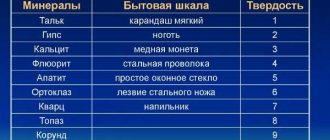

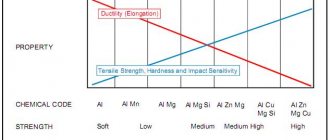

Metal hardness call its property of resisting plastic deformation during the contact action of a standard tip body on the surface layers of the material.

Hardness testing is the main method for assessing the quality of heat treatment of a product.

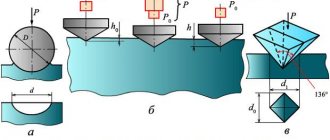

Determination of hardness using the Brinell method . The method is based on inserting a steel ball into a flat surface under load. Hardness number HB

determined by the ratio of the load to the spherical surface of the print.

The Rockwell (HR) method is based on statically pressing a tip into the test surface under a certain load. Steel balls are used as tips for materials with hardness up to 450 HR. In this case, the hardness is designated as HRB

.

When using a diamond cone, hardness is designated as HRA

or

HRC

(depending on load).

Vickers hardness (HV) is determined by statically pressing a diamond tetrahedral pyramid into the test surface. During the test, the indentation is measured with an accuracy of 0.001 mm using a microscope, which is an integral part of the Vickers instrument.

Shor's method . The essence of this method is to determine the hardness of the sample material by the height of the rebound of the striker falling onto the surface of the test body from a certain height. Hardness is assessed in conventional units proportional to the height of the striker's rebound.

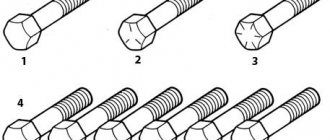

HRC hardness numbers for some parts and tools

| Parts and tools | Hardness number HRC |

| Hinged bolt heads, hex nuts, clamping handles | 33…38 |

| Hinge screw heads, setscrew ends and heads, hinge axes, clamping and removable strips, screw heads with internal hex holes, drive chuck pin | 35…40 |

| Round nut splines | 36…42 |

| Gears, keys, clamps, crackers for machine grooves | 40…45 |

| Spring and retaining rings, tension wedges | 45…50 |

| Self-tapping screws, turning centers, eccentrics, mushroom supports and support plates, mounting pins, collets | 50…60 |

| Installation nuts, locknuts, blockers for machine grooves, circular eccentrics, eccentric cams, clamps for dividing devices, replaceable jaws for vices and chucks, gear wheels | 56…60 |

| Working surfaces of gauges - plugs and staples | 56…64 |

| Copiers, carbon rollers | 58…63 |

| Jig bushings, rotating bushings for boring bars | 60…64 |

Shore hardness measurement

Shor's name was Albert. He was an American industrialist who lived in the 20th century. I developed a hardness scale in order to make my work easier and make the enterprise successful.

The plant produced low-modulus materials. They are characterized by low longitudinal elasticity. This results in high elasticity, even at room temperatures. These are polymers, vulcanization products, rubbers, and some plastics. It is for them that the Shor method was created.

Shore hardness of materials is an empirical method. This means that he is experienced, aimed at studying facts, observation.

The indicator turns out to be “disconnected”. There is no connection with the fundamental characteristics of the test sample. But its hardness affects its performance parameters. So, the Shore hardness of rubber is of interest, for example, to motorists.

They rely on the scale when buying tires. Their hardness standard is from 50 to 75 Shore units. The softer the rubber, the better its grip on the road.

However, the pliability of the material leads to its rapid wear and heating. Soft rubber is noisy and quickly loses its shape. The Shore number allows you to select the ideal tires for specific conditions and needs.

Only now, only about 30% of manufacturers indicate the scale indicator on their tires. The presence of a note indicates a responsible approach to business and the quality of the product. problem in determining Shore hardness . There would be a desire. The apparatus for the experiments is simple, as is the scheme for conducting them.

The only negative is a decent spread of results. But a more convenient method has not yet been invented. Let's move from theory to practice?

