Purpose of heat treatment

Since metal structures and products are subjected to various loads and tests, they must be strong, wear-resistant, and resistant to corrosion and other destructive factors. To increase their durability and impart other necessary properties, they resort to heat treatment, which changes the physical and mechanical characteristics of the alloys. Sometimes this is an intermediate stage in the production of metal products, sometimes it is the final stage.

During the process, major changes occur in the structure of the metal. Depending on the type of heat treatment chosen, the result will differ. In the metalworking industry, using such technologies, alloys with unique characteristics are created. If the purpose of heat treatment is to increase compliance and ductility, after it the metal will be easier to cut and give it the desired shape.

But some operations increase characteristics such as hardness and cyclic strength. In addition, with the help of heat treatment it is possible to eliminate defects that are caused by errors or miscalculations at previous production stages.

Hardness parameters and its indicators

Hardness is one of the most interesting indicators for assessing the properties of a material and metal structures and parts. Based on hardness, strength, machinability parameters, and wear resistance can be calculated.

The last indicator is the most important, since it is responsible for the service life and safety of a metal or alloy product. Several types of hardness testing of products have proven themselves in the metallurgical industry:

- Rockwell hardness. This is an option for a fast, automated testing method. In this case, a specific tool of conical or spherical shape is used, made of ultra-strong materials, in particular diamond or carbide. This tool applies pressure to a sample of the part being tested. First, a test amount of force is applied to the sample, and then an additional force is applied for the required period of time. After this, the additional impact is removed and the hardness is calculated based on the penetration depth and the numerical indicators N and S.

- Brinell hardness. This method is used in a wide variety of designs, for metal from low to medium hardness. In this case, the tool chosen is a hardened steel ball. The final value depends on the force applied, the diameter of the ball, as well as the diameter of the resulting print.

- Vickers hardness. Method of application regardless of the hardness of the metal. Applies to structures that have undergone chemical and thermal hardening. The test tool is a diamond pyramid with an apex angle of 136°

- Knoop hardness. This method is very similar to the Vickers method, but the resulting print has the shape of an elongated diamond. For the calculation, indicators of the applied force and parameters of the large diagonal of the rhombus are required.

- Ball print hardness. In this case, the method is more suitable not for metal, but for products made of hard rubber. The tool used is a hardened steel ball with a diameter of 0.5 cm. The test sample should not have a thickness less than the diameter of the ball.

- According to Martens. This evaluates plastic and elastic deformation by penetrating a pyramid-shaped tool into the test sample.

- Scleroscope. This method helps to establish the hardness of bulky and large metal structures.

Regardless of the method of establishing strength indicators, after proper qualified heat treatment the metal becomes stronger.

See also: Metal forming

Advantages of heat treatment of metals

With a properly chosen mode and duration of procedures, it is possible to achieve the specified characteristics. Heat treatment is valued for the following advantages:

- the metal's resistance to wear increases;

- by improving technical indicators, the service life of metal structures and products increases;

- the number of parts unsuitable for use is reduced;

- Due to increased strength, durability and wear resistance, financial costs are reduced.

In order for steel to achieve the desired properties, special equipment is needed. These are high-tech furnaces in which, due to high temperatures, strong heating is achieved, causing changes in the structure of the metal. However, for high-quality heat treatment, it is important to adjust the power and other settings. Since each metal requires its own temperature regime. It is also selected for the purposes of heat treatment - depending on what properties need to be imparted to the steel or non-ferrous alloy.

Purpose of the technological process

You can work with both blanks and finished products. For the former, internal stress is relieved after various types of casting and stamping, the material becomes more plastic, and it is much easier to work with, especially cutting it. If a whole part is processed, then the following goals are pursued:

- increased strength;

- protection against premature rusting;

- increased resistance to temperature changes, the upper and lower temperature thresholds at which the item can be used become larger;

- extension of potential service life.

Heat treatment principle

Although the processes differ in temperature, duration and other subtleties, in general the procedure follows the same principle. Heat treatment of steel is performed in the following sequence:

- Heat.

- Excerpt.

- Cooling.

For the first stage, it is extremely important to accurately select the temperature and perform heating to the specified limit. The temperature regime is determined by whether you are working with steel or other alloys, and what properties should be imparted to the metal.

