- Metal grid

August 22, 2018

635

In the construction industry, reinforcement is widely used during the construction of structures of various functional purposes. If we are talking about this type of reinforcing materials like masonry mesh, how to choose it correctly? We will try to give a detailed answer in our article.

Let's start with the main thing. There are, figuratively speaking, two roads, two paths. The first way is to use the current regulatory framework. There are several main regulatory documents that will help us resolve the issue of choosing a material, among them:

- Determines the product range - GOST 2715-75, ;

- GOST 8478-81, which establishes technical conditions for welded mesh, including masonry mesh;

- Another standard is GOST 23279-2012, which defines the technical conditions for the type of metal products we are considering (this is important; many still use the old-fashioned way to indicate the no longer valid GOST 23279-85 standard).

If you approach the issue more carefully and balancedly, and construction is carried out on the territory of the Russian Federation, then you can use the national standard GOST R 52265-2016. There are also technical specifications - TU 1275-012-00187205-2002, TU 14-169-153-99. And if we are talking about the construction of walls not from piece materials, but from monolithic reinforced concrete, then TU 14-1-5254-2006, TU 14-1-5570-2008. We think these documents are sufficient for now to fully consider the issue.

The second way is in the phrase - any whim for your money. Manufacturers can produce masonry mesh according to customer requirements, without taking into account regulatory documents. Or the masonry mesh is formed directly at the construction site from certain types of rolled metal. Read about this further in our material. In such a situation, we recommend using common sense, since reinforcement is usually carried out on load-bearing walls, and they do not forgive mistakes. It is necessary to develop design and estimate documentation, a feasibility study, and only then engage in amateur activities.

Masonry mesh - how to choose the right one

The first question that needs to be answered is: “Is masonry mesh necessary at all?” The answer lies in the main uses of this material. And there are three main ones:

- reinforcement of walls, if we are talking about piece materials, then horizontal masonry joints;

- forming bonds in multilayer masonry to connect layers;

- reinforcement of the plaster layer of walls.

There are many other ways to use masonry mesh. We note such as pouring interfloor slabs, erecting foundations, creating screeds, decorative finishing of premises, forming gabions and other enclosing structures. In this case, you can use not only masonry mesh, but also other types of mesh. For example, such a type of product as a road mesh.

Next important question. From the experience of practical use, one bad practice has developed, but it still exists. The point is that the material began to be divided according to the direction of use. For example, masonry mesh for bricks, masonry mesh for aerated concrete, and even masonry mesh for foundations. This is not the entire list. There is no such division in regulatory documents, but it appears in price lists. Whether or not to use this selection criterion is up to you.

To make it simple and clear. Let's take GOST R 52265-2016 as a basis. It precisely defines the standards for masonry mesh, and will be supplemented with other documents indicated above.

So, the basic selection parameter is the material of manufacture. Masonry mesh can be purchased made from ferrous rolled metal and composites.

Metal mesh for reinforcement and masonry

Prices for masonry mesh

- Mesh 50x50 Vr1 neozinc.

- Mesh 50x50 Vr1 galvanized.

- Mesh 50x100 Vr1

- Mesh 100x100x3

- Mesh 100x100x4

- Mesh 100x100x5

Types of mesh for masonry

Masonry mesh is used in the construction industry to reinforce brick walls and concrete products. In this case, the main task of strengthening the entire structure is solved. Masonry mesh is:

- steel

- basalt

- fiberglass

Metal masonry mesh

At APEX METAL you will buy metal masonry mesh. The main material for the manufacture of mesh is galvanized and non-galvanized wire BP1. The most common cell size is 50x50 mm, with a wire diameter of 3 to 5 mm:

| Cell size, mm | Theoretical weight of 1 m2, kg |

| Mesh 50x50x3 | 2,22 |

| Mesh 50x50x4 | 3,86 |

| Mesh 50x50x5 | 5,92 |

In addition, depending on the scope of application, mesh of other sizes is used - 50x100, 100x100 mm:

| Cell size, mm | Theoretical weight of 1 m2, kg |

| Mesh 50x100x3 | 1,66 |

| Mesh 50x100x4 | 2,96 |

| Mesh 100x100x3 | 1,13 |

| Mesh 100x100x4 | 2,00 |

| Mesh 100x100x5 | 3,10 |

The dimensions of welded masonry mesh are standardized and regulated by GOST 23279-85. You can find out the cost using the links above in the “Prices for masonry mesh” block or in the “Welded mesh” section of the Catalog.

How is reinforcement carried out?

The mesh is laid on every 4-5 rows of bricks. The mass of the wall acts on the reinforcing wire, causing it to clamp and work with the masonry as a single whole structure. The need for the masonry reinforcement procedure increases significantly if ventilation holes must be made between the facing brick and the wall.

