Criteria

The determining factor when purchasing a concrete mixture is the conditions and objectives of its use. There are two classification designations for concrete solutions - brand and class. They inform the buyer about the properties of the building material. The first is the value of average strength, and the second is guaranteed strength, which means that the properties of concrete products are ensured in 95 or more cases out of 100.

The brand and class are determined by the values:

- resistance to compression (design, brand);

- frost resistance, exposure to high temperatures, moisture resistance.

Brand

This index is designated numerically and with the letter M. There is an extensive list of concrete grades from 50 to 1000 grades, about a dozen are most often used. The determining conditions for the properties of concrete are the quantity and quality of the cement mixture in the powder composition. The grade depends on the design compressive strength - this is the value in kgf/cm2 at the time of hardening of the solution (on day 28).

The higher the number in the index, the stronger the concrete. This means that it has more cement of better quality. This type of concrete is more expensive. Therefore, the main task when choosing is to find a balance between price and required properties when constructing a specific structure.

It is more difficult to work with a high-strength solution - the mixture dries faster, and this is fraught with consequences when working slowly: you need to deliver the solution and work with it faster.

Class

The class is designated by the letter B and a digital index after it. The list of concrete classes is also quite impressive - from 3.5 to 80 (21 in total), this depends on its division by strength to the load arising from compression, but about a dozen positions have also become the most popular (B15; B20; B25; B30; B40 etc.) The number means MPa (megapascals).

Each class can be equated to a specific brand and vice versa. In most cases, design documents indicate this, and not the brand of concrete, and vice versa in orders for the purchase of the mixture.

Determination of bending strength

Strength is the property of a solid body to resist external forces. Typically, the strength of a body is characterized by the magnitude of fracture loads during compression, tension, bending, torsion, etc. The tensile strength is the ratio of the maximum load before failure to the original cross-sectional area of the sample. The strength of a hard alloy is one of its main properties. Considering that hard alloy products are mostly exposed to bending loads, bending strength is its main characteristic. The flexural strength is inversely related to hardness and increases with increasing percentage of cementitious metal (cobalt). Thus, the flexural strength of metal-ceramic hard alloys is decisively influenced by the chemical composition of the alloy, as well as the size of the carbide grains and the thickness of the cementing metal (cobalt) layers. Titanium-tungsten alloys are less durable than tungsten alloys, since titanium carbide is more brittle than tungsten carbide.

The size of the interlayers of the cementing (cobalt) phase is of great importance for the ultimate bending strength, since the thicker this interlayer, the lower the local stresses and the greater the strength. With a decrease in the interlayers of the cementing phase, the strength of the alloy decreases. The thickness of the interlayers, in turn, depends on the chemical composition of the alloy and the size of the grains of the carbide phase. The thickness of the interlayers increases with increasing content of the cementing phase in the alloy and the grain of the carbide component.

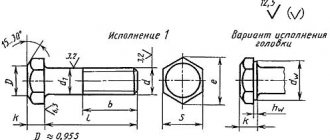

To determine the ultimate strength during transverse bending of hard alloy samples, the method of breaking a sample freely lying on two supports with one concentrated force is used. In this type of test, a hard alloy sample lies freely on two supports, and a static load is applied at the center of the sample.

The tensile strength under concentrated load bending is calculated using the formula

where M = Pl/4 - maximum bending moment, kg*mm2;

W = bh2/6 moment of resistance of a rectangular sample, mm3;

P—breaking load, kg;

b—width of the sample, mm;

h—sample height, mm;

l — distance between supports, mm.

Bending tests on samples are carried out on universal testing machines with a capacity of 4-5 tons. They have a special device for installing samples with replaceable carbide supports with a diameter of 5-6 mm, made of VK8, VK15 or VK20 hard alloy. The surface of the supports is polished to 6-7 class of cleanliness. The distance between the supports should be 30±0.5 mm.

The bending test is carried out on samples in the form of a regular square block with dimensions 5±0.2 * 5±0.2 * 35±1 mm. Samples are prepared in single-cavity molds; the side of the pressing punch is indicated on the sample

Pressed samples must be deburred. The surface of the samples is not polished after sintering. The loading speed during testing should be constant within the range of 4-10 mm/min. 20 samples of each batch of the mixture are tested.

