Description and features

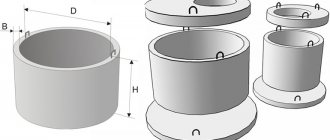

Based on the name, it is clear that the reinforced concrete ring consists of metal and high-quality concrete. This makes it durable and allows it to resist loads from the outside and inside. External loads mean the soil pressure on the ring. As for the internal loads, this is the water that the rings hold back, preventing it from getting into the ground.

The latter is especially important when installing septic tanks and drainage pits. The rings undergo additional waterproofing, which makes them completely sealed. The reinforced concrete rings in the photo have the shape of a cylinder.

Well rings, also known as reinforced concrete products, are available on the market in different diameters. This expands the scope of application of the material, allowing it to be used for the needs of private developers and capital construction. Such rings weigh quite a bit, so you won’t be able to deliver them yourself.

Basically, for their delivery, a manipulator is used, which simultaneously delivers them to the site and independently unloads and performs installation. For installation and unloading, each ring has special hooks. They are part of reinforced concrete structures, so the geometry of the ring itself is not disrupted during unloading.

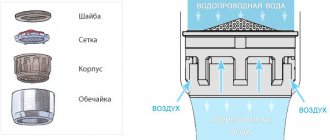

The rings come complete with a bottom and a top cover. This allows you to achieve maximum tightness, comply with SNiP standards, and install the septic tank correctly.

A well is not just rings

Concrete rings are only one of the elements of the well, for the assembly of which other products are needed, in particular:

- bottoms;

- covers;

- support rings;

- floor slabs with holes for hatches;

- cast iron, steel, concrete, plastic hatches;

- ladders or brackets for descending into the well.

Elements are also produced that perform two functions at once: - concrete rings with a bottom;

- rings with lid.

For wells where an increased density of the trunk is required, rings with a quarter are made - a ridge is made along the perimeter of the ring for half its thickness, from the outside on one side and from the inside on the other.In this case, concrete rings for the well, placed on top of each other in a cement-sand mortar, form a tight joint that protects the working environment of the well from penetrating groundwater, and the soil from the flow of wastewater when the sewer well or septic tank overflows.

Types of reinforced concrete rings

Speaking about the types, it should be noted that the reinforced concrete ring for a well is represented by several main classes. This is a drainage variety used for sewer systems, for arranging drainage pits and wells. There are wall options. They are convenient to use where it is necessary to equip a well.

Such systems have a number of important hooks, which makes it possible to form a single, powerful block. On sale are a version with a lock, as well as those with a lid and base. The latter allows you to achieve tightness.

There are also additional options available for sale that are relevant for production on individual orders. These options are developed according to the customer's specific dimensions and are always made to order.

Reinforced concrete rings come with holes

Reinforced concrete rings for sewerage always go through the reinforcement stage. Thanks to this, they have a single, powerful design. During installation, the hooks are bent to form grooves. The ring, the second in line, which is lowered onto the previous one, falls together through metal elements. The presence of a groove, even when the rings are in liquid, does not allow them to rise and rotate relative to each other. This property is relevant.

Regarding the species, I would like to note the difference in the diameter of the rings. For the construction of wells and well pits, a ring with a height of 90 centimeters is often used. The internal and external diameters of reinforced concrete rings are individual indicators of the manufacturer.

These should be taken into account at the time of purchase. The wall thickness may also differ, which indicates the strength of the product.

The best manufacturers of concrete rings

Concrete rings are produced by many Russian enterprises. Among them are companies whose products are in particular demand.

Place #1 – in Moscow Region

in Mytishchi has recently begun to produce reinforced concrete rings for various purposes, including sewer rings. Here they make wall products, with a bottom, additional panels, concrete covers, and a separate well bottom.

There are folded rings and those without a lock. There are passports and certificates for everything.

The following products are especially popular:

- KS ring, rebated and straight, with a cross-section of 90 – 100 cm, complete with a lid and hatch;

- product KS with and without a lock with a diameter of 90 – 150 cm in the same configuration;

- KS ring both with and without a lock with a lid and hatch with a diameter of 90 - 200 cm.

The enterprise's capacity is large enough to ship products to all regions of Russia. The cost of one ring is about 2.1 thousand rubles.

Place #2 – Dialog Stroy company

A company from Novokuznetsk, Dialog Stroy, supplies the entire region with reinforced concrete products.

The company provides benefits to its customers during the winter period. Subject to prepayment, price freezes and all kinds of discounts apply

The assortment includes the following product names:

- KS 7-9 – with a wall thickness of 80 mm;

- KS 10-9 – with the same walls;

- KS 15-9 – with walls 100 mm;

- KS 20-9 - with walls of the same thickness.

