A simple method of brassing steel, bluing

Hello, dear readers and DIYers!

Many of you know that bluing technology is used to impart anti-corrosion properties to steel. In this case, the surface is covered with a durable protective layer and has a black or gray color. This solution does not always look aesthetically pleasing, and there are ways to coat steel with “turning gold” - brass. In this article, the author of the YouTube channel “Pask Makes” will tell you about several methods of blueing and brassing of steel.

Materials needed for homemade products. — Steel parts — Sandpaper, fabric — Linseed oil, acetone, spray varnish.

Tools used by the author. — Gas torch — Belt sander — Screwdriver or Dremel — Brass brushes for Dremel — Grinder, vice — Abrasive “coral” cleaning disc Manufacturing process. Here is the author's latest project - a wooden hammer. Its head will still be further shaped on a lathe, after which a metal ring will be put on it, which should prevent the wood from splitting during the striking process.

The original idea was to make a ring from a brass tube. But it was not found in the author’s arsenal. This is how the decision was born to apply a layer of brass to a steel tube.

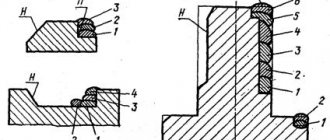

First, a test operation is carried out: a piece of corner steel profile is carefully cleaned on a belt grinder. In this sense, the smoother the initial surface is, the more accurate the bluing and brass plating will look.

The next preparation is to degrease the surface with acetone.

For further operation, a stiff brush with brass bristles is used. It is advisable that it be new, not stained with grease or other contaminants.

The next steps are very simple: the steel surface is heated using a propane torch. And you shouldn’t heat it up too much. Just wait until it changes color to a straw shade.

Now you can start rubbing the heated surface of the part with a hard brass brush. As a result of the temperature, the brass will gradually come off the bristles and be distributed in an even layer over the surface. This layer, of course, turns out to be very thin, and it is difficult to immediately determine how durable it is. However, if you subsequently open it up with mineral oil or wax, it can last much longer than its intended duration.

When the first layer of brass is applied, the whole operation is repeated again: heating the surface of the steel to a straw color and then rubbing it with a brush.

Of course, this procedure can be performed not only manually, but also using electrical devices, for example, an angle grinder with a disc brass brush. This will speed up the process somewhat.

A screwdriver or Dremel with brass brushes are also suitable for processing small parts.

First, the author will use the hot bluing technique using mineral oil. It can be any type of oil, but the master chooses linseed. The workpiece is heated with a gas burner. And here it is important to observe moderation. It is desirable to achieve a tarnish color intermediate between straw and blue.

After this, the surface is wiped with a piece of clean cloth. And then it is wiped with another small piece of cloth, previously soaked in a container with oil.

Then the workpiece is carefully heated again and rubbed with oil again. With each subsequent heating, the surface will become darker and darker. And here the main thing is not to overdo it with heating, otherwise you can “fry” the thin top layer. The author recommends practicing on a separate workpiece. Such a layer on the steel will protect it from any rust for a long time.

Another attempt at bluing is carried out using vegetable oil.

Next, the master moves on to cold bluing. To do this, a special “Super Blue” solution will be applied directly to a clean steel surface. The solution is left for 30 seconds and then washed off thoroughly. Otherwise, the remaining reagents on the steel will continue to work.

The author lays out all his experimental samples on a piece of canvas: the most even coating turned out to be cold bluing. But be that as it may, all samples are usable.

The last method is somewhat rough, but it is good for large furniture pieces. The steel is again cleaned with acetone and then lubricated with a special rust converter. The composition is left on the surface for about 30 minutes and then thoroughly washed off.

By the way, I recently came across an interesting excerpt from a book from the beginning of the last century, “Military Collection”.

I thank the author for simple methods of brass plating and steel blueing.

telegram channel

site so as not to miss new articles.

The author's video can be found here.

Source

Become the author of the site, publish your own articles, descriptions of homemade products and pay for the text. Read more here.

Buy galvanic additives, electroplating additives in St. Petersburg

The catalog of goods/products presents galvanic additives - categories: ;

Galvanic additives are used to create a protective galvanic layer that does not oxidize or rust, which can significantly extend the service life of metal products. Modern chemical products in the KHIMSNAB-SPB catalog: chemicals, substances and compositions used for electroplating processes used in manufacturing and the chemical industry.

Leave a request ON-LINE or call. The company manager will answer your questions. Leave a request ON-LINE

Or call during business hours