Classification by type of manufacture

In the production of metal structures, different methods are used to form elements and connect them to each other. Depending on the manufacturing method, there are the following types of metal structures:

- welded - the elements are connected by welding;

- screw or bolt - assembly is carried out on threaded fasteners;

- forged - made by forging;

- stamped - production is carried out by stamping from sheet metal, the parts do not have joints or seams;

- riveted - structural elements are connected together with rivets.

In addition, combined metal structures are often used, which are manufactured using two or more methods. For example, welding technology is combined with bolted or riveted joints, welding with forging and other methods.

Classification of metal structures in construction

The classification of metal structures is quite broad. Nevertheless, among the many varieties, several main ones can be distinguished:

- by purpose

- load-bearing and enclosing. The former give the structure the shape, bear all the loads, and provide the structure with stability and rigidity. The latter perform protective and, in some cases, decorative functions; - by manufacturing and assembly method

- welded, forged, bolted, riveted, stamped, combined. Welded structures are the most reliable, forged ones are decorative. Stamped ones are obtained without visible connections. Bolted and riveted are distinguished by the speed of assembly according to drawings. But most often, metal structures are manufactured using several technologies; - by material

- cast iron, aluminum, steel. Cast iron is the heaviest and little used in construction, aluminum is light and corrosion-resistant. Steel structures combine the maximum of the best properties; - by type of use

- solid, collapsible and transformable. Solid cast ones are used as stationary structures. The dismountable ones are easy to dismantle and are suitable for installation in a new location. Transformable ones are able to change some parameters due to the presence of moving elements in the structure.

Metal structures are also classified according to their readiness for use. Some can be put into operation immediately after the production processes are completed, while others require assembly.

Types of metal structures by purpose

According to their purpose, metal structures are classified into the following types:

- load-bearing;

- fencing;

- decorative.

Load-bearing metal structures form the frame of buildings, which takes the load from the entire weight of the structure and transfers it to the foundation. They require high strength and rigidity with a relatively low dead weight. Enclosing structures are used to cover the frame. They form a single closed contour of the building. These include fences, facade panels, sandwich panels, gate blocks and other elements. Decorative designs are used to decorate the landscape or interior. They can also perform utilitarian functions. This group includes decorative fences, lanterns, figurines and other types of products.

Construction steel grades and areas of their application

The steel produced by the metallurgical industry is divided according to quality and purpose into standard grades called grades.

Steel grades must meet the requirements of the standards and the additional customer requirements provided for therein. These requirements determine the basic and additional characteristics of the mechanical and technological properties of steel, as well as its chemical composition.

For building metal structures the following are used:

- Carbon steel of ordinary quality, group I, supplied according to mechanical properties: open hearth - grade St. 0, St. 2, Art. Zkp, St. 3, Art. 4, Art. 5;

- Bessemer - grade BSt.Zkp;

- G - manganese,

Varieties by type of materials

For the production of metal structures, different types of materials and alloys are used. Most often they are made of steel and aluminum. Steel structures with relatively low weight are characterized by high strength and load-bearing capacity. Their disadvantage is poor corrosion resistance, which requires the use of protective coatings. Aluminum metal structures are lightweight and resistant to corrosion. Their strength is slightly lower compared to steel. The disadvantage of aluminum is that it is susceptible to electrical corrosion when in contact with other non-ferrous metals.

Features of metal structures

When using metal structures in construction, it is necessary to take into account their features. One of the important characteristics is the susceptibility of metal elements to corrosion. For this reason, they must be supplied with a protective anti-corrosion coating. During operation, painting may be periodically required to restore the coating. Additionally, the limited fire resistance of metal structures must be taken into account. The metal does not support combustion, but with significant heating, its strength qualities are significantly reduced. This can lead to the collapse of structures during a fire. Increasing fire resistance is achieved through the use of special paints and other measures.