During testing, the following sequence must be observed. First, measure the width and height in the middle of the sample with a dial indicator or micrometer with an accuracy of 0.01 mm, then the samples are placed on supports so that a destructive force is applied to the side where the force is applied when pressing them. After this, a load is applied to the middle of the sample through the vertical punch of the device. The load should not be instantaneous, but gradually increasing. The distance between the point of application of force and the middle of the span should not exceed ±0.5 mm.

Source

Marking ratio

It is best to display these indicators in a table:

Read also: How to connect an assembly table in Minecraft

Table Brand-class relationships

| Concrete class (numeric value here - MPa) | Average strength kgf/sq.cm | Nearest brand |

| AT 5 | 65 | M75 |

| B7.5 | 98 | M100 |

| AT 10 | 131 | M150 |

| B12.5 | 164 | M150 |

| B15 | 196 | M200 |

| IN 20 | 262 | M250 |

| B25 | 327 | M350 |

| B30 | 393 | M400 |

| B35 | 458 | M450 |

| B40 | 523 | M500 |

| B45 | 589 | M600 |

| B50 | 654 | M700 |

| B55 | 720 | M700 |

| B60 | 785 | M800 |

Conditions, types of strength

The main property characterizing concrete is its strength. It is measured in MPa (megapascals) or kgf/cm2. Strength depends on the following components:

- quality and composition of the mixture. The higher the quality and composition of the cement, the stronger the concrete;

- mixing conditions. Insufficient stirring reduces quality;

- amount of water. The more water contained in the stirred solution, the less strength it will have;

- shape and fraction of grains. If the grains have an irregular shape and are more rough, the adhesion is better, and the concrete is therefore stronger;

- method and order of installation;

- tamping method. Concrete compacted with vibrators is better;

- hardness increases with age.

A humid environment also provides good strength to concrete.

Classification

There are these types of strength:

- design, when the full load on concrete is allowed, as provided for by regulatory documents (by default - after 28 days);

- normalized - an indicator defined in GOSTs or specifications;

- required - the minimum acceptable value for use, established by enterprise laboratories;

- actual - average value based on test results;

- vacation pay when the product is allowed to be shipped to the consumer;

- stripping, when it is possible to remove concrete from forms.

Strength directly related to the quality and grade of concrete:

- for compression;

- to bend;

- for axial tension;

- transmission

Let's look at them in more detail.

Compressive strength

Concrete is similar to natural stone: it has better resistance to compression than tension. The strength criterion for concrete is its compressive strength limit. This is the most significant indicator of the quality of the solution. For example, concrete class B15, grade M200 has an average compressive strength of 15 MPa or 200 kgf/m2, B25 - 25 MPa or 250 kgf/m2, and so on.

To determine this indicator, sample cubes are created and placed under a laboratory press. The pressure is gradually increased, and as soon as the sample cracks, the value of this characteristic is recorded on the device screen.

The determining condition for assigning a concrete class is the calculated compressive strength. The concrete mixture dries and hardens for a long time - 28 days. In general, this process can last several years, but it is on the 28th day that the solution acquires its basic qualities. At the end of this period, the mixture reaches an indicator determined by its brand (design or calculated strength).

Compressive strength is a characteristic of the mechanical properties of concrete and its resistance to loads. This is an indicator of the resistance limit of the hardened solution to the mechanical effects of compression in kgf/m2. The M800 mixture has the greatest strength, M15 the least.

Classes and grades of concrete

The class of concrete is determined by the indicator - compressive strength and is designated by the letter “B” with numbers ranging from 0.5 to 120. The numbers indicate the withstand pressure in megapascals (MPa). For example, class B25 means that this concrete will withstand a pressure of 25 MPa in 95% of cases.

Based on compressive strength, concretes are divided into classes:

1. thermal insulation - B0.35, B0.5, B0.75, Bl, Bl.5, B2;

2. structural and thermal insulation - B2.5, B3.5, B5, B7.5, B10;

3. structural concrete - B12.5, B15, B20, B25, B30, B35, B40.

It is allowed to use concrete of intermediate classes B22.5 and B27.5.

The class of concrete for axial tensile strength is designated “Bt” and corresponds to the value of concrete axial tensile strength in MPa with a probability of 0.95 and is taken in the range from Bt 0.4 to Bt 6.

