Differences in abrasives for sandblasting machines

Abrasives are materials with a high degree of hardness and are used to process various types of surfaces. All their types differ from each other in characteristics, such as:

- hardness;

- abrasive ability;

- fragility;

- dust formation;

- level of quartz content in free form;

- recovery (number of reuse cycles);

- average consumption for cleaning 1 m2;

- speed of operation;

- price;

- cost of work;

- conditions of use;

- scope of use.

Consumption of quartz sand during sandblasting

Consumption of quartz sand during sandblasting

SAND CONSUMPTION IN EACH SPECIFIC CASE DEPENDS ON VARIOUS FACTORS: POWER OF THE SANDBLASTING MACHINE, AMOUNT OF WORK, DEGREE OF POLLUTION OF THE BASE, SAND FRACTION, SIZE AND TECHNICAL CHARACTERISTICS OF SOP LA AND SOME OTHERS.

FOR AN APPROXIMATE CALCULATION OF THE AVERAGE CONSUMPTION OF SAND, WE GIVE THE FOLLOWING GENERAL RATIO: 30 KG/1 M2. IN THE CASE OF USING LOW-POWER UNITS, THE AIR FLOW OF WHICH IS 200 L/MIN, THE SAND WILL BE USED ABOUT 0.25 KG/MIN. IN HIGH POWER COMPRESSORS OPERATING WITH AIR FLOW UP TO 10 CUB.M/MIN, THE SAND CONSUMPTION WILL BE ABOUT 12 KG.

Their types

For sandblasting, materials are used whose hardness is greater than that of the surface being treated. Their grain has cutting edges and acts like mini-incisors. Crushed mineral substances with high hardness are used as abrasives; they can be artificial or natural. There are several types of sandblasting materials.

Quartz

Sand for sandblasting equipment is distinguished by its quality, low cost and availability. To make it, white quartz crushed into fine dust is used. Quartz sand has several varieties depending on the grain size:

- dust fraction (0.1 mm);

- sand (from 0.1 to 0.4 mm);

- coarse sand (from 0.5 to 1 mm);

- quartz chips (from 1 mm).

The material has a number of advantages:

- does not contain foreign impurities and large fragments due to careful processing using several sieves;

- characterized by chemical homogeneity;

- has a high level of porosity.

The disadvantage is the negative impact on human health.

Important!

When working with quartz sand, crystalline dust released in large quantities may enter the eyes and respiratory tract.

Cooper slag, nickel slag

These materials are the waste left over from the processing of smelted copper and nickel. They contain quartz, the share of which is 1%. The advantages of nickel slag and cooper slag are as follows:

- high abrasive ability relative to quartz chips;

- strength and stability when interacting with sand, metal and concrete;

- high efficiency combined with low consumption;

- possibility of reuse.

Garnet (Pomegranate)

Such material is formed by force or naturally from natural rock. Garnet is mined in quarries, then purified and enriched. Its grains of sand are characterized by a rounded shape, which increases the resistance of the abrasive to damage. During its production from rock, it is destroyed and crushed to obtain the required fraction.

Corundum

The material is industrially produced aluminum oxide and has a distinct crystalline form. Corundum is considered one of the best due to its characteristics similar to diamond. As a rule, it is used for the purpose of decorative processing of metal surfaces. Abrasive has a high cost. Its advantage is that it can be reused.

Plastic granules

Plastic abrasives are a type of soft materials designed for delicate surface treatment. They are usually used for working with soft metals, wood, plastics, various alloys, ceramics or glass. The production of plastic abrasives is based on resins.

Glass granules

Glass beads are widely used in industry. The abrasive is widely used for the following purposes:

- delicate cleaning of various types of surfaces;

- processing of material without changing its color and physical characteristics;

- production of parts intended for galvanic operations;

- obtaining controlled withdrawal values necessary in mechanical engineering, instrument making, as well as in optical and watch production.

Important!

Glass granules are indestructible and can be reused up to 35 times.

Metal shot

Cast iron and steel are used to make these small metal balls. The use of such materials for sandblasting is quite beneficial due to the possibility of secondary use. The shot has a uniform fraction, which allows you to obtain a smooth, defect-free surface.

