The majority of residential suburban areas are not equipped with a centralized sewerage system.

Homemade storage pits do not cope well with the task, and they cause many unpleasant problems.

The presence of waste odor, the need to call specialists to pump out the contents, sewage getting into the ground.

To avoid all these issues and make their lives more comfortable, owners of private houses install septic tanks for sewerage.

How do septic tanks work without pumping?

In fact, this is not an entirely true statement. In any septic tank, sooner or later, a layer of sludge (heavy and non-recyclable particles) begins to settle, which must be removed. Septic tanks without pumping simply allow you to remove sludge as rarely, quickly and efficiently as possible, and most importantly, independently, which is possible thanks to this operating principle of the device:

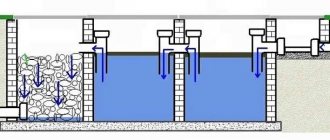

- The system has 2 or 3 chambers, which are connected to each other by a pipe and sealed side walls.

- Domestic wastewater enters the chamber for primary treatment through the sewer pipe.

- Large particles in waste settle to the bottom due to gravity, where they will decompose under the influence of anaerobic bacteria.

- Water with fats and small parts flows through a pipe into the second chamber, where it is purified as debris is absorbed into a layer of sand, gravel or crushed stone.

- Purified water goes into the ground in the third chamber or is poured into the next chamber.

Advantages of septic tanks without pumping:

- cleaning the septic tank from sludge is necessary once every couple of years;

- the system is simple and self-service is possible;

- if necessary (if the system is installed in a country house that you do not visit in winter, for example), the septic tank can be mothballed, and it will not stand idle in vain.

The following video shows a do-it-yourself septic tank with automatic pumping of water:

Design elements

Many septic tanks have a mechanical filter to sediment sediment during the cleaning process. A mechanical filter involves sedimentation of particles without any chemical reaction or introduction of reagents. In septic tanks, wastewater is filtered through a layer of sand, expanded clay or gravel, and in some cases, after leaving the tank, additionally through a layer of soil.

Please note: If it is impossible to drain treated wastewater into the soil in septic tanks located in clay soils, pump pumping into an irrigation tank or drainage ditch.

An exception to the rule may be a single-chamber septic tank device, the operating principle of which does not allow for the gradual sedimentation of large and small fractions and filtering of wastewater. Such devices work only as storage devices. They compare favorably with cesspools in the impermeability of the walls and bottom, but have similar functionality. The single-chamber model is a completely waterproofed septic tank - the installation diagram does not provide for the presence of a filter bottom.

The main elements of all septic tanks are:

- chambers for settling water (in some models, sediment is processed in the chambers),

- pipelines at the inlet and outlet (the latter may be absent if treated wastewater is drained into the ground through the bottom),

- ventilation system,

- maintenance devices (hatches, inspection wells).

The photo shows a diagram of the installation of a septic tank from three chambers with soil post-treatment of wastewater on a filtration field.

The principle of operation of a septic tank is based on the flow of wastewater through communicating vessels (chambers) from one to another with a gradual decrease in the amount of impurities and clarification of the water.

Ancient times.

We all know from history that the Greeks were one of the first engineers, and in the case of devices for processing human waste, they succeeded back in 3700 BC. The first cesspools appeared in Greece, then India and, of course, the Romans took a step forward in this direction. There are documents dating back to 500 BC in which the Romans describe laws regulating places of defecation, as well as establishing the amount of a fine if someone accidentally steps on excrement. Subsequently, there were no big changes; the Middle Ages are generally famous for unsanitary conditions.

Victorian early septic tanks.

Then comes the time of Victorian septic systems and the law of 1848 AD which prescribes sanitary requirements for every home, now every home must have a septic tank. In the 19th century, or more precisely around the 1860s, the first septic tank similar to the modern one was created by the inventor of the septic tank, John Mouras.

The septic tank was registered in the patent office in 1881. Mouras started with a simple prototype, the main tank was made of concrete and the piping was made of clay. The pipeline carried wastewater from the house to the main tank where it settled, and more or less clean water fell into the soil. The success of the inventor of the septic tank, John Mouras, spread throughout the world, the next country in which the first septic tanks spread was the USA in 1883. Since without proper attention to the conditions and materials of septic tank production, it can be dangerous for both humans and the environment, the US authorities regulated production standards. Because of the Massachusetts State Council's report on the link between disease and contaminated wastewater, the State of Massachusetts became the regulator of septic tank safety and production standards.

Modern septic tanks.

During the post-war economic boom of the 1940s, septic tanks became significantly cheaper and became popular among the people. In those years, septic tanks became truly popular devices for wastewater treatment. In the 1960s, outdated septic systems began to fail, and the construction of wastewater treatment plants could not keep up with the pace of urban growth. Then in the 70s there were significant changes in the standard of septic tanks; now treatment facilities must withstand a larger volume of wastewater. Then the Texas Commission on Environmental Quality was created, and from 1993 to this day they have administered safety standards for septic tanks.

