Design and principle of operation

The device of a rolling hydraulic jack is a trolley on wheels. This type is very convenient to use; it has a large load capacity and smooth lifting. The hydraulic drive is the basis of the operating principle.

To raise the car to the required height, roll the jack under it, place the load-bearing stop at the point of the car body intended for lifting. There are special places on the car body where you need to rest the jack. The next step is to swing the handle up and down, the support should begin to rise, and with it the car.

The main design element is hydraulic cylinders; by pumping the handle, a certain pressure is created in the cylinders, due to which lifting is carried out. The main work, lifting, is performed by the plunger and direct valve. By turning the check valve knob, the pressure in the system will decrease, resulting in the vehicle lowering to its original position. In different models, the handle is located in different places, read the instructions for the rolling jack, everything is explained there clearly.

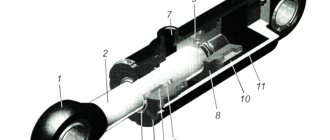

Hydraulic jack design

Let's take a closer look at the design of the jack.

The most important elements of the jack are lever 1, pump plunger 2, piston 3, rod 4, check valves 5 and 6, bypass valve 7, container with working fluid 8.

Let's look at the operating principle of a manual hydraulic jack step by step.

When moving upward, lever 1 drags pump plunger 2 along with it, creating a slight vacuum in cavity 8. Due to this vacuum, valve 5 opens and valve 6 closes. The increased volume of the chamber under the plunger is filled with liquid from container 8, which enters through check valve 5.

Moving down, lever 1 affects plunger 2, which also moves down, reducing the volume of the working chamber and increasing the pressure in it. Under the influence of pressure, valve 5 closes, valve 6 opens, and the working fluid rushes into the cavity under piston 3, forcing it to move upward.

After this, the cycle is repeated, the lever moves up, the pump cavity is filled, down - the liquid is forced out under the piston.

Under these conditions, the liquid is incompressible, which means the amount of movement of piston 3 will depend on the volume displaced by plunger 2. The figure shows that the volume displaced by the plunger is small, which means the piston will move a small amount. However, the force exerted by the piston 3 with the rod 4 attached to it will be several times higher than what was applied.

If the jack rod needs to be moved down, the bypass valve opens, and the piston moves down under the influence of gravity, and the liquid from under it into container 8.

What causes an increase in force in a hydraulic jack?

As noted earlier, the force in a hydraulic jack is enhanced by mechanical and hydraulic levers; let’s look at this using our example.

That is, if arm l1 is three times greater than l2, then the force applied to plunger F2 will be three times greater than that applied to the handle. But this is only the first stage of strengthening in a hydraulic jack.

Where Spor and Splun are the areas of the piston and plunger, respectively. That is, if the diameter of the plunger is 4 times smaller than the diameter of the piston, then the force on the piston with the rod will be 4^2 = 16 times greater than that applied to the plunger. As a result, we find that the initial effort has increased by 16 * 3 = 48 times. And this is not the limit; if you increase the difference in the length of the lever or in the ratio of the pump plunger and the output piston, you can increase the force ratio.

Main characteristics

- Load capacity . Load capacity starts from 2t and above. For a simple passenger car for everyday needs, a carrying capacity of 2 tons is enough. This tool does not take up much space; it can be stored in the garage and taken with you on a trip. If you have an SUV, a load capacity of 3t or more is recommended. In any case, it is better to know the weight of the car in advance and be guided by its value in the choice.

- Maximum lift height. It is different for each model. SUV owners need to pay maximum attention to this parameter. There is no point in paying for a tool that lifts the car by 2 cm. The maximum lift height for SUVs starts at 450 mm.

- Minimum height. The parameter determines the ability to roll the device under a car. A rolling jack with a minimum height greater than the ground clearance of your car will not help you. Be sure to measure the ground clearance before choosing.

- Ease of use. Rubber pad, on the supporting support.