The length of exposure also matters. Alloys undergo desired changes in structure only when the temperature is maintained in a particular range for a certain time.

The cooling rate is an equally significant constant. In some cases, when working with steel during heat treatment, it is left in the furnace, where it cools for a very long time along with the equipment. But sometimes it is necessary to lower the temperature of the metal more quickly so that undesirable changes do not occur in the structure. And then, after heat treatment, the workpiece is left to cool in air.

Steel normalization

The process involves heating steel, briefly holding it at a certain temperature and then cooling it in air rather than in a furnace.

Widely used as an intermediate treatment of steel to improve the structure of the metal before hardening, and to soften it before cutting. At its core, normalization resembles the annealing process.

The normalization process is mainly used for heat treatment of carbon steels. As a result, there is no need to harden steel with a medium carbon content.

During processing, complete recrystallization of the steel occurs and the coarse grain structure is eliminated. Normalization is also often used for heat treating low-carbon steel instead of full annealing. For steel alloys with high carbon content, complete annealing is necessary.

Annealing

One of the most popular types of heat treatment is annealing, which is performed to reduce hardness and relieve internal stress. It is often necessary after hot forming of steel. For example, workpieces are subjected to such heat treatment after forging, rolling and stamping. Sometimes annealing is resorted to after welding. It is also used if mistakes were made at the previous stage of working with steel and defects arose.

The essence of this heat treatment is heating above the critical point, subsequent holding and cooling. Thanks to this, the structure becomes balanced, and subsequently it is easier to work with steel by cutting.

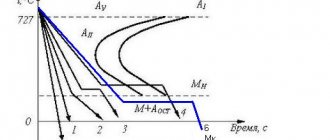

The influence of cooling methods on hardening

Depending on the method of cooling the steel, hardening is classified as follows:

- Hardening in one environment is the simplest and most commonly used heat treatment method in industry. Its main disadvantage is the possibility of internal stresses in the metal.

- Quenching in two media - using this method, the material is cooled alternately in two liquids. Water and oil can be used for the process.

- Isothermal hardening - the principle of this method is similar to step hardening. Molten salt or oil is used to cool the material. This type of hardening is widely used for hardening small parts - washers, springs, bolts.

- Step hardening – the product is cooled using a salt solution having a temperature of 200–300˚C. After a certain period of exposure, the steel is finally cooled in the open air. Step hardening helps relieve internal stresses and reduces the possibility of cracks.

Hardening

This heat treatment is performed to increase the hardness of the alloy. If we talk about the processes that occur with steel, then in its structure, instead of pearlite, martensite is formed, passing through the austenite stage.

By exposing the metal to high temperatures, an austenitic transformation is first achieved. To avoid an intermediate structure, the workpiece is placed in oil. There, the steel rapidly cools to martensitic transformations. However, further decline in temperatures should slow down. Otherwise, the decomposition of austenite will be incomplete and it will not be possible to impart the desired hardness to the steel using heat treatment.

Vacation

This heat treatment is carried out to increase ductility while reducing brittleness. At the same time, it is possible to maintain the high strength of steel. Tempering is divided into three types, depending on the level of heating of the metal. It happens:

- low temperature;

- medium temperature;

- high temperature.

In the first case, heat treatment is performed by bringing the alloy to 250 degrees. This method is mainly applicable to hardened steel. Tools made of carbon and low-alloy metals are also subjected to low-temperature tempering.

The second type involves heat treatment of steel with heating up to 350-500 degrees. It provides increased elasticity and endurance. Another valuable property improves – relaxation resistance.

Medium-temperature tempering occurs with cooling in two stages - first in water and then in air. This imparts compressive residual stresses to the steel, which improves endurance.

High temperature tempering is heating to 500-680 degrees. Thanks to this heat treatment, it is possible to combine high strength with ductility and toughness. Such properties are especially valued in the production of parts that will be subject to increased shock loads. For example, these are shafts and gears.

These types of heat treatments lead to the decomposition of martensite. Polygonization and recrystallization also occur during the process.

Classification and types of heat treatment

The fundamental parameters affecting the quality of heat treatment are:

- heating time (speed);

- heating temperature;

- duration of holding at a given temperature;

- cooling time (intensity).

By changing these modes, you can obtain several types of heat treatment.

