Well pumps are selected to lift water from great depths and are installed directly into the drilled well. Pump relay connection diagram In some cases, in order to save the final cost of the pump kit, the connection is made without a control unit.

Borehole head. A flexible installation option is preferable, as it allows you to adjust the immersion depth of the unit.

These indicators are indicated in the passport of the water source. Well connection. Aquarius pump / Connection wells. Pumps for wells - where and which ones are used Digging a well is only a small part of the work that will have to be done to provide your home with water. The only condition is proper connection, including to automation.

Possible errors when connecting equipment Types of check valves Pump failure cannot be avoided if the height of its suspension is incorrectly determined. Preference is given to screw, centrifugal structures, their advantages: low cost, resistance to pressure; synchronous operation with automation; productivity - high efficiency with the required pressure.

When the hydraulic tank is full, water is consumed within 3-4 hours, preventing the well pump from being turned on frequently. Sometimes with a hydraulic controller.

We cut off the pressure pipe at the level of the lid and insert an angle fitting into it to connect to the water main laid in the trench to the house.

Electrical connection diagram It is not recommended to connect a well pump without automation. Depending on the needs of the user and his financial capabilities, you can choose one of the methods for connecting the deep well pump to the electrical network.

Assembling a pumping group for connecting the PART2 submersible pump

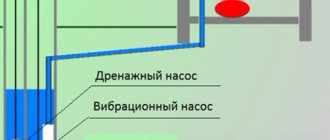

Types of submersible pumps

- Well drainage.

Used to quickly pump out large volumes of water and professionally clean wells.

The best mobile application for experienced Bettors has appeared and you can download 1xBet absolutely free on your Android phone with all the latest updates and discover sports betting in a new way.

Advantages:

- Pumping of clean and contaminated water;

- Produces tens of cubic meters of water;

- Used in sewer and drainage systems.

- Submersible centrifugal.

Stainless steel was used in the construction. Has the shape of a cylinder.

The well unit consists of:

- Centrifugal engine;

- An impeller that removes water.

In order for the submersible device to be constantly cooled, it must be completely placed in water. To prevent pumping out all the water from the well, special devices are used that signal that there is a minimum amount of water in the well. These include:

- Bimetallic switch;

- Electronic automatic system;

- Frog float.

A pump that has a float exhibits good performance characteristics.

Advantages:

- Immerses to a depth of up to 20 meters;

- Raises water up to sixty meters;

- Produces 3.5 m3/hour.

- Submersible vibration.

This type of submersible pumps is used as seasonal equipment for summer cottages.

Advantages:

- Easy operation;

- High wear resistance;

- Water rise up to 60 meters.

Principle of operation. The reciprocating movements of the moving piston create water pressure. The piston is attached to an inductive coil, which exerts pressure using an electromotive force. When current is applied, it creates a magnetic field that moves the core and piston. When the piston is retracted, the working chamber is filled with water. At the limit point of retraction, the contacts open and the field stops working. A spring acts on the piston, creating water pressure.

Pump installation

All well pumps have the same installation technology.

- The pump is attached to a tight cable, which is fixed to the holes located on the device.

- Supporting the equipment, they lower it into the water. Install the device no less than 30 cm from the bottom.

- During installation, it is advisable not to touch the walls of the well with the pump.

What are deep-well pumps?

Let us recall that a pump is a mechanism designed to move liquids, as well as liquid suspensions. Let’s take a closer look:

Depending on the type of liquid: its density, viscosity, temperature, chemical activity - the type, design and material from which the pump unit is made is determined.

Deep pumps for wells are a very important part of the water supply system, so the reliability, stability and durability of the entire water supply system depend on the correct choice.

Design options and operating principle

Owners of country houses, country houses and personal plots are faced with the issue of choosing a pump. After all, you always need water and you need a lot of water, and the process of supplying liquid can be mechanized with your own hands. So:

- Modern pumps and accessories for them make it possible to organize both a completely autonomous water supply at home and simplified systems for supplying water from a well to some intermediate containers, or for irrigation systems through garden hoses.

- Depending on the complexity of the system and the power of the pumps, their prices vary greatly.