Table of relationships between hardness numbers according to Brinell, Rockwell, Vickers, Shore

Rockwell, Vickers and Shore hardness values indicated correspond to Brinell hardness values determined using a 10 mm diameter ball.

| According to Rockwell | According to Brinell | Vickers (HV) | By Shore | |||

| H.R.C. | HRA | HRB | Imprint diameter | HB | ||

| 65 | 84,5 | — | 2,34 | 688 | 940 | 96 |

| 64 | 83,5 | — | 2,37 | 670 | 912 | 94 |

| 63 | 83 | — | 2,39 | 659 | 867 | 93 |

| 62 | 82,5 | — | 2,42 | 643 | 846 | 92 |

| 61 | 82 | — | 2,45 | 627 | 818 | 91 |

| 60 | 81,5 | — | 2,47 | 616 | — | — |

| 59 | 81 | — | 2,5 | 601 | 756 | 86 |

| 58 | 80,5 | — | 2,54 | 582 | 704 | 83 |

| 57 | 80 | — | 2,56 | 573 | 693 | — |

| 56 | 79 | — | 2,6 | 555 | 653 | 79,5 |

| 55 | 79 | — | 2,61 | 551 | 644 | — |

| 54 | 78,5 | — | 2,65 | 534 | 618 | 76,5 |

| 53 | 78 | — | 2,68 | 522 | 594 | — |

| 52 | 77,5 | — | 2,71 | 510 | 578 | — |

| 51 | 76 | — | 2,75 | 495 | 56 | 71 |

| 50 | 76 | — | 2,76 | 492 | 549 | — |

| 49 | 76 | — | 2,81 | 474 | 528 | — |

| 48 | 75 | — | 2,85 | 461 | 509 | 65,5 |

| 47 | 74 | — | 2,9 | 444 | 484 | 63,5 |

| 46 | 73,5 | — | 2,93 | 435 | 469 | — |

| 45 | 73 | — | 2,95 | 429 | 461 | 61,5 |

| 44 | 73 | — | 3 | 415 | 442 | 59,5 |

| 42 | 72 | — | 3,06 | 398 | 419 | — |

| 40 | 71 | — | 3,14 | 378 | 395 | 54 |

| 38 | 69 | — | 3,24 | 354 | 366 | 50 |

| 36 | 68 | — | 3,34 | 333 | 342 | — |

| 34 | 67 | — | 3,44 | 313 | 319 | 44 |

| 32 | 67 | — | 3,52 | 298 | 302 | — |

| 30 | 66 | — | 3,6 | 285 | 288 | 40,5 |

| 28 | 65 | — | 3,7 | 269 | 271 | 38,5 |

| 26 | 64 | — | 3,8 | 255 | 256 | 36,5 |

| 24 | 63 | 100 | 3,9 | 241 | 242 | 34,5 |

| 22 | 62 | 98 | 4 | 229 | 229 | 32,5 |

| 20 | 61 | 97 | 4,1 | 217 | 217 | 31 |

| 18 | 60 | 95 | 4,2 | 207 | 206 | 29,5 |

| — | 59 | 93 | 4,26 | 200 | 199 | — |

| — | 58 | — | 4,34 | 193 | 192 | 27,5 |

| — | 57 | 91 | 4,4 | 187 | 186 | 27 |

| — | 56 | 89 | 4,48 | 180 | 179 | 25 |

Determination of hardness of metals and alloys

The essence of the method is to press a ball (steel or hard alloy) into a sample (product) under the influence of a force applied perpendicular to the surface of the sample for a certain time, and measure the diameter of the indent after the force is removed.

Brinell hardness is designated by the symbol HB or HBW:

- HB - when using a steel ball (for metals and alloys with a hardness of less than 450 units); HBW - when using a hard alloy ball (for metals and alloys with a hardness of more than 450 units).

The symbol HB (HBW) is preceded by the final hardness value of tpex significant digits, and after the symbol the diameter of the ball, the value of the applied force (in kgf), and the duration of exposure if it differs from 10 to 15 s are indicated.

