LLC "Servomechanizmy" invites you to consider the possibility of using in projects of newly created and modernization of existing equipment all kinds of lifting systems (lifts) based on screw jacks with trapezoidal or ball screw (ball screw) transmission.

The basis of a screw lift (lifting unit) is a screw jack, Model A or Model B, consisting of a worm gearbox, a screw drive, camshafts with couplings (KTR), BEVEL GEARBOXES, (TRAMEC, STM) bevel gearboxes and an electric motor. Over many years of work, the technical staff of NPP Servomekhanizmy has been faced with the relevance of using various mechanized complexes based on electric (mechanical) jacks and linear actuators.

A large selection of standard sizes and models allows you to create mechanical (electromechanical) lifts of various configurations, which are a good alternative to such equipment as: hydraulic, trolley, rack and pinion, automobile, pneumatic jack; scissor, two-post, electro-hydraulic, cargo lifts; lifting platforms and tables.

The scope of application of the systems covers metallurgical, cable production, production of lifting and transport systems, press production, production of various screw supports and railway jacks and other industries. NPP "Servomechanizmy" completes mechanical screw systems with all kinds of tracking systems based on encoders, stepper motors, and controllers. Upon request, it is possible to complete control boxes with the required functions and all ballasts.

Lifting systems are equipped with two types of screw jacks

With moving screw (Model A) With moving nut (Model B)

Typically, a screw lifting system includes several lifting points.

The number and location of jacks in the system depends on:

- dimensions and configuration of the load being lifted;

- required lifting height;

- full load (static, dynamic);

- configuration of the lifting system itself (presence/absence of guides, etc.)

In addition, the design of the lifting system is influenced by the specific requirements of the project. The lifting system being designed can be very complex, so when choosing jacks, many different technical and operational factors must be taken into account to create a functional and safe design.

How to choose a car lift for a car service

They start with a business plan.

Assess the activities of the car service center and development prospects. Define:

- a list of services that are provided to clients, it is planned to do this in the future;

- types of vehicles serviced;

- energy sources;

- the area that can be allocated for installation of equipment;

- finances that are planned for the acquisition.

The choice depends on the following:

- type, number of lifts for service stations;

- load capacity of devices;

- equipment manufacturers.

For small car repair shops and garages

Such car services include service stations that have no more than 2 workplaces. Among them - 70% are family or garage. Their peculiarity is the limited list of services provided, which affects the provision of lifting equipment.

When specializing:

- for tire fitting, a compact screw lift is sufficient to operate, or better yet a mobile pneumatic lift, which is powered by a compressor, which is mandatory at such service stations;

- on wheel alignment and the presence of a hole - you can get by with 1 ditch device, which is installed with the ability to move along the latter;

- on a wider list of services, if you have the appropriate space and finances, it is advisable to add a two-post or mobile column lift to the listed lifts.

For medium-sized car services and service stations

Such enterprises have 3-9 work positions and employ 5-20 people. These car services are often universal: they repair chassis, engines, electrical equipment, do tire fitting, and check the correct installation of wheels.

If there is sufficient space and resources, the equipment of car services should include various lifts. Among them are often stationary and mobile two-post, plunger, and scissor ones. For small urgent work it is necessary to have screw and pneumatic ones.

For large car services

Large and large service stations are considered to have 10-70 employees and 10-35 jobs. Those exceeding these indicators are classified as super-large.

Car service centers provide all types of services that motorists need. For this purpose, enterprises are equipped with the necessary lifting equipment:

- two-post stationary devices that are used in the repair and maintenance of vehicles;

- four-post, the platforms of which have special equipment for restoring the geometric parameters of cars that have been in an accident, controlling wheel alignment, and tire fitting;

- mobile lifts of different lifting capacities for individual work, moving vehicles, components, spare parts.

Hydraulic jacks

The most common among them are hydraulic bottle jacks.

