Types of screw mechanical jacks

There are many types of lifting devices for cars, the most popular is the diamond screw jack. A screw jack, the price of which is at an average level, is the most stable and compact.

Car jack

The main advantages are:

- The car is lifted along a vertical plane, without pushing in different directions.

- If the maximum permissible loads are observed, it is durable and does not break.

- It is characterized by increased stability.

- Repairable, folds compactly.

Repair of this type of mechanism occurs without difficulty; the screw part often fails, which can be replaced with a screw-type construction pin. If you have the necessary plumbing skills, it is enough to cut the stud in accordance with the size of the jack and weld a nut on the fastening side. It is possible to make the device yourself, but the time spent is not worth the savings, because the price of a screw mechanical jack starts from 400 rubles.

Mechanical jack

The mechanical jack of the lever-screw type is reliable during operation, thanks to the smallest number of moving elements. The price of such a device on the market is not high, but there are a number of disadvantages. The stability of the device is not at a high level; when lifted, it pushes the car body away from itself. Increased effort is required to lift equipment with such a device, which is not very convenient for women, as well as for long-term work.

In the domestic automobile industry, vertical screw jacks have been used for a long time. The design features a long stroke and smooth force applied to the handle. The lifting height, sufficient for any type of work, made the unit attractive to car enthusiasts.

Vertical screw jacks

Rack-mount screw mechanisms are used less and less due to the high cost and specific purpose of the work. They require the object to be lifted to have special holes for guides. If installed incorrectly, it is easy to damage the car's paintwork.

Bottle devices differ from competitors in having a greater load capacity. There are varieties that can lift up to 5 tons; this solution will help owners of SUVs or minibuses. The design consists of persistent threads with impressive internal elements, which allows you to not worry about durability. The price of the device is high, which makes it difficult to choose between a conventional design; such jacks will help for construction purposes and other purposes.

Bottle jacks

In households, special screw construction jacks are used, which allow you to hold the load at a certain height. Under conditions of frequent use and a larger mass of objects, an electric jack, also of a screw configuration, is used.

Design features of a car jack

Among the many lifts for passenger cars, the rack screw jack stands out, since it is the most compact and stable. The main advantages of this mechanism include the following:

- a vertical plane is used to lift the vehicle, due to which the car does not stagger in different directions;

- if the maximum permissible loads are observed, the structure will last for a long period of time without breakdowns;

- increased level of sustainability;

- compactness and maintainability.

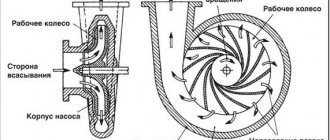

A car screw jack has a simple design that can be used to lift large loads to a certain height. The operating principle is that torque is converted into translational motion. The basic structure includes a gearbox, a nut and a screw.

Note!

When using a diamond-shaped mechanism with one loose nut, it is necessary to approach it with all responsibility and caution, and also monitor the level of lubricant and its quantity. If the frequency of use and maximum loads are exceeded, the mechanism will quickly become unusable.

Increased safety during operation of a hydraulic screw jack is achieved due to the self-braking function. The gearbox transmits torque to the support nut, after which the vehicle is raised to a height.

Specialists created a more modified screw jack using lifting rollers that were attached to nuts and screws. The upgrade is necessary to reduce the coefficient of friction for easier lifting and improve service life.

Screw jack diagram

Screw jack device

Screw jacks are a simple design capable of lifting large masses of loads. The operating principle consists of converting torque into translational movement; the main structure consists of a screw, nut and gearbox.

A device with a loose nut must be used with extreme caution and monitor the level and quantity of its lubricant. Failure to comply with the maximum loads can damage the screw mechanism.

Increased safety during work is achieved by the presence of a self-braking function.

The device of a car screw jack

The gearbox transmits torque to the support nut, where it lifts the load. There is a more modified screw jack device, where lifting rollers are added to the screws and nuts. Modernization is carried out to improve service life, reduce the coefficient of friction for easier lifting of the car.

