X

In all types of repair and construction work, in the finishing of various premises, in the production of furniture and other structures, various types of self-tapping screws are widely used. The article will tell you how wood screws differ from other types and what sizes they come in.

A self-tapping screw is a universal fastening element in the form of a metal rod with a head and an external thread. When screwed into the materials being fastened, the sharp edge of the threaded spiral independently forms an internal thread in the material, which ensures a reliable connection.

There are several types of self-tapping screws, the choice depends on the specific purpose. The main parameters by which this type of fastener is distinguished are manufacturing technology (determines corrosion resistance), pitch of the threaded spiral (different for different materials) and size.

Helpful information:

- PVC sewer pipes: dimensions, properties and installation

- Self-tapping screws for concrete

- Standard openings and sizes of entrance doors

- Classification and table of concrete density

Types of self-tapping screws according to manufacturing technology

Regardless of the type of product, they are made from brass, stainless steel, or high-strength carbon steel. The latter are divided into the following types:

Phosphated . This type of fastener has a matte black color due to treatment with phosphates. Black wood screws are characterized by low corrosion resistance, but are easily screwed into any materials. The most inexpensive in price. They are used for both wood and metal, but only where they are not exposed to high humidity. For example, in a room when making plasterboard partitions.

Oxidized . Also black, only with a shiny surface. Thanks to the oxide film, such screws are more resistant to corrosion.

Chrome plated . Treated with chromic acid, they have a silver color. Stainless chrome plated screws are scratch resistant due to the protective film formed. Decorative, used in prominent places.

Anchors for concrete

Galvanized wood screws. Silver or yellow in color, depending on the type of zinc alloy with which the product is coated. The zinc layer provides high resistance to rust. Such self-tapping screws can be used in any premises and structures, but they are also more expensive.

Yellow passivated . In addition to galvanizing, they have another protective layer formed by treatment with chromic acid. This type of fastener is resistant to corrosion and mechanical damage. Yellow wood screws are used in cases where fasteners with decorative qualities are needed, for example, when assembling furniture (with fittings of the corresponding color).

When choosing the color of self-tapping screws for fastening wooden structures, it is necessary to take into account the level of humidity that will affect them. For outdoor service or in damp areas, it is worth purchasing a galvanized, chrome-plated or yellow-passivated version.

Screw sizes

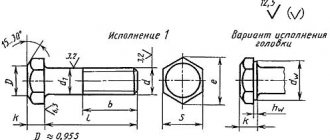

The main dimensions of self-tapping screws, like screws, are their diameter and length. The diameter of a fastener is the distance between any two of their points that are opposite to the center of the circle formed by the protrusions of the thread. Self-tapping screw diameter dimensions

standardized. Their values range from 1.6 mm to 12.0 mm. However, this does not mean at all that all types of self-tapping screws are manufactured with such diameters. This is simply not necessary, since for the use of fasteners for their intended purpose, in most cases a limited number of such parameters is sufficient. For example, specialized small-sized screws, such as ln screws (screws-bugs, seeds, tex, self-tapping screws-fleas) for a metal profile have only two diameter sizes: 3.5 mm and 3.9 mm. Self-tapping screws for drywall with a carob-shaped countersunk head (tn self-tapping screws, black self-tapping screws, gypsum board screws) have the following range of diameter sizes: 3.5, 3.8, 3.9, 4.2, 4.5 and 4.8 mm.

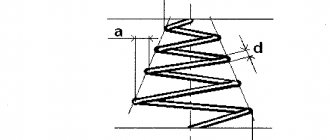

Enterprises can produce fasteners with only one diameter size. An example is self-tapping screws for concrete with a diameter of 7.5 millimeters. The thread of fasteners can be single-start and made with a large pitch (wood screws) or a fine pitch (metal screws). Or maybe a two-way one. In the latter case, the fastener has two different diameter sizes.

Fasteners manufactured, for example, according to domestic standards have an expanded range of lengths and diameters. These are precision class B parts with nominal thread diameters from 2.5 millimeters to 8.0 mm, such as self-tapping screws GOST 11650, with a semicircular head, and self-tapping screws GOST 11652, with a countersunk head, designed for working with metal, wood and plastic. The length dimensions of self-tapping screws of such standards range from 6 mm to 50 mm.