Designation examples:

250 HB 5/750

— Brinell hardness 250, determined using a steel ball with a diameter of 5 mm at a force of 75 kgf (7355 N) and a holding time of 10 to 15 s;

575 HBW 2.5/187.5/30

— Brinell hardness 575, determined using a hard alloy ball with a diameter of 2.5 mm at a force of 187.5 kgf (1839 N) and a holding time of 30 s.

When determining hardness with a steel ball or a hard alloy ball with a diameter of 10 mm at a force of 3000 kgf (29420 N) and a holding time of 10 to 15 s, Brinell hardness is indicated only by the numerical value of hardness and the symbol HB or HBW.

Designation example:

185 HB, 600 HBW.

Vickers method.

The method for measuring the hardness of ferrous and non-ferrous metals and alloys under loads from 9.807 N (1 kgf) to 980.7 N (100 kgf) according to Vickers is regulated by GOST 2999 - 75 * (as amended in 1987).

Hardness measurement is based on pressing a diamond tip in the shape of a regular tetrahedral pyramid into a sample (product) under the influence of a force applied for a certain time, and measuring the diagonals of the indentation remaining on the surface of the sample after removing the load.

Vickers hardness under test conditions - a force impact of 294.2 N (30 kgf) and a holding time under load of 10 ... 15 s, is indicated by numbers characterizing the hardness value and the letters HV

.

Designation example:

500 HV

- Vickers hardness obtained with a force of 30 kgf and a holding time of 10 ... 15 s

Under other test conditions, the load and holding time are indicated after the letters HV.

Example of designation:

220 HV 10/40

- Vickers hardness obtained with a force of 98.07 N (10 kgf) and a holding time of 40 s.

There is no general accurate translation of hardness numbers measured with a diamond pyramid (Vickers) to hardness numbers on other scales or to tensile strength.

Therefore, such translations should be avoided, except in special cases where, thanks to comparative tests, there is a basis for translation.

Rockwell method.

The Rockwell method for measuring the hardness of metals and alloys is regulated by GOST 9013 - 59* (as amended in 1989).

The essence of the method is to introduce a diamond conical (scales A, C, D) or steel spherical tip (scales B, E, F, G, H, K) into the surface of a sample (or product) under the action of sequentially applied preliminary and main forces and in determining the depth of penetration of the tip after removing the main force.

Rockwell hardness is designated by the symbol HR, indicating the hardness scale, preceded by a numerical hardness value of three significant figures.

Example designation:

61.5 HRC

- Rockwell hardness 61.5 units on the C scale.

In order to ensure the uniformity of measurements, a special state standard has been introduced to reproduce the Rockwell and Super-Rockwell hardness scales and transfer them using standard measuring instruments (working standards) to the working measuring instruments used in the country (GOST 8.064 - 94).

The ranges of the Rockwell and Super-Rockwell hardness scales reproduced by the standard are given in the table.