Let's talk about modern septic tanks; now plastic septic tanks continue to gain popularity instead of concrete ones. Modern plastic septic tanks with bacterial cleaning were invented in 1994 in the Czech Republic by Jan Paul and the first model was called “Topas”. In Russia there is no consensus on which model of plastic septic tank was the first imported; it is only known that the Topas model was imported in 1997. A few years later, Russian entrepreneurs realized that they could make their own septic tanks even cheaper than imported ones. One of the first Russian models was the Tver treatment system. The production of the Topas septic tank in Russia began after the end of the inventor’s patent.

We install sewerage with our own hands

There are many ready-made septic tanks on sale, but this pleasure is expensive. At the same time, installing a local sewer system is quite within the power of a home craftsman. You need to follow a few simple rules:

- The distance from the house to the septic tank is at least 10 meters.

- The water source - a well, a spring - must be at least 20 meters away; these are sanitary requirements. If the distance is shorter, the runoff contaminates drinking water.

- The average water consumption per person per day is 200 liters; the size of the tank is calculated from this norm.

One cubic meter of water is 1000 liters.

- Size of a sump tank for an average family of 4 people: depth 2 meters, width 1.5 meters, length 2-3 meters.

This is the minimum required tank. If you make the sump larger, it will simply need cleaning less. The depth must be calculated based on the characteristics of use. In areas with severe winter frosts, the sump tank must be deepened to prevent it from freezing. This is done even when the house is used only in the warm season. For year-round living, the sump tank must not only be deepened, but also insulated.

Septic tank Topas how it works

Septic tanks of the Topas series are very popular systems, characterized by high efficiency and ease of operation. This is achieved thanks to the following structure:

- 4 chambers, therefore, 4 cleaning stages;

- several airlifts;

- special system for collecting non-recyclable particles.

Important! The model range of Topas septic tanks is very diverse - you can choose an option for a small family or an entire work pavilion for up to 150 people. In the following video you can clearly see the diagram and operating principle of the Topas septic tank:

In the following video you can clearly see the diagram and operating principle of the Topas septic tank:

The size of these systems is small, installation is simple, and the septic tank does not make noise during operation. Uses very little electricity. It’s also nice that a domestically produced unit will cost you little in terms of maintenance.

The advantage of this series of septic tanks is very deep biological treatment (95-99%).

Probably the only problem you may encounter when using it is power outages. The system is completely dependent on electricity, so when it is turned off, it is strictly forbidden to use the septic tank. This may cause serious damage or render it inoperable.

What local sewer options are there?

Before choosing the most suitable option for arranging the local sewer system of a private house, you need to get answers to several questions:

- Is it planned to use the house as a permanent home or will it only be a place for periodic recreation?

- How many people will use sewerage in a private house;

- What set of plumbing fixtures is planned to be installed in a private house?

- What is the size of the site and how much area can be allocated for the construction of a treatment plant;

- At what level do soil waters lie in a given area?

- What is the type of soil on the site;

- What are the climatic conditions in this area?

Only after receiving answers to the questions posed above will it be possible to make the optimal choice of the type of local sewage system.

Storage capacity

One of the simplest ways to construct a local sewer system is to install a storage tank. A fairly large tank is simply installed on the site, into which wastewater from the house will flow through pipes. It is very important that the tank is sealed.

Once the wastewater fills the tank, it will need to be pumped out. To do this, you will have to contact a company that provides sewerage services. The advantage of this option for local sewerage is its simplicity; you can install a ready-made tank with your own hands. In addition, the storage tank can be used with any soil structure and even with a high location of soil water.

Advice! You can buy a storage tank in a store, or you can make a sealed storage tank yourself, for example, by concreteing a pit.

The disadvantage of this option is the high cost of maintenance, since you will have to pay for each call of the vacuum cleaners. Therefore, the storage sewer system is most suitable for a private house in which water consumption is low. If water consumption is high, you will either have to install a very capacious tank (and a large tank is not cheap), or often use the services of vacuum cleaners.

Single-chamber septic tank without bottom

A single-chamber septic tank with a filter bottom is essentially the same cesspool. The design of such an installation is extremely simple. This is an ordinary well, at the bottom of which there is a filter made of crushed stone and sand.

The wastewater entering the well from the house gradually seeps through layers of sand and crushed stone, being purified by 50 percent. That is, this sewerage option cannot be called environmentally friendly.

When constructing a sewer system for a country house, it is recommended to use a septic tank without a bottom only if permanent residence outside the city is not planned. In addition, such a treatment plant can be planned to be installed only in areas with low-lying soil water.