The length dimensions of self-tapping screws with countersunk and convex (semicircular, trapezoidal, hexagonal) heads have their own characteristics. For the first, the length of the fastener is equal to the distance between its end and the end of the head. And for the second, the length is the distance from the base of the head to its end. These parameters are also standardized and have a range of sizes that includes a range of product lengths from 7 mm to 300 mm. Self-tapping screws of the same diameter can have several versions with different length sizes.

Catalog products:

| Self-tapping screw DIN 7981, GOST 10621 |

| Self-tapping screw for drywall on wood RMZ TU 7811-7357 BY 010 |

| Self-tapping screw for plasterboard countersunk thread RMZ TU 7359 BY 009 |

| Self-tapping screw with press washer with drill RMZ TU 7811-7356 BY 012 |

| Self-tapping screw with drill DIN 7504 K without washer for connecting metal profiles |

| Tweet |

comments powered by Disqus

Varieties by type of thread

Another important parameter for choosing self-tapping screws is the pitch of the threaded spiral. There are three main types, they can be seen in the table below:

| Type of thread | Appearance of the self-tapping screw | Scope of application |

| Rare pitch (large carving) | They are used when working with wood, as well as for fastening parts made of MDF, particle boards, plasterboard and fiberboards. | |

| Frequent pitch (fine thread) | Designed for fastening elements made of hard wood, as well as for metal structures (frames). | |

| Double thread (variable thread) | Used for fastening materials with different densities (for example, for fastening drywall to a wooden base) |

When working with wooden structures, self-tapping screws with a rare thread pitch are usually used. It is this structure that allows for maximum preservation of the structure of the materials being bonded. For the same purpose, before screwing a self-tapping screw into wood, a hole of a smaller diameter than the screw itself is first drilled in it (the diameter is measured by the thread). Some craftsmen additionally moisten the product with oil to facilitate screwing and reduce the destructive effect on the wood. The fasteners are screwed in using a screwdriver of the appropriate shape or a screwdriver.

Self-tapping screws for concrete

In addition to color and thread, it is worth paying attention to the structure of the screw head. As a rule, self-tapping screws designed for working with wood have a flat or slightly concave head that completely fits into the material being fastened and does not protrude above its surface. This type is also called secret. Some varieties are closed on top with a decorative button in the color of the material (for example, when assembling furniture).

Features of the use of fasteners

The most common area of application for screws is fastening parts made of wood, wood materials, and plastic. The threaded part of the fastener quite easily cuts threads in the body of such materials when screwed in. A special feature of using screws when working with soft materials is the need to pre-drill the mounting hole. The fastener is inserted into the hole, after which it is screwed in using a screwdriver, screwdriver, wrench or other tool, depending on the shape of the head. The standard size of the part is selected based on the load that will be applied to the screw after assembling the connection.

In addition, screws are used to fasten parts and structural elements to solid materials - concrete, brick, building blocks, etc. In this case, it is used in conjunction with a plastic dowel. A mounting hole is drilled into the body of the solid material into which a screw is screwed. When screwed in, the dowel expands, so due to the frictional force, a strong connection with the concrete is created. The diameter of the threaded fastener is selected 1–3 standard sizes smaller than the diameter of the dowel. The length of the screw shaft must be selected taking into account the length of the dowel and the thickness of the attached part. Therefore, it is important to consider which screw the dowel is selected for.

Before carrying out installation work, it is recommended to prepare a sufficient number of fasteners. Their number should correspond to the number of connections being performed with a small margin.

Safety precautions and useful tips

When working with screws, not only screwdrivers are often used, but also power tools such as drills and screwdrivers, and such tools should be handled very carefully.

Under no circumstances should you work without safety glasses. Hardware may break and fly off into an unprotected area. If this happens, you should immediately seek help from a doctor. Fasten your sleeves when working with power tools, as fabric can get pulled into the device. Remove children from the area where work is being done. All hardware is very sharp, and a child can be attracted to these small objects. As a result, he will get hurt or swallow them. When working with a screwdriver, always select the correct attachment. If this is not done, the head of the hardware will deteriorate, and all the notches for engagement will simply be erased. In this case, the screw will have to be thrown out, but at first this will be complicated by the fact that it will be difficult to remove it from the attached surface

And also apply sufficient force when tightening, because if you press lightly on the screwdriver, the same incident described above will occur. Pay special attention to marking work. No one will be pleased if inaccurate markings become noticeable only after the bulk of the work has been done.

