The modern building materials market is saturated with a variety of products. Here the land owner can choose blanks to suit every taste to make a beautiful, durable and reliable fence. Every buyer strives to purchase what he needs at an affordable price, wisely saving money on landscaping. A fence made of welded mesh meets all these requirements. Purchasing this product and installing it on site is a profitable investment. Welded mesh has simple external characteristics, but at the same time has higher strength characteristics than the usual chain-link.

Detailed steps for installing a welded mesh fence

Welded mesh for a fence is one of the types of material for fencing a plot of land. Its external characteristics are simple, but its design is more durable than a chain-link. In addition, you can do the installation yourself, since the material is quite liftable.

- Characteristics and types of fence sections

- Main parameters and characteristics

- Let's look at all the pros and cons

- Types of mesh material

- Step-by-step instructions for installing a fence

- Nuances at work

DIY plastic mesh fence

Not so long ago there was no talk about plastic fences in Russia, but recently such fences can be seen in some summer cottages. One of the advantages of plastic fences is ease of installation. The owner of the property is quite capable of putting up such a fence himself; this article will help him. Types The enclosing fabric itself is made in the form of a mesh. There are the following types of plastic mesh: garden, facade and chain-link mesh. Sadovaya is produced by extruding the polymer mass with an extruder in two axes. At the same time, certain values of the main parameters of the technological process are maintained - pressure and...

Main settings

The strength of the fabric is determined by two characteristics: the dimensions of the cage and the diameter of the wire. The smaller the cell of the mesh material, the stronger the fence will be. But material with such parameters costs more. Standard cage: 50x50 mm, 100x100 mm (the most common), as well as 150x150 mm, 200x200 mm.

Metal mesh can be light or heavy, which is determined by the thickness of the wire.

In the first case, the diameter varies between 3-6 mm. Heavy fencing is erected using mesh material with a wire thickness of 8 to 40 mm. Section dimensions (standard sizes): 1000x2000 mm, 1500x3000 mm, 2000x3000 mm.

Where is welded mesh used?

Welded mesh is a multifunctional product that is used in various industrial fields. Let's list the most important ones:

1. Construction . Welded mesh is used to strengthen walls and facades of buildings, as well as for the construction of reinforced belts to evenly distribute the load from load-bearing structures and walls. In addition, welded mesh is used to reinforce the walls of the pool and under floor stone coverings.

2. Road works . The use of welded mesh in road construction allows you to increase the possible service life of the coating by improving its resistance to increased mechanical stress. The mesh prevents deformation of the road surface under heavy loads and as a result of natural soil movements. Laying paving slabs in pedestrian areas and arranging paths in suburban areas is also indispensable without welded mesh.

3. Agriculture . Durable mesh products are often used for fencing pastures and fields, and are also used as a building material in the manufacture of pens and cages for housing animals and birds.

4. Arrangement of fencing . This is the most common way to use welded mesh. It is especially popular among owners of summer cottages, but it is worth noting that within the city limits there are also fences made of this type of material.

Types of mesh

There are several types of mesh material made by contact welding:

The scope of application of these varieties: strengthening the road surface and other structures, wall decoration, construction of fences. Polymer mesh has proven itself well in domestic conditions - it is used to build fences.

Galvanized material with a polymer coating has the best characteristics: a sectional fence will last longer thanks to double protection against corrosion, and it is more attractive in appearance.

Sequence of work

4.1 Preparation of pillars

As mentioned above, a profile pipe was used for the pillars, which was purchased at a metal trade. Such a pipe is usually sold 6.0 m long, but for ease of transportation it was immediately cut into 2.0 m sections.

Of course, in some cases it makes sense to cut the pipe into two parts of 3.0 m each, but here it is necessary to proceed, firstly, from the depth of the pillar, and, secondly, from the required height of the fence. Columns 2.0 m high were enough for me.

