also activated using a lamp. However, this will increase the cost of the fountain pump.

On a note!

The lamp will disinfect the water from bacteria and protect it from the appearance of mud.

It is recommended to install models that can process water with various natural impurities. Many of them have a special recess in the upper area of the sprinkler, which is filled with a granular mixture.

Fountain pumps have 2 types:

- submersible;

- superficial.

The submersible type is installed on the bottom of the pool, and the surface type is fixed so as not to provide contact with moisture. Features of the submersible model:

- Used for fountains up to 2 meters high.

- It is advisable to use additional parts. They will protect the fountain pump from various contaminants.

- In addition, the base is made of brick.

- The two structural elements are connected to each other by a rubber tube.

It is worth considering that the pressure force will depend on the cross-section of the pipes and underwater hoses. The flow strength depends on the width of the pipeline. This electric pump will operate from a wall outlet. It is powered by a voltage of 24 V. These models are classified as low-voltage, which means that a standard transformer is enough for them.

Basic elements of an indoor fountain

A closed fountain has 3 main elements, which will be discussed in this chapter.

Fountain pump

The heart of such a fountain is an electric pump that pumps water through the system. The operating mode of the entire structure will depend on its parameters.

A fountain for a pond in a country house is cascading - powerful pumping equipment is required to organize a waterfall

- For fountains, they sell special pumping stations, consisting of the pump itself and filtration equipment. The filter protects the pump from damage by small particles of stones, sand, and organic matter, and at the same time is responsible for purifying the water in the tank. It needs to be cleaned or replaced at some intervals.

Attention! A clogged filter causes a drop in pressure in the system. The pump begins to wear out and gets very hot. This mode of operation will lead to rapid failure, which is why it is so important to inspect the equipment in a timely manner. For the same reason, stones are not placed around the filter, since the effective suction area is reduced.

- The structure of pumping equipment varies. There are submersible models, and there are ground-based ones, which are mounted in special boxes and disguised as the surrounding landscape. The last option is easier to maintain.

All equipment is housed in one building

- The pumping station can be in the form of separately spaced units, or everything can be installed in one compact housing. The configuration is selected according to the shape of the reservoir and its size.

- The equipment also comes with a water supply system and a set of nozzles that allow you to change the shape and height of the jet.

Set of pumping equipment with replaceable nozzles

- The pumps can be powered from a 220V public network or from solar panels - the second option is more economical, but it cannot be called stable. You can, of course, provide a battery in case of cloudy weather, but its capacity may not be enough to maintain normal operation, and the cost of the solution increases.

Attention! If you connect a submersible pump to the network, you need to be careful and follow all technological standards prescribed by the manufacturer. The power cable must be insulated and connected to a protection system consisting of RCDs and other circuit breakers.

Operating principle of a submersible pump

When choosing a pump, consider the following parameters:

- The power of the equipment will tell us how much water it will pump per hour. This is important for pumps operating in waterfall mode.

- Continuous operation time - if the pump periodically needs to be turned off for rest, then it is unlikely to be suitable for a normal fountain.

- Availability of an overheating protection system. Since the pump is cooled by water passing through it, a clogged filter can cause serious overheating (does not apply to all types of equipment). It would be good if there is a temperature sensor inside, which will protect the station from damage.

- Also look at power consumption. No one will be happy if tens of kilowatts of energy are generated per day.

Requirements for the characteristics of pumping equipment

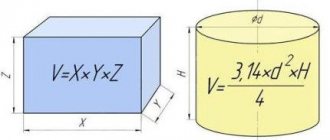

When choosing a fountain pump, you need to take into account the parameters of a specific architectural form, as well as your desires regarding the appearance and height of the jet. For the correct selection, it is better to contact a specialist, providing him with complete information about the source of water. You can focus on the following indicators: when choosing a submersible fountain with a power of 40 V and a capacity of 3000 l/h, the jet will rise by 3.2 m, surface equipment with a capacity of 800 l/h - 1 m, 2000 l/h - 1.5 m.

The power should be selected based on the fact that the desired jet height is achieved when the pump operates at an average level. This will make the device more durable. If it constantly pumps water at minimum or maximum speed, it will fail faster. For small structures, pumps with a capacity of up to 3000 l/h are suitable. For large structures it should be larger.

When purchasing equipment, in addition to power, productivity and maximum height of water lift, you should also familiarize yourself with the following characteristics:

- life time;

- warranty obligations.

Important! The maximum productivity of the fountain decreases in proportion to the height of the water rise.

Building a fountain at your dacha with your own hands

Now let's look at how fountain equipment is installed using two examples - a ready-made solution from a store and a homemade one.

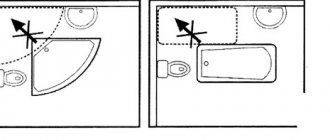

How to make a fountain with your own hands - place for installation

Work begins with choosing the installation location. Usually they try to choose the most noticeable and picturesque place on the site.

Without a purification system, the water in the fountain will quickly bloom

You also need to take into account the following factors:

- You should not install the structure at a point that is exposed to direct sunlight for more than 6 hours a day, otherwise the water will actively evaporate, and due to heating, the water will actively bloom.

- The close proximity of large trees is also undesirable, since their root system can damage the waterproofing of the bowl. They will also constantly shed leaves and branches that will rot in the water.

- The fountain is also not placed very close to the house, so that water does not fall on the walls.

- The place should be sheltered from the wind so that it does not disrupt the jets.

The area for the fountain should be landscaped, with lush, low-growing vegetation.