Types of deep-well pumps and operating principles

The following table shows the main characteristics, advantages and disadvantages of pumps most often used for the private sector:

| Equipment typeCharacteristics | Vibration pumps | Centrifugal pumps (borehole and well) |

| Principle of operation: |

|

|

| Application area: |

|

|

| Advantages | Simplicity of installation and connection design. Low cost. | Reliability, durability, smooth, uninterrupted flow. High performance and pressure. |

| Flaws | Often the plastic body, noise during operation, rise of sand and silt, as a result, accelerated erosion of the walls of the well, is short-lived. | Relatively high cost, sensitivity to the content of solid impurities (it is better to choose a pump with metal impellers rather than plastic ones). |

| Notes |

Note. They are cooled by the water in which they are immersed; “dry” inclusion is unacceptable. |

Note. They are cooled by the water in which they are immersed; “dry” inclusion is unacceptable. |

For cases where there is a lot of sand in a well or borehole, special screw pumps are also used. They are less susceptible to wear during operation. In appearance and installation method they are identical to borehole ones.

How to choose

A normal supply of water to a home, cottage or bathhouse is only possible with the correct selection of all parameters. And you need to choose:

- pump type and performance;

- accumulator dimensions;

- location.

First of all, you need to find out whether water is flowing into the well or well quickly enough. If the flow rate of a well or borehole is less than 1.7 m3/hour (the amount of incoming water in one hour), the required pressure cannot be provided. The equipment is designed for higher productivity.

Selection of pump type

One of the most difficult and important stages is choosing a pump. It must create enough pressure to raise the water to the required height. At the same time, its productivity must meet the needs for water, but at the same time, it must not exceed the capacity of the well or well.

Self-priming vortex and centrifugal type pumps are used in pumping stations. Both of them can be monoblock or console-mounted. But such pumps can lift water from a relatively shallow depth:

- a pump with a built-in injector will provide supply from a depth of 8-9 meters;

- normally suction from a depth of 7-8 meters.

If water needs to be supplied from a greater depth, it will be necessary to use a submersible pump. They buy it, and a pumping station is assembled on its basis; the second option is to install a unit with a remote injector.

The pump is one of the main components of the system

When using a remote injector, it will be possible to lift water from a depth of about 42 meters, but the efficiency of the system is low, and the energy costs are much higher - essentially two pumps operate simultaneously. But sometimes this is the best way.

A system with a submersible pump for large well depths will be the best option. It is effective and “pulls” a little energy. The only caveat: submersible equipment is quite sensitive to the purity of water. To prevent sand, silt and other foreign particles from getting inside, a special mesh filter is installed on the inlet pipe of the pump.

https://youtube.com/watch?v=p1twcgiduZg

Power selection

Productivity is selected taking into account the maximum water flow. Estimate how many taps can be open at the same time, calculate the volume of water that flows through them. This will be the required pump power. In general, it is better to take this parameter with a reserve, since working at the limit sharply reduces the “life” of the equipment.

On average, for a family of 3-4 people, the consumption is 2-4 m3/hour, and the equipment is selected accordingly.

Selecting the volume of the accumulator

In general, it is advisable to install a tank as large as possible. This will ensure that the pump turns on less frequently. After all, the less often it turns on, the longer it will last: starting currents have a destructive effect on the motor. On the other hand, a large hydraulic accumulator needs to be installed somewhere, and it also costs a lot of money. But if the power goes out, you will have a supply of water in your system equal to the volume of your tank.

The larger the water tank, the less frequently the pump will turn on.

Just be careful. There are membrane expansion tanks for gas boilers. They are much cheaper, but make the water undrinkable. And they are not designed to work with liquid, so they will soon fail.

Having selected all these components, you can begin to select a pumping station that will meet your requirements.

What to consider when choosing a well pump?

The choice of pump for water supply from a well directly depends on the technical characteristics of the unit. The selected option must meet certain parameters, so before purchasing a specific model you need to find out the required values of the main parameters.

Power. This parameter shows the ability of the pump to create a certain pressure and affects the performance of the device. However, you should not think that for the effective operation of the entire system it will be enough to choose the most powerful device.

Power that exceeds the required parameters can create excess pressure in the pipeline, and because of this, gaskets can be constantly squeezed out and ruptures can occur. Moreover, due to the powerful unit, the water level will quickly drop, which is why the device will constantly turn on and off, and this is fraught with rapid wear.

Performance. This value demonstrates how much water the unit can pump in a certain time. Correct determination of this parameter will make it possible to uninterruptedly provide you with water even during peak loads.

To calculate this parameter, you will need to sum up the water consumption at all water intake points in the house. If exact data is not available, you can use the following data as guidelines: washbasin - 300 l/hour, shower - 700 l/hour, toilet - 83 l/hour. If a bathhouse and an irrigation system are also connected to the water supply, you need to add another 1000 l/h for each facility.