Holes were prepared in the pipe for installing bolts to fasten the crossbars. The height of the holes must be taken depending on the immersion depth of the pipe and the desired height of the transverse runs. For these purposes, an electric drill and a metal drill ø10 mm were used.

You can make holes after installing the post in the ground, but doing this is extremely inconvenient

Before immersing in the ground, the pipe must be treated with paints and varnishes to protect against corrosion.

For these purposes, I selected the following paintwork materials:

- Soil GF-021

- Enamel PF-115

Primer GF-021 is intended for coating steel and wooden surfaces before applying enamel.

PF-115 enamel has good adhesion and is suitable for outdoor use. Operating temperature range from -50 to +60 °C.

Before applying the primer, the profile pipe must be cleaned of pockets of corrosion; for this you can use metal brushes, sandpaper and special abrasive attachments on an angle grinder.

After cleaning, the surface of the pipe must be wiped with a rag soaked in solvent or degreaser.

Next, primer is applied. For these purposes I used a brush. The drying time of the GF-021 primer is about 24 hours at an ambient temperature of 20 °C.

Then the enamel is applied. To apply the enamel, I already used a roller, since this applies the paint more evenly, which is important from an aesthetic point of view. The enamel was applied in two layers.

The drying time for PF-115 enamel is 24 hours under normal conditions - humidity up to 65% and temperature about 20 °C.

4.2 Preparation of crossbars

As already mentioned, a 25x100x6000 mm edged board was used for the crossbars. The board was planed with an electric planer and treated with a special antiseptic composition.

4.3 Installation of pillars

There are several ways to install pillars in the ground:

1) Using a special auger, a hole is drilled in the ground to a depth that depends on the depth of soil freezing. Then a post is lowered into this hole, and the free space is filled with cement-sand mortar.

2) Columns from a profile pipe are simply driven into the ground using a sledgehammer. In order not to damage the end of the pipe, you need to use a wooden lining made of a board 40-50 mm thick.

I used the second method, since it is faster and cheaper, and the soil on my site is non-heaving with a good filtration coefficient.

The main stages of building a fence

A fence made of welded mesh is built using the following materials: sections of fence cloth; metal pillars with embedded parts, but they can be secured with your own hands using a welding machine; concrete solution.

Scheme of sectional fencing made of welded mesh

Basic tools: welding machine, screwdriver (if the sections will be attached to the poles using a threaded connection), tape measure, building level, shovel/hand drill.

Step 1: Marking work

A fence made of welded mesh, like any other fencing, requires preparatory work: cleaning the area, checking the difference in soil surface levels, marking.

The construction of the fence begins with markings. To create the desired line, pegs, rope and tape are used.

First of all, you should outline the location of the fence. To do this, drive stakes into the corners with your own hands, and string a rope between them. Next, you need to determine the location of the fence posts. They are placed at a distance that is 15-20 cm greater than the length of the section.

The reserve is allocated for the embedded parts with which the fence is attached.

Step 2: Installation of support posts

A fence made of welded mesh is usually erected using metal posts. They are strong enough to support the structure of a section made of frame and mesh. In addition, in most cases, the fence is fastened by welding. Another nuance: a metal fence lasts much longer.

And if the wooden posts fail, you will have to repair the fence ahead of time.

To prepare cement mortar, one part cement, one part water and three parts sand are used.

A sufficient cross-section of pillars for a sheet of wire 3-5 mm thick is 60x60 mm. The depth of the holes for the support posts is determined based on data on the structure of the soil and the depth of its freezing. Fence made of polymer mesh chain-link? On average, a columnar foundation 0.8-1 m deep is installed for a mesh fence.

It is important that the support is recessed to a level equal to a third of its length. The holes are dug with a shovel, but you can use a hand drill. This will speed up the work.

The diameter of the holes in the soil should be several centimeters larger than the posts.

Welded mesh fences are most often installed by completely concreting the supports. This will further strengthen the structure. To make the solution, sand and cement (3:1) are used.