Types of heat treatment of steel:

- Annealing

- I – kind: homogenization;

- recrystallization;

- isothermal;

- removal of internal and residual stresses;

- full;

- Hardening;

- Vacation:

- short;

- average;

- high.

- Normalization.

Heating temperature of steel during heat treatment

Vacation

Tempering in mechanical engineering is used to reduce the strength of internal stresses that appear during hardening. High hardness makes products brittle, so tempering is used to increase impact strength and reduce the hardness and brittleness of steel.

Vacation low

Low tempering is characterized by the internal structure of martensite, which, without reducing hardness, increases viscosity. Measuring and cutting tools are subjected to this heat treatment. Processing modes:

- Heating to a temperature of 150°C, but not higher than 250°C;

- holding time - one and a half hours;

- cooling - air, oil.

Average holiday

For medium tempering, transformation of martensite into trostite. Hardness decreases to 400 HB. Viscosity increases. Parts that operate under significant elastic loads are subjected to this tempering. Processing modes:

- heating to a temperature of 340°C, but not higher than 500°C;

- cooling - air.

High holiday

With high tempering, sorbitol crystallizes, which eliminates stress in the crystal lattice. Critical parts are manufactured that have strength, ductility, and toughness.

Annealing steel

Processing modes:

Heating to a temperature of 450°C, but not higher than 650°C.

Annealing

The use of annealing makes it possible to obtain a homogeneous internal structure without stress on the crystal lattice. The process is carried out in the following sequence:

- heating to a temperature slightly above the critical point, depending on the grade of steel;

- holding with constant temperature maintenance;

- slow cooling (usually cooling occurs together with the furnace).

Homogenization

Homogenization, otherwise known as diffusion annealing, restores the non-uniform segregation of castings. Processing modes:

- heating to a temperature from 1000°C, but not higher than 1150°C;

- exposure – 8-15 hours;

- cooling: oven – up to 8 hours, temperature reduction to 800°C;

- air.

Recrystallization

Recrystallization, otherwise low annealing, is used after plastic deformation treatment, which causes hardening by changing the grain shape (hardening). Processing modes:

- heating to a temperature above the crystallization point by 100°C-200°C;

- holding – ½ – 2 hours;

- cooling is slow.

Isothermal annealing

Alloy steels are subjected to isothermal annealing to cause austenite decomposition. Heat treatment modes:

- heating to a temperature of 20°C - 30°C above the point;

- holding;

- cooling: fast - not lower than 630°C;

- slow – at positive temperatures.

Stress Relief Annealing

Removal of internal and residual stresses by annealing is used after welding, casting, and machining. With the application of work loads, parts are subject to destruction. Processing modes:

- heating to a temperature of – 727°C;

- holding - up to 20 hours at a temperature of 600°C - 700°C;

- cooling is slow.

Complete annealing

Full annealing makes it possible to obtain an internal structure with fine grains, which contains ferrite and pearlite. Full annealing is used for cast, forged and stamped workpieces, which will subsequently be processed by cutting and subjected to hardening.

Complete annealing of steel

Processing modes:

- heating temperature – 30°C-50°C above point ;

- excerpt;

- cooling to 500°C: carbon steel – temperature reduction per hour no more than 150°C;

- alloy steel – temperature decrease per hour is no more than 50°C.

Partial annealing

With incomplete annealing, lamellar or coarse pearlite is transformed into a ferrite-cementite grain structure, which is necessary for welds produced by electric arc welding, as well as tool steels and steel parts subjected to processing methods whose temperature does not provoke grain growth of the internal structure.

Processing modes:

- heating to a temperature above the point or, above 700°C by 40°C - 50°C;

- curing - about 20 hours;

- cooling is slow.

Hardening

Hardening of steels is used for:

- Promotions:

- hardness;

- strength;

- wear resistance;

- elastic limit;

- Reductions:

- plasticity;

- shear modulus;

- compression limit.

The essence of hardening is the fastest cooling of a thoroughly heated part in various environments. Heating is performed with and without polymorphic changes. Polymorphic changes are possible only in those steels that contain elements capable of transformation.

Steel hardening

Such an alloy is heated to a temperature at which the crystal lattice of the polymorphic element undergoes changes, due to which the solubility of alloying materials increases. As the temperature decreases, the lattice changes structure due to an excess of alloying element and takes on a needle-like structure.