26. Ranges of Rockwell and Super-Rockwell hardness scales reproduced by the standard according to GOST 8.064 - 94

| Scales | Measuring ranges | |

| Rockwell | A | 70 - 93 HRA |

| IN | 25 – 100 HRB | |

| WITH | 20 – 67 HRC | |

| Super Rockwell | N 15 | 70 - 94 HRN 15 |

| N 30 | 40 - 86 HRN 30 | |

| N 45 | 20 - 78 HRN 45 | |

| T 15 | 62 - 93 HRT 15 | |

| T 30 | 15 - 82 HRT 30 | |

| T 45 | 10 - 72 HRT 45 | |

27. Comparison of hardness numbers of metals and alloys on various scales

| Vickers HV | Brinell NV | Rockwell HRB | sв, MPa |

| 100 | 100 | 52,4 | 333 |

| 105 | 105 | 57,5 | 350 |

| 110 | 110 | 60,9 | 362 |

| 115 | 115 | 64,1 | 382 |

| 130 | 120 | 67,0 | 402 |

| 125 | 125 | 69,8 | 410 |

| 130 | 130 | 72,4 | 430 |

| 135 | 135 | 74,7 | 450 |

| 140 | 140 | 76,6 | 470 |

| 145 | 145 | 78,3 | 480 |

| 150 | 150 | 79,9 | 500 |

| 155 | 155 | 81,4 | 520 |

| 160 | 160 | 82,8 | 530 |

| 165 | 165 | 84,2 | 550 |

| 170 | 170 | 85,6 | 565 |

| 175 | 175 | 87,0 | 580 |

| 180 | 180 | 88,3 | 600 |

| 185 | 185 | 89,5 | 620 |

| 190 | 190 | 90,6 | 640 |

| 195 | 195 | 91,7 | 650 |

| 200 | 200 | 92,8 | 665 |

| 205 | 205 | 93,8 | 685 |

| 210 | 210 | 94,8 | 695 |

| 215 | 215 | 95,7 | 715 |

| 220 | 320 | 96,6 | 735 |

| 225 | 225 | 97,5 | 745 |

| 230 | 230 | 98,4 | 765 |

| 235 | 235 | 99,2 | 785 |

| 240 | 240 | 100,0 | 795 |

| 245 | 245 | 21,2 | 815 |

| 250 | 250 | 22,1 | 835 |

| 255 | 255 | 23,0 | 855 |

| 260 | 260 | 23,9 | 865 |

| 265 | 265 | 24,8 | 880 |

| 270 | 270 | 25,6 | 900 |

| 275 | 275 | 264 | 910 |

| 280 | 280 | 27,2 | 930 |

| 285 | 285 | 28,0 | 950 |

| 290 | 290 | 28,8 | 970 |

| 295 | 295 | 29,5 | 980 |

| 300 | 300 | 30,2 | 1000 |

| 310 | 310 | 31,6 | 1030 |

| 320 | 319 | 33,0 | 1060 |

| 330 | 328 | 34,2 | 1090 |

| 340 | 336 | 35,3 | 1120 |

| 350 | 344 | 36,3 | 1150 |

| 360 | 352 | 37,2 | 1180 |

| 370 | 360 | 38,1 | 1200 |

| 380 | 368 | 38,9 | 1230 |

| 390 | 376 | 39,7 | 1260 |

| 400 | 384 | 40,5 | 1290 |

| 410 | 392 | 41,3 | 1305 |

| 420 | 400 | 42,1 | 1335 |

| 430 | 408 | 42,9 | 1365 |

| 440 | 416 | 43,7 | 1385 |

| 450 | 425 | 44,5 | 1410 |

| 460 | 434 | 45,3 | 1440 |

| 470 | 443 | 46,1 | 1480 |

| Vickers HV | Rockwell H.R.C. | Vickers HV | Rockwell H.R.C. | Vickers HV | Rockwell H.R.C. | Vickers HV | Rockwell H.R.C. |

| 490 | 47,5 | 600 | 54,2 | 720 | 60,2 | 840 | 65,1 |

| 500 | 48,2 | 620 | 55.4 | 740 | 61,1 | 860 | 65,8 |

| 520 | 49,6 | 640 | 56,5 | 760 | 62,0 | 880 | 66,4 |

| 540 | 50,8 | 660 | 57,5 | 780 | 62,8 | 900 | 67,0 |

| 560 | 52 | 680 | 58,4 | 800 | 63,6 | 1114 | 69 |

| 580 | 53,1 | 700 | 59,3 | 820 | 64,3 | 1220 | 72 |

Note.

The error in converting Vickers hardness numbers into Brinell units is ± 20 HB; In Rockwell units - up to ± 3 HRC (HRB); values of sв up to ± 10%.

The table shows approximate relationships between hardness numbers determined by various methods. With a sufficient degree of accuracy, for structural carbon and alloy steels of the pearlitic class, for which 150 HB, one can take s0.2 = 0.367 HB, for steel HB < 150 s0.2 » 0.2 HB. For low-alloy and carbon structural steels (НВ "150) sв" 0.345 НВ. For a more accurate conversion of NV to HRC, it is recommended to use GOST 22761-77.

