To pump flammable materials, pumping units of different power are used, the design of which is calculated in accordance with the viscosity readings of diesel fuel, gasoline, and technical oil. A 12-volt gasoline pump can pump diesel fuel in a volume of 20-80 liters per minute.

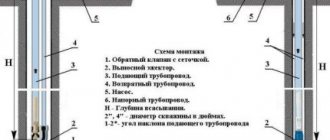

The consumer market offers pumps for pumping fuel from world brands with technical characteristics that allow fuel to be supplied at a horizontal distance of up to 30 meters and a height of up to 2 meters. The device for transferring diesel fuel from storage to the power unit can be self-priming and submersible.

Purpose of pumping equipment

A compact pump for pumping fuel with your own hands can be made from any hydraulic system: from a loader, manipulator or tractor. The device can be used in various areas of the national economy:

- Car park.

- Boat station.

- ONE HUNDRED.

- Private garage.

A productive device for transporting diesel fuel with a power of 12 volts is used when refueling boats, motor boats, and private flying club aircraft. The most popular are portable devices from well-known companies: Adam Pumps, Petroll, Piusi, Gespasa. Fuel units for fuel transfer have been tested in different climatic zones of the Russian Federation, high efficiency indicators are formed by protection class 1 and an automatic ventilation engine.

Criteria for selecting a fuel transfer pump

A fuel transfer pump is an indispensable assistant on construction sites, in garages, auto repair shops, in flammable materials warehouses and gas stations. It is used to move oils, gasoline, diesel, kerosene and other types of fuel from a common container into a tank or canister, as well as to supply liquids from individual containers. Based on the fact that the unit works with flammable, combustible materials, one of the main requirements for it is safety.

A number of criteria will help you choose the right pump. By defining each of them for yourself, you will narrow your search to several models that have approximately the same indicators, which will greatly simplify the choice.

- Amount of work (productivity, maximum pumping speed). This parameter indicates how many liters the equipment pumps per minute.

- Type of liquid (type of pumped fuel) . When choosing pumping equipment, pay attention to what liquids it is intended for and what kind of fuel you intend to move. The difference is not only in the viscosity of the liquid the pump can pump, but also in the materials that ensure the protection of the housing, and therefore your safety. In the description you will find characteristics such as “for technical liquids” or “do not overfill flammable liquids”, which will also clarify and facilitate your search.

- Connection method and operating voltage . The equipment operates “in the field” from 12V or 24V car batteries. Stationary units are connected to a 220V network. And if autonomy is important to you, then choose hand pumps - they do not require much muscular strength and are effective for small volumes.

- Equipment and additional functions . When choosing a pump, pay attention to whether the hoses are included or need to be purchased separately. Useful additional functions include meters for the pumped volume of fuel, which allow you to control the level of liquid transfer. Useful little things - grease fittings, filters, lubricators - will also be a pleasant bonus in the package.

- Guarantee . The higher the quality of the product, the more confident the manufacturer’s promises are - this also applies to pumping equipment. When choosing it, pay attention to the warranty service period. It would be a good idea to check the availability of service centers in your region.

Important nuances when choosing a pump for pumping fuel

- Do you need to organize fuel transportation over a distance of 30 meters or more? Several in-line pumps will be required.

- High pressure is best created by centrifugal-type devices.

- Do you need to pump a large amount of fuel, but the pressure force is not important? Give preference to axial pumps.

- Jet pumps are the most in demand on the market, since their design has no moving elements, which means there is a lower risk of breakdown.

- Do you need something compact, light and inexpensive? Your choice is a vortex pump.

Advantages of a diesel pump

The positive qualities of the device for diesel fuel, kerosene and gasoline include a number of features that distinguish the devices from analogues. Special purpose fuel pumps from well-known companies have a long service life. They differ from domestically produced devices:

- Affordability.

- Build quality.

- Mobility.

- Small in size.

- High working potential.

The 12 volt diesel pump has reliable IP 55 protection against explosion, a guarantee for a long period of operation, reliability and efficiency at temperatures down to -300C. The working parts of the gasoline pump are housed in a durable cast iron housing with anti-corrosion coating.

The ability to quickly install a 12 V device on the neck of the container and a backup route (bypass) helps to return power units (motors) to working condition even at low air temperatures and ensure full functionality of the device.

A household appliance for pumping fuel can be manufactured with a power of 12, 24 and 220 V. The devices are conventionally divided into two types:

- Positive displacement pumps.

- Dynamic pumps.

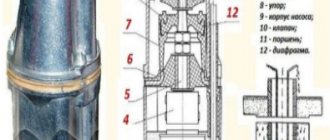

Volumetric fuel pumps for pumping fuel into the engine fuel tank are equipped with a suction function and meters. The high performance of the devices is ensured by the tightness of the housing and the pressure difference in the pressure and suction hoses. The main groups of devices include piston, plunger, diaphragm, plate, gear-rod and screw type pumps.

