Pressure sewer is a wastewater disposal system.

It can be installed on your own site without much effort. This type of sewer system is carried out only if it is not possible to equip a gravity sewer system. Often, there are situations in which it is necessary to perfectly understand: exactly how the sewer system functions in a house, the features of its operation and installation in principle. In this article we will consider in detail all the necessary information about pressure sewerage, as well as all aspects of this device and the necessary criteria for its installation.

In fact, the pressure sewerage device itself is nothing more than a structure that consists of special sealed pipelines. Such pipelines ensure the movement of wastewater to the place where collection and treatment takes place. This process is carried out using pressure exerted by a powerful pump.

What is a pressure system?

In this type of drainage, wastewater is moved using a special pump, and not under the influence of gravity, as in gravity systems. This allows you to organize the supply of wastewater to the outlet pipe if it is located above the zero point.

Gravity (A) and pressure (B) sewers

Pumping units (stations) are an important unit for pressure water disposal; depending on their functional purpose, they can be:

- In-house , designed to serve individual buildings. Such installations are a sealed container equipped with a pump and a grinder. The small dimensions of the device allow it to be installed in the basement of a building. Below is a drawing depicting the main structural elements of the Sololift station.

Figure 2. Main elements of a sewage pumping station for a private house Sololift

Designations:

- A – Top cover with carbon filter.

- B - outlet tube with a check valve, which plays the role of a valve when the vacuum pump is turned off. Insertion into a common riser is allowed.

- C – chopper.

- D – input cleaning filter.

- E – pumping mechanism.

- F – reservoir.

— External pumping stations serving several residential buildings at once. In this case, wastewater (including stormwater) is drained by gravity into a common container from several areas, from where it is pumped to a central collector or treatment plant.

An example using an external pump station

Examples include equipment from Wavin, Rehau, Evac, etc.

Smooth products

When difficulties arise when laying a standard sewer system, it is worth resorting to the pressure version of the system. The price for such work increases because additional equipment must be involved in installation, including the following:

- fecal pumps;

- collection manifold;

- forced pump.

If you want to save money, you can replace a pipe with a diameter of 110 mm with its equivalent with a cross-section of 50 mm. The depth of the trench is not very large, which can be explained quite simply: the pipeline does not require a gravity slope. As a result, the number of excavations is reduced, while the reliability of the system remains unchanged.

PVC products are equipped with sockets into which rubber seals are inserted. These products can be used in vacuum lines and pressure networks.

Strengths and weaknesses of pressure systems

Let's start with the advantages of NK, these include:

- Lack of strict requirements for the angle of rotation, inclination of pipes and installation of revisions.

- The pump stations are equipped with shredders, which makes it possible to reduce the diameter of the pipes without the risk of clogging.

- Due to the pressure created, the pipeline is self-cleaning.

- The absence of tilt requirements allows you to place plumbing equipment anywhere.

This drainage system also has significant disadvantages, the main one being its dependence on power supply. If it is turned off, there is a high probability of clogging, so it is recommended to install UPSs as backup power sources.

The negative side also includes the high cost of equipment and the cost of its regular preventive maintenance.

Steel

Some believe that using steel pipes for sewerage is not only impractical, but also very short-sighted, because this material is susceptible to corrosion and can last quite a long time.

Of course, there is some possibility that in some case a very high pressure sewer may be needed, which will be used for a very short time. This option is justified only in such rare exceptions.

However, we note that the main advantages of steel pipes are the mechanical strength of the pipe body and welds designed for high pressure.

But among the disadvantages one can highlight electrical conductivity, a tendency to oxidation and corrosion, poor resistance to chemical reagents, a tendency to clog and reduced clearance.

Thus, if you need durable and reliable sewerage, then steel pipes are not suitable for you.

Rationale for application

In most cases, when organizing a local sewage system for a private home, a gravity-flow scheme is used, since it is more economical and easier to maintain. But in some situations, the installation of NK is not only justified, but also has no alternative. The basis for making a decision in favor of installing a water pumping station may be:

- complex terrain, which does not allow providing a constant slope necessary for organizing a gravity system;

- the presence of rocky or moving soil, which complicates or makes it impossible to lay the pipeline at the calculated depth.

- the pipeline route is long, which eliminates the creation of conditions for gravity movement of water.

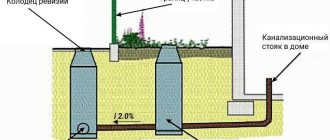

- The drainage point is located below the inlet pipe, a clear example is shown in the figure below.

Simplified sewerage diagram in a private house

The figure shows in red the nodes where the installation of a toilet pump or other plumbing equipment is required.

Please note that moving a toilet in an apartment, as a rule, is not possible without appropriate repair and plumbing work. To avoid this, you need a household low-power SPS, such as Sololift in Figure 2.