Types of pencils by hardness and softness

Table of softness and hardness of pencils

| A country | Soft | Solid | Hard-soft | Hard-thin | Hard-soft and hard | Very hard |

| Russia | M | T | TM | — | — | — |

| Europe | IN | N | NV | F | — | 2H |

| USA | 1 | 3 | 2 | — | 2,5 | 4 |

The marking of the pencil will depend on the manufacturer whose company you buy the pencils from. You should pay attention to this when choosing materials in the store so as not to make a mistake.

So again:

Hard pencils are light-colored pencils that are marked T or N. If you press too hard on them, they can damage a piece of paper.

Soft pencils are darker and bolder pencils, marked M or B, with such pencils it is very easy to draw, do shading and shading.

Hard-soft - TM or HB, the middle type of pencils between the first two types. More or less a universal pencil that can be used to make the entire basic drawing.

Now let's take a closer look at each type of pencil.

Application of Shore measurement

Shore hardness is a table that can indicate the nuances of using products. So, if the eraser indicator is 20 units, then it is artistic. Creators need soft erasers that do not damage drawing paper and can delicately shade, for example, pencil sketches.

For office purposes, schools, or offices, erasers with a hardness of about 50 Shore units are better suited. When buying sealant for construction or housework, it is important to know whether it will be easy to open. For example, we fixed some seams in the bathroom.

If the sealant darkens or cracks, it will have to be scraped out. This is more difficult than cleaning regular grout. The softer and more pliable the sealant, the easier it will be, so to speak, to dismantle it.

The sealant should have a Shore hardness of 10-25 units. Otherwise, the product is not of high quality.

For bicycle tubes, acceptable Shore hardness units are much lower than for car tires. For a bike, 30 points is enough.

Skateboard wheels are cut. Even mild variations should have 75 units. For hard skateboard wheels, the figure is completely equal to the recommendations for solid forklift tires - 95-98 units.

For comparison, plastic construction helmets for protection during work guarantee only 75 points. Purchasing low-quality headgear with a Shore hardness of 40-60 can cost your life.

Marking pencils and their classification

Class H leads

Class H pencil leads, due to their hardness, are very resistant to feathering and smudging. This pencil will allow you to make a clear but light drawing with straight lines. A pencil with this marking is ideal for drawing and sketching.

Due to the fact that this pencil is difficult to rub on paper, all left-handed people can easily use it without fear of getting dirty and ruining the drawing by accidentally touching it with their hand.

But such pencils also have disadvantages. The fact is that such a hard lead tears the paper very easily. The harder the pencil you use, the more likely it is that it will ruin the paper if you press harder.

Class F and HB leads

As you remember from the table above, HB and F pencils are something between a hard-soft and a hard pencil. They also practically do not smear on paper. Their ideal purpose is writing on paper.

Class B leads

Soft pencils with which you can do shading, darkening, as they smear easily, and also create smooth lines. For these purposes, choose a pencil with the largest B marking, that is, with a larger number.

The softer the pencil, the easier and better it glides across the paper and allows you to quickly and efficiently make a drawing. This pencil format is also ideal for sketches and quick sketches.

The softest pencil can be designated as 9B or even 10B.

Translation of hardness measurement results using various methods [edit | edit code ]

The results of hardness measurements using the Brinell method can be converted using tables into hardness units using other methods, such as the Vickers method and the Rockwell method. In turn, hardness measurements using the last two methods can be converted into hardness units using the Brinell method. Conversion of hardness numbers should be used only in cases where it is impossible to test the material under given conditions. The resulting hardness conversion numbers, both tabular and calculated using equations according to ASTM E140 - 07, are only approximate and may not be accurate for specific cases. From a physical point of view, such a comparison of hardness numbers obtained by different methods and having different dimensions is devoid of any physical meaning.

The hardness of a metal is its property of resisting plastic deformation during the contact action of a standard tip body on the surface layers of the material.

Read also: What is galvanized metal

Hardness testing is the main method for assessing the quality of heat treatment of a product.