For individual orders, it is possible to produce rings with other parameters. The price of products starts from 1.7 thousand rubles.

Place #3 –

The products are popular among consumers. Here they produce reinforced concrete rings for sewer wells, hatches for them, bottoms, and additional rings.

The average cost of a ring is about 2.7 thousand rubles. The company is located in Kirov, but deliveries are carried out throughout Russia.

Place #4 – YugStroyKomplekt enterprise

Krasnodar also produces a wide range of reinforced concrete products. The height of the rings is 0.9 m, the diameter is from 100 to 200 cm. The price of one product is from 1.4 thousand rubles.

Characteristics and dimensions

Speaking about the most important characteristics of concrete rings, it is worth noting their resistance to moisture. It is in a humid environment that they will be used most often, since they are used to construct wells, as well as drainage pits, pits for wells, and other places with high humidity.

That is why the rings should not react in any way to water. This is facilitated by the quality of concrete. The higher quality the concrete, the higher its waterproofing properties. For rings that will be used as a pit, that is, in damp conditions, the concrete grade M100 M150 is suitable; for reinforced concrete rings that will stand in a septic tank, it is best not to save money and buy products made of concrete grade M300 no less.

Reinforced concrete rings and their sizes

Pay attention to characteristics such as outer and inner diameter. The outer diameter will allow you to understand the diameter of the recess before installation. The internal diameter will allow you to calculate the volume that the liquid can fill during operation.

The difference between the inner and outer diameter is the wall thickness. The thicker it is, the stronger the purchased products. Internal reinforcement also affects strength. The reinforcement for the ring is a wire with a diameter of at least 4-6 mm. This is enough to ensure that the concrete does not deteriorate from time and moisture.

The dimensions of reinforced concrete rings are important, especially the internal diameter. On sale, reinforced concrete rings used for wells can be supplied with an internal diameter from 60 cm to 2 meters, inclusive. The larger the diameter, the greater the volume of liquid the ring can contain.

This is convenient because you don’t have to often hire equipment to pump out wastewater. In the case of a drinking well, so that the water column is always at the proper level, it is best to choose prefabricated reinforced concrete rings with a diameter of 90 to 160 centimeters, inclusive.

When we look at the label of a product when choosing it in a store, we always see two numbers. The first number indicates the height, the second the internal diameter. Height will also ultimately affect volume.

Table of sizes of reinforced concrete rings for a well

| Name | Diameter D, mm | Diameter d, mm | Height h, mm | Thickness, mm | Concrete volume, cubic meters | Weight, tons |