They differ slightly in shape and greatly in carrying capacity (from a ton to tens of tons) and, accordingly, in price (from 1.5 thousand rubles to 10 thousand rubles, 100-ton trucks are hardly interesting to us here). Stable, durable jacks. All have a guaranteed 25% reserve of load capacity from the declared one, but if the load exceeds this indicator, the safety valve is guaranteed to operate.

The main disadvantage is the high starting height. To this should be added work only in a vertical position, weight and inconvenience of installation.

The test results determined the leading position among these devices with a lifting capacity of 2 tons of the domestic jack "Sorokinstrument", which cannot but cause a feeling of pride.

A type of hydraulic jacks is rolling jacks.

But this equipment will most likely be useful at a tire service; not many people will want to carry such jacks in the trunk.

Vertical devices

The design of vertical screw jacks was developed 30 years ago, and since then it has remained virtually unchanged. The main structural elements of the devices are the screw and the steel housing. Load capacity - up to 1 ton.

Main advantages:

- Insignificant force applied to the handle.

- Large working stroke.

- Load stability.

- High lifting height.

- Low cost.

- Small mass.

Minuses:

- Small support area, low stability.

- Can only be used for lifting vehicles with special lugs.

- Large dimensions.

To avoid “undermining,” experienced car enthusiasts advise additionally placing logs, bricks, etc. under the body of a raised car.

Rack-mount mechanical

Rack-and-screw structures are available with one or two screws and can lift loads weighing up to 3 tons. The operating principle of single-screw devices is the same as that of vertical ones. In twin-screw jacks, the role of the support nut is played by the housing. A second screw with a large thread is screwed into the first screw with a large diameter. When the handle rotates, a screw of a larger circle is brought out, from which a screw with a smaller diameter emerges, due to which the lifting height increases.

Rack-mount screw structures are stable and have a rigid frame. The disadvantages include high weight, and for jacks with one screw - a relatively low lifting height.

Lever-screw

Multifunctional devices used to lift vehicles weighing up to a ton. The main elements are the screw, lower and upper arms. The upper lever has a nut and a catch, the lower one has a support platform and a screw stop. The angle between the lever with a pick-up and the lever with a platform is changed by rotating the handle.

Advantages of the devices:

- Relatively small mass.

- Large working stroke.

- Low starting height.

The disadvantages include low structural rigidity and poor stability.

Screw jacks have a rigid structure and a large support surface; they are universal in use. The disadvantage is the small working stroke.

Diamond jacks

Using screw mechanical rhombic devices, machines weighing up to 2 tons are lifted. The load-bearing component kit includes four levers connected by hinges, which are arranged in a diamond shape. Lowering and raising are carried out by changing the angles of the diamond.

The drive of rhombic mechanisms can be:

- mechanical;

- hydraulic;

- electrical;

- manual.

Using these devices, you can lift a load weighing up to 1.5 tons. The design is small in size, reliable, and allows you to lift loads to a considerable height. The disadvantage is the rather high price.

Combined lever-screw products are a kind of combination of a rhombic and lever jack. They are oversized and have a low starting height. The disadvantages are low stability and insufficient rigidity.

The described types can be classified as devices for use mainly in everyday life. Each variety is represented by models of different power. Thus, the screw mechanism, which is used in construction, has large dimensions and can lift very heavy weight.

Types of screw mechanical jacks

So, a mechanical screw jack can be:

3. Combined lever-screw.

4. Screw-mounted.

5. Screw bottle.

Diamond jack

Despite the fact that it would be more logical to place the diamond jack between the combined and rack jacks, based on its cost (and then the row would be lined up strictly according to the price indicator), it deservedly takes first place as the most common of all mechanical automotive jacks. This is not surprising, because with its carrying capacity (mostly from a ton to one and a half) and price range (from 450 rubles to 1 thousand), it has the following advantages:

- stable;

- carries out strictly vertical lifting without pushing the car away;

- fits compactly;

- durable in operation if you do not subject it to loads greater than those prescribed;

- easy to repair.