Reinforcement with masonry mesh is divided into two types:

- longitudinal

- transverse

In the case of transverse reinforcement, the rods absorb transverse tensile loads associated with compression of the masonry. As a result, the mesh prevents the destruction of bricks subjected to tension or bending, thus increasing the load-bearing capacity of the wall.

Areas of application

Metal mesh for masonry from APEX METAL is used for the following purposes:

- plastering works

- fencing of scaffolding, building facades, construction areas

- arrangement of drainage of horizontal terraces, walls

- reinforcement of gypsum panels

- reinforcement of concrete, facades, floors, walls, arches

- reinforcement of reinforced concrete products, structures

- identification of underground communications

- pavement reinforcement

- mechanical protection of pipeline lining

- laying heating pipes when installing heated floors

Corrosion protection

The main method of corrosion protection is the hot-dip galvanizing method.

The mesh can also be supplied in non-galvanized form. But in this case, in order to provide anti-corrosion protection, the brickwork mesh is covered with a layer of mortar, which protects the steel from contact with the atmosphere.

Steel masonry mesh

Regarding ferrous metal products. GOST 2715-75, GOST R 57265-2016 and GOST 8478-81 use the term steel wire. GOST 23279-2012 indicates the use of steel reinforcement. A number of regulatory documents also contain such a very rare type of mesh as expanded metal. In other words, the masonry mesh used for reinforcing structures can be made from such types of rolled products as:

- steel wire (B1 and BP1);

- fittings of classes A500C, B500C, A240 (AI), A600C, A-400 (AIII);

- strip (cold-rolled black metal sheet).

The material of manufacture is ferrous metal; non-ferrous metal, as a rule, is not used (in general practice). Often these are low-carbon steel grades (they weld better). Less commonly used are austenitic steel grades (chromium-nickel, molybdenum-chromium-nickel, and they are simply called “stainless steel”).

Presence or absence of protective coating

When purchasing steel masonry mesh, pay attention not only to the steel grade, but also to the presence or absence of a protective coating. Most regulatory documents indicate the need for a protective layer. That is, they directly indicate, for example, the use of only galvanized masonry mesh. At a minimum, the mesh can be painted as necessary. According to regulatory documents, galvanizing and application of polymer materials are used.

Please note that the properties of galvanized or polymer-coated masonry mesh directly depend on the technology for applying the protective layer and its thickness.

If we take galvanized mesh, then among the main technologies for applying a layer of zinc we note the following types of galvanizing:

- galvanic (electrolysis, in an electrolyte environment);

- hot (by dipping in molten zinc);

- thermal diffusion (sherardization, in a special oven at high temperatures, often with additional rotation);

- cold (paint or primer with a high content of zinc powder (up to 98%), which is applied to the surface of the mesh with a spray gun).

Galvanized masonry mesh is resistant to corrosion, this is its main advantage . Galvanic, hot and thermal diffusion galvanizing is carried out under production conditions. Cold galvanizing is carried out using improvised means. Sometimes this is an additional service performed at the request of the customer. This is provided along with services such as cutting and customization.

The second way to protect the masonry mesh is to apply a layer of polymers. They are used in different ways. Often polyurethane, polyvinyl chloride and many others. The polymer coating is also applied using several technologies, such as:

- dipping the mesh into the polymer melt;

- by applying liquid polymer using the roller method (Coil Coating);

- using the electrostatic method and spraying of polymer in powder form;

- a number of other ways.

It is very rare, but a combined coating of masonry mesh is also found.

Composite masonry mesh

Now about composites, or more precisely composite fibers. For the purpose of reinforcing masonry from piece building materials and erecting monolithic reinforced concrete walls, various materials are used. To systematize everything, identifying all regulatory options, we will use GOST R 52265-2016. It states that masonry mesh can be made from:

- glass composites (ASC), fiberglass;

- basalt composites (ABC), basalt fiber;

- polymer materials.

Among the polymers, carbon composites (AC) made from carbon fiber and aramidocomposites (AAC) made from aramid fiber are designated. Not specified in domestic regulatory documents, but other polymers are widely used in the production of products. We note polyester (polyester, PET), polyamide (PA), polypropylene (PP), polyethylene (PE and HDPE), polyvinyl alcohol (PVA). That's not all. We must also take into account such a concept as combined composite masonry mesh. All of these composite masonry meshes are made from fibers of certain materials. Polymer or bitumen impregnation is often used.

Materials for strengthening masonry

To reinforce brick structures, steel and composite reinforcement is used, in the form of individual rods and meshes made from them.

To produce the mesh, metal rods of class A240 and B500 are used, as well as composite - glass and basalt-plastic reinforcement. The minimum diameter of rods for the production of reinforcing mesh is 3 mm.