- Type of mechanism drive. Cardan and gear. The recommended cardan type, it has proven its reliability and is also more repairable.

Hydraulic jack pumping technology

Bleeding a hydraulic device begins with flushing the hydraulic device mechanism.

Washing the instrument ensures normal operation of the instrument. During operation, contaminants penetrate into various parts of the mechanism, which can cause serious damage, including the failure of the unit to operate.

After draining the working fluid, the container is filled with special flushing fluid. During the washing process with a special liquid, all contaminants are removed from the device. After removing contaminants, the special flushing fluid is drained and the tank is filled with working fluid. During the pumping process, the working oil passes from the filling container into the working cavity; this process is carried out quite quickly and does not take much time.

During the procedure, air is gradually displaced from the working cavity. The pumping operation should be repeated until all air bubbles are forced out of the reservoir. All operations to replace the working fluid and flush the device should be carried out in full accordance with the instructions supplied with the device by the manufacturer. The fact is that hydraulic devices of different designs have different technologies for replacing the working fluid.

After completing the work, close the bypass valve and the oil reservoir opening.

A hydraulic jack is a mechanism that allows you to lift an object to a certain height. Most often used in technical maintenance services.

Advantages and disadvantages

The main advantages of rolling hydraulic jacks:

- Minimum effort for lifting large masses.

- The horizontal arrangement of the cylinder, due to this, a high load capacity is achieved.

- The rise is smooth.

- A stable support platform ensures safe operation.

- It is very convenient to use; the operator does not need to crawl under the vehicle.

Disadvantages of rolling jacks:

- The ascent speed leaves much to be desired, which is critical for cars with high ground clearance.

- Under prolonged load, subsidence occurs due to a drop in pressure in the system.

- When used in low temperatures, the liquid may freeze.

- To ensure long-term performance, preventative maintenance should be performed.

- Low lifting height compared to other types of jacks.

Basic malfunctions and their elimination

- Overall breakdown, the working rod does not rise;

- The hydraulic rolling jack does not hold the load;

- Problems when lifting loads;

- Leaks in seal areas;

You can repair hydraulic rolling jacks yourself, with your own hands. You will need a repair kit or purchase spare parts. Most often, gaskets and various seals fail, resulting in oily smudges on the body.

The first point of repair is to drain the oil into a previously prepared container. It is not recommended to reuse, it is better to fill it with a new one. Which fill is indicated in the rolling jack instructions. Regular motor or hydraulic oil is usually suitable. It is better to use those that do not interact with rubber parts.

The second point of repair is the disassembly stage. We remove the pistons and examine them for plaque, dirt and rust. Having identified dirt and rust, we eliminate them. To do this, you should use special solvent liquids, gasoline, diesel fuel, white spirit. If you find plaque and corrosion inside, you should get rid of the oil. There is no need to refill it, the rust did not just appear.

If everything is in order with the pistons, inspect the shape of the rod. If it's crooked, it's very bad. Most likely it will not be restored. It is necessary to prevent bending of the rod during the operation stage by not loading the rolling jack with a mass greater than it can lift. Be sure to read the instructions so that it serves you longer.

Another malfunction, clogged valves. Often they can be simply cleaned or replaced.

When repairing a hydraulic rolling jack, all seals and gaskets should be replaced. They come in a special repair kit, sold in specialized stores. The last step is flushing, and then filling with fresh oil and pumping.

How does a bottle jack work?

We will look at the operating principle of a hydraulic jack using the example of their most common type - a bottle plunger hydraulic jack. They come in different lifting capacities - 3 tons, 5 tons, 10 tons, etc.

Everything is quite simple: there is a piston in the cylinder and either in a separate reservoir or in the same cylinder above the piston there is hydraulic oil - the working fluid of the jack.

The hydraulic jack is activated by a plunger - a small pump that forces oil through the bypass valve into the cavity under the piston. Due to the difference in diameters of the plunger and the jack cylinder, the applied force is minimized. The liquid pumped under the piston pushes it out, lifting the load above it.