Then the hole is filled with cement mixture with your own hands, a pillar is installed there and leveled. Spacers are used to secure the support. After a few days, you can continue building the fence.

Step 3: Attaching the fence cloth

The use of rolled mesh requires the use of special clamps or brackets. In this case, a continuous fence sheet is attached. If you plan to use a more durable mesh, prepare a frame made from a corner or profile pipe.

Each post is equipped with 4 fasteners that secure the mesh.

The base material is welded to it with your own hands. The finished section is attached to the embedded parts using a welding machine or using a threaded connection method (bolts, nuts).

Features of installing a fence made of galvanized mesh

There are two ways to install galvanized mesh:

- Tension of the fabric between the pillars;

- Installation of sections.

The first option is cheaper and easier to do yourself. But the second option is considered more aesthetically pleasing and stronger.

If you do not purchase ready-made welded spans, you will have to make the sections yourself from angles or profiles.

Fence posts can be either wooden or metal. Of course, if you build thoroughly, you should use steel supports with a cross-section from 6 to 12 cm.

Return to contents

Installation of pillars

- Perimeter marking. To ensure that the fence is level, the cord is pulled and the location of the posts is determined. The supports must be located at even intervals of at least 2.5 m.

- Installation of fence posts. Holes 120–150 cm deep are prepared for the pillars, the bottom of the wells is filled with crushed stone and sand 10–15 cm thick.

Each layer is moistened with water and compacted. The pole is installed in the hole, checked for verticality and supported. - Mixing mortar and concreting pillars. Concrete is poured into the well and carefully compacted with a crowbar or reinforcing rod. You can start installing sections and stretching the mesh no earlier than in a week, then the composition will be strong enough.

Return to contents

Installation of mesh on supports

To tension the rolled mesh, hooks are welded onto the posts. Also, special poles with hooks can be purchased ready-made. The galvanized mesh is hooked onto the first post and stretched with tension to the next support and put on the hooks again.

One of the options for attaching fence sections to posts

To make the galvanized mesh fence stronger, wire with a diameter of 4 mm is threaded through its top and bottom. The wire is welded to the post. It is difficult to pull the mesh evenly with your own hands, so it is advisable to invite an assistant and, by threading a crowbar or rod through the bottom and top of the welded mesh, pull them. After installing the fence, the hooks are bent. A sectional fence is either welded to posts or secured using pipes and clamps. Return to contents

Recommendations for arranging a fence

The use of galvanized mesh does not require coating with paints and varnishes. But if the section is made by hand, the protective coating can be damaged during welding. Then it is necessary to provide additional protection with paints and varnishes.

The use of welded rolled mesh involves two solutions: cutting the material yourself to make sections; installation of the fence sheet using clamps, no need to cut it.

If galvanized mesh is used for the second option, the installation process will take less time, since there is no need to prepare sections. But in this case, the fence will lose strength.

But the thicker the wire used in the production of the material, the stronger the structure will be. The cell sizes of the rolled mesh are also responsible for this quality.

Tips you should know

When installing a fence made of galvanized or non-galvanized mesh, the following nuances should be taken into account:

- It is recommended to use metal posts as supporting elements, since wooden products will not be able to support a mesh with a large weight;

- it is better to install the structure in the autumn or spring, when the ground is still loose and easy to dig;

- if you plan to use the mesh in rolls, you will need to unfold it and leave it in this position for approximately 24-48 hours so that the material straightens and can be easily installed and secured in the future;

- The cement solution should be prepared for each hole separately so that it does not harden.

https://youtube.com/watch?v=NzbmeCXJTiA

Installing a mesh fence is not difficult, you just need to take into account all the nuances and follow the installation rules.

Installation of a welded mesh fence on the site

If earlier in the time of our grandparents we didn’t think long about what to make a fence from and chose wood or stone, but today the development of industry allows us to choose from a fairly long range of different building materials.