Choosing a pump for pumping fuel: 7 useful tips

Choosing a pump for transferring fuel is not easy, especially if the buyer does not have experience working with such equipment. We have prepared 7 recommendations that will help you make your choice faster. As a bonus, you save time and money.

No. 1. Determine the tasks for which you will use the pump

Choose the type of pump depending on what fuel you are going to work with. Not all diesel and kerosene pumps are suitable for pumping gasoline or water.

Non-submersible pumps are used away from the working fluid, which can be different. For example, for pumps “Antey” and “Standard”, brand “BelAK”, this liquid is diesel fuel and kerosene. Hermes pumps highly flammable fuels and oils. "Neptune" - diesel and water, and "Sirius" - diesel and gasoline.

Submersible pumps operate below the working fluid level. For pumping small volumes of diesel fuel at home, a submersible self-priming centrifugal pump is convenient. It connects to car batteries and consumes 12 or 24 Volts. Such pumps are presented in the BelAK trade line and differ in diameter. For example, pumps with a diameter of 38 mm are intended for canisters and tanks with a narrow neck, 50 mm for large containers. In this case, you can choose models with a built-in filter to remove impurities, removable or without it.

Pumps with large intake tubes are suitable for pumping technical liquids from barrels. They can be manual (for example, “Titan” under article number BAK.00100) and electric (like “Olympus” BAK.00101).

No. 2. Consider the conditions and place of use

Pumps with low power ratings do not require high energy consumption, are easy to operate, reliable and economical. Pumps with a voltage of 12 and 24 volts are suitable for refueling equipment in the field, as they receive energy from a car battery. For pumping large volumes, pumps with a voltage of 220 volts or more are provided.

Mini fuel dispensers have been developed for stationary pumping. They are used, for example, by private companies with small fleets (up to 20 cars), as well as for refueling equipment at agricultural enterprises.

In the BelAK product catalog you can find both ready-made solutions for pumping fuel in various conditions, and you can independently select a pump and the necessary components: a mechanical or electronic meter, a filling nozzle with the required spout diameter, with or without a cut-off valve, the necessary fasteners and fittings, etc. depending on the place and purpose of use of the equipment.

No. 3. Take an interest in the features of the electric motor

Motors for non-submersible fuel transfer pumps are usually of the asynchronous type. During voltage fluctuations in the network, such devices will operate stably.

Ask the seller what materials the engine parts are made of. Thus, inside BelAK pumps there are electric motors with elongated graphite brushes, which ensure continuous contact between the wires connected to the power source and the motor contacts. Thanks to this element, electric motors have a long service life until the first major overhaul. Moreover, pumps with a vane mechanism produced by BelAvtoKomplekt have blades made of composite materials that have little wear on the stator, the stationary part of the pumping mechanism.

No. 4. Inspect the wires of the product

This is the vulnerable part of the pump, and if the wires are not thick enough, they will quickly become unusable. BelAK engineers tried to reduce the wear of this element and increased the cross-sectional diameter of the power cables by 25% compared to competitor models.

No. 5. Evaluate the pump package

See if the device has filters and if the necessary fasteners are included. Some pumps come with guns and meters. However, these additional but important pumping accessories can be purchased separately. “BelAvtoKomplekt” has a large selection: pistols with and without cut-off valves, mechanical and electronic meters, coarse and fine fuel filters, fittings, seals, platforms for mounting pump elements (you can assemble the station yourself), rotors for pumps and terminals.

No. 6. Check for instructions

Working with fuel equipment contains nuances that the average user may not know. Therefore, it is important that the product is accompanied by a detailed description.

No. 7. Please note the warranty

The better the quality of the product, the more confident the seller is in it. Thus, BelAvtoKomplekt provides a 1-year warranty on fuel pumps. The quality of the transfer pumps was confirmed by experts from the field of auto parts and components: in 2016, BelAK fuel equipment received the prestigious National Award “Automotive Component of the Year”.

Piston fuel pumps

Electrical devices allow fuel to be pumped through a reciprocating motion. The water plunger pump is highly reliable due to the placement of the piston inside the sleeve of the device. The moving mechanism does not come into contact with the walls of the sleeve and does not wear out from friction.

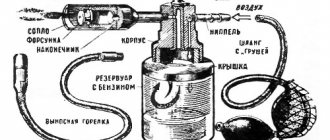

The lightweight diaphragm fuel pump performs its operating functions by oscillating the plate under the action of the drive. An electrically driven vane pump has a rotor in its design, during operation of which pressure is created that presses the vanes to the inside of the housing. Compact electric pump with a power of 12-24 V, has high efficiency, reverse injection.

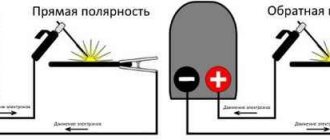

Dynamic devices for pumping out liquid media are divided into two groups, each of them has certain operating parameters and a method of fuel supply. When studying the design of devices, the following features should be highlighted:

- Dangerous pumps operating on a centrifugal or axial type. In centrifugal devices, fuel injection is carried out by rotating mechanisms. The axial pump operates on the principle of a fan.

