Advantages and disadvantages

The characteristics of chemical fasteners show high reliability of connections, the operation of which is accompanied by static, dynamic and vibration loads.

The tensile strength is 2.5 times higher than that of conventional anchor bolts. Like all materials in construction, adhesive anchors have their pros and cons. There are quite a lot of positive aspects.

- After installation, the hole is sealed and airtight.

- The scope is very wide.

- For installation, the technician does not require special training or experience - installation is as simple as possible.

- After the adhesive has hardened, the strength of the fastener increases.

- The load-bearing capacity is increased, that is, the anchor can withstand tensile moments and tensile loads.

- High resistance to external aggressive environment. Resistant to corrosion and chemical influence.

- There are specially developed compositions for work in conditions of high humidity, as well as for structures installed under water.

- Capitalism and durability. Service life can reach at least 50 years.

- Environmentally friendly. Manufacturers produce compounds suitable not only for external, but also for internal work.

- Chemical anchors are not affected by high temperature changes. Thermal expansion corresponds to the coefficient of expansion of the material into which the fastener was installed.

To avoid any troubles during work, do not forget about the negative aspects.

- The curing period of the adhesive directly depends on the air temperature. At +20°C – this is 25-40 minutes, at +5°C – 5.5-6 hours, but if the temperature is even lower, then polymerization will take up to several days.

- Short shelf life. Unopened packaging should be used within a year. If the cartridge is opened, then it must be used immediately, since liquid anchors are not stored at all when opened.

- The high price of fasteners is a turnoff for many buyers.

Scope of application

A chemical anchor is most suitable for aerated concrete, stone, concrete, and brick (including hollow brick), although it can be used when working with a wide variety of materials.

Important! The use of anchors is especially important in situations where traditional fasteners and dowels cannot ensure a reliable connection. This applies to work with materials such as limestone, expanded clay concrete, cellular concrete, sandstone

Dowel for aerated concrete

Areas of application of chemical anchor:

- house building – installation of roofing, balconies, building canopies, gazebos, gates;

- fixation of any steel elements;

- installation of handrails in tunnels and other work requiring electrical insulation;

- installation of ventilation systems on weak foundations;

- fastening of large-sized structures;

- arrangement of various underwater structures;

- installation of lifts at ski resorts, advertising elements, scaffolding;

- strengthening the foundation of buildings, connecting to the foundation;

- replacement of reinforcement in critical structures - bridges, stairs, ceilings, support columns, overpasses;

- installation of auxiliary equipment - plumbing, satellite dishes, lights.

Installation of metal structures

The metal fastener itself, suitable for working with a chemical anchor, can be made of stainless steel, carbon or galvanized steel. The composition can be used in conditions of any humidity, including under water.

Application areas for chemical anchors

First, we list for what types of structural connections it is advisable to use a chemical anchor:

- during the construction of high-rise buildings

- when forming the foundation of prefabricated buildings, even under difficult working conditions (humidity)

- during the construction of bridges: suspension, drawbridges, arches

- when fastening heavy concrete beams

- when attaching metal beams to a stone base

- when creating reinforcement outlets during monolithic construction

Most of the listed areas of application of chemical-based fasteners can be safely attributed to responsible construction, that is, the construction of structures that are subsequently operated by a large number of people or are subject to extra loads.

Let's also consider more specific examples where a chemical anchor is a reliable fastening in various areas of modern responsible construction:

- energy industry (nuclear power plants, state district power plants, power line supports, transformers)

- mining industry (monorails, funiculars, ski lifts)

- airports (expansion of runways and taxiways, installation of match and radio antennas and navigation equipment)

- port construction (reconstruction and repair of quay walls, fastening of mooring bollards and bollards, locks, oil terminals)

- industrial equipment (distillation columns, conveyors, machines)

- prefabricated buildings (fastening load-bearing frames to strip foundations)

- industry of water parks, swimming pools and other water facilities

In addition, chemical anchors are used in the construction of temporary structures that require a certain strength, and the like:

- elevators (reconstruction of shafts, fastening of elevator equipment, escalators)

- construction equipment (elevators, scaffolding, cranes)

- warehouse equipment (racks, conveyors, lifts)

- fastening of building structures (columns, consoles, balconies)

Examples of using chemical anchors in repair work:

- strengthening of structures (metal clips, injection of masonry walls)

- strengthening foundations

- restoration of architectural monuments

It is advisable to fix hinged elements that have certain installation requirements to chemical anchors:

- ventilated facades

- road construction (noise barriers, barriers, information boards, lighting masts, speed bumps)

- decorative elements (railings, canopies, lighting, molded decorative elements)

- advertising structures (signs, banners, banners, roof installations)

As you can see, the chemical anchor is universal in application: for fastening solid structures and monolithic, porous materials; when working on structures made of concrete, brick, natural stone.