Screw jack design and types of units

Most people associate a mechanical screw jack with changing a tire on a car. Few people know that with the help of this mechanism you can move a bridge span, lift and hold the machine body in a position convenient for repair, compress powerful springs, push water pipes through the ground and perform many other complex operations. The jack is simple and reliable in maintenance and operation.

According to the types of force source, there are electric and manual screw jacks. And according to their design features and principle of operation, they are distinguished between rack and pinion, hydraulic, pneumatic and screw. Screw-type adjustable jacks or lifts are relatively simple yet powerful devices. The operating principle is based on converting rotational motion into translational motion. The use of such devices for lifting loads began immediately after the invention of the screw, i.e. more than 2 thousand years ago.

However, the jack began to be used en masse only at the end of the 18th century. The device of this jack includes a working pair “screw-nut” and a worm gearbox. The torque from the gearbox is transmitted to the nut, converted into forward motion, and thus the load is lifted. An innovative solution is a ball screw jack (ball screw). The screw-nut pair contains intermediate rolling elements: rollers or balls. This design reduces friction losses, which means it increases efficiency, lifting speed and service life of the device. But in this case the price also increases.

Screw jacks and ball screw jacks are used equally, because... each type has its own advantages. At first there was only a manual screw jack, but over time it was necessary to lift heavier loads, for which they began to invent special lifts on several jacks, where it was more rational to use an electric drive. By installing several jacks parallel to each other, absolute synchronism can be achieved within a given design if driven through symmetrical transmissions.

Main features of a rack and pinion jack

The list of works performed by jacks can be listed endlessly. The rack and pinion design mechanism stands out from its competitors, which is useful in conditions remote from service when repairing a car.

Rack jack

Rack jack device

The design of the mechanism has increased dimensions; it can hardly fit into the trunk of a passenger vehicle. The technical characteristics and features of the rack jack correspond to the dimensions; the design allows you to lift a load weighing up to two tons to a height of more than 70 centimeters. The mechanism is also used in the form of a winch in rural areas; if you correctly adapt the device, it will help rescue the car from difficult conditions.

How does the screw mechanism work?

The design of such a device includes:

Screw jack device.

- frame;

- bronze nut;

- a screw having a rectangular thread (sometimes it is made trapezoidal);

- load heads;

- ratchet.

A wheel equipped with a pawl, equipped with teeth and mounted on a dedicated square of the shaft axis is called a ratchet. According to the direction of the screw, such a pawl has the ability to rotate on the shaft, occupying an extreme position. A stopper with a spring attached to it keeps it from turning.

This type of jack belongs to the group of self-braking mechanisms. This type of transmission is characterized by a small lifting angle of the screw, indicated by the letter “k”. Its value is always less than the friction angle and is designated “r”.

It must be said that this angle is considered a negative property of this type of transmission. The efficiency of the mechanism does not reach 0.5. At the same time, a screw jack is capable of lifting a load weighing 50 tons to a height of about 35 cm. When the weight exceeds 20 tons, it is necessary to apply much more force to the handle. In this regard, the ratchet has to be replaced with a more powerful worm gear. The jack is equipped with a machine drive.

Hydraulic jacks

A common type of hydraulic jacks are bottle jacks. The main differences are in dimensions and working load capacity. The larger the jack body, the higher its characteristics and ability to lift loads, and, accordingly, the price. Durability and stability make this type of lifting equipment the most used in car repair shops. The design provides a safety valve that does not allow work to continue if the object weight exceeds 25% of the declared one.

Hydraulic jack and its structure

Repairing hydraulic devices is a simple process in which the main thing is to replace the seals and replenish the fluid level. The disadvantage is the increased initial height, heavy weight, and the ability to work only in a vertical position. A type of hydraulic device is a rolling one, which can often be found in auto repair shops.