Lowering the jack is accomplished by slowly bleeding hydraulic oil from under the piston into the top of the cylinder or reservoir.

This is the principle of operation of all hydraulic jacks.

Another thing is that not all of them are equipped with a plunger pump, and the role of a plunger can be either a separate hand-held device connected to a jack or a hydraulic station.

And now is the time to take a closer look at the types of hydraulic jacks, places and methods of their use.

Flushing with cleaning fluid

Open the hole for filling. Drain all the oil into a prepared container. Next, add cleaning fluid. This procedure removes remaining oil and other dirt from the system. Next we follow the following algorithm of actions:

- Fill in the cleaning liquid.

- We move the lever, the liquid spreads throughout the system.

- Add fluid and pump the lever until the rod rises to the top position.

- Next, we open the check valve, the rod returns to its initial position, and part of the cleaning liquid is squeezed out of the system.

- If the squeezed out liquid is dirty, repeat the algorithm several times.

How to bleed a hydraulic rolling jack yourself?

Having cleaned the system, we proceed to the oil filling procedure. Be sure to drain the cleaning fluid completely before starting. Bleeding is essentially adding oil. It requires so much liquid that it can lift a certain load to a certain height.

- Leave the drain hole open

- Pour oil, operate the lever until the rod rises slightly

- Add and operate the lever until the rod rises to the upper value

- Open the shut-off valve, the rod will return to its original state, excess liquid will flow out of the hole

- Drain hole, close. Wipe down the jack. All is ready.

Don't forget to monitor the amount of oil. Check the rubber seals; it is recommended to change them from time to time. If there are smudges on the jack, then the seals need to be replaced.

Jack device

The operating principle of all hydraulic jacks is the same

- Turntable resting on the bottom.

- Hydraulic cylinder rod. Due to reciprocating movements and through a system of power levers, it controls the lifting of the thrust platform.

- Main cylinder of the hydraulic system. Main power unit.

- Lever or handle. Has the ability to rotate 360°. Acts as a pump lever to move the working fluid into the hydraulic cylinder reservoir. In addition, it can perform a control function - turn on/off a pressure valve or a drain valve. Usually, for ease of use and storage, the handle is removable.

- Plunger. Performs the function of a pump.

- Bleed valve control screw. Allows you to lower the car, releasing pressure in the system.

- A spring that creates a force to return the jack piston to its original position when the pressure in the system decreases.

- Removable transport handle. On some jacks it may be absent or stationary.

- Hydraulic repair kit. Required set of seals for maintenance.

- A cover that protects the main cylinder rod from dust and dirt.

- Metal wheels.

- Leverage.

- Frame. Can be made of steel and aluminum. Professional rolling jacks are distinguished by more massive and stronger bodies, which is associated with more intensive use.

A hydraulic rolling car jack operates on liquid. The operating principle is based on the movement of the piston. The pressure required to lift the load is created by pumping the working fluid into the working cylinder using a plunger. The plunger is driven by a long lever. The cylinder is located horizontally and is connected through a system of levers to a thrust platform. The presence of valves and the use of communicating chambers greatly increases the force applied to the lever. The appearance of oil in the piston cavity causes it to move, extending the rod. To prevent the oil from flowing back, a shut-off valve is used to close the outflow. The platform is lowered by turning the screw, which opens a special valve. As a result of the pressure release, the liquid is released from the working cavity, and the load is lowered to the required height. The height of the rolling mechanisms is small, but they have very high stability. They acquired this quality thanks to the large platform, which serves as a support and also gives strength to the structure itself. The jack also has a shut-off valve, the purpose of which is to secure the load during lifting. For greater reliability and safety, you can use a rolling jack with a lock. The locking pawl allows you to keep the weight at the required height without unnecessary effort.