| K-10-10 | 1160 | 1000 | 990 | 80 | 0.27 | 0.68 |

| K-10-5 | 1160 | 1000 | 490 | 80 | 0.14 | 0.35 |

| K-12-10 | 1410 | 1250 | 990 | 80 | 0.33 | 0.82 |

| K-12-5 | 1410 | 1250 | 490 | 80 | 0.17 | 0.42 |

| K-15-10 | 1680 | 1500 | 990 | 90 | 0.44 | 1.1 |

| K-15-5 | 1680 | 1500 | 490 | 90 | 0.22 | 0.55 |

| K-20-5 | 2200 | 2000 | 490 | 100 | 0.33 | 0.82 |

| K-7-1.5 | 840 | 700 | 145 | 70 | 0.024 | 0.06 |

| K-7-10 | 840 | 700 | 990 | 70 | 0.17 | 0.42 |

| K-7-5 | 840 | 700 | 495 | 70 | 0.084 | 0.21 |

| KS 7.6 | 840 | 700 | 590 | 70 | 0.3 | 0.25 |

| KS10.18a | 1160 | 1000 | 1790 | 80 | 0.46 | 1.15 |

| KS10.3 | 1160 | 1000 | 290 | 80 | 0.08 | 0.2 |

| KS10.6 | 1160 | 1000 | 590 | 80 | 0.16 | 0.4 |

| KS10.9 | 1160 | 1000 | 890 | 80 | 0.24 | 0.6 |

| KS10.9a | 1160 | 1000 | 890 | 80 | 0.22 | 0.55 |

| KS13.6 | 1410 | 1250 | 590 | 80 | 0.2 | 0.5 |

| KS13.9a | 1410 | 1250 | 890 | 80 | 0.28 | 0.7 |

| KS13.9b | 1410 | 1250 | 890 | 80 | 0.24 | 0.6 |

| KS15.18 | 1680 | 1500 | 1790 | 90 | 0.804 | 2.01 |

| KS15.18a | 1680 | 1500 | 1790 | 90 | 0.75 | 1.88 |

| KS15.18b | 1680 | 1500 | 1790 | 90 | 0.72 | 1.8 |

| KS15.6 | 1680 | 1500 | 590 | 90 | 0.265 | 0.66 |

| KS15.6b | 1680 | 1500 | 590 | 90 | 0.22 | 0.55 |

| KS15.9 | 1680 | 1500 | 890 | 90 | 0.4 | 1 |

| KS15.9a | 1680 | 1500 | 890 | 90 | 0.35 | 0.88 |

| KS15.9b | 1680 | 1500 | 890 | 90 | 0.32 | 0.8 |

| KS20.12a | 2200 | 2000 | 1190 | 100 | 0.67 | 1.68 |

| KS20.12b | 2200 | 2000 | 1190 | 100 | 0.64 | 1.6 |

| KS20.18b | 2200 | 2000 | 1790 | 100 | 1.02 | 2.55 |

| KS20.6 | 2200 | 2000 | 590 | 100 | 0.39 | 0.98 |

| KS20.6b | 2200 | 2000 | 590 | 100 | 0.3 | 0.75 |

| KS20.9 | 2200 | 2000 | 890 | 100 | 0.59 | 1.48 |

| KS20.9b | 2200 | 2000 | 890 | 100 | 0.44 | 1.10 |

| KS25.12a | 2700 | 2500 | 1190 | 100 | 0.87 | 2.18 |

| KS25.12b | 2700 | 2500 | 1190 | 100 | 0.76 | 1.90 |

| KS25.6 | 2700 | 2500 | 590 | 100 | 0.48 | 1.2 |

| KS7.3 | 840 | 700 | 290 | 70 | 0.05 | 0.13 |

| KS7.9 | 840 | 700 | 890 | 70 | 0.15 | 0.38 |

| KTs12.9 | 1410 | 1250 | 290 | 80 | 0.30 | 0.75 |

| KTs25.12 | 2700 | 2500 | 1190 | 100 | 0.97 | 2.42 |

| PK-7S | 870 | 650-670 | 360 | 100-110 | 0.036 | 0.09 |

Application area

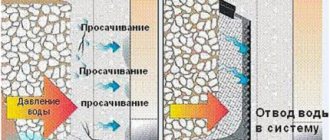

The scope of application concerns the arrangement of structures characterized by high tightness. That is why reinforced concrete products are used to construct a septic tank. A septic tank is the same drainage pit, but with the ability to treat wastewater. A septic tank of two or three parts can be installed on one site.

The more well rings you use, the cleaner the water will be when it comes out. In the case of three rings, the septic tank can produce almost pure water at the outlet, which can be used to water the garden.

When using rings as a basis for a septic tank, they must be additionally sealed. To do this, the outer diameter of the hole in the ground is dug out larger, a septic tank is installed, and then the outside is coated with bitumen.

Using reinforced concrete rings for cesspools

Using well rings, today you can equip a pit for a well. This is a recess of up to 2 meters, where equipment can be installed in the future. By default, the well head is located on the base of such a pit. It is recommended to install well equipment in homes, since here it will be less exposed to moisture. This way the pressure switch can work longer without failure.

Reinforced concrete rings are also used for constructing wells. In this case, they can be with a base and a lid. This will keep the water used for drinking and irrigation clean. The diameter is not chosen to be the largest so that the water column meets the customer’s wishes.

Otherwise, reinforced concrete rings are used for the needs of sewer systems, for laying communications underground, and for constructing underground drainage holes. They are able to withstand significant external loads from the soil, and not collapse under the influence of moisture for a long time. By performing the necessary sealing of the joints, you can achieve 100% insulation, which is important when installing cables, pipes and other communication systems inside the rings.

The principle of operation of a septic tank consisting of several chambers

Overflow septic tanks equipped with filtration systems are becoming increasingly popular today. Some systems are created from two wells. One is equipped with a sealed bottom, while the other is completely absent. A layer of sand and crushed stone is installed under the concrete rings.

The operating principle of such a system:

- Wastewater from the living area flows into the first well.

- Feces and solid waste sink to the bottom as sediment, while fatty waste rises to the top.

- The resulting clarified water between two layers of different densities is discharged into a second container through an overflow pipe, which is installed at a height approximately corresponding to 2/3 of the first well. The pipe is installed at a certain angle to allow unhindered passage of water into another well.

- The clarified water enters the second well, where it seeps through a layer of sand and fine gravel.

In such a system, the first well can be considered as a sump, and the second as a filter device. After a certain time, the volume of fecal matter in the first chamber will be so high that you will have to turn to the services of a sewer. The frequency of such procedures depends on the volume of the septic tank chamber. To prevent an unpleasant odor, special impurities are added to the first well to promote the decomposition of the resulting fecal mass.

Two-chamber septic tanks are made from concrete rings without much difficulty. However, it must be taken into account that such two-chamber systems can be installed on land plots where groundwater is located lower than 1 m from the layer of sand and crushed stone.