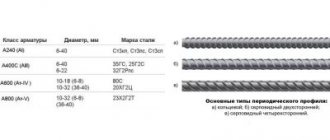

Weight, dimensions and characteristics

As many people have probably noticed, it is usually customary to put hardware in boxes and stick some information on them. So, these labels, in addition to batch numbers, information about certificates and manufacturers, also contain markings of metal products. This is useful information. Let's understand its meaning.

And some more technical information. It will help you understand the principle by which metal types of anchor bolts for concrete are classified.

Main characteristics of hardware:

- Weight. This value depends on the material, size and design of the hardware. The lightest ones are the driving elements. They can weigh as little as 4g. The largest wedge bolts can weigh up to 738g.

- Screw cross-section diameter. The whole variety of fasteners can be divided into small (diameter up to 8 mm), medium (diameter from 8 to 12 mm) and large (diameter from 12 mm to 30 mm).

- Rod length. For each screw diameter, there is usually a choice of 4-5 options of different rod lengths. The maximum length of large anchors can reach 220 mm, and the minimum length is 40 mm for products of small diameters.

Chemical-based fasteners also have their own classification. The main dimensions are the diameter and length of the capsule. The smallest ampoules have a diameter of 10 mm. The maximum capsule diameter reaches 42 mm. The length varies between 80-360 mm.

Another characteristic that distinguishes fasteners from each other is of more practical importance. This refers to the shape of the head of the bolts:

- Using a hook or ring, you can install hanging structures.

- The L-shaped end allows you to hang removable items.

- Fastening with anchors to concrete with a screw-on nut and washer ensures a tight and durable fit of the structure to the wall.

The following are tables in which you can find the sizes of anchor bolts and their weight characteristics.

Advantages of chemical anchor

Chemical anchors differ from conventional ones in a number of advantages. Fastenings using injection masses are resistant to vibration, dynamic and static loads. In such connections, the tensile strength is 2-3 times higher than when using mechanical analogues.

Unlike expansion dowels and anchors, chemical ones do not cause stress in the base material, so they can be fastened close to a corner without fear of chipping and cracking, and also leave a minimum distance between the fastening points. No other fastener will provide such a high load when installed in cellular bricks and other hollow and porous materials.

In addition, the chemical anchor fills all cracks and chips in the base and increases the contact area of the metal product with the material, so even if one or more internal partitions are destroyed, the load-bearing capacity is not lost. For this reason, the injection mass is optimal for dilapidated foundations.

It allows you to install fasteners in holes of any configuration, including cone-shaped ones, and use non-standard hardware and fittings. In the case of traditional installation using plastic dowels or wedge metal anchors, only standard product sizes are used. The adhesive does not harden immediately, so the position of the metal rod can be adjusted. This is not possible when working with conventional anchors and dowels. Another advantage is the tightness of the connection and the resistance of chemical anchors to aggressive environments; they are also often used to fix structures under water.

In short, the following features of chemical anchors can be distinguished:

- Suitable not only for threaded fasteners, but also for fittings

- Vibration resistance

- High load-bearing capacity and tensile strength

- Can be used in aggressive environments and underwater

- There are no strict requirements for the shape of the installation hole

- Monolithic connection, equal strength to the base material

- Ideal for porous and hollow materials

- Tightness and durability of the connection (about 50 years according to EU regulations)

- Easy installation without special skills

Did you like the material?

Installation technology

The advantage of chemical anchors is their high strength and ability to create high-quality adhesion of surfaces.

They can be used for dense and porous blocks. When installing this anchor, special injections are used, which are polyester resin and hardener. When working with cartridges, use a special gun. The resin and hardener are separated in the cartridge, they are in different packages and are connected at the moment of extrusion. In the case when construction work is carried out according to design documentation, before starting installation work, specialists must check the correspondence of the markings in the documentation and on the anchors themselves. The expiration date of the chemical solution is also checked before using it.

Drilling holes

When installing mechanical anchors, builders prefer a diamond machine. If drilling is done for a chemical anchor, a hammer drill is suitable for the work. During the drilling process, the location of the reinforcement is taken into account, and if the drill hits it, the hole is drilled in another place.

The diameter of the hole must be drilled 2-3 mm larger than the diameter of the stud. Having drilled a hole of the required diameter and length, it must be cleaned of any dust that has formed. Uncleaned crumbs will reduce the strength of the joint.

The size of the required screw is selected depending on the type of robot

At this stage of work you need:

- brush of the required diameter;

- construction vacuum cleaner;

- compressor.