The impossibility of polymorphic changes during heating is due to the limited solubility of one component in another at a rapid cooling rate. There is little time for diffusion. The result is a solution with an excess of undissolved component (metastable).

To increase the cooling rate of steel, the following media are used:

- water;

- water-based brine solutions;

- technical oil;

- inert gases.

Comparing the rate of cooling of steel products in air, cooling in water from 600°C occurs six times faster, and from 200°C in oil 28 times faster. Dissolved salts increase the hardening ability. The disadvantage of using water is the appearance of cracks in places where martensite forms. Industrial oil is used to harden alloy alloys, but it sticks to the surface.

Metals used in the manufacture of medical products should not have a film of oxides, so cooling occurs in an environment of rarefied air.

To completely get rid of austenite, which causes high brittleness in steel, products are subjected to additional cooling at temperatures from -40°C to -100°C in a special chamber. You can also use carbonic acid mixed with acetone. This processing increases the accuracy of parts, their hardness, and magnetic properties.

If parts do not require volumetric heat treatment, only the surface layer is heated using HDF (high-frequency current) installations. In this case, the depth of heat treatment ranges from 1 mm to 10 mm, and cooling occurs in air. As a result, the surface layer becomes wear-resistant, and the middle is viscous.

The hardening process involves heating and holding steel products at temperatures reaching about 900°C. At this temperature, steels with a carbon content of up to 0.7% have a martensite structure, which, during subsequent heat treatment, will transform into the required structure with the appearance of the desired qualities.

Normalization

Normalization produces a fine grain structure. For low-carbon steels this is a ferrite-pearlite structure, for alloyed steels it is a sorbitol-like structure. The resulting hardness does not exceed 300 HB. Hot-rolled steels are subjected to normalization. At the same time, they increase:

- fracture resistance;

- processing performance;

- strength;

- viscosity.

Steel normalization process

Processing modes:

- heating occurs to a temperature of 30°C-50°C above the point ;

- maintaining in a given temperature range;

- cooling - in the open air.

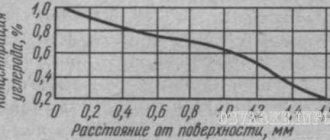

Chemical-thermal treatment

The essence of such events is heating and exposure to chemically active environments. Through such heat treatment it is possible to change the chemical composition, and not just the structure and properties of steel.

The procedure is indicated for workpieces in which surface hardness and core viscosity must be maintained. It also improves corrosion resistance and fatigue resistance.

Chemical-thermal treatment is carried out using liquid, solid and gaseous media. Depending on what substances the metal is saturated with, the following types of procedures are distinguished:

- cementation;

- nitriding;

- cyanidation, etc.

If heat treatment is combined with the application of carbon, as in the first case, the steels are given high strength and abrasion resistance. The process occurs by immersion in a powder mixture, in salt baths or in an oven with cementing gases.

The essence of nitriding is to saturate steel with nitrogen. Heat treatment is carried out in an oven, changing the duration of the process, depending on the desired depth of penetration of the chemical.

Cyanidation involves saturation with carbon and nitrogen simultaneously. Thanks to this, steels are given high hardness, resistance to abrasion and corrosion. This heat treatment is carried out using cyanide salts, nitriding gases, powders and pastes.

Hardenability and hardenability of steel

The following indicators are characteristic of hardening - hardenability and hardenability of the material:

- Hardenability determines the hardness that steel acquires after hardening. Hardness is directly dependent on the carbon content in the metal being processed. For example, hardening is not applied to a material with a carbon content below 0.3% due to its ineffectiveness.

- Hardenability determines the depth to which the hardening region extends. This indicator depends on the chemical composition of the steel, as well as on the cooling rate. The faster the metal cools, the deeper the workpiece is calcined. Carbon content also has an impact on this indicator - the higher its content, the greater the degree of calcination. The size of the workpiece or part is another factor that determines the depth of processing - larger parts require more time to cool, therefore, the calcination will spread to a shallower depth.

Thermo-mechanical treatment

This technique is relatively new. It allows you to maintain plasticity, perform plastic deformation and strengthen the structure.