Continuing the topic of various fencing, today we will look at an option such as a fence made of welded mesh, its main advantages, types, cost, as well as the method of self-installation.

After reading our article, you will acquire useful knowledge that will allow you to better navigate among the different types of fences.

Where are welded fences used?

The widespread use of these fences in a variety of areas is due to a combination of low price, ease of construction and maintenance, as well as a long service life. Fences made of welded mesh provide protection from unauthorized access to objects and can be easily included in the general system for protecting the borders of the territory. Customers of such fences are enterprises of the defense industry and simple production, construction organizations, administrative institutions, parking lot owners and individuals. The areas of application of welded enclosing structures are as follows:

- construction. The material is used for reinforcing facades, swimming pools, and floor coverings. Welded mesh fences enclose the construction site;

- Agriculture. With the help of welded mesh fences, livestock pens and cages are built. Fencing of fields, pastures and lands is carried out;

- Men at work. Fencing work areas. Strengthening the road surface from impact loads;

- dacha farms. Welded mesh (polymer and simple galvanized for fencing) is used for fencing the boundaries of plots and decorating the internal territories of farms.

Characteristics and types of welded mesh for fence

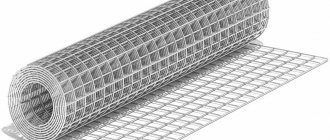

I think you can imagine what a regular grid looks like. In our case, this is an interweaving of metal wire at right angles, welded at the points of contact of the elements (spot welding method). The result is a canvas, which is usually sold in rolls, with square or rectangular cells (but can also be found with rhombic, trapezoidal and other shaped cells).

The weight of one roll varies and is within the following limits: from 50 to 500 kg. Also, a roll can be from 15 m to 33.3 m, height - up to 2 m. When purchasing, you should pay attention to the cell size, as well as the diameter of the wire.

In addition, everyone knows that metal tends to rust when exposed to moisture. Therefore, the wire is usually coated with protective materials, which increases its service life many times over.

The following types are distinguished:

- Welded fence mesh with polymer coating (polyvinyl chloride) . How to decorate a chain-link fence? It is usually green, but can also be supplied in other colors. It is first welded and then coated by dipping into polymer or powder paint is applied in special cabinets.

- Galvanized welded mesh. The coating can be applied in several ways (electrolytic, hot). Moreover, the order of assembly and coating may be different. First they weld and then galvanize and vice versa. Rolls are usually packaged in paper.

- Non-galvanized mesh. For its manufacture, steel wire with a diameter of 1.2-10 mm is used. It is also suitable for making fencing. It is usually supplied in plastic packaging (China) or without it (for example, Ukraine).

- Welded mesh, which is first galvanized and then polymerized . This is the most durable option, but also the most expensive; not everyone can buy it, and for a fence there is no need to purchase such a strong mesh.

The price will depend on the type of coating, cell size and wire thickness. For example, welded mesh 250x50x2, 8 galvanized 1, 725x118 (204 sq. m in a roll) will cost about 250 rubles. per sq. m. PVC mesh 25x25x1.4 green (roll size 1x25m) costs approximately 195 rubles. per sq. m.

Why is this material chosen for making a fence?

Firstly, a sectional fence made of welded mesh is lightweight , durable, and resistant to various adverse weather conditions.

Secondly, you can install the fence yourself , which is not very difficult.

Thirdly, the optimal price-quality ratio will satisfy you fully . Also, this option is suitable for those who do not like solid fences, because the mesh does not create shadows, and if the territory of the site offers a picturesque view that you do not want to hide, then this option is one of the few suitable in this case.

Today, a metal fence made from 3D welded mesh has become very popular. Originally curved wire rods create a three-dimensional effect and give the fence a relief.