Installing the sleeve

If work is carried out on hollow and porous materials (aerated concrete, foam concrete, slotted brick), a mesh sleeve must be installed before pouring the connecting mortar. It performs the function of holding the chemical in the hole until it hardens. These sleeves are sold in the form of finished elements or stockings and special plugs are offered for them.

Pouring chemical substance

Before pouring a chemical, you must read its instructions. In order to properly harden the material, it is necessary to create a special temperature; the heating itself can be done with a hair dryer. The filling process takes place using a special dispensing gun. Pouring the substance into the hole with a gun should be squeezed out 2/3 through the sleeve.

Installing the stud

After pouring the mixture, immediately install the threaded rod. We bring it all the way, then twist it several times to evenly distribute the chemical around the pin. Before hardening, remove excess chemical. During the hardening process, the stud is not subjected to any stress.

Freezing

It is necessary to wait for the complete hardening process of the substance for long-term operation of the anchor. The hardening time depends on the temperature of the base material and averages 45 minutes. The lower the temperature, the longer the chemical solution will harden (in winter it may take up to 6 hours). After hardening, begin tightening the nut.

How much does a chemical anchor cost?

For a more complete picture of future costs when using liquid dowels, we present you with a table of prices for compositions (all prices are as of December 2021):

| Brand | Manufacturer | Tube volume | Cost, rub |

| Akfix C900 | Akfix (Türkiye) | 300 ml | 720 |

| Fischer FIS V 360 | Fischer (Germany) | 360 ml | 1574 |

| Sormat ITH 300 PE | Sormat (Finland) | 300 ml | 1460 |

| Hilti HIT-RE 500 | Hilti (Russia) | 500 ml | 2000 |

| BIT-EA | Bit (UK) | 400 ml | 1098 |

| "Moment Fastener CF900" | Henkel (Germany) | 280 ml | 800 |

As you can see, the price range is relatively small. So you can choose chemical anchors not by cost, but by manufacturer and technical characteristics.

The design of a mechanical anchor is familiar even to a novice builder. What is a chemical anchor, and how to work with it? In the article, we will consider this concept in more detail, get acquainted with the varieties and methods of using the liquid composition, and also test its strength.

A chemical anchor is an adhesive liquid mass that reliably fixes metal fasteners and the mounting base together. The European Technical Standards Organization calls it an adhesive anchor, and among amateurs and professionals you can hear the terms “injection mass”, “adhesive anchor system”, “liquid anchor”, “chemical dowel”. However, the most common name among residents of the CIS countries remains “chemical anchor”.

The principle of fastening with its help is simple. The prepared hole in the base is filled with a liquid binder, after which a metal rod is inserted into it. After some time, the mixture begins to harden, securely fixing the rod in the base. Thus, a strong monolithic fastening is created, which, depending on the quality of the manufacturer, correct installation and type of construction, can withstand significant loads of several tens of tons. The use of chemical anchors is quite extensive. It is used for fixing fasteners in concrete, brick, stone, metal, wood foundations and other complex load-bearing structures such as bridges, balconies and canopy buildings.

The strength of fixation with a chemical anchor is much higher than with an expansion anchor. Liquid dowel can withstand 2.5 times more tensile load. So, what are the main advantages of a chemical anchor:

- increased fastening strength compared to a metal anchor several times;

- widespread use of liquid composition, the ability to create durable fastening in less durable bases (foam and aerated concrete, porous brick);

- resistance to aggressive environments (alkali, water), use of a fixing composition in wet conditions and even under water;

- does not cause stress on the walls of the hole, unlike spacer fasteners, suitable for installing railings and parapets;

- creates complete sealing of seams;

- has durability, the operation of the fastening exceeds 50 years.

Manufacturers carefully hide the proportions of all components of the chemical anchor. However, so that you have at least a rough idea of the composition of this adhesive mixture, here is a list of components: artificial resins based on polyurethane, acrylic and polyester, quartz sand and astringent mixtures (cement), hardener. The only thing that is known for sure is that a chemical anchor is a mixture of two components. The first is the adhesive composition, and the second is the hardener. Liquid anchor is produced in two versions - in ampoules and tubes, cartridges of different volumes. Ampoules are intended for one-time use for a specific hole, and cartridges and tubes can be used repeatedly to work with a large number of fasteners.

Chemical anchor in ampoules

Also, chemical anchors are divided depending on the temperature of use. You can distinguish summer, winter and spring-summer-autumn products. Summer anchor is used at temperatures from 5 to 40 °C, spring-summer-autumn - from -10 to 40 °C, and winter anchor can harden at -26-20 °C. Due to the fact that the shelf life of a chemical anchor is short, it should be selected based on weather conditions during the period of work.