Results

The hydraulic rolling jack is an excellent tool used in car services and garages of ordinary people. Its design is very convenient and effective. It should be remembered that a jack is a lifting tool, not a holding tool. When working for a long time, you should take care of reliable support.

When choosing a jack, pay attention to the load capacity, the minimum (necessarily less than the ground clearance of the car) and maximum lifting height. Once the criteria have been determined, we recommend buying a jack in the middle price category for individuals, and car repair shops are advised to pay attention to a professional tool.

How to use a jack: general operating rules

Like any other technical device, the jack requires compliance with safety precautions during operation. Its use is not difficult, the main thing is to know where to put the jack and what to do with it next. This is far from a new device; most samples have been tested by time and personal experience.

Classic rack and pinion jack

Driver's courses do not teach how to properly use and install this device. You need to study everything yourself. In addition, most people, not knowing clear rules, believe that with its help you can not only lift and lower a load, but also hold it for a long time. To avoid possible health risks, you need to learn how to install a jack correctly.

A specially developed list of rules can help with this:

- The vehicle must only be placed on a level surface. There should not be any slopes or other irregularities. The machine must be parked in such a way that there is no likelihood that it will move.

- All wheels must be locked very securely. Bricks, wooden wedges, stones or any other objects are suitable for this.

- The car should rise and fall very smoothly, without sudden movements or jerks.

- It is important to clearly know where to place the jack correctly. To lift the car on the bottom there are special mounts for the jack hook. Under no circumstances should you attach it to the front or rear bumper, or to any other parts of the car that are not intended for this purpose.

- It is necessary to engage reverse or forward gear, put the car on the handbrake and block the wheels on the opposite side from the side being lifted.

- It is necessary to use a support because the jack can only lift loads, but not hold them. A do-it-yourself jack stand is suitable, but it is important that it is made of wood, iron or any other material other than brick or other unreliable material.

- Before lowering yourself under the car, it is important to check the security of the machine and the device several times. To do this, you can simply rock the car in different directions.

- After completing the work, you need to know how to lower the jack along with the car. The same rules apply here - no sudden movements, smoothness.

Jacks exist in three types: mechanical, hydraulic and pneumatic (inflatable). Each of these types has its own specific operating rules.

DIY hydraulic jack maintenance and repair

To know how to repair this device, you need to study its structure and operating principle. The cross-sectional diagram is shown in the figure:

The working cylinder (4) is tightly screwed into the powerful base (10).

The connection must be reliable, since the pressure of the working fluid (6) when lifting heavy objects is quite high.

A working piston (5) with a sealing ring is placed in the cylinder. An extension screw (3) is screwed into the working piston (also known as the lifting rod), which, if necessary, is unscrewed by 2/3 of the length of the rod.

The screw ends with a support platform (7), which has anti-slip corrugation.

Around the working cylinder there is a protective casing (2), which serves as a container for the working fluid (6).

Nearby there is a pressure cylinder (plunger) (8), hermetically screwed into the base.

It is equipped with two valves. The intake valve, when the pressure piston moves upward (9), fills the cylinder with working fluid.

When the injection piston is lowered, the liquid enters the working cylinder through the supply valve and presses from below on the working piston (5).

Under pressure, the rod moves upward, lifting the load. The cycle is then repeated until the required lift height is reached.

At the end of the work, the bypass valve (1) opens, and the liquid from the working cylinder (4) flows into the container body (2).

The valve has a ball valve that can withstand high pressure. The working piston lowers under the weight of the load, displacing all the liquid into the container.

The jack is ready for the next lifting cycle.

How to Use a Rack and Screw Jack

When using rack and screw jacks, the above rules and recommendations, plus some specific ones, apply.

Screw device

Rack and pinion devices, like screw devices, have become widespread due to their simplicity of design. They are mainly popular among off-road enthusiasts. The design of such devices allows you to lift a lot of weight, which plays a decisive role. They can be used in any conditions due to their unpretentiousness and small dimensions, which is an advantage compared to hydraulic lifts, which are massive and take up a lot of space in the trunk.