Of course, the probability of all points operating simultaneously is very small. This calculation demonstrates not the nominal, but the maximum maximum value of water consumption. A submersible pump with automation that does not provide the required performance will not only cause interruptions in the water supply, but during its operation there is a possibility of accidents due to water-sensitive equipment.

Pressure This parameter determines the possibility of raising water to a certain height from the well shaft and transmitting it through a horizontal pipeline to water intake points. During the summation of lifting and pumping pressure, every horizontal 10 meters of distance is equal to 1 meter of lift.

For example, if the depth of the well is 7 meters, and it is located 20 meters from the house, then the calculation formula will look like this: 7 + 20/10 = 9 meters.

If the building has more than one floor and the water intake points are on the upper level, this must also be taken into account in the calculations. If this example is used to calculate, for example, to bring water to the second floor, then the calculation will look like this: 7 + 20/10 + 4 = 13 meters, where 4 is the approximate height to the second floor of the house.

The dynamic water level in the well demonstrates the intensity of water in the mine. This parameter is also called source debit. This parameter is determined if water is pumped out of the mine. When, regardless of the operation of the pump, the water stops decreasing, it means that the dynamic level of the well has been reached.

In sources that have a sufficiently high dynamic level, the position of the water surface does not change significantly during pumping. This parameter is very important due to the fact that the pump must be located below it. The diameter (or side length during a square section) of the shaft is needed to calculate the volume.

Availability of additional equipment. Additional equipment helps ensure safe pump operation and normal water supply. The purpose of floats and sensors is to protect against the formation of air pockets, air suction and “dry running”.

Economical operation and uninterrupted water supply depend on whether a hydraulic accumulator or storage tank is available. Hydraulic accumulators are equipped with a pressure switch, the task of which is to turn the pump on and off.

Thus, you need to carefully study the parameters of the unit before selecting any specific model of well pump.

Well pump kit

Using construction ties, every 1.5 - 2 meters it is necessary to secure the cable in the pipe. Connects and disconnects the well pump. As a rule, the installation and connection of a submersible pump begins with tying up the hydraulic accumulator and installing equipment on it.

The pressure limits in the storage tank are adjusted using a relay. It is better to connect electrical devices through stabilizers, and complex and expensive electrical equipment through special control and protection stations. The pump cable can be connected directly to the electrical network, then the use of additional devices is not required.

The membrane prevents liquid from flowing out of the pipe. Third generation control units Third generation automation is reliable, high quality and expensive. A check valve is a bypass membrane that is installed directly at the outlet of the power unit, preventing the reverse flow of liquid from the pipe. We will consider only the main points that will help you understand what it means to set up your own water supply system. The latter have minimal noise levels and consume less energy than single-stage ones. The pressure pipe is cut off at ground level and, together with the cable, is led through the head into the technical room in an insulated tray.

Scheme for a surface well pump

Borehole head. For this purpose, the main bus of the house is used, connecting to the existing ground loop of the building.

Metal-plastic fittings and pipes leading into the house. A nozzle with a narrowed cross-section is mounted in the ejector body. A flexible installation option is preferable, as it allows you to adjust the immersion depth of the unit. Conclusion The presented electrical diagrams for connecting a well pump are the simplest, but most common in the private sector for home water supply. Steel cable for attaching the electric pump to the head.

As water is consumed, the cycle repeats. Recommended location for effective work and safety: a few meters, closer to the water intake; as far as possible from the populated area; indoors, with exhaust ventilation; on a solid foundation. Such a pump will work, but its effectiveness will be debatable. Extends the life of the pump by increasing the time the engine is turned on and off by accumulating water in the reservoir. Borehole head. ►Connecting the well pump to the water supply system

Preparation of materials accompanying installation

A stuck pump in a casing can be a major headache. And you need to pull it out (as well as lower it) using a special cable. If the pump is already equipped with a polymer cord, you need to make sure that it is of high quality and of sufficient length. Sometimes it makes more sense to purchase this item separately.

It is believed that a reliable cable or cord must be designed to withstand a load that is at least five times the weight of the equipment attached to it. Of course, it must withstand moisture well, since part of it will constantly be in water.

If the device is suspended relatively shallowly, less than ten meters from the surface, care must be taken to provide additional shock absorption for the equipment during operation. To do this, use a piece of flexible rubber or a medical tourniquet. Metal cable or wire is not suitable for suspension as it does not dampen vibration but may destroy the mount.