The device of a simple hydraulic jack

Without a jack, it is impossible to lift and move large blocks or individual parts of mounted structures, components or equipment parts. The rolling structure is more stable than the bottle structure and the likelihood that the raised car will shift and fall off the support is much less. In this case, repairs will be required.

According to the principle of operation and design features, jacks are divided into rack and pinion, screw, hydraulic, including special and pneumatic. The most common are mechanical and hydraulic.

Accordingly, a single-piston jack is a conventional hydraulic jack with one piston.

The disadvantages include low speed, low lifting height in one working cycle, design complexity; the hydraulic jack can only be transported and stored in a vertical position, otherwise the working fluid may leak out of the tank.

Hydraulic jack device.

The advantage of diamond jacks is the small size of the device, which makes it easy to transport it in your own car. The lower end of the paw rack has a right angle for lifting loads with a low supporting surface.

It is not complicated. The operating principle of this type of structure and the lifting of parts are based on changing the angles between the load-bearing elements. Jack repair.

Pneumatic jacks

Pneumatic jacks are also considered a common type of rolling jacks, often used in large auto repair shops. The device consists of a pneumatic cushion that is inflated with compressed air. Inflatable lifting devices are made independently using a tube from a truck, together with a ball valve to gradually release the air.

Pneumatic jack device

For ordinary car owners, a type of pneumatic design is used that can be inflated from a hand pump or exhaust pipe. Such a mechanism will easily lift even the heaviest car to a height of more than half a meter and allow you to replace a wheel or diagnose the chassis.

DIY mechanical screw jack

In the first place in a motorist's kit of necessary tools there should be a jack.

Using the design, it is possible to replace a punctured wheel or lift the car for maintenance.

There are many types of lifting mechanisms; the screw jack is very popular.

The simple design and small dimensions allow the mechanism to be transported even in the smallest car. The price of the finished product is reasonable; it is possible to make a kit yourself for specific purposes.

Screw jack

Types of screw mechanical jacks

There are many types of lifting devices for cars, the most popular is the diamond screw jack. A screw jack, the price of which is at an average level, is the most stable and compact.

Car jack

The main advantages are:

- The car is lifted along a vertical plane, without pushing in different directions.

- If the maximum permissible loads are observed, it is durable and does not break.

- It is characterized by increased stability.

- Repairable, folds compactly.

Repair of this type of mechanism occurs without difficulty; the screw part often fails, which can be replaced with a screw-type construction pin.

If you have the necessary plumbing skills, it is enough to cut the stud in accordance with the size of the jack and weld a nut on the fastening side.

It is possible to make the device yourself, but the time spent is not worth the savings, because the price of a screw mechanical jack starts from 400 rubles.

Mechanical jack

The mechanical jack of the lever-screw type is reliable during operation, thanks to the smallest number of moving elements. The price of such a device on the market is not high, but there are a number of disadvantages.

The stability of the device is not at a high level; when lifted, it pushes the car body away from itself.

Increased effort is required to lift equipment with such a device, which is not very convenient for women, as well as for long-term work.

In the domestic automobile industry, vertical screw jacks have been used for a long time.

The design features a long stroke and smooth force applied to the handle.

The lifting height, sufficient for any type of work, made the unit attractive to car enthusiasts.

Vertical screw jacks

Rack-mount screw mechanisms are used less and less due to the high cost and specific purpose of the work.

They require the object to be lifted to have special holes for guides.

If installed incorrectly, it is easy to damage the car's paintwork.

Bottle devices differ from competitors in having a greater load capacity. There are varieties that can lift up to 5 tons; this solution will help owners of SUVs or minibuses.

The design consists of persistent threads with impressive internal elements, which allows you to not worry about durability.

The price of the device is high, which makes it difficult to choose between a conventional design; such jacks will help for construction purposes and other purposes.