Follow all the above rules and advice, and then the repair or any type of construction event will take place without complications.

If you carefully study all the above characteristics, you can easily find exactly the version of the self-tapping screw that is suitable for a particular situation. Using self-tapping screws, you can provide very good fastening, but if it is used only for a specific purpose.

As we have already found out above, a screw for metal can be very easily distinguished from one for wood. Self-tapping screws for wood have a much larger pitch than for metal. This is explained by the fact that the density of wood is less, it is softer, and the structure of the fibers is porous. Screws for wood products are usually made with sharp and narrow tips, and therefore the holes that are made with them have smooth walls. It is also worth noting that hardware for wood has a much lower price than those elements that are made for fastening metal products.

Thanks to the information about wood screws, sizes, and a table with thread pitches, you can consider yourself fully prepared to purchase the right tools for successful construction.

The main types of screws were presented. On the Internet they are called more colloquially, and therefore you can find the names “grouse grouse”, “seed” and the like. It's best to use official "names" in stores to avoid confusion.

https://youtube.com/watch?v=rp2GUvJnBwg

Classification

Self-tapping screws are classified into separate groups depending on different criteria - type of head and coating, type of tip, material.

By head type

Types of fasteners:

Self-tapping screws for metal with a press washer. Designed for joining metal sheets up to 1 cm thick. Thanks to the large head, the parts are securely fixed. Hemispherical. Large fasteners that are designed for fixing various metal workpieces. Cross-shaped. They are considered the most reliable and versatile. For tightening, you can use standard Phillips bits for a screwdriver. They fit tightly into the material without disturbing its structure. Self-tapping screws with straight slot. Such fasteners are often used to connect wooden parts. Hex head. Screwed into different materials. To tighten it you will need a special key or a screwdriver bit. Secret head. To tighten the self-tapping screw, you need to pre-drill a hole of a smaller diameter

It is important that the cap fits tightly to the material and does not protrude outward. Reduced hidden hat. Small diameter head

It is easy to hide in the material being joined.

Self-tapping screws with a press washer (Photo: Instagram / anna_shelepneva)

By tip type

Depending on the type of tip, there are several types of fasteners:

- Self-tapping screws for metal with a drill. The tip of such fasteners is a drill consisting of two feathers. Suitable for fastening metal sheets up to 2 mm thick.

- Fasteners with a sharp tip. The rod has a thread for easy screwing. Suitable for securing metal sheets up to 0.9 mm thick.

By type of coverage

Types of self-tapping screws:

- Phosphated - black hardware. Made from carbon steel. They undergo additional treatment with phosphates. Suitable for fastening parts located in conditions with high levels of humidity.

- Oxidized - made of carbon steel, black in color. A protective film is applied to metal surfaces.

- Galvanized - carbon steel is used for manufacturing. The surfaces are coated with a layer of zinc. Used for mounting metal parts outside and indoors.

- Galvanized yellow - products similar to standard galvanized fasteners, but differing in appearance.

- Without coating - suitable for indoor work at normal humidity levels.

Self-tapping screws of different types (Photo: Instagram / stroi_s_nami82)

By material

Material:

- Carbon steel is an alloy based on carbon and iron, which is not supplemented with foreign impurities. They stand out for their high strength.

- Brass is an alloy based on copper and zinc. To change the technical characteristics, manganese, lead, nickel, tin, and iron can be added. Brass fasteners are distinguished by their high wear resistance and reliability. The material is impervious to prolonged exposure to moisture and temperature changes.

- Stainless steel is a material that contains about 10.5% chromium. Stainless steel has an increased strength index. The material is resistant to rust.