How to use a hydraulic jack

Hydraulic devices have become widespread in auto repair shops. They can be rolled or bottled, have a lot of weight, but are easy to move. They can lift a car to a height of 40 centimeters. For the correct use of such devices, the following set of recommendations must also be observed:

- Before lifting it is necessary to check the fixation. The surface should be as level as possible and the wheels should be locked.

- When working with the front wheels, it is necessary to block the rear ones and vice versa. If you need to move the device to another location, you need to make sure that the strength is sufficient to hold the machine.

- Do not lift more weight than specified in the instructions.

- The hydraulic jack operates smoothly, but do not raise or lower the vehicle too quickly.

Hydraulic lift

Types of hydraulic jacks

Take a factory one or assemble a homemade one – it’s up to you. There are different types of hydraulic jacks on the market. Each of them has its own characteristics, which you should know about before purchasing the device.

- Bottle type unit. The most common and at the same time the most structurally simple variation of a hydraulic jack. Bottle lifts lift loads weighing up to 100 tons, have an impressive supporting area and a compact body. Widely used for work in car repair shops. The bottle hydraulic jack has two modifications - single-rod and double-rod. The first ones have a simple design and are used in construction, repair of railway cars, and in the manufacture of pipe bending and pipe cutting units. The two-rod mechanism can operate in vertical and horizontal positions.

- Rolling. The rolling device looks like a cart moving under the lifted load. Control is carried out by a manual lever, adjustment is carried out by oil valves. It performs well when lifting a load on one side; it is important to use when replacing wheels on a car. But work requires a flat, hard surface. Sometimes homemade.

- Hybrid. It combines a bottle jack and a rolling hydraulic jack and is widely used in car repair shops. Control is carried out by levers and foot pedals.

- Diamond. Relevant for car service. Its supporting structure is connected by hinges and forms a rhombus, which influenced the name of the device. Compact, relatively lightweight, easy to transport.

- Hooked. They are used where it is necessary to lift a load from a small height. For its operation, a bottle circuit is used. Maybe homemade.

Assembling a homemade unit with your own hands, or buying a bottle-type hydraulic factory jack is your personal decision.

How to use an inflatable jack

This type of lift is a pneumatic device. In this case, a special pillow is installed under the bottom of the machine, which is subsequently inflated with a special device. To work with such a device you need:

- Place the cushion under the car and spread it evenly.

- Place special mats on top and bottom that are included in the kit. They are designed to avoid pillow punctures.

- Close the lock connecting the valve and hose tightly. This is necessary to avoid air leakage from the pillow.

- Connect the end of the hose to a source of air or gas supply. Special compressors are used.

- The pillow is inflated with air or vehicle exhaust gases.

It is important to monitor the process of inflating the pillow. It should pass evenly in all directions. If any side lags, then it is necessary to check and correct the position of the pillow or lower it and start the process again.

Hydraulic jack malfunctions and their elimination

Hydraulic jacks are used when carrying out activities involving lifting various objects to a certain height. The units may differ in load capacity, type, purpose, but their structure and operating principle are identical, therefore, problems with lifting mechanisms are similar.

What kind of work can you do with a bottle jack?

Table of characteristics of jacks.

The scope of application of bottle jacks is car service related to the maintenance and repair of cars. The bottle type of jack is widely used in the railway industry, as it allows for the repair of trains.

We use a hydraulic jack as a power unit for presses, pipe benders or pipe cutters. If, after inspecting the mechanism, it can be concluded that the device is working properly, then work should begin. Combined with a large load capacity, the compact size of the tool allows it to be used in garages and workshops. The device can be transported in the trunk of a car, which allows you to replace broken tires if necessary.

The mechanism of bottle-type jacks is reliable. Hydraulic jacks are used in the process of car repairs, which need to be lifted and fixed at the desired height. For example, the mechanism allows you to remove a car wheel for its subsequent balancing using special equipment.