Determination of hardness using the Brinell method . The method is based on inserting a steel ball into a flat surface under load. Hardness number HB

determined by the ratio of the load to the spherical surface of the print.

The Rockwell (HR) method is based on statically pressing a tip into the test surface under a certain load. Steel balls are used as tips for materials with hardness up to 450 HR. In this case, the hardness is designated as HRB

.

When using a diamond cone, hardness is designated as HRA

or

HRC

(depending on load).

Vickers hardness (HV) is determined by statically pressing a diamond tetrahedral pyramid into the test surface. During the test, the indentation is measured with an accuracy of 0.001 mm using a microscope, which is an integral part of the Vickers instrument.

Shor's method . The essence of this method is to determine the hardness of the sample material by the height of the rebound of the striker falling onto the surface of the test body from a certain height. Hardness is assessed in conventional units proportional to the height of the striker's rebound.

Shore measurement principle

Shore had to develop the hardness device himself. This happened in 1920. The device is called a durometer. It has a support platform with a hole in the center, an indenter, that is, a presser, and a calibrated spring that applies a certain force to it.

The last element of the machine is the indicator. It determines the degree to which the indenter “nose” extends beyond the supporting surface.

The device has several measuring scales. There are two main ones, A and D. The breakdown is necessary for the accuracy of the experiments, because the subjects are materials with different hardnesses. Soft ones are checked on scale A, and more elastic ones - on D.

Measuring Shore hardness requires attention to external conditions. Some polymers react, for example, to air humidity, or soften under the influence of direct sunlight. It is necessary to exclude factors that influence the parameters of the material. There are ISO standards for this.

Requirements also apply to the thickness of the test sample. It should not be less than 6 millimeters. The width of the material should allow for an indentation from any of the edges of at least 12 millimeters. The smoothness of the subject is also important.

Rough materials may not adhere tightly to the supporting surface, which will distort the measurement results.

To determine, for example, the Shore hardness of polyurethane , the durometer is installed vertically. The “nose” of the indenter, in this case, must be 12 millimeters from the edge of the sample.

You need to press the supporting surface to the sample as quickly as possible, without pushing, keeping the parallel between the planes. All that remains is to apply pressure to the supporting surface to ensure reliable contact with the material being tested. For this purpose, a load is used. But, manual bench press is also allowed.

Instantaneous measurement is carried out in 1 second. However, usually the readings are taken after 15 seconds. To be sure, take 5 measurements in different places on the surface.

The average value is the hardness number. It can be from 0 to 100. This is the Shore hardness scale. Let's try to apply measurements not only when choosing car tires.

Hardness equivalent table

Table of the ratio of hardness of processed materials according to various scales Vickers Brinell NV Rockwell Shore HS S MPa(1) Standard ball D10(mm) Hard

