How to use thread locker?

The principle of operation of this glue and the method of its use can be analyzed using the example of one of the tests of this anaerobic fixative. For the experiment, a fastening element is prepared, the thread of which is M10 × 1.25 (nuts and bolts). For all products being tested, a bolt is taken with a nut already screwed onto it. The bolts must first be cleaned and degreased. Then you need to treat the threaded part of the bolt with a clamp, and then screw the second nut onto it. The latter should have a small fixed tightening torque. The tightening should not be too tight. Otherwise, it will affect the test results. And its ultimate goal is to record the moment of unscrewing. This way the effect of the fixatives is exclusively tested. After a day at room temperature, all connections must be clamped one by one on a stationary frame so that only the top nut is captured by the head of the torque wrench. 5 Nm is the value of the initial moment. This is less than 10% of the maximum tightening torque of such fasteners. If the connection copes with the given force, a sequential increase in torque is allowed using 5 Nm steps. The quality of the fastener being tested is assessed according to the following pattern: if the threaded connection unscrews at a very high torque, then the fastener is of high quality and is worth using:

- for brake calipers;

- in the gearbox;

- in the steering mechanism.

One of the most frequently asked questions about the use of anaerobic sealants is the question about dismantling connections: “Is it possible to disassemble the connection on Santekhmaster Gel and Stopmaster Gel sealants?”

All threaded and flanged connections assembled on the anaerobic sealant Santekhmaster Gel and Stopmaster Gel are dismountable, regardless of:

– on the statute of limitations of application; – operating conditions; – thread diameter;

However, even BEFORE starting compaction, it is important to take into account the need to dismantle elements of the entire system in the future, which will require effort and, sometimes, heating with a hairdryer.

It is important to think in advance about the possibilities for dismantling, if it may be required for a given unit and: a) ensure accessibility of connections b) leave room for maneuver of the key and hair dryer

Blue, red, green: which “holds stronger”?

The diameter of the connection, the thread gap and the composition of the metal determine the choice of SMG sealant. For standard threaded and flanged metal connections with a diameter from 1/8” to 1.5”, Santekhmaster Gel Green is ideal. Such units can be disassembled using a regular plumbing or gas wrench without preheating. The same gel is suitable for small-diameter threaded connections that are difficult to access or painted parts. Dismantling such units will be as comfortable as possible based on the effort involved.

Dismantling connections will require slightly more force when using Blue SantekhmasterGel. It, like Green Gel, is used for standard threaded and flanged metal connections. Due to its slightly higher viscosity, its use is possible on diameters up to 2″. Most likely, you won’t need to heat the connection during disassembly; the tool is still the same - a plumber’s wrench or a gas wrench. But the applied force on comparable materials and diameters increases by 1.5–2 times. An exception to dismantling is a connection using Stopmaster Gel Red sealant. The thick and quickly polymerizing gel forms a super-strong connection that requires heating with a hair dryer when disassembling.

How much to “hang” in... grams

The force applied during dismantling is largely influenced by the metal of the connection. For example, gel polymerization on steel joints takes longer than on brass ones. Accordingly, when disassembling a steel connection, more effort will be required than when dismantling a brass connection.

In addition to the metal, it is necessary to take into account the operating conditions of the connection system.

In heating systems, dynamic heating cycles affect seal strength, where it can increase significantly (approximately 1.5 to 2 times). Therefore, given the abundance of painted and nickel-plated elements in such systems, it makes sense to seal with compounds with the lowest fixation force (strength).

When dismantling such connections, you will have to use a hairdryer to apply extreme force, which can lead to damage to the surface.

Disassemble and do not break

Disassembling a connection without damaging the parts is a kind of talent backed by professionalism. Well, Santekhmaster Gel sealants, as they say, will help you.

When dismantling a connection, all gels form crumbs or pieces of polymer, which can be easily removed with a clean rag or wire brush (in case not all of the polymer has fallen out of the thread). Read more about how to remove the resulting polymer in the following article.

When reassembling the assembly, usually no additional thread processing is required. You can safely apply a new layer of sealants Santekhmaster Gel and Stopmaster Gel!

On our website you can purchase anaerobic seals from the manufacturer at the best prices! To do this, you can use our product catalog. If it is not convenient for you to purchase goods via the Internet, you can find our sealants in the nearest store in your city. To do this, use our “Where to Buy” section.

Kinds

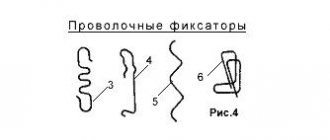

There are three types of thread lockers:

- Reds. Usually considered the strongest, most durable and reliable. Most of the red retainers on the market are heat resistant: they can be used in mechanisms that operate at temperatures above 100˚C. Red thread locker usually falls under the category of “permanent”, although this is a marketing ploy: test results prove that the connections can still be dismantled using a bench tool.

- Blue. This thread locker is also called "removable" or "releasable". Used in a wide range of different activities to protect against vibration loads and when necessary to replace split washers.

- Green. Any thread lock of this type is considered the weakest, and is often called “removable”. The weak clamp has the following area of application - processing thread connections with a small diameter, which are fixed with a small torque.

Removal and reuse of thread lockers

Recycling bolts is very important when carrying out repairs and maintenance of equipment. Connections created using medium- and low-strength threadlockers can be disassembled using conventional tools without damaging the threads themselves.