Types of abrasives

When selecting sand for a sandblasting gun or another type of abrasive, you need to take into account the basic properties and characteristics of the latter in order to carry out the work with maximum efficiency.

Quartz sand

It is quartz sand that is most in demand on the market for sandblasting and grinding products. It is characterized by a low price, decent quality, and is sold everywhere. Quartz sand is made from white quartz by crushing it into different fractions:

- up to 0.1 mm,

- 0.10–0.4 mm,

- 0.5–1 mm,

- more than 1 mm.

The sand undergoes thorough screening, so larger particles are practically not found in its small fractions, and sandblasting can be done without harm to the product. The material has good durability and abrasive ability, especially considering its availability. Sand will not damage delicate products or non-ferrous metals. Waste quartz sand after sandblasting can be sold as a building material.

A significant disadvantage of sand is the release of a large amount of dust, which enters the worker’s lungs and eyes, which is harmful to his health. With the regular use of sand for such grinding in the absence of personal protective equipment, a deadly disease can develop - silicosis. To avoid such problems, all equipment should be equipped with dust removal systems, and each batch of sand should be used no more than 1-2 times.

Cooper slag and nickel slag

These abrasive materials are obtained by processing slag from nickel and copper production. They are considered reusable, economical and more effective than quartz. The particle strength, hardness and abrasive ability of cooper slag is higher than that of nickel slag. Such materials can be used up to 3 times without the risk of dust.

The use of these abrasives is advisable when cleaning expensive and complex structures, which is associated with the high quality of the result, but also with the price of materials. Cooper slag and nickel slag are capable of cleaning the most durable types of metal and concrete; they do not crush along with plaque due to their high strength.

Metal (technical) shot

This material is small metal balls made from steel or cast iron. Technical shot can be cast, chopped, chipped, with the first having a spherical shape, and the rest being acute. Steel and cast iron shots are used for shot blasting and shot blasting of products that require notching (profiling) or descaling. This purpose is associated with the high strength of the materials and the presence of sharp-angled edges on their particles. After treatment, the metal base will have a high degree of adhesion and adhere perfectly to finishing coatings.

Steel shot is of good quality - it is the hardest, has the highest strength characteristics, can be used several times, and does not cause dust. The increased service life is due to additional heat treatment of the shot during its production. Stainless steel shot is used for processing structures made of the following materials:

- steel,

- zinc,

- titanium,

- aluminum,

- copper,

- bronze,

- brass,

- concrete,

- granite,

- marble.

Corundum

This material is prepared on the basis of aluminum oxide and is considered one of the most durable abrasives. Its particles are in the form of crystals, and their characteristics are close to diamond. The price of the material is high, which is why it is used for processing mainly expensive products. Corundum can be reused many times. It is ideal for decorative sanding and polishing of surfaces.

A variety of corundum is electrocorundum - a super-strong material obtained by adding a number of impurities to aluminum oxide. Its particles are not damaged at all during processing of materials, therefore repeated processing can be carried out a large number of times (after sifting). On the Mohs scale, electrocorundum is only one position inferior to diamond, it is so hard. Its grains have sharp edges and have the unique ability to sharpen themselves.

Garnet sand

Garnet, or garnet sand, is an abrasive of mineral origin, which in terms of technical characteristics is superior to quartz sand, nickel slag, and cooper slag. The material can be used repeatedly, used both for sandblasting and for hydraulic cutting of metal.

Features of abrasives used for processing

When choosing a material for sandblasting a surface, it is necessary to study its characteristics in detail.

Fraction

Fraction is the size of particles used to treat various surfaces. When crushing certain components using a press, fine crumbs are obtained. Subsequently, it is sifted through sieves with different cell sizes, which determine the fraction. When choosing this indicator, it is necessary to take into account the characteristics of the surface being processed: condition and material of manufacture.

Important!

To clean thick layers of plaque, a coarse fraction is used, and a fine fraction is used for finishing work.