Multi-chamber septic tank

For a home with permanent residence, a more advanced autonomous sewage system is needed - this is a septic tank consisting of 2-3 sealed chambers and a filter well (or filtration fields). Such a facility carries out multi-stage cleaning. First, the wastewater enters the receiver, where the largest inclusions are deposited.

Then, the initially purified water is poured into a second well, where the settling process is repeated, and smaller inclusions precipitate. The final purification of the wastewater occurs when it passes through a sand and gravel filter on the filtration fields or in a drainage well.

Thanks to the use of a multi-stage scheme, it is possible to get rid of 90-95% of contaminants, so such a sewage system will not harm the ecology of the site.

The disadvantage of installing a multi-chamber septic tank is the need to allocate a significant area for the construction of a treatment plant. In addition, the treatment plant will only work effectively if built on well-permeable soils and with low-lying soil waters.

Advice! If the soil waters are located high, then when building a multi-chamber septic tank with your own hands you will need to use special technologies. Thus, settling chambers must be made completely sealed (the option of prefabricated chambers made from well rings will not work). In addition, for post-treatment of wastewater, it will be necessary to install an above-ground filter cassette, since the drainage well or filtration fields will not function under such conditions.

Septic tank with aeration

In septic tanks with aeration, a full cycle of wastewater treatment is carried out, so the outlet water does not need additional treatment and can be sent for discharge (into a ditch, storage well or the nearest body of water).

In essence, such an installation is a compact plastic septic tank for sewerage, in which special devices are installed - aerators that supply air into the chamber. In an oxygen-saturated environment, biological wastewater treatment occurs, and the level of purification reaches 98-99%. The advantage of this option is:

- Compactness. To install a cleaning station you need very little space;

- High quality cleaning, allowing you to do without installing aeration fields.

The disadvantages of such septic tanks include:

- Requires power connection. The main processes in such a septic tank occur due to air injection, which is why the stations are equipped with compressors;

- High price.

General principle of operation of the treatment plant

The operation of an autonomous sewage system is based on the rules of gravitational settling, supplemented by biological filtration (forced, natural). A complex system collects impurities, then microorganisms decompose the remains. Special bioenzymes and biofilters are often used.

The sequence of processes is divided into 4 stages:

- Primary cleansing. Wastewater flows through pipes into a tank, where large elements are mechanically collected. Heavy particles remain at the bottom of the container, and light particles move to the next chamber.

- Decomposition. The sank insoluble substances are fermented for 72 hours, crushed into water, carbon dioxide and thick sediment.

- Additional treatment. In the second tank, bacteria and drugs trigger re-decomposition processes.

- Jet outlet. Depending on the quality of the treatment plant, clean liquid remains for watering the garden or waste water for ground filtration.

Simple septic tanks in chambers free the drains from impurities, after which the residues go into the ground through the drainage layer. Deep cleaning designs are represented only by factory models. More expensive structures reach a maximum degree of filtration (90-98%).

Operating principle of the treatment plant.

Volume calculation

An important point in the operation of an autonomous sewage system is the efficiency of using the system, since the design must collect and thoroughly process all discharged water, therefore it is necessary to correctly calculate the required volume of the cesspool.

There are several calculation methods:

1. Ready tables. Manufacturers of sewerage systems have calculated the required volume for two- and three-chamber tanks, taking as a basis a certain number of people permanently residing in the house. The calculation results are inaccurate and require adjustments in the form of correction factors. The values of the coefficients depend on the number and name of household appliances in the house that consume water.

2. Easy calculation method. For some time, water consumption is monitored according to a water consumption meter. Next, we calculate the average water consumption per day, and multiply the resulting volume by three - the number of days required for complete settling of the wastewater.

3. Popular payment method. The average statistical value of water consumption by one person per day is considered to be 200 liters. We take into account the required number of days for settling wastewater by multiplying the data. Next, we multiply the resulting value of 600 liters by the number of permanent residents.

4. The most accurate way. The calculation is made using a special complex formula, which takes into account many factors for installing the treatment system: storage time of sediment fractions, concentration values of suspended matter resulting from sediment, the average temperature of the discharged water, as well as other standard values.

Septic tank "Rostok", all about the advantages of the Advantages and disadvantages of the septic tank "Termite" in our article.

We recommend that you study the design of a septic tank made of concrete rings before you start making it yourself.

Depending on the number of compartments, the resulting required volume is distributed as follows:

- With a two-chamber design, ¾ of the resulting volume is placed in the first compartment;

- With a three-chamber - 1/2 of the resulting volume, and the remaining volume is divided equally into the two subsequent compartments.

With any calculation method, a certain margin should be taken into account. This is achieved by applying a multiplying factor of 1.3.

Basic diagrams of popular models

Manufacturers of autonomous sewer systems are improving technology, so they offer the user many convenient options. The more filtration cycles, the better the result.

Tank – comprehensive cleaning with infiltrator

Tank septic tank scheme - comprehensive cleaning with an infiltrator.