Rice. 35: View of self-loosening curves for various types of fixation of threaded connections obtained during tests carried out using a test bench

Which fastener is better to choose?

In addition to color and basic characteristics, clamps have a number of criteria by which they should be selected:

- element of resistance. To unscrew a small bolt, you do not need as much torque as a bolt with a larger diameter. If you use the strongest possible anaerobic glue on a small bolt, the bolt will tighten forever.

- resistance to process fluids (fuel and lubricant). Almost every thread locker is neutral to these agents, but this must be clarified in the documentation for it.

- state of aggregation. Liquid adhesives tend to run and can be difficult to use. The texture of paste glue is more convenient to use, but this product must be applied using an additional tool. But at the same time, you can understand how liquid glue you need to buy by looking at the size of the thread: if it is small, then you need to take a very liquid retainer, and for a large one, a dense consistency is better.

- ratio of quality and price. The best and strongest retainers are in the mid to high price ranges. Cheap products are usually ineffective.

- polymerization time. The disadvantage of any, even the highest quality fixative, is that it develops its properties over time. Therefore, it is impossible to immediately use the fastened mechanism with a large load. The type of fixative is the determining factor for the amount of time for polymerization: If the repair is not urgent, this selection criterion is not the main one.

Anaerobes. How to unscrew the connections assembled on them?

BIO wrote: What kind of animal?

For example, Unitek GT18 quick-release anaerobic adhesive (as written on the package).

Do you have any personal experience?

But what?

subtleties, tricks, applications.

The packaging is only 30-50% filled with glue. The glue does NOT harden in air. If you apply too much glue, it will squeeze out from under the thread. After a couple of hours it will change color (from blue to cloudy brown-gray). But even after a few days it will NOT harden, but will remain gel-like, soft and sticky. Only after two or three weeks did it harden a little and become rubbery. Excess glue can be easily removed with a cloth. Anaerobic should be applied ONLY to clean threads. The joint must first be cleaned and degreased. You need to apply glue to one fitting, the one with an external thread. The glue is applied evenly over the entire thread. I only filled the inner thread groove with glue. There is no point in applying excess, it will still be squeezed out when screwing in the fittings. In this case, it is necessary to leave one turn free of glue from the beginning of the thread (so as not to get into the pipe). I think it will be better this way, otherwise who knows where a piece of glue will end up in the pipe. It will also fall into the mixer and solidify there. At the end of the thread, you also need to leave one turn free of glue. The glue will still squeeze out there when you screw in the fitting. So why waste extra glue if you then wipe it off the pipe anyway. And also, if the glue is squeezed out at the joint, then leave it for several hours. Let the glue in the fitting set and then wipe off any excess glue that has come out. That's all the subtleties. You can easily master it by experience.

Yes, when disassembling such a connection, it is not necessary to heat the fittings. I haven’t disassembled it myself yet, but here on the forum they write that the connection is quite easy to disassemble with keys. After disassembly, the glue from the external thread is easily removed. But you will have to work with the internal thread. You will need a steel brush. Someone else was using a knife to pick out the remains of the frozen glue.

I almost forgot. Read the packaging carefully! The anaerobically glued joint can only be used after 3-6 hours. Those. It will be possible to add water to the system no sooner than after a few hours. There is, however, one exception: if you need to speed up the hardening process of anaerobic, you can use a hardener. Then the anaerobic will set faster and water can be released earlier. Specifically, what kind of hardener should be used, read on the packaging of the anaerobic product.

How to unscrew a connection with a thread locker

It is possible to unscrew the thread lock, but the outcome will depend on what kind of glue was used initially. The universal method is temperature exposure in the range of 200˚C – 250˚C. This temperature is suitable for red clamps, the reliability of which is quite high. For blue fixatives, a heat of 100˚C is enough, while green fixatives lose their properties even at lower temperatures. You can heat the thread with an electric soldering iron or a hair dryer. The use of universal soaking agents is not suitable in this case. This is due to the fact that the latch is in working condition. To remove residual fixative, you need to purchase a special cleaner. A thread locker is useful and indispensable for many repair jobs. It guarantees the tightness and strength of the connections. It can be used not only for car maintenance, but also in any field that requires joining metals and others. Also, pay your attention and read the article about plastic polishing products and their varieties.

Threadlockers provide sealing and retention

The clamps not only ensure operational reliability. The hardened product that fills the threaded gaps not only prevents relative movement, but also reliably seals the connection. Due to the excellent chemical resistance of the fixatives, they can be used in almost any aggressive media, gases and liquids available in modern industry. With their help, connections are protected from the penetration of corrosive substances and moisture from the outside, which shorten their service life. This advantage makes it possible to make through holes instead of blind holes, which, in turn, significantly simplifies and reduces the cost of the production process.

About the use of threadlockers in the food industry

In the food industry, threadlockers are used in large quantities. Local legislative bodies have developed strict requirements to protect the health of consumers. In addition, only those synthetic products that have been tested and meet current requirements are approved for use.

*There may be various differences in the rules developed by local authorities to protect consumer health. All manufacturers must not only know them well, but also strictly observe them.

Rice. 36: Sample certificate for use in the German food industry of a thread locker.