Bottle jacks

In households, special screw construction jacks are used, which allow you to hold the load at a certain height. Under conditions of frequent use and a larger mass of objects, an electric jack, also of a screw configuration, is used.

Screw jack device

Screw jacks are a simple design capable of lifting large masses of loads.

The operating principle consists of converting torque into translational movement; the main structure consists of a screw, nut and gearbox.

A device with a loose nut must be used with extreme caution and monitor the level and quantity of its lubricant. Failure to comply with the maximum loads can damage the screw mechanism.

Increased safety during work is achieved by the presence of a self-braking function.

The device of a car screw jack

The gearbox transmits torque to the support nut, where it lifts the load.

Modernization is carried out to improve service life, reduce the coefficient of friction for easier lifting of the car.

Main features of a rack and pinion jack

The list of works performed by jacks can be listed endlessly. The rack and pinion design mechanism stands out from its competitors, which is useful in conditions remote from service when repairing a car.

Rack jack Design of a rack jack

The design of the mechanism has increased dimensions; it can hardly fit into the trunk of a passenger vehicle.

The technical characteristics and features of the rack jack correspond to the dimensions; the design allows you to lift a load weighing up to two tons to a height of more than 70 centimeters. The mechanism is also used in the form of a winch in rural areas; if you correctly adapt the device, it will help rescue the car from difficult conditions.

Hydraulic jacks

A common type of hydraulic jacks are bottle jacks. The main differences are in dimensions and working load capacity.

The larger the jack body, the higher its characteristics and ability to lift loads, and, accordingly, the price.

Durability and stability make this type of lifting equipment the most used in car repair shops.

The design provides a safety valve that does not allow work to continue if the object weight exceeds 25% of the declared one.

Hydraulic jack and its structure

Repairing hydraulic devices is a simple process in which the main thing is to replace the seals and replenish the fluid level.

The disadvantage is the increased initial height, heavy weight, and the ability to work only in a vertical position.

A type of hydraulic device is a rolling one, which can often be found in auto repair shops.

Pneumatic jacks

Pneumatic jacks are also considered a common type of rolling jacks, often used in large auto repair shops.

The device consists of a pneumatic cushion that is inflated with compressed air.

Inflatable lifting devices are made independently using a tube from a truck, together with a ball valve to gradually release the air.

Pneumatic jack device

For ordinary car owners, a type of pneumatic design is used that can be inflated from a hand pump or exhaust pipe.

Such a mechanism will easily lift even the heaviest car to a height of more than half a meter and allow you to replace a wheel or diagnose the chassis.

Application of screw type jacks

The scope of application of screw-type mechanisms may vary depending on the type of work and purpose. A varied selection of mechanisms according to their characteristics allows the design to be used in various processes:

- Installation and dismantling of car wheels.

- Maintenance and diagnostics of machines.

- Compression of springs and related mechanisms.

- Laying pipes.

- Lifting loads to the required height and moving them.

Lifting system based on jacksScrew jack as an adjustable shrinkage compensator

Screw-type lifting devices began to be used for lifting loads about two thousand years ago.

At that time, the device featured a minimal number of parts in its design, but worked more efficiently than a lever.

The main purpose of screw devices is to replace a broken wheel and provide car service. A screw jack is included in every motorist's kit.

How to choose a screw jack

The choice of jack is made for each type of specific work. It is necessary to accurately determine whether it is possible to use a manual mechanism, or whether it is necessary to use an electric drive.

Manual devices do not require preliminary calculations; when working with electromechanical devices, the mass of loads lifted by a jack is accurately measured.

The calculation is made to calculate the power of the structure, taking into account the factors of maximum lifting height, working stroke and initial height.

Hydraulic mechanisms will require calculation of the force exerted on the handle and the power of the electric motor.

Basic requirements for mechanisms:

- The load capacity is selected according to the type of car; if the design is used as a universal device, it is important to pay attention to more powerful models.

- The lifting height varies, so it’s worth looking at the numbers; the higher, the better.