A special electrical cable is provided to power the pump. Its length should be sufficient so that the cable lies freely and is not strained.

To supply water from the pump to the house water supply, special plastic pipes are used. Designs with a diameter of 32 mm or larger are recommended. Otherwise, the water pressure in the system will be insufficient.

To install a submersible pump, a special cable is used, which is designed for long-term operation under water. Its cross-section must comply with the technical requirements specified in the product passport

Pipes can be used both metal and plastic. There is controversy regarding the connection of metal pipes. Some experts object to the threaded connection as less reliable. It is recommended to use flanges, and the bolt should be on top, this will prevent it from accidentally falling into the well.

But threaded connections in wells are used quite successfully. During installation, winding must be used. Some experts recommend using linen or “Tangit” sealing tape instead of the usual FUM tape or tow. The linen winding is additionally strengthened with silicone sealant or similar material.

The characteristics of the water supply pipe should be selected in accordance with its operating conditions. For depths up to 50 meters, HDPE pipes designed for a pressure of 10 atm are used. For a depth of 50-80 m, you will need pipes capable of operating under a pressure of 12.5 atm, and for deeper wells, pipes of 16 atm are used.

In addition to the pump, pipes and cord or cable, before installing a submersible pump in a well, it is recommended to stock up on the following materials:

- clamps for securing the electrical cable to the pipe;

- check valve;

- pressure gauge;

- shut-off valve for the water pipe;

- steel fastening unit;

- power cable, etc.

Before connecting the pipe to the pump, attach a nipple adapter to its outlet. Usually modern submersible pumps are equipped with such a device, but if it is not there, this unit must be purchased separately.

It should be remembered that to pump the well immediately after drilling, i.e. To remove large amounts of very dirty water from a well, such a pump cannot be used. It will quickly fail. Usually the well is pumped with a separate pump, which is cheaper and works better when working with dirty water.

Purpose of automation

The use of automation elements installed in the power supply circuits of the equipment will allow you to connect a submersible pump in such a way that the system will operate in automatic mode.

Water pressure switch

The basis of such a circuit is a contactor with a normally open contact group, to the input of which supply conductors (phase, neutral and ground) are supplied. Well, the pump itself is connected to the output of the contactor, receiving power from the mains through it.

The use of such a pump connection diagram requires the presence of a special hydraulic accumulator, which includes a check valve. It is in this unit that a pressure relay sensor is installed, which controls the operation of the contactor group, which supplies and removes voltage from the pump.

The functioning of the entire system in automatic mode is as follows.

- When the pressure in the system drops to a minimum level, the relay sensor issues a signal to turn on; in this case, the contacts of the working group close the power supply circuit of the pump.

- As water enters the system, the pressure in the accumulator gradually increases.

- When the pressure reaches its upper threshold (limit value), based on a signal from the pressure sensor, the contactor is switched off. Its contacts open and the equipment is automatically disconnected from the power supply.

Liquid level sensor

For domestic water supply systems designed for significant volumes of liquid, an electrical circuit using float sensors is more suitable, providing automatic control of the liquid level in the collection tank (hydraulic accumulator). The schematic diagram for connecting the pumping equipment itself in this case does not differ significantly from the previous one, except that instead of a pressure switch, a liquid level sensor is installed in it.

It is worth noting that to connect power to a submersible (well) type pump, you will need a special brand of cables. Waterproof wires under the designation VPP or KVV are best suited for these purposes. The imported AQUA RN8 brand cable also has good water resistance characteristics.

How to choose the right submersible pumps for a well with automation

When choosing submersible pumps for a well with automation, the decisive factors should be what height it should raise water and how far it should be delivered. These parameters are reflected on the packaging and in the instructions. For small wells up to 20 m, any pump can be used if the water is not supplied too far. In the case when the distance to consumers is no more than 50 m, you need to buy a pump with a lift height of at least 20 m. A distance from 50 to 100 m forces you to use a device with a lift height of 40 m.

Scheme of operation of a submersible pump with automation

The choice of pump also depends on the purity of the water. In a well that is cleared of sand and small impurities, any pumps can be used, but in contaminated wells only vibration pumps can be used.

Installation of a submersible pump

The volume of the hydraulic accumulator should be selected based on the needs of the family. For low water consumption, 50–60 liters is sufficient, and for significant water consumption, it is necessary to purchase a cylinder with a capacity of at least 100 liters.