Hardness

The ability of particles to maintain their integrity during processing directly depends on this indicator. The hardness degree is numbered in ascending order. For example, soft materials are designated by the number 1, hard materials by 10.

Abrasive ability

The packaging of the material indicates the period of time it will take to clean a certain surface area.

Mechanical stability

This indicator is used to indicate the degree of resistance of particles to destruction during processing. A high degree of mechanical stability indicates the possibility of repeated use of the same abrasive; a low degree indicates the opposite.

Chemical resistance

The indicator indicates the level of resistance of particles as a result of prolonged contact with acids, alkalis and similar compounds.

Which consumables are best to choose?

When choosing consumables for sandblasting, you need to take into account the characteristics of the surface for which it is intended to be processed. In this case, it is necessary to familiarize yourself with the specifics of using certain types of abrasives:

- Shot blasting. This method is economical and also effective due to dust suppression systems.

- Quartz. A material that is quite common due to its low cost and availability. Used to treat a wide variety of surfaces. When working with it, you must take care of the appropriate equipment.

- Nickel slag. The use of this abrasive allows you to obtain high-quality results. However, due to its high cost, it is purchased mainly for finishing surfaces made of expensive materials.

- Cooper slag. The material is well suited for working in open conditions.

- Metal shot. Makes it possible to initially imagine the final result after processing. This quality is due to the uniform surface of the abrasive. In addition, it increases the degree of adhesion of the material.

- Steel and cast iron shot. Abrasives are used to clean metal from carbon deposits. A greater effect can be achieved using crushed shot.

- Corundum. It is considered the most durable compared to other materials and allows for reuse. Recommended for decorative work with metal parts.

When choosing sand for sandblasting equipment, you also need to take into account the area of the surface being treated and its condition. Working with large fractions can damage the workpiece.

Where is abrasive treatment used?

When choosing an abrasive material, you need to understand the areas of its application:

The concept of abrasive processing

- Cleaning the metal surface from corrosion traces is carried out with preliminary cleaning with dried and sifted sand;

- Crushed sand (particle size – 0.3 mm) will add shine to copper and aluminum products;

- Sand with a particle size of 0.3-0.6 mm will remove old paintwork that is well fixed to the base;

- Sand, nickel, cooper slag, the particle size of which is 0.6-1.6 mm, will remove old corrosion traces;

- Coarse abrasive will remove welding scale and thick bitumen base;

- Steel and cast iron shots will clean and prepare the car body for painting;

- Electrocorundum, garnet sand will clean alloy steel, titanium;

- Clean fine sand, the particle size of which is 0.1-0.8 mm, will allow glass to be processed for further matting and drawing;

- Stainless steel shot and small glass granules will allow you to process a stainless steel product.

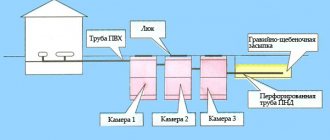

How to make abrasive with your own hands at home?

In some situations, it is not possible to purchase sand in a store. In this case, you can prepare the mixture for sandblasting on your own. It is permissible to take gravel sand as a basis; the manufacturing process includes several stages:

- preparing 2–3 sieves, made independently from a wooden frame and mesh with small cells;

- sifting sand to remove foreign debris;

- sifting to the desired fraction;

- drying the mixture after obtaining the required grain sizes;

- control sifting after drying using a fine sieve.

Can sandblasting be done with regular sand?

Sand is a sedimentary rock of natural origin or an artificial material created from it. Despite the permissibility of using ordinary sand for sandblasting equipment, it is impossible to perform high-quality processing in this way. This is due to a number of reasons:

- leaving dust on the treated surface;

- ability to mask corrosion;

- content in the composition of salt deposited on the workpieces;

- negative impact on equipment, contributing to the formation of blockages.

Important!

In the Russian Federation and Europe, legislation officially prohibits the use for sandblasting of sand whose free quartz content exceeds 1%.

The use of ordinary sand is an uneconomical solution, since the material quickly becomes unusable and cannot be reused. Surface treatment using sandblasting technology is considered an effective method for getting rid of corrosion, scale and various contaminants. To achieve a positive result, the main thing is to choose the right material for the equipment.