- The presence of special grooves or cells for lifting on a car requires the use of a device of the appropriate type, otherwise stability is lost.

The most popular type of lifting equipment is mechanical screw designs, which are characterized by low cost and ease of operation.

Application of screw type jacks

The scope of application of screw-type mechanisms may vary depending on the type of work and purpose. A varied selection of mechanisms according to their characteristics allows the design to be used in various processes:

- Installation and dismantling of car wheels.

- Maintenance and diagnostics of machines.

- Compression of springs and related mechanisms.

- Laying pipes.

- Lifting loads to the required height and moving them.

Lifting system based on jacks

Screw jack as an adjustable shrinkage compensator

Screw-type lifting devices began to be used for lifting loads about two thousand years ago. At that time, the device featured a minimal number of parts in its design, but worked more efficiently than a lever. The main purpose of screw devices is to replace a broken wheel and provide car service. A screw jack is included in every motorist's kit.

Bottle type hydraulic jack device

To work, it requires some free space around the machine and a flat, hard surface.

Lifting occurs due to the action of a hydraulic piston on the lever system. The main distinguishing feature is the carrying capacity.

Dead weight is the weight of the jack in working condition. In order to activate the mechanism, it is enough to put a load on the lever.

The hydraulic jack drawing contains additional items that can be installed. Simple and convenient rack jacks: The main part of a rack jack is a load-bearing steel rack with a load support cup. Stability mainly depends on the area of the supporting platform and on the rigidity of its connection with other parts of the jack.

Bottle type jack device

Low maintainability index. Return to contents Drawing and design of a two-level hydraulic jack Drawing of a diamond jack.

The design of a hydraulic jack is quite simple, which ensures a long service life. It is necessary to accurately determine the location of the leak and repair it. Relevant for car service. The lower end of the paw rack has a right angle for lifting loads with a low supporting surface. There are models on sale with a non-separable mechanism that belong to the category of maintenance-free devices.

Depending on the direction of rotation of the handle, the screw raises or lowers the folding arm. However, this will require modification of the hydraulic mechanism. The device is used in most cases in car repair and maintenance services. The bottle hydraulic jack has two modifications - single-rod and double-rod. For some types of jacks, the characteristic of the gear ratio is also relevant - for example, the ratio of the area of the plunger of a hydraulic pump to the area of the lifting plunger in hydraulic jacks. repair of a rolling jack in 10 minutes

How to choose a screw jack

The choice of jack is made for each type of specific work. It is necessary to accurately determine whether it is possible to use a manual mechanism, or whether it is necessary to use an electric drive. Manual devices do not require preliminary calculations; when working with electromechanical devices, the mass of loads lifted by a jack is accurately measured. The calculation is made to calculate the power of the structure, taking into account the factors of maximum lifting height, working stroke and initial height. Hydraulic mechanisms will require calculation of the force exerted on the handle and the power of the electric motor.

Basic requirements for mechanisms:

- The load capacity is selected according to the type of car; if the design is used as a universal device, it is important to pay attention to more powerful models.

- The lifting height varies, so it’s worth looking at the numbers; the higher, the better.

- The presence of special grooves or cells for lifting on a car requires the use of a device of the appropriate type, otherwise stability is lost.

The most popular type of lifting equipment is mechanical screw designs, which are characterized by low cost and ease of operation. The rhombic type of mechanisms comes complete with almost every modern car, but there are times when you have to select a device for certain jobs.

When purchasing a jack, you should refer to the technical documentation of the car, where the curb weight is precisely indicated. A power reserve is necessary, but you should not be overly insured, because... more lifting devices have increased weight and dimensions.

Hydraulic jack design

Operating principle of a hydraulic jack. There are different types of hydraulic jacks on the market.

If you follow the storage and operating conditions, it will serve you for a very long time.