- The friction pump is used in the chemical industry; the operating principle of the unit is based on the action of friction.

- A vortex electrical device sucks and expels fuel from the system. The positive properties of the pump include the ability to transfer fuel under high pressure, ease of maintenance, and availability of spare parts.

Assortment of manufacturing companies - units for private and commercial use

Choosing fuel dispensing equipment today is not difficult. If you are going to equip your enterprise with pumps for pumping 220V fuel, pay attention to the products of the following brands:

GESPAS

The Spanish company GESPASA offers consumers a wide range of fuel pumps operating from a 220V network. Budget options include Gespasa Iron 50. This 220V fuel pump has a capacity of 50 liters per minute and is equipped with a special filter. It makes it possible to eliminate impurities, extending the life of the unit. A more expensive option is Gespasa AG100. This is a professional 220 volt fuel pump with a power of 1000 W. It operates with a capacity of 100 liters per minute and is lightweight and compact.

PETROLL

The Chinese brand PETROLL also produces a wide range of diesel fuel pumps. The company's model line consists of diverse units. If you need a budget 220V pump, pay attention to the Petroll Helios 60. It is convenient, easy to use, and lightweight. Operates with a capacity of 60 l/m. Belongs to the lobed type. If there is no need for high speed characteristics of the unit, you can choose Helios 40. This pump has a capacity of 40 l/m. The power of the unit is 350 W.

PIUSI

The Italian company PIUSI produces 220V diesel fuel pumps of various capacities. Among the most popular is Panther 56. This unit operates with a capacity of 56 l/m and has a power of 600 W. The upper part of the pump is treated with a special anti-corrosion compound. A more powerful option is PIUSI E 80. The productivity of this unit is 70 l/m. It can be used both in enterprises and in private households.

If you need a high-quality 220V diesel fuel pump, you will certainly find it in our catalog. We have a wide range of units from well-known global manufacturers.

Fuel filling kit

Refueling kits presented on the consumer market are designed to supply fuel to the fuel tank of engines of vehicles of various categories, as well as pumping fuel into storage stations at gas stations.

Unlike pumps, the filling kit, containing a 12-volt unit, has individual design features of the model. The performance characteristics of the device are determined by the presence of component elements:

- Mounting plates.

- Hoses.

- Refueling pistol.

- Fuel meter.

- Filters

- Fastening elements.

Frequently asked questions about choosing a fuel transfer pump

- I want to organize my own small gas station in a garage for a dozen cars. Which pump to choose?

Gas stations, even small ones, usually require regular pumping of fuel with the ability to record the transferred volume of liquid. This task is best handled by a pump pump equipped with a meter that records readings. On the Autolong website you can select a complete set of technical equipment to organize a full cycle of your own mini-gas station: refueling nozzles, meters, fuel hoses.

- Frequent power surges occur in the network. Which pump to choose so that it does not fail?

Most fuel transfer pumps have an asynchronous motor , which allows the equipment to operate stably during voltage fluctuations. However, if this particular indicator is important to you, check with our managers about the type of electric motor for the selected unit.

- Can any fuel transfer pump be used for water?

We strongly do not recommend using the pump for purposes other than its intended purpose, ignoring the operating conditions specified in the instructions and the list of working fluids. At a minimum, the device will simply rust, and if there is sand in the water, the operating time will be limited to a couple of minutes before failure. On the Autolong website you will find models designed, including for water, therefore, carefully study the descriptions and products and choose a product that suits your needs.

Specifications

The 12 volt gasoline jet pump included in the refueling kit has specific characteristics. The technical properties of a pump for pumping fuel form:

- Capacity 30−70 l/min;

- IP protection class;

- Lifting fuel to a height of up to 7 m;

- Delivery at a distance of 30 m;

- Continuous operation;

- Adaptation for all filling systems;

- High functionality at low air temperatures.

An industrial and home-made device for working with diesel fuel, kerosene or gasoline has a long service life and quick payback. In addition, a pump for pumping diesel fuel, equipped with filters, supplies liquids purified from polluting particles into the vehicle tank.

Fuel pumps for pumping fuel into diesel are produced by world-famous companies: Gespasa, Adam Pumps, Petroll and Piusi. In addition to already well-known models of pumps and kits, companies produce compact nozzle pumps that can be powered by a 12 V battery, electric drill, screwdriver or car cigarette lighter.

Types of pumps for pumping diesel fuel

- Centrifugal pumps are simple and safe to use. The TECHMASH trading house produces various models of units with additional seals that are capable of pumping explosive liquids.

- Screw pumps. The equipment is highly wear-resistant and safe to use. Pumps have a high speed of pumping thin liquids.

- Cantilever monoblock pumps for pumping fuel. The pumps operate at high and low temperatures without loss of original performance.

Pumping units are widely used in industrial enterprises. They are safe to use and operate smoothly. The design of screw pumps includes a rotor that rotates evenly and stably supplies diesel fuel. The equipment has the ability to self-prime, and during operation the unit creates minimal noise.