Also, sophisticated drainage systems are being developed from concrete rings to prevent soil contamination. The number of chambers does not generally affect the quality of liquid passage through them. In this matter, the volume of the septic tank and the possible duration of residence of water in all chambers will play a certain role.

Additionally, as an example, we can consider a septic tank consisting of several reinforced concrete wells connected to each other by an overflow pipe. Domestic waste flows into one container and, as it accumulates, flows into another. In the second section, the next stage of mechanical cleaning is carried out, followed by output to the filtration field.

How to install correctly and what tools are needed

It is difficult to install reinforced concrete rings with your own hands, but sometimes this is done due to the impossibility of special equipment access to the territory. Otherwise, you buy reinforced concrete rings at the construction site, hire a manipulator, and he performs loading, delivery to the customer’s site, and unloading. Unloading can be understood as direct installation.

Before installation, experts recommend going deep to the required depth, compacting the bottom, and adding a cushion of sand. Concrete will draw moisture from the ground, so a pillow is simply necessary. Do not skimp on this layer, and fill up to 10 centimeters of sand, inclusive. To some extent, this will level the base. Place a concrete bottom on the sand, then begin the phased installation of the rings.

Each of them has special hooks. They serve to secure the manipulator slings and to connect the rings together. After the first reinforced concrete product is lowered, the slings are released, the metal hooks are bent, and the second product is installed. Then, all the screams can be linked together using a welding inverter. The work is not difficult and even a novice welder can handle it.

When a well is being constructed and the work is done manually, it is not always possible to use the services of a manipulator. In this case, install the first ring and gradually dig inside it, which allows the rings to fall down.

Next, when the first one is lowered to its own height and stands parallel to the ground at the top, the second reinforced concrete product is installed and work continues in the same way. Experts recommend using a hole drill, with the ability to drill to a depth of 10 meters or more.

This will allow you to drill through the entire internal diameter, install the ring and dig manually only under its walls. You will save the required amount of time and get the job done professionally. To make your work easier manually, you will need a powerful winch. It should be firmly fixed, which will facilitate the process of raising and lowering the products.

Price

Those who need well rings, also known as reinforced concrete products, are interested in the cost of reinforced concrete rings . It cannot be said that by paying for the rings, you will be able to fully cover the costs of the project estimate. This is not true, since you also need to pay for the services of special equipment, order the bottom, lid, hatch, pipes, sealant and other things that may be required when installing and arranging a septic tank or other structure.

As for the rings, depending on the city, as well as on the task for which they are intended, the price can vary from 2000 rubles per unit. The larger the diameter, the more expensive the product costs. Remember that with an increase in diameter you will be able to deliver a much smaller number of pieces on a manipulator, which will require either renting 2 machines or making several trips.

In any case, rental of special equipment is hourly, so be prepared to pay for the amount of time. The cost of a well made of reinforced concrete rings , taking into account delivery, installation and excavation work, can reach 50 thousand rubles.

Advantages and disadvantages

The material has advantages and disadvantages. They are important at the time of selection. We suggest you first familiarize yourself with the advantages:

- High speed of work performed. For example, you decide to build a drainage pit. Previously, for its construction it was necessary to lay out a rectangular base and red brick walls. This took time, provided you were working alone. Now, you have bought reinforced concrete rings, hired a manipulator, prepared a hole in the ground using an excavator, delivered the contents and carried out installation. This will take no more than 3 hours.

- Moisture resistant. This is what makes reinforced concrete rings most beneficial for individuals and companies. With their help, entire tunnels are built underground, where communications are then laid. Well rings are used for arranging a septic tank, as well as for a pit in a well. Here, the equipment and the general contents of the internal volume will be protected from groundwater, which is important during operation.

- Long service life. Even if your septic tank constantly contains water and you do not pump it out in a short time, worry about it, this will not at all affect the condition of the concrete. With high-quality concrete, the tightness retains its 100% values.

- Affordable price. Despite a number of significant advantages, you can buy this material for little money. Delivery will also be inexpensive, since the rental is based on the number of hours spent.

Among the disadvantages, I would like to highlight the need for additional sealing of the seam. Be that as it may, one ring fits on top of the other, and in order to reduce the level of seam leakage, it must be sealed. Sealing is necessary both from the inside and from the outside, where the latter involves laying and additional excavation of soil in order to gain access.

Bitumen is used for sealing, and each of the seams must be coated with cement or glue. This will allow the rings to better adhere to each other. The latter will not allow them to move during operation under internal water pressure.

Another disadvantage is that the rings are supplied without inlet holes. These holes could be used for laying communication pipes and cables. You will have to do them yourself after installing all the cells of the block. When installing pipes and parts of the drain/overflow system in a septic tank, plastic products must be fixed with foam.