A popular septic tank with a soil treatment design. A plastic tank with rigid ribs can be installed in any soil. The system consists of removable units, so an additional module can be added if necessary.

The Tank cycle is “classical” biological filtration. In the first tank, mechanical separation of sewage occurs. In the second container, anaerobes are broken down into simple compounds.

Two-chamber models complete the work in an infiltrator, and versions with 3 components are subjected to additional bacterial treatment.

Topas – multi-stage biofiltration

The vertical septic tank is divided into 4 sectors, between which wastewater circulates. The components are connected to each other by hoses. A pipe pump transfers purified liquid, dirt, and debris from one part to another. The device runs on electricity.

In the first sector, aerobic microbes decompose wastewater into light components. In the next compartment, the water is removed from small particles. In the settling tank, sewage is converted into sludge. The last chamber accumulates pure liquid. If the tank is full, the equipment warns the owner with a signal.

Triton – non-volatile cleaning system

An inexpensive model without pumping will not take up much space on the site. The unit carries out rough and biological separation, and additionally performs soil purification. The equipment consists of 2 containers, which are connected by pipes. The liquid settles in the first tank and gradually flows into the second. The proprietary infiltrate treats water with bacteria.

Ecopan - six-stage wastewater filtration

Ecopan septic tank scheme - six-stage filtration of wastewater.

The device consists of 6 parts, each of which contains complex processes:

- separation;

- anaerobic treatment;

- aerobic digestion;

- cleaning with a dolomite bioreactor;

- removal of sediments.

Liquid accumulates in the storage tank, which can be used for technical purposes. 3 settling tanks provide high-quality removal of impurities.

Microbes need oxygen to live, so the model is connected to electricity.

Rodlex - storage type septic tank

The sewer tank works on the principle of a cesspool. The hollow tank with legs and screw neck is made of durable polymer material that will last at least 50 years. Seamless technology ensures a sealed housing. The special shape of the tank allows it to withstand soil pressure.

The septic tank model is buried to a depth of 2.5 m, and drain pipes are connected. To prevent sewage from spilling, you need to install a rubber cuff lubricated with silicone sealant at the entry point of the hose. The capacity of the device is 4000 liters, so you need to periodically pump out the liquid.

Fast – aerobic recycling technology

A vertical type self-regulating apparatus quickly processes waste. In the receiver, aerobic bacteria act on the wastewater. The fan supplies oxygen, increasing the rate of breakdown into water and sediment. The airlift moves the liquid to the segment with anaerobes, where clarification occurs and the pure residue is released.

The Fast septic tank adapts to wastewater with chemical additions and large parts. Under the influence of an aggressive environment, microorganisms die. The cellular structure of the module protects useful components from destruction and creates favorable conditions for development. The self-regulating system does not take up much space on the site.

A septic tank is a modern autonomous sewer system that will provide comfort in a country house. Models differ in operating principles, installation complexity and price, so you can choose the appropriate option to suit your needs. Popular types are easy to use and will serve property owners for decades.

Kinds

How to make a septic tank with your own hands for a private house, how to choose, stages of work. Read all about the advantages and disadvantages of storage plastic septic tanks.

And here learn about the advantages of storage fiberglass septic tanks.

Plastic

It is one of the frequently used solutions for organizing sewerage. The main advantages of such structures are: tightness, simple installation, corrosion resistance.

The disadvantage of this design is its low weight, since there is a possibility that the structure can be crushed under heavy soil or pushed to the surface by the force of groundwater movement.

To avoid all the above-mentioned troubles, polymer septic tanks should be installed in pre-prepared concrete wells with the bottom secured with special anchors embedded in the concrete bottom.

Plastic septic tanks with a reinforced structure, designed for installation in a regular pit, are also on sale.

Brick

It is carried out by laying brick walls in a pre-prepared pit . The disadvantages of such septic tanks include their relatively low tightness, so brick walls require careful waterproofing.

For this purpose, cement mortar is used. The main advantages of a device of this type of septic tank are considered to be uncomplicated installation and wide availability of materials .

Reinforced concrete

It is a reliable and durable cleaning device. Depending on the type of device, they can be monolithic or prefabricated. To install a monolithic septic tank, a pit of the required size is first dug, then formwork is installed and filled with solution.

A prefabricated septic tank is constructed from ready-made factory products - reinforced concrete rings, where special attention is paid to sealing the joints.

Metal

Such devices differ in the number of compartments, which can be from one to three. The number of containers depends on the required quality of cleaning and the daily volume of incoming wastewater. Most often, such septic tanks are made from two adjacent chambers.

A device of this type is considered irrational due to its low resistance to aggressive environments and, consequently, its short service life. Of course, you can use stainless steel, but such a cleaning system will be too expensive.

The process of installing the product is also complicated, as it requires the use of special lifting equipment.