Along with the class, the strength of concrete is also determined by the grade and is designated by the Latin letter “M” . The numbers indicate the compressive strength in kgf/sq.cm.

The indicators of class and grade of concrete are very similar and differ only in that the grades use the average strength value, while the grades use strength with guaranteed security. Despite the fact that brands have been canceled for more than 10 years, many builders who are accustomed to using this indicator often resort to a comparison table.

Flexural strength

This indicator increases with the growth of the brand's numerical index. Tensile and bending values are much less than the load capacity of concrete. For young concrete this ratio is about 1/20, for older concrete it is 1/8. Flexural strength is taken into account at the design stages of construction.

It is determined in the following way. Concrete is poured in the form of a beam with dimensions, for example, 120x15x15 cm. After final hardening, it is placed on supports located at a distance of 1 m, and a load is placed in the center, which is gradually increased until the sample is destroyed. The size of the beam being tested and the distance between supports may vary.

Read also: Beautiful ax with your own hands photo

The bending strength indicator is calculated by the formula:

where L is the distance of the supports (1 m in our case); P – load weight + sample weight, N; b, h – width and height of the beam section (0.15 m). This strength is indicated by Btb and a number from 0.4 to 8.

Compressive Strength

Compressive strength is an important mechanical property. It is characterized by the ultimate compressive strength of the rock in a dry state. The current standard for blocks divides rocks according to this indicator into three classes: strong (over 80 MPa), medium strength (40-80 MPa), and low-strength (5-40 MPa).

Rice. 16. Diagram of a hydraulic press for testing samples for compression

The standard for side stones (GOST 6666-81) allows the production of these products from rocks with a compressive strength not lower than MPa: for igneous rocks - 90, metamorphic and sedimentary - 60. The standard for side stones (GOST 23668-79) allows their manufacture from igneous rocks with a tensile strength of at least 100 MPa. Wall stones made of rocks (GOST 4001 - 84), depending on the compressive strength, are divided into 14 grades (from 4 to 400).

1 – bed; 2 – hydraulic cylinder; 3 – piston, 4 – lower plate; 5 – tested stone sample; c – top plate; 7 – setscrew; 8 – pressure gauges; 9 – pump

Determination of the compressive strength of rocks is carried out on five cubic samples with an edge of 40-50 mm or cylinders with a diameter and height of 40-50 mm. Before testing, each sample is cleaned with a brush from loose particles and dust and dried to a constant weight. The edges of the samples to which the load will be applied are then carefully processed on a grinding machine to ensure that they are parallel. After this, the samples are measured with a caliper, placed in the center of the press support plate (Fig. 16), which has markings for centering the samples, and pressed with the top plate of the press, which should fit tightly over the entire surface of the upper edge of the samples.

The load on the sample during testing is increased continuously and constantly at a rate that ensures its destruction 20-60 s after the start of testing. The magnitude of the breaking load must be at least 10% of the maximum force developed by the press. The moment of sample destruction is determined by the beginning of the reverse movement of the force meter pointer when the loading device is operating.

Axial tension

Axial tension is usually not taken into account when designing load-bearing structures. It is necessary to determine the ability of the material not to crack due to temperature changes and humidity fluctuations. Tensile is defined as some component of flexural strength.

This indicator is the most difficult to determine. One way is to stretch beam samples using special stretching equipment. Concrete collapses from two opposing tensile forces. Resistance to axial tension is important for concrete used for tanks, road surfaces, where cracking from this type of load is unacceptable.

Fine-grained compounds have better durability than coarse-grained compounds (at the same compressive strength). According to this indicator, concrete classes are designated Bt in the range from 0.4 to 6, the numbers indicate the MPa index.

Transfer strength

This value is a standardized indicator of the strength of concrete of stressed elements during the transfer of tension from reinforcing parts to it. Transfer strength is provided for by regulatory documents and technical conditions for a specific type of product.

In most cases, it is assigned to at least 70% of the design grade and depends on the properties of the reinforcement. The recommended value of this indicator is at least 15 or 20 MPa for various types of reinforcement. In short, this is an indicator indicating the level when the reinforcing rods do not slip when removed from the conductors.