It is convenient to transport, which is done exclusively in a vertical position, since oil can flow out in a horizontal position of the tool. In general, its service life is determined by the number of gaskets and seals in its design.

The design of a bottle-type hydraulic jack and its features

Bottle type jack device.

The design of a bottle-type jack is shown in the figure. Each element included in the structure corresponds to a specific number, implying the presence in the mechanism:

The suction valve is located on the tank outlet. This should prevent the fluid from returning back to the reservoir if the pump plunger is lowered. The location of the discharge valve refers to the cylinder pipe, which prevents hydraulic fluid from leaving the cylinder when the pump plunger is lifted.

The valve is opened with a special screw, which allows the pressure in the device to be released. The load is then lowered to the ground. In general, this design is time-tested.

The connection of the bottle jack to the pump or pumping station is carried out due to the presence of a coupling half, which is a quick-release coupling. It eliminates fluid loss as a result of disconnection of the instrument from the pressure source. The main design elements are:

The quick-release coupling half of the bottle jack eliminates fluid loss as a result of disconnecting the tool from the pressure source.

- Frame.

- Retractable plunger (piston).

- Working fluid (hydraulic oil).

The housing is a guide cylinder for the plunger and at the same time a special reservoir for the working fluid. If the jack has a lifting capacity of up to 20 tons, then the location of its lifting heel is marked in the part of the screw that is screwed into the plunger. Therefore, the initial height of the mechanism can be increased by removing the screw.

The plunger must pump oil from one common reservoir to another, located under the piston. When oil appears under the piston, it must move. The oil no longer returns to the common reservoir due to the operation of the valve. While the plunger is working, more and more oil flows into the reservoir located under the piston from the common reservoir.

An integral element of a bottle jack is a liquid that has the characteristics of an incompressible working material. This allows you to smoothly lower and raise the load, as well as fix it at a certain height, ensuring precision when braking.

Spindle oil allows you to smoothly lower and raise the load, as well as fix it at a certain height.

The speed of the process of lowering the load can be controlled by the hole required for the flow of a special liquid coming from the cylinder, which can have a different composition. It is possible to use non-freezing mixtures, which include the following components:

- Alcohol.

- Water.

- Technical glycerin.

- Spindle oil.

Spindle oil hardens at temperatures below 35°C. When choosing a bottle jack, lifting and lifting heights are taken into account, not just lifting capacity. The lifting capacity may be sufficient to lift the vehicle, but the stroke will be low. This requires control over the level of hydraulic fluid, oil seals and their tightness.

Possible problems

Of all the reasons why a jack (diamond-shaped, rolling or bottle) may not function, 3 key situations should be distinguished: a malfunction of the rod, a clogged system or failure of the valves. Let's look at each point in more detail.

System clogged

It can be caused by the penetration of dirt, dust or air into the oil. When air enters, the supporting rod of the jack may stop rising, begin to spring intensely, or completely sit down under the load.

Accumulated lumps of dirt can inhibit the movement of valves, which will no longer seal the channels hermetically, allowing oil to pass in both directions.

In this situation, the emphasis will not be held in one position, gradually descending to the starting point.

Ball valve malfunction

In addition to blockages, mechanical defects may occur . The ball valve at the tip of the spring, resting against the cone-shaped groove, can separate or get caught on other components of the system. Then the rod will not come out at all, since the oil circulation in the system is disrupted, and pumping does not occur. This malfunction is more complicated and requires disassembling the jack. If there are signs of wear on the ball valves, they must be replaced.

A bent rod may be a consequence of failure to comply with storage or maintenance conditions and may result from working with heavy loads and as a result of non-compliance with the rules of use. In the first episode, the piston may become covered with rust, which will weaken the tightness of its connection to the surface of the cylinder, as a result of which oil will leak. If you lift loads higher than the permitted limit, the rod may bend. The possibility of such a malfunction increases with the maximum extension of the screw and the jack installed crookedly on the ground. A bent rod is a very serious malfunction that can rarely be corrected even by specialized services.