Components of a septic tank

All treatment structures consist of:

- Tank for settling wastewater. Such containers are most often made of plastic or metal. If you build a septic tank with your own hands, then such a tank is built underground from concrete or brick.

- Pipeline: incoming and outgoing. The drainage overflow pipes are installed at a slope so that the liquid flows smoothly between the tanks.

- Maintenance elements: wells and hatches. There must be at least 1 well on the external route of the sewerage pipeline. If the length of the structure exceeds 25 meters, there should be 2 wells.

- Ventilation system. It is necessary for air exchange, which ensures the maintenance of the desired temperature, the removal of methane and the normal functioning of microorganisms. The simplest ventilation is constructed from 2 risers: 1 is installed at the beginning of the sewer system, 2 - at the outermost section of the septic tank.

What is a septic tank?

Before dwelling on how a septic tank works for a private home, you need to find out what this word is called. This device is a local treatment plant, which is intended for the construction of a sewer system that will be independent of centralized networks. The main task of any such structure is the collection of wastewater and its subsequent purification - filtration. Such installations are as convenient as possible; they are superior to conventional cesspools in every way, so septic tanks are gradually replacing these “relics of the past.”

Despite the fairly wide range, all autonomous treatment facilities have a lot in common. They consist of several combined containers, which are designed for the gradual purification of sewage. If we consider the materials from which homemade autonomous systems are created, then there are quite a few contenders on the list. These are reinforced concrete rings, reinforced concrete, bricks, blocks, plastic containers (Eurocubes), car tires, flat slate, etc.

Materials for modern septic tanks

If we talk about the models that have “flooded” the market, they are made either from polymers or metal. There are several types of plastic with different characteristics.

- Polyethylene. This is the simplest, inexpensive representative. The advantage of the products is good tightness. The downside is the fear of hot water.

- Polypropylene. This material does not have the disadvantages of the previous one. Such septic tanks are durable, they are not afraid of either an aggressive environment or sudden temperature changes. But polypropylene's fatigue threshold can cause the molecular bonds to break down over time.

- Fiberglass is the best option, since this material is as resistant as possible: both to adverse conditions and to chemically active components. Super-strong fiberglass structures have one disadvantage: they are the highest price among polymer products.

The advantage of the latest reinforced type is its long service life: it is at least 50 years.

The last contender, a vulnerable metal, is not one of the favorites. The reasons are heavy weight, potential corrosion (internal, external), the need for insulation and high-quality waterproofing of the septic tank.

Treatment plant

Any treatment system is a sealed tank, which is divided into several sections, each of which performs its own stage of work. The chambers of factory septic tank models are separated by partitions, and liquid flows between them thanks to overflow pipes. Homemade structures can be a device of 2-3 separate containers connected by pipes.

The house sewer drain pipe is connected to the first compartment; from the latter, either almost perfectly purified water or semi-purified liquid is discharged into the ground, which then undergoes further soil treatment in one way or another.

The daily volume of wastewater is a factor on which the choice of site owners largely depends. Single-chamber septic tanks allow you to collect up to 1 m3 of waste per day. Two-chamber structures - up to 10 m3, three-chamber - more than 10 m3.

Septic tank elements

Despite the fact that all models differ in many characteristics, they all contain several required elements.

- Storage containers. They are designed for temporary storage of sewage waste. Such sections are made of concrete, brick, metal or plastic. If we talk about the best materials, then products made from polypropylene or fiberglass are considered optimal. These models are sealed, lightweight, but resistant to all adverse conditions and resist abrasion well, especially the latest models.

- Elements designed to control the operation of septic tanks, as well as for their regular maintenance. These are hatches, inspection wells. Such devices must be installed on the external sewer route. The minimum is one element. If the length of the route is more than 25 m, then the installation of another, additional revision is required.

- Ventilation. This system is always present; its necessity does not depend on the type of bacteria that “work” in the septic tank - anaerobic or aerobic. The task of ventilation is to ensure the vital activity of microorganisms, air exchange, thanks to which the optimal temperature is maintained and methane is removed in a timely manner.

- Pipeline: incoming, outgoing. To ensure unimpeded flow of liquid, all elements of the system are mounted at a slight slope.

The ventilation system deserves more attention. If we consider the simplest scheme, then these are two risers, one of which is located in the first chamber, the other in the last section. When filtration fields are constructed, each drainage pipe is often equipped with such ventilation ducts.

Advantages and disadvantages

Uninterrupted drainage, collection and subsequent treatment of sewage is a benefit: both for residents and for the environment. However, the list of advantages does not end there. These include:

- long service life of the installation;

- no risk of soil contamination;

- possibility of self-installation;

- savings due to rare calls for sewage disposal equipment;

- no additional expenses if the option with drainage is chosen;

- complete absence of unpleasant odors in the local area, problems with sewerage;

- ease of operation, ease of maintenance, if the choice is made in favor of a completely autonomous bio-installation, which contains all the elements for waste decomposition.