Popular types of concrete

There are ordinary or heavy concrete (M25-M800) and light concrete (M10-M200). Let's take a closer look at them.

Lungs

From M5 to M35 are used for non-load-bearing structures - they are not particularly strong. M50 and M75 are suitable for preparatory work before pouring concrete. M100-M150 – for low-rise construction, structures, lintels.

M200-M300 are used for most construction tasks. M200 corresponds to class B15, its strength is 196 kgf/m2 or 15 MPa. M250 (B20) has an average strength of 262 kgf/cm2 or can withstand a pressure of 20 MPa, like the above brand, it gains 70% of its strength after 28 days, and the remaining 30% within six months. These are lightweight concretes. Screeds, floors, blind areas, foundations, stairs, supports, curbs are most often made from it. It freezes at sub-zero temperatures and loses up to 5% of its resistance when defrosted.

Lightweight concrete can be checked by hitting it with a hammer or rubbing it with a sharp object - quite distinct marks will remain on the surface.

Regular

M350 (class B25) - a cubic meter of this concrete can withstand a load of 25 MPa, it corresponds to M250. M400 (class B30) - withstands a load of 30 MPa. These grades and higher are used for multi-storey buildings, load-bearing, monolithic structures, swimming pool bowls. Most often used for road surfaces and floor slabs, as it is waterproof (class W8), frost-resistant (F200).

Grades from M350 (classes from B25) and more relate to more durable concrete, they have a high density and better resistance to frost and humidity, but are much heavier.

Tensile strength

— mechanical stress σ B

> , above which material destruction occurs. In other words, this is a threshold value, exceeding which mechanical stress will destroy a certain body made of a specific material. It is necessary to distinguish between static and dynamic strength limits. There is also a distinction between compressive and tensile strength limits.

Determination of compressive strength

⇐ PreviousPage 6 of 22Next ⇒

12.1 The compressive strength of products is determined according to the GOST 8462 method, taking into account the additions of GOST 530. Samples are tested in an air-dry state. The test sample consists of two whole bricks laid on top of each other.

12.2 The preparation of the supporting surfaces of products is carried out by grinding. The deviation from the flatness of the supporting surfaces of the tested samples should not exceed 0.1 mm for every 100 mm of length. The non-parallelism of the supporting surfaces of the test samples (the difference in thickness values measured along four vertical ribs) should be no more than 2 mm.

12.3 The test sample is measured along the center lines of the supporting surfaces with an error of up to ± 1 mm. Axial lines are applied to the side surfaces of the sample.

12.4 The sample is placed in the center of the compression testing machine, aligning the geometric axes of the sample and the plate, and pressed with the top plate of the machine.

During testing, the load on the sample should increase as follows; until approximately half the expected value of the destructive load is reached - arbitrarily, then the loading speed is maintained such that the destruction of the sample occurs no earlier than after 1 minute.

The breaking load value is recorded and recorded in Table 8.

12.5 Compressive strength of products R

compressor, MPa (kgf/cm2) of a separate sample, calculated using the formula

R

сж =

P/S

( 6)

where P

— the greatest load established when testing the sample, MN (kgf);

S

— cross-sectional area of the sample (without deduction of void area); calculated as the arithmetic mean of the areas of the upper and lower surfaces, mm2 (cm2).

When calculating the compressive strength of samples made of two whole bricks with a thickness of 88 mm, the test results are multiplied by a factor of 1.2.

The compressive strength value of samples R

calculated with an accuracy of 0.1 MPa (1 kgf/cm) as the arithmetic mean value of the test results of all samples.

The test and calculation results are recorded in Table 8.

Table 8 - Results of determining compressive strength

| Sample No. | Sample area, cm2 | Breaking load, Pmax, (kN, kgf) | Ultimate compressive strength, MPa (kgf/cm2) | ||

| upper surface s1 | bottom surface s2 | cross section S | separate sample | average of five samples | smallest for an individual sample |

Establishing a strength grade

The strength grade of brick is determined by the values of compressive and bending strength, which for solid bricks and hollow products with vertical voids must be no less than the values indicated in Table 9.