Pond with a fountain in the country - store kit

So, let's start installation. Before us is a ready-made structure that only needs to be assembled. What steps does the step-by-step instruction include:

- The first stage is installing a plastic container in the ground. It is necessary to do this. So that the sides are slightly higher than the ground and less dirt gets inside. Around it is filled with crushed stone or small pebbles.

Do-it-yourself fountain at the dacha - installing a pump

- Next, a pump is installed - it has suction cups so that it is securely fixed to the bottom of the tank.

Laying decorative stone

- Stones are placed on the bottom to give the container a natural look.

Filling with water

- Water is poured into the reservoir. It should be enough to completely cover the pump housing by a few centimeters. We remember that it is the liquid that cools it.

Fountain decoration

- We decorate the fountain as your imagination dictates. You can use various minerals, artificial and natural plants, as well as various garden decor.

A small fountain is started.

We start the pump and rejoice at the result. As you can see, everything is extremely simple to do.

How to build a fountain in a country house from concrete

We bring to your attention an interesting fountain made from scrap materials.

Creating a Shape to Fill

- Take a piece of plywood and place it on the ground. It will serve as a working platform for us. We form the formwork for our fountain. For this you will need a small plastic bucket. Make a hole in the bottom in the center and insert a piece of plastic pipe into it.

Cardboard formwork

- We take a piece of paper tube and put it on top - this will be the external formwork. Pour concrete from above to the very edge and bayonet it with a stick. Reinforcement can be provided to strengthen the structure.

- We do the same thing, only we take the lampshade from the lamp as formwork. We insert the same plastic pipe directly into the concrete, sealing its lower end with tape so that concrete does not get inside.

Pouring a concrete ball

- We secure the pipe with tape so that it does not float up.

Fixing the pipe

- Once the concrete has hardened, the outer formwork will need to be removed. Be careful with the glass, first wrap everything with film and carefully break it with a hammer. The cardboard is simply cut with a knife.

- All protruding parts of the pipes are cut off with a file. The ball is pierced with tape that was used to cover the end of the pipe.

- The fountain's container is buried in the ground. A pump is installed in it, then everything is carefully filled with stones.

Installation of the container

- A hose is connected to the pump outlet, which is then threaded into a pipe embedded in a concrete cylinder. The same is done with the ball. The hose is shortened so that it does not stick out. After this, the concrete parts are secured with silicone.

Base installation

- Stones are added to completely hide the container and water is poured into the system.

Working homemade fountain

Now you can turn on the pump and admire the result.

Step-by-step example of micropump assembly

Making a water blower will not benefit the fountain owner. However, the self-assembly procedure will allow guests to demonstrate their knowledge of the structure of circulation pumps and skills in working with polymer materials. If a pump is needed to create a tall fountain or cascading waterfall on a site, it is made from a motor from a cordless screwdriver.

Housing design

The main part of the pump is its body. In factory models it is made in a curved, snail-shaped shape. This design allows for maximum efficiency of the unit. At home, the body is made from a plastic cover. Manufacturing sequence:

- A hole is made in the center of the part (on the flat part). Its diameter should be equal to the size of the motor axis. The hole is drilled with a screwdriver or pierced with an awl.

- A hole is cut out on the side of the cylindrical part, equal in diameter to the body of a ballpoint pen or felt-tip pen.

- The motor axis is inserted into the central hole, and the junction of the motor and the housing is sealed with superglue.

For your information!

You can connect the parts with hot glue using a heating gun.

Making a paddle wheel

The impeller is assembled on a finished base - a gear. The latter is attached to the axis of the motor. Assembly order:

- Cut out 2 blades for the wheel from flat plastic. They are made from a plate with dimensions of 10 x 20 mm.

- The edges of the blades are bent at an angle of 30° in opposite directions.

- The blades are glued to a gear mounted on the engine axis. The blades are fixed at an angle of 90° relative to each other.

Assembling the injection area

The pressure zone is formed in the internal cavity of the lid. After assembling the impellers, the discharge area is sealed:

- Cut out a cover for the housing from thin plastic. It is made in diameter slightly larger than the size of the latter. A hole is drilled in the center of the lid for a ballpoint pen.

- Glue the end plate to the pump housing. During assembly, control the smooth rotation of the impeller. If the latter does not rotate or touches the lid, the edges of the blades are trimmed with a sharp knife or erased with fine-grained sandpaper.

- Suction and supply pipes are formed from plastic handles. The first is made in the form of a flat tube, which is inserted into the central hole of the injection area. One edge of the supply pipe is cut at an angle of 45 °. It is connected to the outlet of the pump housing.

Gluing all elements

Before assembling all parts, their surfaces are thoroughly cleaned of burrs that formed during the manufacturing process. In addition, it is necessary to remove the inscriptions and degrease each element. Otherwise, the structure will not be strong and may fall apart over time. During assembly, the parts are pre-fixed with electrical tape or tape. When the pump takes the desired shape, a thin layer of glue is applied to the joints. After the latter has dried, remove the auxiliary fasteners. Then the main layer of glue is applied.

Ideas for designing a country pond

What to look for when choosing

When choosing the right model, you should pay attention to details. Pay attention to several important factors:

- The power must correspond to the volume of the water tank. The height of the jet produced depends on this indicator.

- Voltage . There are low-voltage mini-pumps operating from 12-24 V. For them, it is necessary to lay the appropriate electrical network.

- Hoses must be of the correct cross-section. For weak motors it should be at least half an inch. A high-performance unit will require at least 1 inch. If this is not observed, large energy losses are possible.

- Filters. Preferably on submersible pumps.

- Corrosion resistance.

- Set of documents. Quality certificates and warranty card.

You need to check the package contents and compliance with all parameters when purchasing. Fountain pumps are varied.