Main types of self-tapping slots

The following types of self-tapping screw slots exist:

- direct, the most traditional, but recently used less and less;

- cross-shaped Ph or H (Phillips) replaced the straight slot and significantly accelerated the screwing process;

- cruciform Pz or Z (Pozidrive), thanks to a smaller angle at the apex and an improved shape of the internal recess, is able to transmit more torque without breaking the tool;

- star-shaped Torx allows even greater forces, but is less convenient due to the complex shape of the tool;

- internal hexagon, used to a limited extent, in particular when assembling furniture on ties (the so-called “Confirmat”).

Roofing screws for fastening to metal structures

| Head | Hexagonal with press washer |

| Tip | Drill |

| Material | Steel C1022 |

| Coating | galvanized |

| The self-tapping screw is designed for fastening sheet roofing materials to metal structures. Combines with EPDM gasket with diameters 8, 10 mm to seal holes in fastening points. | |

Table 1. Main dimensions of roofing screws for fastening to metal structures

| Designation of self-tapping screw based on the outer diameter of the thread | D outer diameter, mm | P thread pitch, mm | C flange thickness, mm | Df flange diameter, mm | K head height, mm | S spanner size, mm | Dp drill diameter, mm | T drill length, mm | Dw washer diameter, mm | Ar rubber thickness, mm | A washer thickness, mm |

| 5,5 | 5,28 — 5,46 | 1,80 | 1,00 | 10,00 — 11,00 | 5,25 — 5,40 | 7,78 — 8,00 | 4,55 — 4,70 | 7,50 — 9,00 | 13,80 — 14,20 | 2,30 — 2,70 | 0,9 — 1,10 |

| 6,3 | 6,03 — 6,25 | 1,80 | 1,00 | 12,20 — 13,50 | 5,75 — 5,90 | 9,78 — 10,00 | 5,40 — 5,55 | 8,00 — 9,50 | 15,80 — 16,20 | 2,30 — 2,70 | 0,9 — 1,10 |

Table 2. Length and approximate weight of roofing screws “for metal”

| Designation | 5,5×19 | 5,5×25 | 5,5×32 | 5,5×38 | 5,5×51 | 5,5×64 | 5,5×76 | ||||

| L length, mm | 18,00 — 20,00 | 24,00 — 26,00 | 30,75 — 33,25 | 36,75 — 39,25 | 49,75 — 52,55 | 62,75 — 65,25 | 74,50 — 77,50 | ||||

| weight 1000 pcs., kg | 5,60 | 6,33 | 7,55 | 7,84 | 9,45 | 10,96 | 12,27 | ||||

| Designation | 6,3×19 | 6,3×25 | 6,3×32 | 6,3×38 | 6,3×50 | 6,3×60 | 6,3×80 | 6,3×100 | 6,3×130 | 6,3×150 | 6,3×175 |

| L length, mm | 18,00 — 20,00 | 24,00 — 26,00 | 30,75 — 33,25 | 36,75 — 39,25 | 48,75 — 51,25 | 58,75 — 61,25 | 78,50 — 81,50 | 98,50 — 101,50 | 128,50 — 131,50 | 148,50 — 151,50 | 173,50 — 176,50 |

| weight 1000 pcs., kg | 7,42 | 8,40 | 9,50 | 10,40 | 12,60 | 14,00 | 17,30 | 24,00 | 40,00 | 45,00 | 50,00 |

Recommendations for choosing roofing screws

Experts advise following these tips when purchasing roofing fasteners:

The first step is to decide on the material of the supporting structure of the roof.

Each type of material requires different types of screws. Pay attention to the standard size of fasteners. Remember that the screws must withstand the planned load. When purchasing branded hardware, check for a stamp on the head

Very often, sellers try to sell low-quality material, passing it off as products of well-known brands. Ask the store to show you certificates and certificates of conformity for roofing fasteners. Using them you can determine the thickness of the zinc layer. For the best self-tapping screws for roofing, this indicator cannot be less than 12 microns. When buying self-tapping screws, it would be a good idea to conduct the following experiment. Take one fastener and compress its washer with pliers. If the paint retains its integrity and the seal remains pressed tightly, then the product is of high quality.

Purchasing fasteners such as roofing screws requires a responsible approach. It is necessary to take into account all the nuances to get a high-quality result. It is also advisable to buy products from trusted manufacturers - they will not skimp on quality.