Advantages of galvanized mesh

They produce galvanized mesh from metal wire. Its rods are arranged perpendicularly and are fastened at the connection points by welding. The cells of the welded mesh are made rectangular, square, less often diamond-shaped, trapezoidal or other shapes. The wire for the mesh is galvanized or with an additional polymer coating. Fencing made of welded galvanized mesh has its advantages:

- Affordable price;

- Simple and quick installation of the mesh can be done with your own hands;

- Light weight, does not require foundation construction;

- Transparency and good visibility allow it to be used at protected sites;

Fence design made of galvanized mesh and metal corners

- Possibility to build fences from 50 cm;

- Ideal for boundary lines where blind fences cannot be used between areas;

- A mesh fence fully transmits the sun's rays and does not interfere with the growth of plants in the garden;

- Can become the basis for creating a hedge of climbing plants;

- Galvanized mesh is a fairly strong fence that is not easy to bite or bend;

- The fence does not require maintenance or painting;

- Quite a pleasant appearance: a galvanized fence looks appropriate on any site.

Return to contents

Wire diameter and cell shape

Welded mesh is made from steel wire. The latter is first leveled and then cut into pieces of the required length, after which bends are formed using a bending machine, which will eventually become stiffeners. The final stage is spot welding, after which it is possible to apply a protective zinc layer, and possibly a polymer one.

The diameter of the wire in the welded mesh does not exceed 4 mm, and products made from wire with a diameter of 5-6 mm are usually called welded panels . Naturally, the thicker the wire, the stronger the structure.

Cells of different shapes can be formed from wire , but the following options are usually used:

- square and rectangle;

- rhombus;

- trapezoid (usually made to order).

Welded mesh (diameter up to 4 mm) is transported in rolls. At the installation site, the roll unrolls easily, and the mesh itself quickly comes into shape. Welded profiles are made from thicker and stronger wire, so it cannot be bent into a roll - such products are transported by cards, i.e. ready-made sheets that remain secured to the support.

Advantages and disadvantages

Welded fences with PVC coating have the following advantages:

- long, up to 50 years, service life due to reliable coating;

- resistance to precipitation, low temperatures;

- do not shade vegetable crops planted nearby;

- due to the small windage, even hurricane winds are not scary;

- the shape of the mesh is maintained throughout operation;

- quick installation and ease of height adjustment of welded sections;

- installation of mesh with a polymer coating will cost less than the construction of a fence from profiled sheets;

- Application not only for fencing, but also as a frame for greenhouses.

Among the shortcomings, they note poor protection from intruders and visibility of the territory from the street. In summer, bushes are planted along the fence to protect from prying eyes.

Varieties

The produced welded mesh is divided into several types. This depends on the type of steel used and the coating characteristics of the finished product. These characteristics affect the performance and cost of the product.

- Non-galvanized. This type of mesh does not have a protective zinc coating. The main advantage of such a product is its low cost, but immediately after installation the fence requires painting.

- Galvanized. During the manufacturing process, the manufacturer coats each section of the fence with a zinc layer. Galvanization reliably protects the metal from contact with moisture and prevents rust.

- Coated with polyester powder paint. Such products are often called PPL fence. Most often, such products are produced in green.

- Galvanized with a layer of polymer. Such products have double protection, so they will last for several decades. In addition, a fence made of such a mesh looks aesthetically pleasing.

- Stainless steel mesh.

- Rabitz. This type of fence is the cheapest and lightest product. Cell sizes may vary.

Useful tips

When starting installation, you should take into account several tips from professional builders. This will help install the fence faster and better.

- When installing supports for welded mesh, do not choose wooden posts. Under the weight of the metal mesh, the fence may become deformed.

- If the choice is made in favor of a rolled chain-link, it should be deployed in advance (1-2 days before installation). In this case, the product will have time to rest, and there will be fewer errors in the work.

- It is better to carry out excavation work in the off-season (autumn or spring). At this time of year, the ground is more loose, so making holes will not be difficult.

- Experienced installers advise preparing a cement mortar designed for 1 hole. This will prevent the total mass from solidifying and will reduce the cost of constructing the fence.