Table of the relationship between the hardness of processed materials on various scales Vickers Brinell NV Rockwell Shore HS S MPa(1) Standard ball D10(mm) Carbide ball D10 (mm) HRA HRB HRC HRD 940 85.6 — 68.0 76.9 97 920 85.3 — 67.5 76.5 96 900 85.0 — 67.0 76.1 95,880 — (767) 84.7 — 66.4 75.7 93,860 — (757) 84.4 — 65.9 75.3 92,840 — (745) 84.1 — 65.3 74.8 91,820 — (733) 83.8 — 64.7 74 .3 90 800 — (722) 83.4 — 64.0 74.8 88,780 — (710) 83.0 — 63.3 73.3 87,760 — (698) 82.6 — 62.5 72.6 86,740 — (684) 82.2 — 61.8 72.1 84,720 — (670) 81.8 — 61.0 71 .5 83 700 — (656) 81.3 — 60.1 70.8 81 690 — (647) 81.1 — 59.7 70.5 — 680 — (638) 80.8 — 59.2 70.1 80 670 — 630 80.6 — 58.8 69.8 — 660 — 620 80.3 — 58.3 69.4 79 650 - 611 80.0 - 57.8 69.0 - 640 - 601 79.8 - 57.3 68.7 77 630 - 591 79.5 - 56.8 68.3 - 620 - 582 79.2 - 56.3 67.9 75 610 - 573 78.9 - 55.7 67.5 - 600 - 564 78.6 - 55.2 67.0 74 590 — 554 78.4 — 54.7 66.7 — 2055 580 — 545 78.0 — 54.1 66.2 72 2021 570 — 535 77.8 — 53.6 65.8 — 1985 560 — 525 77.4 — 53.0 65.4 71 1950 550 (505) 517 77.0 — 52.3 64.8 — 1905 540 (4 96) 507 76.7 — 51.7 64.4 69 1860 530 (488) 497 76.4 — 51.1 63.9 — 1825 520 (480) 488 76.1 — 50.5 63.5 67 1795 510 (473) 479 75.7 — 49.8 62.9 — 1750 500 (465) 471 75.3 — 49.1 62.2 66 1705 490 (456) 460 74.9 - 48.4 61.6 - 1660 480 488 452 74.5 — 47.7 61.3 64 1620 470 441 442 74.1 — 46.9 60.7 — 1570 460 433 433 73.6 — 46.1 60.1 62 1530 450 425 425 73.3 — 45.3 59.4 — 1495 440 415 415 72.8 — 44.5 58.8 59 1460 430 405 405 72.3 — 43.6 58.2 — 1410 420 397 397 71.8 — 42.7 57.5 57 1370 410 388 388 71.4 — 41.8 56.8 — 1330 100 379 379 70.8 — 40.8 56.0 55 1290 3 90 369 369 70.3 — 39.8 55.2 — 1240 380 360 360 69.8 (100.0) 38.8 54.4 52 1205 370 350 350 69.2 — 39.9 53.6 — 1170 360 341 341 68.7 (109.0) 36.6 52.8 50 1130 350 331 331 68.1 — 35.5 51.9 — 1095 340 322 322 67.6 (108.0) 34.4 51.1 47 1070 330 313 313 67.0 - 33.3 50.2 - 1035 Vickers Brinell NV Rockwell Shore HS S 5 E MPa(1) iff ha O 5 Carbide ball D10(mm) HRA HRB HRC HRD 320 303 303 66.4 (107.0) 32.2 49.4 45 1005 310 294 294 65.8 — 31.0 48.4 — 9 80 300 284 284 65.2 (105.5) 29.8 47.5 42 950 295 280 280 64.8 — 29.2 47.1 — 935 290 275 275 64.5 (104.5) 28.5 46.5 41 915 285 270 270 64.2 — 27 .8 46.0 — 905 280 265 265 63.8 (103.5) 27.1 45.3 40 890 275 261 261 63.5 — 26.4 44.9 — 875 270 256 256 63.1 (102.0) 25.6 44.3 38 855 265 252 252 62.7 — 24.8 43.7 — 840 260 247 247 62.4 (101.0) 24.0 43.1 37 825 255 243 243 62.0 — 23.1 42.2 — 805 250 238 238 61.6 99.5 22.2 41.7 36,795 245 233 233 61.2 — 21.3 41.1 — 780 240 228 228 60.7 98.1 20.3 40.3 34,765 230 219 219 — 96.7 (18.0) — 33 730 220 209 209 — 95.0 (15.7) — 32 695 210 200 200 — 93.4 (13.4) — 30 670 200 190 190 — 91.5 (11.0) — 29 635 190 181 181 — 89.5 (8.5) — 28 605 180 171 171 — 87.1 (6.0) — 26 580 170 162 16 2 — 85.0 (3.0) — 25 545 160 152 152 — 81.7 (0.0) — 24 515 150 143 143 — 78.7 22 490 140 133 133 — 75.0 21 455 130 124 124 — 71.2 20 425 120 114 114 — 66.7 - 390 110 105 105 - 62.3.2 95 90 90 — 52.0 90 86 86 — 48.0 85 81 81 — 41.0 Note: the parameters indicated in brackets are used for comparison only. Index Hardness correspondence table Hardness correspondence table of processed materials