Read also: Shaft with key drawing

Let us slightly focus your attention on the last advantage. Most often, a screw pair fails in such jacks, which can be very well replaced by an ordinary construction screw stud, cut to a given size, paired with a tall nut with the same thread. An eye for the handle is welded to the stud, and the nut is welded to the drilled rear standard one. In general, it will not be difficult for a person with certain plumbing skills to make such a jack with his own hands, but the relatively low cost of a factory-made product makes it unprofitable.

Lever and screw jack

This is the most affordable in price, on average it costs a hundred less than the rhombic one. Soviet cars of the 80s were equipped with such screw jacks. Easy to use, reliable due to the small number of parts. Its disadvantages include less longitudinal stability compared to the rhombic one, and the tendency to push the car away if installed incorrectly. And one more thing - a lot of physical effort, especially at the beginning of the climb. Women especially note this disadvantage.

Combination jack

It combines both the advantages and disadvantages of the two previous designs and, in the full sense, occupies an intermediate position between them. In practice, both he and the lever-screw jacks, more than others, need additional devices to ensure safety.

Screw rack jacks

They are gradually being replaced by their more technologically advanced counterparts listed above. Such jacks were equipped with classic VAZ cars and 24 Volgas.

It required special lugs, but quite often its upper part caused injuries to the car - on soft soils, when these same lugs wore out, etc.

Quite expensive (on average 1 thousand rubles). Their varieties are used in various fields and will still serve, due to the fact that no other design of jacks will allow the lifting leg to be lowered so low.

All of the above jacks are mainly designed to work with loads of up to one and a half tons. In parallel with the carrying capacity, the price also increases, which is natural.

Bottle jacks

The most load-bearing of screw ones: up to 3, and sometimes up to 5 tons, which is useful for heavy SUVs, often loaded with belongings, the total weight of which is greater than the weight of the car itself. They use powerful thrust threads, and the diameters of the screws are quite impressive.

And with a powerful setup, their functionality can be significantly expanded. Basically, the price of such jacks starts from 1.5 thousand rubles. and is not limited to 3 thousand.

In addition to the load capacity and price, an important indicator of any jack is the lifting height. The lifting height of all the listed jacks ranges from 200 to 300 mm, which is quite enough to change a wheel on all cars and most SUVs and minivans.

Design and principle of operation

The screw car lift can have a lifting capacity from 1.5 to 14 tons. The units can be equipped with 1, 2, 4 and 6 racks.

Screw lift design:

- The floor-mounted two-post unit consists of two posts and a cross member.

- There is a lead screw in the rack; a lifting nut with sliding arms moves along it.

- The running bearing rotates by transmitting torque from the motor through a gearbox located on the rack.

- The movement is transmitted to the other bearing through a chain drive, which is installed inside the cross member.

The mechanical lift is attached to the floor using anchors. Thrust rollers prevent bending loads from being applied to the screws. There are four-post designs, for example P-150, and six-post ones - P-102. They are used to lift trucks or buses. Single-rack P-238 devices are used in a set of four or six racks. The stands are mobile and can be installed in a room where there is a flat floor surface. The machine is controlled from a mobile station.

The electromechanical screw lift consists of the following parts:

- racks;

- crossbars;

- screws;

- nuts;

- pick-ups;

- electric motor;

- gearbox;

- anchor;

- chain transmission.

In such designs, the screws rotate, but the nuts remain stationary. There are also devices in which the screws are stationary and the nuts rotate. In such designs, the gearbox and electric motor are mounted on the lifting frame, and the nuts rotate through a chain drive, which is mounted in the lifting frame box.

Electromechanical screw devices are reliable and safe to operate and have a simple design. The disadvantage is low efficiency, the need for constant lubrication and cleaning of cargo screws. The calculation of electromechanical devices is carried out in the same way as for screw jacks. In units with a rotating screw, to prevent the action of the bending moment, support rollers are installed on the nut.

How to do it?