Determination of brand by frost resistance

According to frost resistance

products are divided into

brands

F25, F35, F50, F75, F100, F200 and F300. The numbers in the mark designation for frost resistance reflect the number of cycles of alternating freezing at a temperature of minus 15 ° and thawing at 20 ° C, which the brick must withstand in a water-saturated state without any visible signs of damage or destruction (cracking, peeling, spalling, spalling).

The frost resistance grade of facial products must be at least F50. It is allowed, by agreement with the consumer, to supply face products of frost resistance grade F35. The frost resistance grade of products used for the construction of chimneys, plinths and basement walls must be at least F50.

The frost resistance grade is determined according to GOST 7025 methods.

Table 9 - Brands of ceramic bricks by strength

| Product brand | Ultimate compressive strength, MPa | Bending strength, MPa | ||||||

| solid brick | hollow bricks of format less than 1.4 NF | hollow brick 1.4 NF format | ||||||

| Average for five samples | Smallest for an individual sample | Average for five samples | Smallest for an individual sample | Average for five samples | Smallest for an individual sample | Average for five samples | Smallest for an individual sample | |

| M300 | 30 0 | 25,0 | 4,4 | 2,2 | 3,4 | 1,7 | 2,9 | 1,5 |

| M250 | 25,0 | 20,0 | 3,9 | 2,0 | 2,9 | 1,5 | 2,5 | 1,3 |

| M200 | 20,0 | 17,5 | 3,4 | 1,7 | 2,5 | 1,3 | 2,3 | 1,1 |

| M175 | 17,5 | 15,0 | 3,1 | 1,5 | 2,3 | 1,1 | 2,1 | 1,0 |

| M150 | 15,0 | 12,5 | 2,8 | 1,4 | 2,1 | 1,0 | 1,8 | 0.9 |

| M125 | 12,5 | 10,0 | 2,5 | 1,2 | 1,9 | 0,9 | 1,6 | 0,8 |

| M100 | 10,0 | 7,5 | 2,2 | 1,1 | 1,6 | 0,8 | 1,4 | 0,7 |

Conclusion on the work

1 Tested batch _____________________________________________________.

(ordinary / facial) ( full / hollow)

ceramic bricks, with nominal dimensions ______________________.

manufactured using the _______________________________________________ method.

(semi-dry pressing / plastic molding)

in terms of deviations from nominal dimensions and shape requirements of GOST 530_____________________ and acceptance______________________________.

2 In terms of appearance, the tested batch of ceramic bricks meets the requirements of GOST 530___________________________________________.

3 The products belong to the medium density class ___________ and the thermal characteristics group ____________________________________.

4 The hollowness of a brick is ______%.

5The rate of initial absorption of water by the supporting surface is _________ kg/(m2*min), which ___________________ the requirements of GOST 530.

6 The water absorption of brick is ________%, which ________________

requirements of GOST 530.

7 The tested batch of ceramic bricks, in terms of compressive and bending strength, belongs to the strength grade ______________..

16 Test questions

1What are ceramic materials and products? Where are they used?

2Define ceramic brick as a building material.

3 Describe the methods for producing ceramic bricks.

4List the quality indicators of ceramic bricks.

5Explain the methodology for assessing the possible deviation of ceramic bricks from the nominal dimensions and shape.

6What indicators are used to evaluate the appearance of front and regular products?

7Explain the method for determining the presence of efflorescence.

8How is the presence of spalls caused by carbonate and other intumescent inclusions determined?

9Give a method for determining the average density and establishing the class of a product based on this indicator.

10 Outline the methods for determining the rate of initial absorption of water by the supporting surface and water absorption of ceramic bricks.

11Describe the method for determining compressive strength.

12How is the bending strength of products determined?

13What data do you need to have to determine the brand of ceramic brick by strength?

14At what temperatures is brick freezing and thawing carried out when determining its frost resistance and what parameters are controlled?

15What do the numbers mean in the designations of ceramic brick brands in terms of strength and frost resistance?

16How is the compliance of a batch of bricks with the requirements of GOST 530 determined (acceptance carried out)?

LABORATORY WORK No. 4

"Testing of building gypsum in accordance with the requirements

GOST 125-95 “Gypsum binders. Technical specifications""

General information

Construction gypsum is an airy binder obtained by firing dihydrous natural gypsum at a temperature of 110-160 0C until it turns into semi-hydrous gypsum, the dehydration reaction CaSO4 2H2O → CaSO4 0.5H2O + 1.5H2O, followed by grinding into a fine powder.