What to do?

Doesn't hold under load

The lowering of the rod when it rests on the lifted load and sometimes without much pressure happens for 2 reasons: lack of oil or failure of the valves. Let's consider each option separately.

The lack of oil is due to normal leakage due to poor sealing; the jack bypasses oil. As a rule, this is the result of prolonged storage of the jack with the shut-off valve turned off or the wear of the gaskets. The issue can be resolved by adding oil and bleeding the device. It is advisable to use specialized oils for hydraulic systems; at worst, ordinary technical oils will do. If after filling the oil leaks even with the tap tightly closed, you need to buy a repair kit and change all the seals.

Recommendations

To increase the service life of the jack, it is advisable to follow the following rules.

- The lifting device oil must be changed twice a year. If the hydraulic jack is used every day, then it must be replaced at least once a month and must be washed.

- Any replacement oil can be used . But for the winter season, it is advisable to fill exclusively with synthetic types of oils.

- To prevent the lubricant from thickening in winter, the jack should be kept in a dry and warm room.

- When lifting work is carried out in winter, it must be remembered that if the device is used for a long time in severe frost, it can become unusable. In this regard, it is recommended to work with it in the most extreme cases and for a short time.

The ideal “repair” of a lifting device is preventative work to prevent breakdowns, in other words, continuous maintenance and timely replacement of the working fluid with pumping. Since eliminating any malfunction will require spending personal time, and sometimes some money. In this regard, it is necessary to follow all instructions for using hydraulic lifting devices, in which case they will work for quite a long time.

For repairs to a hydraulic jack, see below.

Bleeding the jack

Bleeding the jack is a preventive measure that helps prevent damage to the device. Prevention must be carried out regularly.

Why is pumping needed?

The number of preventative pumping depends only on the frequency of use of the device. In car services, bleeding can be performed once every few weeks, but in a garage or when the device is rarely used, the number of preventive actions can be reduced to 2 times a year.

Prevention will be required if:

- The presence of contaminants in the oil in excessive quantities. Foreign matter can reduce the efficiency of the structure and lead to serious damage.

- The appearance of bubbles. Bubbles in the oil indicate that air has entered the system. Although air rarely enters the piston, you will also need to check its condition.

- Reduced actual load capacity. If the jack cannot lift the declared weight, then it is worth carrying out preventive work or taking it to a workshop to overhaul the device.

Modern jacks come with a one-piece design, so it is not always possible to reassemble it. Even if repairing the device is impossible, bleeding the system would be an excellent solution.

Work order

Pumping is carried out in several stages. First of all, unscrew the valve and remove the plug from the oil tank. It is recommended to change the oil before bleeding, so the old oil must be drained.

The oil must be drained until only air remains in the device. This manipulation will prevent further damage that may occur due to residual contaminants.

Depending on the owner’s wishes, the internal surfaces can be cleaned using special compounds. Special washing removes various deposits well and helps extend the life of the jacks.

Next, grease is added. There are two types of oils for hydraulic jacks. Summer oil copes well with its tasks in the warm season, but in winter it can lead to deterioration in performance. If the jack is used constantly in a room where the average temperature does not fall below zero, then you can safely fill in summer oil. When operating a hydraulic jack in difficult operating conditions, it is necessary to take care of the safety of the structures and fill in winter oil.

Oil is poured until the cylinder is completely filled, and the piston at this moment should be at the lowest point.

At this stage, it is considered that the work is completed, but it is better to immediately bleed the jack. To do this, the oil valve opens, and the device is intensively pumped using a lever or pedal.

Since malfunctions that lead to the appearance of air in the system are often caused by faulty cuff gaskets, they should be replaced immediately. You should not rely on their integrity, since minor defects on them are almost impossible to notice.