Equipping your country house with a submersible pump for a well with automation will solve all problems with organizing water supply. Water will be supplied automatically and uninterruptedly to any consumer inside the house and in the garden for watering plants.

Vibrating Submersible Pumps

The device of the vibration submersible pump "Rucheek"

Such units are much simpler than centrifugal ones and cost significantly less. They consist of a housing, an electromagnet and a vibration mechanism; there are no rotating parts or bearings in them. Some models have a thermal relay to protect against overheating.

Vibrating pumps lift water using a piston (elastic membrane) driven by electromagnetic pulses through the vibration of an armature.

The pressurized hydraulic chamber is separated from the electrical chamber by a rubber diaphragm.

The inlet valve allows water to enter the working chamber and prevents it from flowing back. To prevent solid impurities present in the liquid from causing the rubber piston to quickly wear out, the water intake should be equipped with a filter, which must be cleaned regularly and changed at least once a year.

Vibration pumps are not capable of providing the same pressure and flow as centrifugal pumps and have a shorter working life, but all this is compensated by their low cost. Even if the device lasts one season under severe operating conditions (and with its help you can not only pump water for domestic needs, but also drain a flooded basement, clean or deepen a well, etc.), the cost of it will be more than justified.

Submersible well pumps of both types are easy to install: just lower them into the source, hanging them by the eyes on a polymer cord (the metal cable quickly corrodes). The only limitation is that the vibrating units should not touch the surfaces of the tank

Pressure and flow

The main indicators of pumping equipment are pressure (N; measured in meters of water column or bars), which determines the height of water rise, and flow (Q; l/min. or m³/h), previously referred to as flow rate or productivity. For submersible well pumps with Q of at least 1 m³/h, the H value reaches 40 m.

Since pressure and flow are interdependent parameters, they are reflected in the form of a general pressure characteristic.

The highest flow is noted at the pump outlet, and the smallest at maximum pressure: the higher the pressure, the lower the flow, and vice versa. In this case, the maximum flow should be equal to the sum of the flows of all simultaneously switched on water collection points. The water pressure required to ensure maximum flow depends on three quantities. The first is the distance from the water surface at the source to the highest point of water consumption; the second is the operating pressure in the system (normally 2 bar, which corresponds to 20 m of pressure) and the third is the pressure loss along the entire length of the water pipeline, in the suction and supply sections.

Since most ordinary buyers, to put it mildly, find it difficult to understand all the intricacies of this “hydraulics,” it makes sense to contact a consultant from the selling company who will help you choose the right pump model. You just need to provide him with the necessary data about the water source, material and diameter of the pipes and provide a plan for the location of water collection points.

Design and operation of an automatic water supply system

In order for submersible well pumps with automation to operate smoothly, the entire system must be installed correctly. And its structure is as follows: A pump is located in a well or borehole in the water column or on a float. From it comes a pipe containing a nipple and a check valve that prevents water from flowing down. The pipe is connected on the surface to the cross through a nipple and a check valve. It contains a pressure sensor connected through a flexible line to the control unit.

From the cross, one pipe goes to the hydraulic accumulator, and the other to all consuming elements: taps, toilet, shower, washing machine and other household appliances. The wire from the pump is connected through a socket to the control unit. The unit itself is connected to a 220 V network through circuit breakers designed for current from 10 to 16 amperes. This parameter depends on the power of the equipment. Switches provide protection for automation and pumps from network overloads.

Submersible well pumps

Submersible well pumps with automation operate as follows: when first turned on, the pump pumps water into the accumulator through a check valve and filters until the pressure in it reaches the maximum. The pressure sensor is triggered and gives a signal to the automation to turn off the pump. The system is now ready for use. By turning on a tap or household appliance that consumes water, we allow water under pressure to exit the accumulator. The water in it can be from 30 to 100 liters.

Pump piping diagram for a well with hydropneumatic automation and caisson

When most of the water comes out, the membrane, under the action of a spring, will increase the volume of the chamber with air, which reduces the pressure. If the level is critically low, the sensor will send a signal to the control unit to turn on the pump. Water, having filled the accumulator, will again increase the pressure and the cycle can be repeated again and again.

Design and principle of operation of submersible pumps

Vibration pumps

The main elements of a submersible vibration pump are:

- a power unit, inside of which there is an electric magnet;

- a vibrator or second part of an electromagnet that drives the stroke piston;

- a chamber for collecting water connected to the outlet pipe;

- suction chamber. The compartment where water from the source first flows;

- a shock absorber necessary to ensure smooth movement of the working piston;

There are devices on sale that are not equipped with shock absorbers. However, they quickly fail, since sudden movements of the piston lead to mechanical damage.