It is necessary to monitor the firing temperature, because... starting from 170 0C, gypsum dihydrate completely separates the water of crystallization and turns into anhydrous gypsum - soluble anhydrite, which reduces its properties.

Technical requirements

Depending on the compressive strength, the following grades of gypsum binders are distinguished: G-2, G-3, G-4, G-5, G-6, G-7, G-10, G-13, G-16, G -19, G-22, G-25.

Depending on the setting time, there are different types of gypsum binder, shown in Table 1

Table 1 - Types of gypsum binder according to setting time

| Type of binder | Timing index | Setting time, min |

| hardening | start, not earlier | end, no later |

| Fast-hardening | A | |

| Normal hardening | B | |

| Slow-hardening | IN | Not standardized |

Depending on the degree of grinding, there are different types of gypsum binders, shown in Table 2.

Table 2 - Types of gypsum binders by degree of grinding

| Type of binder | Grinding index | Maximum residue on a sieve with a clear cell size of 0.2 mm, %, no more |

| Coarse | I | |

| Medium grind | II | |

| Fine grind | III |

The scope of application of gypsum binders is determined by a combination of indicators of grinding fineness, setting time and grade of building gypsum.

Selection of a laboratory sample for testing. From each batch of binder to be tested, a sample weighing from 10 to 15 kg is taken. When the binder is supplied without packaging, the sample is taken directly from the vehicles in equal parts in four places. When delivering binder packed in bags, a sample is taken from 10 bags; a sample weighing from 1.0 to 1.5 kg is taken from the middle of each bag.

The selected sample is thoroughly mixed, then by quartering a final sample weighing from 5 to 7 kg is taken from it for testing, which is divided into two equal parts and stored in closed containers. One of the final samples is used for testing, the second is stored as an arbitration sample at a temperature of (293±3) K (20±3) °C.

The areas of application of gypsum binders are given in Table 3.

Table 3 - Areas of application of gypsum binders

| Areas of application of gypsum binders | Recommended brands and types |

| Manufacturing of gypsum building products | G-2...G-7, all setting times and degrees of grinding |

| Manufacturing of thin-walled products and decorative parts | G-2...G-7, quickly and normally hardening, medium and fine grinding. |

| Production of plastering works Sealing joints and for special purposes | G-2...G-25, normal and slow-hardening, medium and fine grinding |

| Manufacturing of molds and models in porcelain, ceramics, engineering and other industries and medicine | G-5...G-25, normal hardening, fine grinding |

| For medical purposes | G-2...G-7, fast and normal hardening, medium and fine grinding |

Control methods

⇐ Previous6Next ⇒

Recommended pages:

Use the site search:

Tensile strength values [edit | edit code ]

Static tensile strength [edit | edit code ]

Static tensile strength, also often called simply tensile strength, is a threshold value of constant mechanical stress, exceeding which constant mechanical stress will destroy a certain body made of a particular material. According to GOST 1497-84 “Methods of tensile testing”, a more correct term is temporary fracture strength

- stress corresponding to the greatest force preceding the rupture of the sample during (static) mechanical tests. The term comes from the idea that a material can withstand any static load indefinitely if it creates stresses less than the static tensile strength, that is, not exceeding the temporary resistance. Under a load corresponding to the temporary resistance (or even exceeding it - in real and quasi-static tests), the material will collapse (the test sample will be crushed into several parts) after a finite period of time (possibly almost immediately - that is, no longer in less than 10 s).

Read also: How to change the fuse in a Samsung microwave

Dynamic tensile strength [edit | edit code ]

The dynamic tensile strength is the threshold value of alternating mechanical stress (for example, during impact), exceeding which the alternating mechanical stress will destroy a body made of a particular material. In the case of dynamic impact on this body, the time of its loading often does not exceed several seconds from the beginning of loading to the moment of destruction. In such a situation, the corresponding characteristic is also called conditionally instantaneous tensile strength

, or

brittle-short-term tensile strength

.

Compressive strength [edit | edit code ]

Compressive strength is a threshold value of constant (for static tensile strength) or, accordingly, variable (for dynamic tensile strength) mechanical stress, exceeding which the mechanical stress will result (in a finite, fairly short period of time) compressing a body made of a specific material - the body will collapse or becomes unacceptably deformed.