The metal is brought to an austenitic state. With rapid cooling, martensite begins to form. At the same time, hardening of the austenite is performed - by rolling, stamping or forging. Due to this, the physical and mechanical properties of steel are improved.

Depending on the temperature used, thermomechanical treatment is:

- high temperature;

- low temperature.

In the first case, the highest critical point is exceeded, plastic deformation begins and is completed by hardening. In the second, heating first occurs, then cooling to a temperature where austenite is preserved, but recrystallization has not yet begun. At this stage, plastic deformation is carried out.

What kind of oxidation occurs in different steels?

Chromium-nickel steel - it is called heat-resistant because it practically does not lend itself to oxidation.

Alloy steel - it forms a dense but thin layer of scale, which protects against further oxidation and prevents cracking during forging.

Carbon steel - it loses about 2-4 mm of carbon from the surface when heated. This is very bad for the metal, as it loses strength, hardness and the steel deteriorates when hardened. And decarburization is especially detrimental for forging small parts with subsequent hardening. To avoid cracks on high-alloy and high-carbon steel, they must be heated slowly.

Be sure to refer to the iron-carbon diagram, which determines the temperature for the start and end of forging. This must be done so that when the metal is heated it does not acquire a coarse-grained structure and its ductility does not decrease.

But overheating of the workpiece can be corrected by heat treatment, but this requires additional energy and time. If the metal is heated to an even higher temperature, this will lead to burnout, which will reach the point where the bond between the grains in the metal is broken and it will completely collapse during forging.

Cryogenic treatment

To change the properties of metals, not only high but also low temperatures are used. As with heat treatment, it is possible to remove residual stresses and increase the wear resistance of parts. The hardness of the workpieces and their strength increases. In the process, retained austenite is transformed into martensite. These activities are performed in a cryogenic processor.

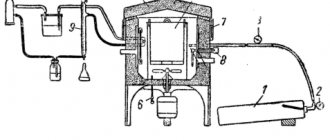

Equipment used

There are various installations in thermal shops. Since the purpose of heat treatment varies, there is a need for several types of furnaces:

- mine;

- chamber;

- vacuum;

- with a retractable floor.

The first ones are called universal. They can be heat treated in different ways. Shaft furnaces accommodate workpieces of any size. Parts are sent here for heating before hardening, for annealing and tempering, and for carburizing. Moreover, they work not only with steels, but also with non-ferrous metals.

Chamber furnaces primarily process medium- and small-sized workpieces. They are installed at various enterprises both as independent units and as part of an automated complex.

In vacuum furnaces, in addition to heat treatment, you can perform soldering and sintering of materials. The equipment is valued for the fact that it strictly adheres to the specified technological parameters. The temperature does not deviate from the desired limit by more than 5 degrees. Such furnaces are used for heat treatment of structural steel. They undergo a variety of procedures involving titanium alloys and refractory metals.

Ovens with a sliding tray are especially convenient when it is necessary to process a very large part or assembly. Special cranes and overhead cranes are usually used to load and unload steel. However, equipment of this type has significant disadvantages. Firstly, it is bulky, so not every enterprise has the space to install it. Secondly, due to the specific design, heat loss is high.

Basically, furnaces with a sliding tray are used for annealing welded structures. In them, large-sized workpieces are brought to an austenitic state. Another way to use it is in preparation for forging.

Story

The technology of heat treatment of metal has been known to mankind since ancient times. During the Middle Ages, blacksmiths heated and cooled sword blanks using water. By the 19th century, people learned to process cast iron. The blacksmith placed the metal in a container full of ice and poured sugar on top. Next, the process of uniform heating begins, lasting 20 hours. After this, the cast iron billet could be forged.

In the mid-19th century, Russian metallurgist D.K. Chernov documented that when a metal is heated, its parameters change. From this scientist came the science of materials science.

Features of heat treatment of non-ferrous alloys

Non-ferrous metals require a special approach to processing, in contrast to working with steels. An individual approach is determined by the structural features of the crystal lattice. The mode and nature of the effect are also selected taking into account thermal conductivity and chemical activity. But many processes with non-ferrous metals take place in the same furnaces where steel is processed.

The metal structures plant ChZMK heat treats various steels and non-ferrous metals. For this purpose, the enterprise is equipped with a variety of modern equipment. High qualifications and professionalism of specialists are the key to excellent results.