- washers that affect the performance of the submersible device. By increasing or decreasing the number of washers, you can independently change the pump power;

- a rod or base for the movement of the piston;

- check valve The device is installed to prevent the reverse flow of liquid from the pump. By using a check valve, you can increase the rated performance of the equipment;

- a nut necessary to secure the piston to the rod;

- a piston, which is the main working element of the pump;

- channels designed to transfer water from the collection chamber to the water supply system.

Main elements of vibration type equipment

The operation of a vibration-type submersible pump occurs due to the movement of the piston. When electrical power is applied, an electromagnetic field is created in the power unit, and the vibrator is attracted, giving the piston movement. At this time, a discharged pressure is created in the intake and suction chambers, and the free space is filled with water through check valves. Likewise, the liquid passes through the channels and enters the pipeline.

Several movements of the piston occur per second, which causes water pressure in the pipeline.

Centrifugal pumps

The centrifugal submersible pump consists of the following elements:

- the impeller is the main element of the equipment;

- impeller blades that create centrifugal force to suck in water;

- a housing that protects the impeller from mechanical damage;

- a suction area through which liquid is pumped;

- a pressure pipeline that transfers water from the pump to the water supply system;

- check valve that prevents water from flowing out of the pump into the source;

- a protective mesh necessary to protect the working part of the pump from impurities that negatively affect the operation of the device.

Working parts of a submersible pump operating due to centrifugal force

Operation of submersible centrifugal pumps equipped with a protective mesh is also possible in slightly contaminated water.

The operating principle of a submersible pump with this design is quite simple. Due to the supply of electricity, the impeller begins to rotate. A centrifugal force is created along the perimeter of the blades, which forces water to move from the suction pipeline to the pressure pipeline connected to the house’s water supply system.

You can learn more about the design and operating principle of a centrifugal pump from the video clip.

Vortex pumps

Now let's look at how a vortex-type submersible pump works. The design and operating principle of the equipment is similar to a centrifugal pump. The differences are in the following aspects:

- the impeller of the vortex pump is solid, and the centrifugal force creating the vortex flow is formed as a result of the movement of the stiffeners;

- water entering through the check valve accumulates in the cells and it is from them that it is transferred to the pressure pipeline.

Design and principle of operation of the vortex device

Vortex pumps, due to their design, are capable of delivering greater fluid pressure at low energy costs.

Screw pumps

Screw pumps (also called screw pumps) operate by rotating a working screw located inside a fixed housing.

Internal structure of screw equipment

The pump performance is directly proportional to the screw rotation speed.

Any type of submersible pump can be controlled manually or using an automatic system, which is installed additionally. Any pump can be equipped with a float that prevents operation in “dry” mode, which is unacceptable when using submersible devices.

To eliminate voltage drops in the electrical network, which can damage equipment, stabilizers are used. To improve the design of the submersible pump and maximize its service life, a hydraulic accumulator is built into the water supply system of the house.

Operating principle and design of a submersible pump

A submersible pump operates in water. It lifts liquid even from very deep wells and wells to the surface. It is worth distinguishing between well and borehole devices. Boreholes, as a rule, have a more elongated shape for working in narrow wells and a higher pressure for lifting water from great depths.

Well pumps

These types have minor differences in design. Basically, all units consist of the following parts:

- The impeller, which is the main structural element. It sets in motion all other parts of the structure;

Impeller of the device

- Wheel blades. They generate centrifugal force, which is necessary for the rapid absorption of water;

- Suction area;

- Impeller housing. It protects it from the negative influence of the environment;

- Valve - retains water in the pump and prevents it from flowing back into the well;

- A protective mesh is necessary to protect drinking water from harmful impurities that can negatively affect the health of the residents of the house.

Submersible unit design

- A pipeline whose function is to transfer water from the pump to the water supply system.

Sectional view of the device

A submersible blower operates using electricity. It causes the impeller to rotate. Thus, the liquid flows from the well or well into the pipeline, which, in turn, conducts water to the plumbing system.

System operation diagram

As we can see, the principle of operation, as well as the design of the supercharger itself, are elementary. Now let's find out what types of these devices exist and how to choose a submersible pump for a well.