If you decide to make a lift yourself, then it is better to give preference to a screw platform device. It consists of two parts, which are presented in the form of channels. They are laid down with their ribs, and the position is fixed using a drive mechanism with a screw. As a result, the structure rises easily and can withstand heavy loads.

The main feature of this device is that lifting is provided not by two shafts, but by four. But there is one important drawback. It lies in the difficulty of carrying out suspension repairs. This is due to the fact that the vehicle's wheels are not in the air. They are installed directly on the channels.

This design can also be made with a chain drive. Its use complicates the entire process, since it is necessary to coordinate all the work. Specifically, we are talking about the electric motor drive and braking system.

To make a foot type of lift, you will need a hydraulic drive. But this is more a recommendation from experts than a rule. Therefore, some craftsmen practice using other mechanisms. For example, chain or screw drive.

How the device works

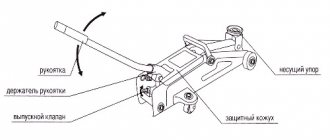

A screw mechanical jack is a simple, powerful mechanism whose operating principle is to convert torque into translational movements. This design consists of three elements:

- worm gearbox;

- nuts;

- pairs of screws.

The torque is supplied to the nut by a worm gearbox, due to which it is converted into translational movements, with the help of which the load is raised and lowered. In modernized screw jacks with a ball screw drive (ball screw), the design consists not of a pair, but of a triple - a screw, a roller or ball, and a nut.

Due to the added elements, the efficiency of the mechanism increases, which helps reduce frictional resistance.

Thanks to this, the lifting speed of the vehicle increases, as does the service life of the structure. But if we compare the cost of an improved lift with an ordinary screw device, it is slightly higher.

After the invention of the conventional screw mechanical jack, experts decided to invent a mechanism with a ball screw drive. Over time, there was an urgent need to lift very massive objects, as a result of which mechanical devices that had an electric drive were invented. With the help of such synchronously operating devices and their symmetrical transmission, it became possible to lift loads with an impressive mass.

Note! Using double-screw jacks, you can lift vehicles weighing 3 tons to a sufficient height. As for the maximum lifting capacity of screw lifts, it reaches 16 tons, but such devices are used only at service stations. Screw structures are usually equipped with a manual drive, but there are many models that have an electric drive, which makes lifting work easier

Electric lifts are controlled using a remote control that regulates lifting speed and height

Screw-type structures are usually equipped with a manual drive, but there are many models that have an electric drive, which makes lifting work easier. Electric lifts are controlled using a remote control that regulates lifting speed and height.

Electric screw jack

How to install a lift in a car service center

They start by choosing the location and location of the device. This takes into account:

- lift dimensions;

- dimensions of vehicles serviced on it;

- the need for free space around for the car mechanic to move;

- possibility of free access;

- required distance from car washing and painting areas.

Sufficient room height is required to place the device. At the same time, it must ensure free placement of not only the lift, but also the car at maximum lift. With low ceilings, you can save on height by installing a lift and making a service area in a recess.

Installation of the mechanism requires a high-quality foundation. The strength and evenness of the foundation determines the correct placement of racks, support frames, operational safety, and the service life of components and the entire structure.

When installing a lift with 4 racks, the thickness of the foundation is taken to be at least 15 cm; concrete M300 and higher is used for pouring. The same is done for two-column units, which have lower synchronization, and with upper or no synchronization, the minimum grade of concrete is M400, the layer thickness increases to 30 cm.

To save room height, scissor lifts are mounted in a recess placed in the floor.

Construction and principle of operation of the lift

The vehicle service lift consists of the following main systems:

supporting system (tackle frame, racks)

drive system (power transmission mechanism)

electrical drive control system.

The supporting system includes: columns with built-in load-bearing bolts (4 pcs.), transverse beams (2 pcs.) and longitudinal mounted beams (2 pcs.). The longitudinal beam is rigidly attached to the transverse beams and has a drive chain running through it.