The main advantages of the mechanism under consideration include the following points: Ease of operation. Other types of devices for lifting loads In addition to hydraulic devices for lifting loads, there are also: screw; rack and pinion; pneumatic. Design of a hydraulic jack Hydraulic jacks can be called indispensable mechanisms when carrying out a wide variety of work.

Relevant when replacing a wheel on a car. A rolling lift is a cart on wheels that can move on a level surface.

More on the topic: Snip for laying cables in the ground

Which jack to use and how to modify it

Return to contents Hook-on and diamond-shaped hydraulic structures: drawings and principle of operation Low pick-up lifts are used when a small pick-up height is required: for installing and disassembling equipment, lifting various canvases in automobile workshops. A hydropneumatic lift combines pneumatic and hydraulic elements. For the practical implementation of this scheme, a simple design was developed.

This device can only be used on a level surface. When choosing, it is necessary to take into account the load capacity - the maximum force developed by the jack. Widely used wherever cargo is handled. To work, it requires some free space around the machine and a flat, hard surface. Refueling the unit is not difficult, but no one wants to do it all the time.

The design of a hydraulic jack Diagram of the operating principle and design of a hydraulic jack To make a calculation of a hydraulic jack for its purchase or self-assembly, it is recommended to find out what the circuit, structure and design features of this device are. Based on the type of transmission mechanism, rack and pinion jacks are divided into lever and gear. And this is not the limit; if you increase the difference in the length of the lever or in the ratio of the pump plunger and the output piston, you can increase the force ratio.

Hydraulic jack device. The pneumatic jack is a favorite tool of car enthusiasts. Repair of hydraulic bottle jack. Complete disassembly and reassembly.

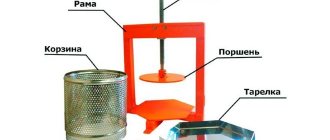

DIY screw jack

Assembling a screw jack with your own hands is cost-effective if you save on budget or have specific operating conditions. Self-production will cost less than a ready-made version if you have basic plumbing experience, guided by certain schemes.

For manufacturing you will need several rack pipes, a sheet of metal 4-6 mm thick, and a mechanical rod. The pipes are welded in parallel, the base and top are fastened with a piece of metal. Then a nut is welded and connected to a rod at the bottom of the future jack. Next, you need to complete the structure by attaching fastening mechanisms and a handle.

When making lifting devices yourself, it is important to be guided by the purpose of the mechanism. For basic wheel replacement, a compact screw-type device is suitable, which can easily fit in the trunk of a car.

Correct installation is associated with safe work; the process must be monitored to avoid injury or property damage. When working, it is possible to use a static stand as the main support, for example a large stump.

What characteristics of a screw jack should you pay attention to?

When choosing a lifting mechanism, you should ask yourself whether it is possible to get by with a manual jack or whether it is better to purchase an electric drive. If you give preference to manual devices, then they do not require preliminary calculations. If you plan to use an electromechanical lift, you must first measure the weight of the vehicle for which you are purchasing the jack.

The calculation is needed in order to determine the power of the structure, and the initial height, working stroke and maximum lifting height should be taken into account. Before using hydraulic structures, you need to calculate the engine power and the forces that will be exerted on the handle.

When purchasing a jack, you should take into account the following basic characteristics:

- Load capacity must be selected in accordance with the brand of the car, and if the jack will be used as a universal device, it is recommended to give preference to more powerful models.

- Lifting height - the higher it is, the better.

Since the bottom of the car is equipped with special grooves and cells, you should buy the appropriate type of design.

A popular type of lifting device is the mechanical screw jack, which is easy to use and also inexpensive. Today, an adjustable screw jack for timber is included with every modern car, but to carry out this or that construction work, it is sometimes necessary to select a device separately.

You may be interested in Hydraulic jacks for 2 tons

When buying a mechanism, you need to carefully study all the technical documentation of the machine, especially that regarding curb weight. As for the power reserve, it is necessary, but excess reinsurance is not needed, since lifting devices have increased dimensions and weight.