Reinforcement of classes A240, A300, B500, as well as fiberglass rods are used as longitudinal and transverse rods, as well as anchors and ties. The selection of diameter depends on the type of masonry and the required strength of future brick walls.

It should be noted that the diameter of the rods in the horizontal joints of the walls should be no more than:

- 6 mm – if the reinforcement in the seams intersects;

- 8 mm – the reinforcement does not intersect.

One of the most popular meshes used by builders to reinforce brickwork is basalt mesh. It gained its popularity due to its properties:

- Not affected by alkalis, resistant to corrosion.

- Low thermal conductivity.

- High adhesion due to polymer binder impregnation (acrylate).

- Light weight.

- Does not create magnetic fields and does not conduct current.

- Easy to use and safer than metal ones.

Which material to use depends on the future loads to which the brick wall will be subjected. This will also affect the choice of option for performing the work.

Main features of grid selection

How to choose masonry mesh, taking into account a number of other parameters. Let's look at them briefly. One of the criteria is the configuration of the cells; it can be:

- rectangular (in a wider range of quadrangular), longitudinal and transverse wires are located at a certain angle to each other, for example, 90° (rectangular or square cells) and are welded by spot welding (welded masonry mesh);

- half-timbered, with triangular cells, also belongs to the welded category;

- wicker, similar in the shape of the cells to half-timbered, but the joints are not welded, but intertwined (woven masonry mesh, the number of turns of transverse wire around the longitudinal wire is at least 1.5);

- expanded metal, unlike other types of mesh, is made not from wire rod or reinforcement, but from a sheet using the technology of cutting and subsequent drawing, the configuration is appropriate.

We briefly mentioned the shape of the cells. Steel mesh in accordance with GOST 2715-75 can be produced not only with square and rectangular cells. Products are also produced in diamond-shaped, hexagonal, and trapezoidal shapes. But such solutions do not occur often. In other words, either a square or a rectangle. Moreover, if you mean a composite mesh, then there are no other options.

Regarding production technology. As you can see there are several of them. If we take steel masonry mesh, then the main technology is welded. Especially when these are reinforced concrete monolithic structures. But there is an indication in regulatory documents that the use of technology is allowed. They provide the required strength of the connection, while preventing a decrease in the strength of the reinforcement elements being connected.

Which masonry mesh is best for bricklaying

To determine which masonry mesh is better for masonry - basalt, steel or fiberglass, you have to take into account the type of masonry, type of brick, thickness of the structure, operating conditions, and temperature characteristics of the area. Steel mesh is suitable in almost all cases, especially when a thick layer of cement joint is being made. Basalt mesh will be less expensive. It is advisable to use it in the construction of objects with increased fire hazard. If you focus on the cost-effectiveness of the estimate, a fiberglass stack for bricklaying will be more profitable.

Dimensions and other characteristics

Now regarding the sizes. If you need masonry steel mesh, how to choose depends on its characteristics. They are determined not only by production technology, the presence or absence of a protective layer and steel grade, but also by the size of the rolled products used. In general, the main meanings are as follows. Wire VR-1 with a diameter of 3 mm, 4 mm or 5 mm. Reinforcement according to GOST 23279-2012 from 4 to 40 mm. Applicable for the construction of walls made of monolithic reinforced concrete. If we take GOST R 52265-2016, then from 4 to 10 mm. This mesh is actively used in the construction of walls made of artificial or natural materials. Strip for expanded metal mesh, galvanized, 0.4 mm thick, made of austenitic steel (stainless steel) - 0.3 mm. The diameter of the fibers of composite reinforcement is determined based on the calculation of the cross-sectional area of the reinforcement.

The next important parameter is the cell size. If it is a steel mesh, then according to GOST R 52265-2016 from 10075 to 500[sc name=»cross»]400. Selected depending on the dimensions of the piece materials used. Please note that, based on the design documentation, a grid with a smaller cell size can be used. According to other regulatory documents from 5 to 100 or according to individual requirements. The values are selected based on the specifics, architectural and construction solutions used at the site. For example, a masonry mesh with a cell size of 50x50 is often used. Composite mesh is used with cell sizes from 4x4 to 200x200.

Features of masonry mesh: design, purpose and materials

According to GOST 6727-80, masonry mesh is made from wire with a diameter of 3-6 mm.

Its main purpose is to reinforce brickwork. This is a special technological technique that makes it possible to provide walls with strength and resistance to destruction, and prevent excessive shrinkage and deformation. As a result, it is possible to increase the service life of the building and go longer without repairs. Important: the mesh retains the masonry mortar, preventing it from penetrating into the voids of the building material. This is very important to ensure the required level of thermal insulation.

Laying mesh on brickwork

In what cases is it necessary to use masonry mesh:

- Construction of high-rise or capital buildings with walls of 2 or more bricks.

- Simultaneous construction of two brick or stone walls, different in shrinkage, creep and other characteristics.