The right longitudinal beam is movable, which allows you to change the distance between the mounting beams in accordance with the front track of the vehicle being serviced, which makes it universal.

The power transmission mechanism consists of an electric motor-gearbox assembly, which, through a closed circuit loop, transmits the drive to the four nuts of the main load-bearing bolts. The nuts, rotating on the stationary load-bearing bolts, cause vertical movement of the longitudinal impact beams of the lift.

The main features of this lift are:

Electromechanical drive;

Design with 4 electric motors (one for each of the columns) and mechanical synchronization;

Built-in electronic security system;

Smooth platforms for using lifts at metalwork stations;

Automatic lubrication of screw pairs using forced lubrication systems built into each of the columns;

Maximum convenience in servicing vehicles due to the fact that the front part of the platforms is moved outside the lift base, which provides better access from below to the engine and gearbox of the vehicle.

lift drive electromechanical four-post

The electrical drive control system consists of movement control buttons: “up”, “stop”, “down”, two contactors and limit switches “up” and “down”.

Limit switches are used to automatically delay (stop) the lift in extreme positions.

The lift's operation is synchronized using cardan shafts and gearboxes located under the platforms.

Automatic lubrication of the screw pair by a plunger pump is carried out during lifting and lowering.

Table 1.1 - Technical data of the prototype

| Electric motor type SZJKe | 1 PC. |

| Motor power | 5.5 kW |

| Rated rotation speed | 720 min-1 |

| Supply voltage | 220/380 V, 50 Hz |

| Maximum load capacity | 8 tons |

| Lifting height | 1500 mm |

| ascent speed | 2 m/min |

| distance between columns | 2500×3860 mm |

| distance between the axes of the mounted beams: maximum minimum |

|

| length | 5000 mm |

| width | 2800 mm |

| height | 1650 mm |

| Own weight | 700 kg |

Table 1.2 - Equipment for the prototype.

| Normal: | |

| foundation bolts and nuts | 12pcs. |

| protrusion wedges for vertical installation | 12pcs. |

| special key for chain tension, hex 24 | 1 PC. |

| single-sided wrench RWPA-41 | 1 PC. |

| single-sided wrench for round nuts RWPe-55-62 | 1 PC. |

| chain tie | 1 PC. |

| hand crank | 1 PC. |

| handwheel diameter 12 | 2 pcs. |

| Special: | |

| maintenance platform | 1 PC. |

| adjustable stands | 1 PC. |

Table 1.3 - Initial data.

| Load capacity | 8000 kg |

| Lifting height | 1500 mm |

| Lifting speed | 2 m/min |

Characteristics of pneumatic jacks

This type of equipment is used for lifting and moving cargo during repair, installation and rescue work. Such devices are irreplaceable when there is very little gap between the load and the support. The pneumatic variety of jacks is indispensable when the most precise installation is required. If work is carried out on marshy, uneven and loose soil, then the choice will be obvious.

These types of jacks are used for joining pipeline systems of impressive diameters, sometimes this parameter reaches 1200 mm. Such equipment has the form of a rubber-cord flat shell, which is made of reinforced fabric. It increases in height when compressed air is supplied. The source can be mobile or stationary compressors, compressed air cylinders, and automobile pumps.

The main disadvantage of pneumatic jacks is their impressive cost, which is influenced by expensive manufacturing technology, design complexity, as well as small batches of industrial production. When considering such jacks, the types and design of which should be studied by you before purchasing, it should be mentioned that such devices may be unsafe when the engine is turned off. As for the load capacity, it is determined by the pressure in the pneumatic drive.

Choosing a quality tool

The choice of jack must be made based on further goals. The main criterion: where will it be used? Will it be a car repair shop or a car enthusiast's private garage?

For car enthusiasts, everything is simple: to choose a device, you need to know the weight of the car and make a probable allowance. The lifting speed of the machine does not matter. A 3-ton rolling jack is suitable for this, with a small margin.

Service stations or tire shops have different requirements. For them, the lifting speed and load capacity of the device are important, so the choice of a rolling jack will be different.