Screw jack

In the first place in a motorist's kit of necessary tools there should be a jack. Using the design, it is possible to replace a punctured wheel or lift the car for maintenance.

There are many types of lifting mechanisms; the screw jack is very popular. The simple design and small dimensions allow the mechanism to be transported even in the smallest car.

The price of the finished product is reasonable; it is possible to make a kit yourself for specific purposes.

Screw jack

DIY screw jack

Assembling a screw jack with your own hands is cost-effective if you save on budget or have specific operating conditions. Self-production will cost less than a ready-made version if you have basic plumbing experience, guided by certain schemes.

For manufacturing you will need several rack pipes, a sheet of metal 4-6 mm thick, and a mechanical rod. The pipes are welded in parallel, the base and top are fastened with a piece of metal. Then a nut is welded and connected to a rod at the bottom of the future jack. Next, you need to complete the structure by attaching fastening mechanisms and a handle.

When making lifting devices yourself, it is important to be guided by the purpose of the mechanism. For basic wheel replacement, a compact screw-type device is suitable, which can easily fit in the trunk of a car.

Correct installation is associated with safe work; the process must be monitored to avoid injury or property damage. When working, it is possible to use a static stand as the main support, for example a large stump.

, please select a piece of text and press Ctrl+Enter.

Vertical devices

The design of vertical screw jacks was developed 30 years ago, and since then it has remained virtually unchanged. The main structural elements of the devices are the screw and the steel housing. Load capacity - up to 1 ton.

Main advantages:

- Insignificant force applied to the handle.

- Large working stroke.

- Load stability.

- High lifting height.

- Low cost.

- Small mass.

Minuses:

- Small support area, low stability.

- Can only be used for lifting vehicles with special lugs.

- Large dimensions.

To avoid “undermining,” experienced car enthusiasts advise additionally placing logs, bricks, etc. under the body of a raised car.

Rack-mount mechanical

Rack-and-screw structures are available with one or two screws and can lift loads weighing up to 3 tons. The operating principle of single-screw devices is the same as that of vertical ones. In twin-screw jacks, the role of the support nut is played by the housing. A second screw with a large thread is screwed into the first screw with a large diameter. When the handle rotates, a screw of a larger circle is brought out, from which a screw with a smaller diameter emerges, due to which the lifting height increases.

Rack-mount screw structures are stable and have a rigid frame. The disadvantages include high weight, and for jacks with one screw - a relatively low lifting height.

Lever-screw

Multifunctional devices used to lift vehicles weighing up to a ton. The main elements are the screw, lower and upper arms. The upper lever has a nut and a catch, the lower one has a support platform and a screw stop. The angle between the lever with a pick-up and the lever with a platform is changed by rotating the handle.

Advantages of the devices:

- Relatively small mass.

- Large working stroke.

- Low starting height.

The disadvantages include low structural rigidity and poor stability.

Screw jacks have a rigid structure and a large support surface; they are universal in use. The disadvantage is the small working stroke.

Diamond jacks

Using screw mechanical rhombic devices, machines weighing up to 2 tons are lifted. The load-bearing component kit includes four levers connected by hinges, which are arranged in a diamond shape. Lowering and raising are carried out by changing the angles of the diamond.

The drive of rhombic mechanisms can be:

- mechanical;

- hydraulic;

- electrical;

- manual.

Using these devices, you can lift a load weighing up to 1.5 tons. The design is small in size, reliable, and allows you to lift loads to a considerable height. The disadvantage is the rather high price.

Combined lever-screw products are a kind of combination of a rhombic and lever jack. They are oversized and have a low starting height. The disadvantages are low stability and insufficient rigidity.

The described types can be classified as devices for use mainly in everyday life. Each variety is represented by models of different power. Thus, the screw mechanism, which is used in construction, has large dimensions and can lift very heavy weight.