Are there any significant disadvantages to septic tanks? Yes, if we consider the prices of some (for example, polymer) models as such. A large volume of excavation work can also be classified in this category, but only if the owners plan to do the “installation of the installation” themselves.

Features of the operation of different types of septic tanks

In order not to make a mistake in choosing the type of autonomous sewage system, you need to correctly calculate the amount of daily waste. The volume of tanks depends on the number of residents and average daily water consumption. Devices with a filter bottom are prohibited from being installed on clay and loamy soils or in the vicinity of groundwater.

Storage wastewater system

An improved version of a cesspool consists of a sealed tank for sewage. The sewerage scheme is an external pipe system and a storage tank. A single-chamber tank is used for wastewater, which is cleaned as it fills using a sewage disposal service.

To prevent the movement of liquid in the opposite direction, it is necessary to additionally install a special valve. A meter with an alarm will notify you when the container is full.

Sedimentation tanks with ground treatment systems

An overflow device of 2 or 3 segments is used for thorough filtration of sewage. The dirty liquid enters a storage tank, inside of which it is broken down into components under the influence of anaerobic microorganisms. The wastewater goes through several stages of natural separation.

A filter well is used in sandstones. The structure is assembled from brick or reinforced concrete. The base of the structure is filled with drainage (crushed stone). More complex functions are performed by the underground treatment field. A set of perforated pipes is placed on a special platform covered with gravel. Sewage passes through a thick layer, gradually being cleansed.

For thorough filtration of sewage, a sump is needed.

Septic tank with biological treatment

Microorganisms are the basis of the deep filtration base.

The liquid through the sewer enters the tank, where it undergoes multi-level cleaning:

- Sump. Anaerobic microbes mechanically separate heavy and light fractions.

- Decomposition. Aerobic bacteria break down waste. A continuous air supply is required.

- Disinfection. The filtered water is treated with chemicals.

The bioseptic purifies up to 98% of wastewater. Microorganisms function with a regular supply of oxygen. To ensure full operation of the system, the equipment must be connected to electricity. Current drops negatively affect the filtering properties of the structure.

Construction of a homemade storage device made of reinforced concrete rings

Construction of a homemade sump from well rings is one of the most popular options. Let's look at how this work works:

- Preparing a pit for the construction of a settling tank.

- At the bottom of the pit, sand is added; the height of the sand layer is 10 cm.

- A reinforced concrete slab is laid at the bottom of the pit or the bottom is filled with cement mortar. If “blind” rings, that is, having a bottom, were purchased for the lower part of the settling chambers, then concreting the bottom of the pit may not be used.

- The rings are put in place. It is necessary to choose rings with a lock to give the structure greater strength.

- The pipes are being connected. If the rings do not have ready-made holes for inserting pipes, you will have to make them yourself.

- Now you need to seal the chambers. It is necessary to protect the weakest points - the joint of the rings and the insertion points of the pipes. For sealing, a cement mortar prepared with the addition of liquid glass is used, and the outside of the chamber is covered with modern waterproofing compounds.

- The chambers are covered with lids on top, which have holes for installing hatches.

- It is recommended to backfill the pit using clay, this will make the structure even more protected from leaks.

So, settling tanks for local sewage systems can have a variety of designs. In addition, sewerage equipment can be purchased ready-made, then all that remains is to install it in the pit and connect the pipes to it. You can build a septic tank yourself. For this, it is convenient to use well rings made of reinforced concrete.

Types of septic tanks and their design

There are several types of septic tanks, which differ in their operating principle:

- Biological. Liquids are purified from various contaminants without harming the environment using a filter with aerobic bacteria.

- Natural or settling tank without pumping.

- Mechanical. It is divided into several settling tanks with filters for different purposes, through which water is pumped.

- Electric or compressor. Septic tank with forced cleaning. It is divided into several settling tanks into which the liquid is pumped using a pump. This allows you to speed up the purification of water from solid fractions and sludge.

The operating principle of anaerobic septic tanks with mechanical cleaning

Anaerobic septic tanks mainly use the principle of mechanical treatment (sedimentation and filtration). To increase efficiency and to extend the intervals between tank cleanings, cultures of anaerobic (not requiring air) bacteria can be added. However, they do not decompose impurities as actively as aerobic cultures.

How a three-chamber septic tank with gravity cleaning and filtration through a drainage well works is shown in the diagram

The quality of filtration is of great importance in the operation of anaerobic septic tanks with mechanical cleaning. The thickness of the filtration layer, the size of its particles, the speed of passage of water, the method of removing the purified liquid (directly through a bottom filter or through a filtration field formed by horizontally located underground pipes) - all this affects how the septic tank works.

Basic elements of a septic tank

A special treatment facility not only accumulates wastewater, but also gradually filters it from impurities. An independent sewer system is an improved version of an outdated cesspool.