Nuances of using the network

There are several cases when the use of pressure sewerage is necessary. These include:

- the location of the house is below the level of the central sewerage system (for example, in a beam);

- uneven terrain along the route of wastewater to the disposal site;

- the need for open laying of sewer pipes (for example, over the road);

- the inability to dig a trench at an angle to ensure gravity flow of water;

- the need to use channels of small diameter.

A system assembled from small-diameter pipes and not having a sufficient slope must be pressure only, otherwise there will be problems with drainage

The laying of pressure sewers (PVC and other materials) requires coordination of the project with the engineering services of a particular area regarding the intersection with other networks.

Note! It is important in organizing forced drainage to ensure a security zone: no closer than 250 meters from the river bank, 100 meters from the lake and 50 meters from the underground water intake source.

To save money, you can install one system on several farms. This combination is real, since pumps of various capacities are available for sale.

Design

If there are sufficient grounds for arranging the NK, you can proceed to the first stage of construction - system design. It is better to entrust this part of the work to specialists. They will calculate the pumping station, determine the optimal pump power and the need to install a switching chamber, draw up an accurate estimate and explanatory note, observing design standards. An example of such a project and installation estimates can be found on thematic sites and forums.

Note that when connecting to central sewerage networks, the operation service will first of all request a design for the drainage system. When organizing an autonomous NK, some of the problems are eliminated, but, nevertheless, there are nuances that must be taken into account.

Errors in hydraulic calculations, calculations of the minimum pipe diameter, engine power, etc. may lead to unstable operation of the internal or external NK network. In some cases, the situation can be corrected by creating a pressure damping loop (damper well).

Construction of a damper well

The number of such wells in the system is not standardized; their number, the distance between the two nearest ones and their characteristics are determined during the calculation process or based on the results of a hydraulic test. It is not as serious as for an oil pipeline, but, nevertheless, it must be carried out without fail for NK.

Selecting a fecal pump

First of all, it is necessary to determine its power; it depends on the length of the vertical and horizontal pipeline lines. This relationship is shown in the figure below.

Pump power depending on pipeline length

As for the flow rate in the NK system, according to SNiP standards it should be about 2.0 l/s; accordingly, the pump capacity is selected at 120 l/min. Next, you should decide on the type of pumping equipment, it can be:

- Submersible (suction).

- Superficial.

The first ones are more expensive, they are designed for trouble-free operation in an aggressive environment. The latter are somewhat cheaper and easier to maintain, but their installation will require more effort.

Tank volume

The volume is calculated based on the daily rate of water consumption per person, its average value is about 0.20 m3. The reservoir must hold a minimum of three days' flow. For example, if 4 people live in a building, the average daily consumption will be about 0.80 m3; taking into account the three-day norm, the tank must have a volume of at least 3.20 m3.

It is advisable to choose a two-chamber tank design, in which case one compartment will act as a primary settling tank, and the second as a pumping chamber. It is in it that a fecal pump equipped with a grinder will be installed. The filling of the tank is controlled by special sensors; when the wastewater reaches a threshold level, the pump is started to pump it out.

You can purchase a ready-made pumping station with a plastic tank or build a storage tank yourself from concrete rings or bricks and install the necessary equipment.

CNS: a) industrial; c) average power

Choosing a location for a storage tank

In order to avoid claims from the water utility, sanitary and epidemiological services and other regulatory organizations, you should take seriously the choice of location for the storage tank. In accordance with SNiP 020402-84, there must be a sanitary protection zone around a possible source of pollution. The above document stipulates what the minimum distance should be between the pipes (sleeves) of the NK and wells or other sources of drinking water. These SNiPs also regulate the distance from the security zone of residential buildings, site boundaries, bushes and trees, as well as other objects.

Basic norms for the place of pumping stations

In addition, you should take into account the underground communications passing through the site; unfortunately, their designation is not always present on the drawings, which can cause certain difficulties. Information about the availability of such communications can be obtained from the relevant services.

Corrugated products

PP structures are made with a ribbed outer wall, which is usually made of low-density polyethylene. The smooth inner surface is made mainly from high-density polyethylene. Thus, the wear of this layer is reduced when abrasive particles move along with the wastewater. The ring stiffness always remains unchanged.

Corrugations are not installed in internal pipelines, since this design has low longitudinal rigidity. The cylindrical product sags when it begins to be secured with clamps.

In the trench itself, the assembly of the main line is carried out using sockets, which differ from their analogues in compression couplings.

PVC products installed in pressure systems are produced in two layers. The color of the inner wall is different from the outer one.

When forced sewerage works, all initial characteristics, such as pressure and pressure, remain unchanged. As a result, the flow retains its ability to self-purify. Thanks to this, it is possible to install a pipeline from cylindrical products of small diameter, for example, 50 mm.

External sewerage, made of corrugated cylindrical products, is used only in domestic conditions. It is capable of transporting wastewater under high pressure. Perforated drainage pipes cannot be used for such purposes, since the storm drain will only work when gravity flow is applied.

Which pipes are best to make NK from?