Selection of a pump for water supply from a well

To supply water from a well, large pumps with a diameter of 6″ (152.4 mm) are used. The Zagorod company installs DAB Divertron pumps in water supply systems. These are pumps with a diameter of 150 mm, with built-in automation - a pressure and flow switch, a dry-running protection relay. According to the manufacturer, these pumps can operate even without a hydraulic accumulator, but we recommend installing one so that the system operates stably.

DAB Divertron pumps are available in 4 models

| Max. Power, W | Maximum productivity, l/hour | Maximum lifting height, m | |

| Divertron 1000 | 650 | 4800 | 35 |

| Divertron X 1000 | 750 | 4800 | 45 |

| Divertron 1200 | 650 | 4800 | 35 |

| Divertron X 1200 | 675 | 4800 | 45 |

Models marked X are equipped with a hose with a float for sucking water from the surface. Divertron X pumps are suitable for wells with low water levels and can be lowered to the bottom.

To select pumps and pumping stations, a pressure-flow chart is used. The vertical axis shows the pump pressure (lift height) in meters, and the horizontal axis shows its productivity (l/min or m³/hour). The intersection point falls on the graph of one of the pumps or is closer to one of the graphs. Another 30 m is added to the pressure value (with a small margin, taking into account the pressure that the pump must create in the system, approximately 2.8 atm, which corresponds to a water column height of 28 meters). The flow rate of the well is usually less than the productivity of the pump, but there is a reserve of water in the rings, which neutralizes peak flow rates. Therefore, the pump performance is selected taking into account the peak water consumption of plumbing fixtures.

Pressure characteristics of DAB Divertron pumps

In addition to the DAB Divertron, we use Belamos KF pumps with a diameter of 150 mm (6”). These are submersible well pumps with a float to shut off when the water level is low and with built-in thermal protection to shut off when overheating. Immersion depth is up to 50 m. Belamos pumps are reliable and inexpensive. The only condition is that a pressure switch must be installed in the house.

Belamos KF pump models

| Max. Power, W | Maximum productivity, l/hour | Maximum lifting height, m | |

| Belamos KF-30 | 350 | 3500 | 30 |

| Belamos KF-40 | 500 | 3500 | 45 |

| Belamos KF-60 | 800 | 3500 | 60 |

| Belamos KF-80 | 1000 | 3500 | 75 |

| Belamos KF-100 | 1500 | 3500 | 98 |

Pressure characteristics of Belamos KF pumps

Belamos and DAB Divertron well pumps do not require additional protection against dry running. The divertron has a built-in protection relay. Belamos is equipped with a conventional float sensor, which works as reliably as a relay.

Criteria for choosing a station for a well

When purchasing a pumping station, you should pay attention to the pump parameters and factors characterizing the water source (in our case, a well), including its distance from the building. For example, it would be useful to clarify the following values:

For example, it would be useful to clarify the following values:

Maximum depth of water intake. We are interested in the dynamic water level, that is, the average for 1-2 days with constant use of water

If you take into account the static level, you can make mistakes in the calculations.

Nominal head of the unit. Conditional height of the water column that pumping equipment can create

Calculate using the formula, summing up the suction value, the length of horizontal sections of the pipeline, vertical lift and losses for transportation through the pipeline.

Pumping station performance. For calculations, you can take the average water flow at all water collection points (for example, a faucet at a sink - 0.15 m/s, a shower or washing machine - 0.3 m/s). The total value should not be higher than the well's flow rate, otherwise the source will not be able to cope with the supply.

Power supply voltage. In household networks this is 220 V (except for powerful stations with three-phase motors, where the voltage is 380 V).

Power consumption. The spread of energy consumed by stations is impressive. On average 500-2000 W. The choice of circuit breaker type directly depends on the power.

Volume of the hydraulic accumulator reservoir. From 24 l (for a family of 1-2 people) to 100 l (6 people or more).

It is clear that without knowledge of the technical nuances, before choosing and purchasing a unit, it is better to consult with a specialist who is well versed in household pumping equipment.

The characteristics of the pumping station are indicated in the technical data sheet of the product; to select the desired model, they must be compared with your own calculations

The choice of pumping station for a well depends on the depth of the mine. For example, if the depth reaches 12-15 m, a device with a built-in ejector is needed, more than 20 m - with an external ejector. Thanks to the looped suction, the lifting force of water increases, but the efficiency drops sharply and energy consumption increases.

Recommendations for connecting a well pump

Connecting a well pump is available for you to do it yourself. Work should begin with a careful study of the instructions and diagram.