- Construction of a building from lightweight blocks with a large number of voids into which concrete mortar can penetrate.

- Construction of an object in conditions of low temperatures, which slow down the setting process of concrete.

- Construction of large-format blocks with simultaneous brick cladding.

- Screeding of the subfloor to give it greater strength and stability.

- Applying plaster to the walls in a very thick layer (here, without a mesh, the solution simply will not stick to a vertical surface).

Please note : the mechanical strength of aerated concrete is not enough, therefore, in the absence of a mesh, there is a very high probability of cracks appearing in the masonry.

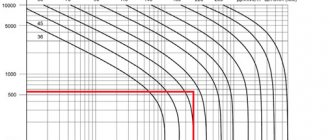

Percentage of brickwork reinforcement

In what places should masonry mesh be used:

- at the intersection of load-bearing walls;

- above the lintel and other openings;

- below under the last row;

- in the corners;

- under the floor slabs (depending on the design of the plinth - under the slab or directly on the foundation blocks {brick}).

The masonry mesh for the blind area is used for the same purposes - to give strength and durability to the structure. The material also allows you to extend the service life of the building’s foundation.

Vertical reinforcement of brick walls

Release form, main dimensions

Next is the release form. There are two of them:

- Rolls, if the diameter of the steel wire or reinforcement is up to 5 mm. Sometimes a little more. Or it is a composite mesh with a fiber diameter from 1.5 to 8 mm.

- Cards (sheets), which is typical for steel masonry mesh with large diameter reinforcement. Although in this case one of the technologies involves purchasing not mesh, but reinforcement. A grid is formed from it directly at the construction site.

By the way, this technology occasionally (due to its high labor intensity) also involves the use of VR-1 wire. Composite masonry mesh with large diameter fibers (over 8 mm) can also be supplied in cards. Take it into account. Steel masonry mesh made of wire and reinforcement with a diameter of up to 5 mm is called light. If the value is higher, the mesh is heavy. Two main groups.

The sizes of cards and rolls differ in their variability and are determined by a number of regulatory documents. Or they are taken into account the individual requirements of the buyer. For example, according to GOST R 52265-2016, the width of the steel mesh can be from 650 to 3800 mm. The length of the cards according to the same document is from 850 to 9000 mm. Everything is purely individual. Pay attention to this when purchasing. Take into account based on your design estimates or specific areas of use. For example, when choosing the width of the mesh, it is necessary to take into account the thickness of the wall and its structural features. The bottom line is that reinforcement can be performed not only to increase the strength of the wall. Sometimes it is required to bind two- or three-layer walls.

When reinforcement of brickwork is necessary

When constructing brick buildings, masonry mesh must be used in the following cases:

- when walls are built from materials with different mechanical characteristics, for example, cinder block walls are lined with ceramic or clinker bricks;

- when constructing wide walls of high-rise buildings, when the thickness of the masonry row is two or more bricks;

- when building from lightweight bricks with voids;

- when constructing brick buildings in low temperature conditions.

Features of installation of masonry mesh

SP No. 15.13330.2012 recommends laying reinforcing mesh at least every 5 rows. In low-rise construction, reinforcement is usually performed through 3 rows of bricks. The thickness of the mortar laid on a brick row is usually no more than 15 mm.

When choosing a mesh, you need to take into account the mesh size so that cuttings of transverse wires longer than 5–7 mm do not form on the sides of the fabric. The masonry of small buildings is reinforced with a mesh with 2.5–3 cm cells made of wire with a diameter of up to 4 mm. The width of the reinforcing mesh strip should be 5–10 mm less than the thickness of the wall so that the masonry mortar completely covers the metal, protecting it from precipitation.

Masonry mesh - how to choose according to operating parameters

The performance characteristics of the masonry mesh itself are also important. There are quite a lot of them. Let's note the basic ones. Among them:

- mesh weight, per unit area of masonry;

- surface density (g/m²);

- ultimate transverse and longitudinal strength (breaking load, kNm);

- elongation at break (mm or%);

- frost resistance (in freeze-thaw cycles, for example, F50, 50 cycles);

- yield strength (N/mm²).

These, of course, are not all the parameters, but the main ones. All information must be displayed on the labeling of metal products. Let's take the symbol XC(Dy/Dy1)BxL as an example. Where:

- X – group of products (from 1st to 3rd heavy mesh, from 4th to 5th light);

- C – release form (C-cards, CP-rolls);

- Dy/Dy1 – rolled diameter (sometimes the steel grade is also indicated);

- B – length;

- L – width.

In other words, if you need a masonry mesh, how to choose depends not so much on the criteria that were discussed. You can rely on them, as well as the need to competently, without errors, draw up design and estimate documentation. This is necessary and important. If you need to buy masonry mesh, please contact us. We will definitely help you with this issue.