When purchasing a jack, you should pay attention to the vehicle's ground clearance; it should be higher than the platform of the lifting device. Pay attention to the maximum lifting height of the mechanism: the higher, the more dangerous, and you can deform the body

The height of the jack that suits you should not be the maximum lifting height.

Pay attention to the maximum lifting height of the mechanism: the higher, the more dangerous, and the body can be deformed. The height of the jack that suits you should not be the maximum lifting height.

There is no need to buy a obviously powerful jack, especially with a small fulcrum. Using such a device can easily damage the body.

The first classification of a rolling hydraulic jack is its lifting capacity. Suffice it to say that this is the most important criterion. The type of vehicle this lift can operate with depends on this parameter.

Three load capacity options meet this criterion:

- two tons - for a car in a garage;

- three tons - for SUVs, in a garage or at a service station;

- five tons - SUVs, minibuses, service stations and vehicle fleets.

The second classification is the platform lift height. On each jack, the manufacturer indicates the digital operating range of the product, that is, the extreme point of maximum compression and lift.

The first number is important for low-slung cars. If the car's ground clearance is less than the height of the jack, it will be impossible to slide the device under the car, especially with a flat tire.

The second is for SUVs. Most of them have quite a lot of ground clearance; the height of the jack may not be enough to remove the wheel.

The third important factor influencing the choice of mechanism is the manufacturer. This criterion influences the quality of the product to a significant extent. The unit can be:

- domestic;

- import;

- Chinese.

It is believed that imported equipment is of much higher quality. It is worth noting that our industry does not stand still. Today the market offers high-quality domestic developments that are not much different from imported analogues. You can buy some pretty good products, saving money on buying products from domestic manufacturers.

What can be said for sure is that the quality of Chinese products is very low. In cases where a person is under a car, his life depends on the quality of the jack, so there is no point in saving money by risking his life.

In addition, there are two ways to use rolling jacks:

- The first is mechanical or manual tools that require human physical strength.

- The second is high-performance mechanisms that use hydraulics to enhance human capabilities.

The effort required to lift a car using a manual jack is directly proportional to the length of the handle used to lift it. When working with a passenger car, you can get by with a short handle. It is easy to use even in the cramped conditions of a standard garage.

But to lift a heavy SUV, a manual jack will not be enough; you will have to put in a lot of effort and, most likely, the height of the mechanism will not be enough. A hydraulic rolling jack can handle this situation easily.

Thanks to their universal capabilities, hydraulic lifts have received well-deserved recognition at vehicle service stations and in private garages.

DIY garage lift

For use in the garage, it is possible to make a kit for lifting a car with your own hands. You will need the necessary components, tools and plumbing skills.

A homemade lift is made using the following parts:

- Steel corners measuring 8x8x1 cm, for making a stable structure.

- Worm type gearbox. A new product can be expensive; it is usually selected during disassembly or removed from a non-working mechanism. It is necessary to pay attention to the load capacity, the indicator starts from 350 kg, the transmission force indicator is 60 kg.

- A steel plate with a minimum thickness of 1 cm is removed from old equipment.

- Set of bolts, mounting hook, star-shaped keys.

- Several iron chains with a link diameter of 2 cm or more. Weak chains will not withstand the load, you should pay attention to the quality of the product, some materials can stretch during operation.

- Steel cable, 5 mm thick.

Assembly and installation of components occurs in the required sequence, following the proposed instructions. The steel corners are fastened to the walls in the opposite direction from the hood of the car. On top of the corners for the lift, a steel plate is installed with your own hands. The connection is made with prepared bolts. Next, you need to install the worm gear, securing it with a key on the drive shaft. A key of smaller diameter is installed on the output shaft of the gearbox.

DIY chain lift

Holes suitable for the diameter of the chain are made in the plate, after which the chain mechanism is installed. It is important to pay attention to safety; holes are made in the frame at a certain distance, and a locking mechanism is inserted with them.