The installation diagram of the well pump looks like this:

Symbols on the diagram:

A – water heater; B – hydraulic accumulator with a volume of 50 l; C – pressure switch; D – water pre-purification filter; E – pump in the well; F and G – lines for supplying hot and cold water to the source of consumption.

The depth of the well depends on the depth of groundwater. The pump is placed at a depth of 1 m from the bottom.

A special well (caisson) will allow you to use the well even in winter.

The bottom of the caisson should be below the freezing level. A trench from the house with laid pipes for water and electrical wiring goes into it.

The pump group control panel is located in the utility room.

The power supply to the well pump is supplied by a submersible cable with reliable grounding. Regular waterproof wire cannot be used.

It is recommended to use a waterproof cable marked VPP or KVV. High levels of water resistance were noted for the imported cable of the AQUA RN8 brand.

The ends of the wire are soldered to the terminals of the well pump. The contacts are insulated using a heat-shrinkable fluid coupling. The material requires experience in handling. Exceeding the thermal exposure time leads to loss of elasticity and water resistance. Insufficient heating does not provide complete waterproofing of the cable.

For networks with voltage fluctuations, it is necessary to install a stabilizer. It is selected with a threefold power reserve relative to the pump power.

What should a good pump be like?

First you need to select and purchase a suitable pump, as well as a number of materials necessary for its successful installation. The pump is usually submersible, but it is highly desirable that it be centrifugal.

Unlike centrifugal models, vibrating pumps cause dangerous vibrations in the well, which can lead to destruction of the soil and casing. Such models are especially dangerous for sand wells, which are less stable than their artesian counterparts.

The pump power must correspond to the productivity of the well. In addition, the immersion depth for which a particular pump is designed should be taken into account. A model designed to operate at a depth of 50 m can supply water from a depth of 60 m, but the pump will soon break down.

A submersible centrifugal pump is the optimal choice for a well. Its performance, size and other indicators should be correlated with the characteristics of your own water source

Another risk factor is the level of quality of drilling work. If an experienced team drilled, the well will better withstand the destructive effects. And for wells created with your own hands or through the efforts of “shabashniks”, it is recommended to use not just a centrifugal pump, but special models for wells.

Such devices better withstand the loads associated with pumping water heavily contaminated with sand, silt, clay particles, etc. Another important point is the diameter of the pump. It must match the dimensions of the casing pipe

It is also important to take into account the power supply features of the pump. Both single-phase and three-phase devices are used for wells

It is easier to find equipment for four-inch pipes than for three-inch pipes. It would be good if this point was taken into account at the well planning stage. The greater the distance from the pipe walls to the pump housing, the better. If the pump fits into the pipe with difficulty rather than freely, you need to look for a model with a smaller diameter.

Scheme for a submersible well pump

To connect the pump to a well in the country, first select a water intake: an open natural reservoir, a well, or drill a water well. In this case, the depth of the horizontal liquid is taken into account. Up to 8 m - the hydraulic unit is fixed superficially, deeper - it is lowered into the drilled hole. Taking into account the depth of immersion and the diameter of the drill, a cylindrical apparatus of smaller diameter is used.

Before immersing the hydraulic mechanism, lower the measuring cord with a load to the bottom, find out at what depth the liquid is located. Using a measuring cord, the exact footage of the descent and the length of the horizontal water layer are determined. If it is at a depth of 60 m, they drill further.

Connecting a submersible pump with your own hands consists of 3 stages:

- Select according to the technical characteristics of the pump model.

- Attaching a cable with an automation electrical cable and a lifting pipe.

- Fastening the head to the hydraulic apparatus body.

Preference is given to screw and centrifugal designs, their advantages:

- low cost, resistance to pressure;

- connection of additional pumps;

- synchronous operation with automation;

- productivity – high efficiency with the required pressure.

The manufacturer provides a deep well pump with a table and graphs that show the ratio of pressure and displacement of liquid at the outlet. If it rises from a depth of 80 m, according to the table, the water supply network receives 30 liters. When pumping, the passage of water along a horizontal plume is taken into account: 5 m of horizon corresponds to 1 m of pressure height.

Instructions for connecting a water well

To immerse the water apparatus and hold it in the well, a steel cable is used, which is passed through the 2 upper holes of the housing head. Secure with plastic clamps parallel to the electrical cable and water-lifting polypropylene pipe. The pipe is connected at the bottom with a collapsible brass or plastic coupling.