Tensile strength [edit | edit code ]

Tensile strength is a threshold value of constant (for static tensile strength) or, accordingly, variable (for dynamic tensile strength) mechanical stress, exceeding which the mechanical stress will result (in a finite, fairly short period of time) tearing a body made of a particular material. (In practice, for a part of any design, unacceptable thinning of the part is sufficient.)

Ultimate strength of steel in compression and tension

The strength of metal structures is one of the most important parameters that determine their reliability and safety. Since ancient times, issues of strength were solved experimentally - if any product broke, then the next one was made thicker and more massive. Since the 17th century, scientists began a systematic study of the problem; the strength parameters of materials and structures made from them can be calculated in advance, at the design stage. Metallurgists have developed additives that affect the strength of steel alloys.

Tensile strength of steel

Tensile strength

Ultimate strength is the maximum amount of stress a material can experience before it begins to fail. Its physical meaning determines the tensile force that must be applied to a rod-like sample of a certain cross-section in order to break it.

How is strength testing performed?

Strength tests for tensile strength are carried out on special test benches. One end of the test sample is fixedly fixed in them, and a drive mount, electromechanical or hydraulic, is attached to the other. This drive creates a smoothly increasing force that acts to break the sample, or to bend or twist it.

Tensile test

The electronic control system records the tensile force and relative elongation, and other types of deformation of the sample.

Types of tensile strength

Tensile strength is one of the main mechanical parameters of steel, as well as any other structural material.

This value is used in strength calculations of parts and structures; based on it, it is decided whether a given material is applicable in a particular area or whether a more durable one needs to be selected.

The following types of tensile strength are distinguished:

- compression - determines the ability of a material to resist the pressure of an external force;

- bending - affects the flexibility of parts;

- torsion - shows how suitable the material is for loaded drive shafts that transmit torque;

- stretching

Types of material strength tests

The scientific name for the parameter used in standards and other official documents is tensile strength.

Tensile strength of steel

Today, steel is still the most used structural material, gradually losing its position to various plastics and composite materials. Its durability, reliability and safety in operation depend on the correct calculation of the strength limits of a metal.

The tensile strength of steel depends on its grade and varies from 300 MPa for ordinary low-carbon structural steel to 900 MPa for special high-alloy grades.

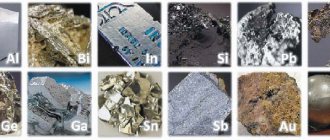

The parameter value is affected by:

- chemical composition of the alloy;

- thermal procedures that help strengthen materials: hardening, tempering, annealing, etc.

Some impurities reduce strength, and they try to get rid of them at the casting and rolling stage, while others, on the contrary, increase it. They are specially added to the alloy composition.

Proof of Yield

In addition to the tensile strength, the related concept of yield strength, denoted σt, is widely used in engineering calculations. It is equal to the amount of tensile strength that must be created in the material in order for the deformation to continue to increase without increasing the load. This state of the material immediately precedes its destruction.

At the microlevel, at such stresses, interatomic bonds in the crystal lattice begin to break, and the specific load on the remaining bonds increases.

General information and characteristics of steels

From the designer’s point of view, the physical and mechanical parameters of steel are of greatest importance for alloys operating under normal conditions. In some cases, when the product is to operate under conditions of extremely high or low temperatures, high pressure, high humidity, or under the influence of aggressive environments, the chemical properties of steel become equally important. Both the physical-mechanical and chemical properties of alloys are largely determined by their chemical composition.

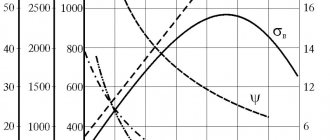

Influence of carbon content on the properties of steels

As the percentage of carbon increases, the plasticity of the substance decreases with a simultaneous increase in strength and hardness. This effect is observed up to approximately 1% share, then a decrease in strength characteristics begins.

Increasing the proportion of carbon also increases the threshold of cold capacity; this is used to create frost-resistant and cryogenic grades.

The influence of carbon on the mechanical properties of steel

An increase in the C content leads to a deterioration in casting properties and negatively affects the ability of the material to be machined.