The units consist of 4 main elements:

- Storage Containers are made of plastic, concrete, brick or metal alloys. Wear-resistant models made of polymers and fiberglass promise tightness for decades.

- Pipeline. The parts are mounted at an angle, ensuring free flow of liquid between the tanks.

- Wells, holes. Maintenance components make it easier to monitor the operation of the treatment system.

- Ventilation. For high-quality wastewater processing, it is necessary to maintain the necessary microclimate for anaerobic or aerobic bacteria. Natural air exchange and temperature are created inside the structure. A simple septic tank consists of 2 risers (at the beginning and the end).

The efficiency of the design depends on the number of tanks. Single-chamber solutions are an improved cesspool that is suitable for summer cottages. In a private house with permanent residence, it is better to install models with 2 or 3 tanks. The more capacities, the better the performance of the device.

How to choose the right septic tank

- For temporary or permanent residence. Temporary housing does not require a stand-alone system or complex installation. A drainage type septic tank is perfect.

- Septic tank volume. It’s easy to calculate on your own, multiply the number of people living by 200 liters (that’s how much water one tenant uses, according to statistics), and triple the resulting figure.

- Material of manufacture.

- Additional equipment (depending on the type of cleaning)

- Groundwater level and location of the septic tank.

- Availability of quality certificates from the seller.

For autonomous installations, there are only two selection criteria - volume and material capabilities.

The principle of operation of septic tanks.

The treatment plant is one of the key parts of the sewer system.

The principle of operation of septic tanks

Processing is carried out through physical and biological processes. In the first case, this is filtration and sedimentation, and in the second, the vital activity of microorganisms. Different types of septic tanks can process wastewater using one or more of the methods listed above. Also, the final degree of purity of the discharged liquid will depend on the number of cleaning stages. And depending on this, it will be discharged directly into the ground, into post-treatment systems, or into special storage tanks for further use for technical purposes (for example: watering plants or washing a car).

The internal part of the septic tank body may consist of one or several departments, in each of which wastewater is processed. The material used in the manufacture of the case is waterproof and has increased strength. Each of the products has a receiving section (or similar) into which wastewater from the sewer pipe initially flows. Here, settling of the liquid most often occurs, in which solid fractions settle to the bottom, and lighter ones rise to the surface in the form of a fatty film. A semi-clarified liquid remains in the middle. The biological part of processing consists of aerobic or anaerobic colonies of bacteria that decompose organic compounds into water, sediment (sludge) and a mixture of various gases.

Ultimately, the sediment (silt) is pumped out by sewer trucks, and the clarified liquid is either gravity-fed or forcibly removed from the septic tank under the action of a pump.

As a result, the water ends up in post-treatment and recycling systems:

- filtration fields take the form of a network of perforated drainage pipes. The entire system is laid in trenches and covered with a mixture of sand and gravel.

- filtration wells look like ordinary wells (only without a bottom), in the lower part of which there is a filter (sand and gravel cushion more than 1 m thick).

- Factory-manufactured products (infiltrators) look like an inverted container. They are also installed on a sand and gravel bed.

- For the removal and accumulation of liquid, which has a purification degree of 95-98%, ordinary wastewater reservoirs and ditches are used.

The after-treatment device is selected based on the parameters of the exiting liquid (the degree of its purification).

The principle of operation of septic tanks

Also, post-treatment plants can be installed only in those areas where sandy, gravel, crushed stone or pebble soils predominate. In places with predominantly clay soil, it is necessary to either connect to a central sewerage system (if available) or use local treatment plants (VOCs) that process wastewater up to 95% purity or more.

Industrial production

Today you can purchase ready-made settling tanks for the construction of a local sewage system. It is quite difficult to describe all types of drives, due to their diversity. Each of them comes with detailed installation and operating instructions, which should be carefully studied beforehand.

Homemade devices are also diverse. The most popular device options are monolithic devices, which are constructed on site, or prefabricated structures made from reinforced concrete rings.

In some cases, various plastic containers that fit the parameters are used to make homemade sedimentation tanks. These can be specially made containers, or any used barrels that are suitable in size.

The principle of operation of homemade settling tanks

Regardless of the chosen option for constructing a homemade sump, all devices have the same operating principle:

- The entrance to the chambers is located 10 cm above the planned filling level.

- The inlet pipe ends with a tee, the outlets of which are directed up and down. The upper outlet is normally closed with a plug; it is used for cleaning.

- All subsequent sump chambers are connected to the first by overflow pipes, which are placed in the upper part of the chambers.

Advice! When choosing the volume of septic tank chambers, it should be taken into account that when completely filled, there should be a free volume of at least 0.5 cubic meters. This is necessary for the accumulation of gases that are formed during the biological decomposition of wastewater.

- Sedimentation tanks, as a rule, are installed at a depth below the freezing level of the soil. If this is not possible, then it is necessary to insulate the chambers.