Since a running pump creates pressure drops in the system, the pipes and fittings involved in it must have:

- sufficient flexibility;

- strength in places of fastenings and joints;

- resistance to frequent changes in pressure.

Cast iron socket and plastic pipes meet these conditions. The former have sufficient strength and performance characteristics, as well as a fairly long service life (25-30 years). But cast iron products have a number of significant disadvantages:

- heavy weight (complicates installation and repair work);

- the material becomes brittle in the cold, which requires mandatory insulation of the pipe if the laying depth is above the soil freezing horizon;

- labor-intensive connection technology.

The listed disadvantages have led to the fact that pipes made of this material are practically not used when laying sewer systems.

Plastic (PVC) and polyethylene pipes (HDPE) are the best option for organizing external and internal drains. Their main advantages:

- light weight;

- the pipe material is not exposed to aggressive environments;

- simple connection technology;

- no deposits form on the inner surface, which reduces the likelihood of blockages and the need to use a plunger for cleaning.

As an example of such products, we can cite the products of Ostendorf, Hemkor, Geberit; these pipes fully comply with GOST standards.

Pipes for internal and external pressure sewerage

Please note that non-pressure sewer pipes designed for gravity flow systems inside and outside the building are not suitable for NK. The joints of such products will not be able to withstand pressure changes within the system, which will lead to the formation of leaks.

The connection of plastic pipes in the NDT system is made using a special soldering station. A description of the soldering technology can be found on our website. Note that there is an alternative connection option using glue; it can only be applied to special glued pipes.

Polyvinyl chloride

PVC pressure pipes for sewerage began to appear on the building materials market not so long ago, however, the demand for them has increased significantly recently.

Among the advantages of PVC pressure sewer pipes are low cost, low weight, as well as the possibility of quick and easy connection using O-rings.

The disadvantages of products in this group include low noise absorption, as well as low ductility.

Types of holding containers

Among the main types of prefabricated containers are cesspools and septic tanks. The first is a type of cesspool, which is dug into the ground and lined with a thick layer of clay. A modern well is a sealed structure into which sewage is drained and then removed using various devices (pumping pump, sewer truck) beyond the boundaries of the site.

Note! To build a cesspool, you can use a variety of materials: brick, concrete, stone or blocks. One of the options is to install reinforced concrete rings, metal or plastic tanks.

A septic tank is an improved cesspool, with the help of which it is possible to dispose of part of the wastewater on site. It can consist of two containers, one of which (prefabricated or cesspool) has a bottom and is sealed, the second - without a bottom, installed on a filter base (gravel, crushed stone, coarse sand), through which clean water enters the groundwater layer.

The best, albeit expensive, option is to install septic tanks in the form of local sewer systems. Such equipment collects waste and almost completely recycles it. Clean water comes out of it (96-100 percent), which can be used to water the area.

Autonomous sewerage must include a septic tank or cesspool

Pump installation rules

There are a number of rules that must be taken into account when installing pumps for pressure sewer networks:

- in the place where the pump is installed, it is necessary to constantly maintain the temperature above zero;

- the site for installing a sewage pumping station must have access and be cleared;

- a support elbow with a special flange must be placed at the bottom of the structure;

- the pressure pipeline rests on the elbow;

- in the upper part of the well, the pipe is secured with a bracket fixed to the wall of the structure;

- the channel must be installed without stress or distortion;

- to prevent reverse flow, a valve and a check valve are provided in the pipeline;

- a guide structure and a chain fixed on it are used to raise and lower the pump;

- a tight connection occurs automatically when the pump reaches the lower elbow.

Pumping stations are divided into indoor and outdoor. The first are designed to drain wastewater from one building and consist of a pump with a grinder and a plastic housing. Such a structure is usually installed in the basement. Outdoor stations facilitate the transfer of wastewater from several houses. They pump liquid from a container where sewage flows by gravity, and then into an existing sewer or treatment plant.

To lower and raise the pump, you need to attach a reliable rope or chain to it.

What to look for when choosing elements

Pressure sewer channels must be protected and highly reliable. Such requirements are explained by the characteristics of the network:

- transfer of liquid under pressure;

- water hammer when starting pumps;

- sudden changes in pressure.

Ideally, products for pressure sewerage will withstand pressure values of up to 1600 kPa. Currently, the most popular are pipes made of polymers (most often unplasticized polyvinyl chloride). They are durable, relatively lightweight and affordable.

PVC-U pressure channels are chosen with a smaller cross-section than for the construction of non-pressure analogues. The connection can be achieved by cold welding or special fittings. It is important to consider that pipes for such systems should not have sockets.

The intermediate tank must have a sufficient volume to accommodate three days' worth of wastewater. This is important for situations where the pump breaks down or there is a power outage, when the sewage system does not function for some time. To carry out the necessary calculations, it is better to use current standards.

The pump power is selected based on the depth of the intermediate tank and the distance to the central sewerage system. For example, 0.4 kW is enough to lift wastewater 2 meters and transport it 200 meters.