Features of the construction of buildings from metal structures

Metal structures for the construction of buildings and structures have a wide range of applications due to their long service life and high strength characteristics. To install them, you do not need to use specialized construction equipment and a large number of personnel, which can significantly reduce the cost of installation work. Thanks to the design features of such materials, it is possible to erect a metal structure on almost any soil using lightweight types of foundation. These elements are the basis for most modern construction processes.

For the construction of structures made of metal structures for any purpose, we will develop a highly efficient project that will take into account the architectural and urban planning features of the area being built up. Before designing, we will conduct a full analysis of information about the given territory to determine the optimal location of the object.

When developing a project for the construction of a facility made of metal structures, our team will perform the following work:

- prepare data about the object;

- conduct topographical and geodetic research;

- will draw up technical specifications;

- will create a preliminary sketch;

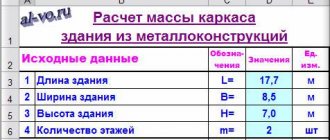

- will calculate the strength parameters of the frame;

- will create design and technological documents;

- calculate cost estimates for construction work;

- approves permits for the construction of a building.

By creating drawing documentation, our employees will assemble metal structures and link them with the technological section of the project. We will draw up papers for supplying electricity, water supply, gas, sewerage, and heat to the building. During the design process, we will determine suitable options for assembling and moving metal structures. The method of delivering these elements to the site depends on their weight.

Do you dream of starting your own business and launching new products? Then order the construction of production facilities from Sinmar Insurance Company, which strictly observes the characteristics of each specific industry. We will draw up competent documentation for all parts of the structure under construction. We will think over the laying of internal and external utility networks and the installation of modern industrial equipment at the site.

We will select a reliable supplier of building materials and proven contracting companies to carry out highly specialized work. After completion of construction, our employees will carry out commissioning work and check the functionality of the installed equipment. We will provide the client with high-quality and safe structures that are capable of clearly performing their assigned functions.

Advantages

Metal structures owe their widespread use to the following advantages:

- small volume and weight compared to reinforced concrete structures of similar load-bearing capacity;

- high strength;

- simple installation, carried out in a limited time;

- possibility of partial assembly in production or directly on site;

- convenient transportation;

- increased rigidity.

These advantages make it possible to quickly construct reliable buildings designed for long service life at relatively low costs.

Construction stages

The installation of metal structures is used in cases where traditional construction is not applicable or is not economically profitable. It does not take much time and does not create a large load on the foundation, which is convenient when arranging technical rooms, barns, pavilions, if time is limited and it is physically impossible to build a full-fledged foundation. The installation of metal structures consists of the following stages:

- Planning. At this stage, technical documentation for the facility is developed. Some people use template options, but they do not allow taking into account the individual characteristics of the structure. The drawn up plan must be agreed upon with the customer. The finished result is more expensive if the object is located in a hard-to-reach place and it is necessary to provide for many factors and circumstances that may arise during construction.

- Manufacturing of metal structures. The necessary components are produced based on a pre-drawn plan. They are coated with an anti-corrosion compound to extend their service life and protect them from aggressive environmental influences (precipitation, chemical compounds and solutions).

- Construction of the foundation. The foundation is carried out during the production of metal structures. They are usually lightweight, so no increased requirements are placed on the site. The work takes a little time, but it all depends on the area of the object.

- Delivery of finished products. Freight costs will be lower than traditional building materials as they are lighter and can save on freight costs.

- Assembly of metal structures. First of all, a frame is installed, which is fixed to the base. It is secured using special elements. There is no welding of parts, which reduces the cost of this type of construction. Most often, craftsmen make do with bolts and screws.

Metal structures have significant advantages over reinforced concrete, wood or stone. They are lightweight and can be delivered to assembly sites without unnecessary difficulties. Any architectural objects are created from such products. This is appropriate if traditional construction is unacceptable due to soil conditions or terrain characteristics.

Metal structures are easy to work with at any time of the year; they are not sensitive to extreme heat or frost. Installation and dismantling do not take much time, and the strength and durability of the material allows the structure to be used for many years. Each element is manufactured in compliance with established requirements, so with minimal care, there is no need for repairs.