- Each of the settling tank chambers must be equipped with a hatch, even if all chambers are located in the same tank. If a structure is being built equipped with a filter cassette, then it is necessary to provide for the possibility of replacing this cassette.

- If the sedimentation tank is installed in soils in which the level of soil water is quite high (the distance to the bottom of the chamber is less than 2 meters), it is necessary to construct strictly sealed chambers with additional waterproofing. And when constructing settling tanks from plastic containers, you need to anchor them - fastening them to a reinforced concrete slab laid at the bottom of the pit.

- When constructing settling tanks, we must not forget about the need for ventilation to remove gases.

Septic tank: installation diagram taking into account SNiP

The legislation requires compliance with a number of standards regarding the construction of a septic tank on the site: the device, design, and layout of communications are strictly regulated by sanitary requirements. Before starting any work on the site, it is necessary to develop a project and approve it with the SES, otherwise sanctions and forced dismantling of the structure are possible.

According to SNiP, when installing an autonomous sewer system, the following distances must be maintained:

- 50 m to a residential building;

- 50 m to a well or well;

- 10 m to a flowing body of water (stream, river);

- 30 m to a body of standing water (lake, pond).

To develop a project, it is necessary to clarify the prices for installation, materials, and excavation work.

Preparation for installation involves calculating the parameters that affect the location of the septic tank on the site. Progress of preparatory work:

- Analysis of relief and soil composition.

- Groundwater level assessment.

- Site preparation.

- Marking.

- Digging a pit for a tank and trenches for communications.

Next, all that remains is to install the septic tank, connect it and put it into operation. When contacting professionals, all activities take no more than one or two days.

How a septic tank is equipped for complete cleaning

When choosing a septic tank for a summer residence, the operating principle of the device is assessed taking into account the requirements for the post-treatment system. There are different ways to bring the level of cleaning to meet the standards. Ground purification is used in overflow structures, where liquid flows from container to container and is separated naturally. The mechanical method provides about 65% of cleaning, so the septic tank is additionally completed.

Septic tank: principle of step-by-step operation and arrangement of compartments

If you wish, it is easy to understand the principle of operation of a septic tank: the sewage system operates according to the principles of gravitational settling and biofiltration (natural or forced). The sequence of cleaning steps for many models of factory septic tanks is standard:

- The cleaning system is a sealed tank that includes one or more compartments.

- The septic tank chambers are separated by partitions. The movement of liquid between them is carried out through overflow pipes.

- A drain pipe is connected to the first compartment from the internal sewage system of the house, and from the last chamber purified water is discharged into the ground or semi-purified water is discharged for soil purification.

How septic tanks with different cleaning technologies work

To treat wastewater coming from the house, different septic tank designs are used.

The traditional scheme is a classic 3-chamber tank, with the first 2 chambers being sealed, in which anaerobic decomposition of sewage is carried out. As the liquid is purified, it moves through overflow pipes into the third chamber, which plays the role of a filtration well. The last container is not airtight. Instead, a layer of crushed stone is poured, through which the clarified liquid is absorbed into the soil. Considering that organic matter decomposes with the release of gas, ventilation is necessarily present in such a scheme. Professionals will remove the air ducts so that the unpleasant odor does not enter the residential building.

A treatment scheme with a filtration platform is necessary in areas with high groundwater levels. In the tank, the wastewater is first decomposed into a fine sludge mixture and clarified water. The latter is forcibly moved using pumps to the filtration field. These are trenches filled with rubble.

A biofilter is another method of wastewater treatment. It is a container with drainage material - expanded clay, crushed stone, plastic “ruffs”. For high-quality post-treatment, a spacious plot of land is required. Thanks to the use of a colony of microorganisms, wastewater is purified by 95% versus 85% in the previous version. Pre-clarified wastewater enters the biofilter from above and, under the influence of gravity, percolates through the drainage, simultaneously undergoing biological and mechanical treatment.

Selecting a construction site

When choosing a location for a septic tank, it will be necessary to take into account the requirements of sanitary standards:

- The optimal distance from the site for the construction of a treatment plant to the house is 5-10 meters. It is impossible to place a septic tank closer, as this is fraught with erosion and premature destruction of the foundation. And when the septic tank is located at a considerable distance, the costs of pipeline construction increase. In addition, the farther the septic tank is located, the further it will have to be buried, since the pipes leading from the house must be laid with a slope;

- Particular care should be taken when choosing the location of the septic tank relative to the drinking water extraction points. Errors in this matter can lead to contamination of aquifers, and this is extremely dangerous for the health of people living in the area. The minimum distance separating the well from the septic tank should be 30-80 meters, depending on the degree of soil permeability.

- When choosing the most convenient place to build a septic tank, you need to take into account the fact that the septic tank will need to be cleaned periodically. Therefore, it is necessary to provide passage for sewer trucks.