Manganese and silicon additives

Mn is contained in most grades of steel. It is used to displace oxygen and sulfur from the melt. Increasing the Mn content to a certain limit (2%) improves machinability parameters such as ductility and weldability. After this limit, further increases in content lead to the formation of cracks during heat treatment.

The influence of silicon on the properties of steels

Si is used as a deoxidizer used in the smelting of steel alloys and determines the type of steel. Quiet high-carbon grades should contain no more than 0.6% silicon. For semi-quiet brands, this limit is even lower - 0.1%.

When producing ferrites, silicon increases their strength parameters without reducing their ductility. This effect persists up to the 0.4% threshold.

The influence of alloying additives on the properties of steel

In combination with Mn or Mo, silicon promotes an increase in hardenability, and together with Cr and Ni increases the corrosion resistance of alloys.

Nitrogen and oxygen in the alloy

These gases, the most common in the earth's atmosphere, have a harmful effect on strength properties. The compounds they form in the form of inclusions in the crystalline structure significantly reduce strength parameters and ductility.

Alloying additives in alloys

These are substances deliberately added to the melt to improve the properties of the alloy and bring its parameters to the required ones. Some of them are added in large quantities (more than a percent), others in very small quantities. I most often use the following alloying additives:

- Chromium. Used to increase hardenability and hardness. Share – 0.8-0.2%.

- Bor. Improves cold brittleness and radiation resistance. Share – 0.003%.

- Titanium. Added to improve the structure of Cr-Mn alloys. Share – 0.1%.

- Molybdenum. Increases strength characteristics and corrosion resistance, reduces fragility. Share – 0.15-0.45%.

Metallurgists also use more complex combinations of alloying additives, achieving unique combinations of physical and mechanical properties of steel. The cost of such grades is several times (or even tens of times) higher than the cost of conventional low-carbon steels. They are used for particularly critical structures and assemblies.

If you find an error, please select a piece of text and press Ctrl+Enter.

Strength characteristics of some materials [edit | edit code ]

The values of the ultimate stress (ultimate strength) for tension and compression for many materials usually differ.

Composites typically have a tensile strength greater than their compressive strength. For ceramics (and other brittle materials), on the contrary, it is typical that the compressive strength exceeds the tensile strength many times over. For metals, metal alloys, and many plastics, as a rule, the compressive strength is equal to the tensile strength. To a greater extent, this is due not to the physics of materials, but to the characteristics of loading, stress state patterns during testing, and the possibility of plastic deformation before failure.

The strength of solids is ultimately determined by the forces of interaction between the atoms that make up the body. As the distance between atoms increases, they begin to attract, and at the critical distance the force of attraction is maximum in absolute value. The stress corresponding to this force is called the theoretical tensile strength and is σtheor ≈ 0.1E, where E is Young's modulus. However, in practice, destruction of materials is observed much earlier, this is explained by inhomogeneities in the structure of the body, due to which the load is distributed unevenly.

Some values of tensile strength σ 0 <0>> in MPa (1 kgf/mm² = 100 kgf/cm² ≈ 10 MN/m² = 10 MPa) (1 MPa = 1 N/mm² ≈ 10 kgf/cm²) [1]:

Tensile strength of cast iron

The method for determining the tensile strength of cast iron is regulated by GOST 27208-87 (Cast iron castings. Tensile tests, determination of tensile strength).

Tensile strength of gray cast iron

.

Gray cast iron (GOST 1412-85) is marked with the letters SCh, followed by numbers that indicate the minimum value of the cast iron's tensile strength - tensile strength (MPa * 10-1). GOST 1412-85 applies to cast iron with flake graphite for castings of grades SCh10-SCh35; This shows that the minimum tensile strength of gray cast iron

in the cast state or after heat treatment varies from 10 to 35 kgf/mm2 (or from 100 to 350 MPa). Exceeding the minimum tensile strength of gray cast iron is allowed by no more than 100 MPa, unless otherwise specified.

Tensile strength of ductile iron

. The marking of high-strength cast iron also includes numbers indicating the tensile strength of cast iron (tensile strength), GOST 7293-85. The tensile strength of ductile iron is 35-100 kg/mm2 (or 350 to 1000 MPa).

From the above it is clear that nodular cast iron can successfully compete with steel.