Catalog

Catalog → Construction fasteners → Chemical anchors → Chemical anchors (cartridges / capsules / tubes)

- Chemical anchor KMP A-PE 300

624.00i

- Chemical anchor KMP A-PE 410

760.00i

- Chemical anchor KMP A-VE 410

828.00i

- Chemical anchor KMP ARCTIC up to -26°С

840.00i

- Chemical anchor KMP A-EA 410

882.00i

- Chemical anchor KMP A-EX 410

1590.00i

- Chemical anchor FISCHER FIS P 300 T

883.44i

- Chemical anchor FISCHER FIS P 380 C

1090.93i

- Chemical anchor FISCHER FIS P 360 S

1357.84i

- Chemical anchor FISCHER FIS VW 300 T winter (up to –15°C)

1334.60i

- Chemical anchor FISCHER FIS VW 380 C winter (up to -15°C)

1526.74i

- Chemical anchor FISCHER FIS VW 360 S winter (up to –15°C)

1828.82i

- Chemical anchor FISCHER FIS VS 300 T

1279.02i

- Chemical anchor FISCHER FIS V 360 S

1828.82i

- Chemical anchor FISCHER FIS V 410 C

1885.13i

Pages: 1

Chemical anchors. Compositions. Application. Installation methods.

Chemical anchors are a two-component composition, when mixed, a very strong fastening connection is obtained. In professional language they are also called: injection mass, injection composition, adhesive anchor and liquid dowel. A liquid, chemical anchor was also called because the free space between the metal anchor and the walls of the hole is filled with a liquid, hardening component.

In construction, chemical anchors are convenient to use. The position of the metal anchor or reinforcement can be easily adjusted while the composition is setting.

Adhesive anchors can be used not only in dry holes, but also in damp environments, as well as under water.

All adhesive anchors differ in their chemical composition.

Varieties of chemical compositions FISCHER (Germany)

1. P series composition: polyester chemical composition, generally not used in concrete, approved for installation in hollow and solid brick masonry, as well as in lightweight concrete blocks. It has a lower load capacity compared to other compounds. Available in tubes of 300 ml (FIS P 300 T), 360 ml. (FIS P 360 S), 380 ml. (FIS Р 380 С). The chemical anchor FIS P 300 T is convenient because it fits a regular (single-piston) dispenser pistol.

2. V series composition (VW, VS, VT): vinyl composition. It is a more universal chemical composition compared to polyester compounds and is used in all building materials (all types of brickwork, concrete of various grades, hollow and solid blocks, foam concrete). These compositions are divided into several subtypes, depending on the requirements for creating a fastening joint and the characteristics of the installation environment.

-Composition V: universal vinyl composition for summer use. Available in 360 ml tubes. (FIS V 360 S)

-VW composition: vinyl composition used at low temperatures, down to -15 degrees C. Produced in 300 ml tubes. (FIS VW 300 T) and 360 ml. (FIS VW 360 S).

-Composition VS: vinyl chemical composition used for installation at high temperatures, having an increased setting and curing time. Available in 100 ml tubes. (FIS VS 100 P), 150 ml. (FIS VS 150 C), 300 ml. (FIS VS 300 T), 360 ml. (FIS VS 360 S)

-VT Compound: Vinyl compound for installing threaded rods and fittings in wet or underwater environments. They produce tubes with a volume of 300 ml. (FIS VT 300 T) and 380 ml. (FIS VT 380 C).

3. Composition of the EM series: universal composition made on the basis of epoxy resin. It is used for installation under water, as well as in holes obtained by diamond drilling. Available in 390 ml tubes. (FIS EM 390 S).

4. Composition of the SB (Superbond) series: a type of chemical anchor with a complex vinylester composition. Used for installation at very low temperatures down to -30, for installation in a humid environment and under water. It is one of the new products and the latest development of the FISCHER company. Available in 390 ml tubes. (FIS SB 390 S).

Chemical anchors are produced (depending on application):

— In glass capsules of various diameters.

— In tubes (cartridges) of various sizes.

Installation of fasteners using capsules with a chemical composition is simple:

• A hole is drilled. Please note that the diameter of the hole should be slightly larger than the diameter of the capsule with the chemical composition.

• The drilled hole is prepared, the dust formed during the drilling process is removed.

• The capsule is inserted into the prepared hole.

• The fastener is directly inserted into the trail behind the capsule with the chemical composition. This could be a threaded rod, a special rod for chemical anchoring, or whatever fastener you need.

• The capsule is destroyed by the impact of a metal anchor on its end, and the chemical composition is mixed.

• The resulting mass firmly holds the fasteners together.

Installation of fasteners using chemical anchors in cartridges (in solid bases):

• A hole is drilled into the base material. Please note that the diameter of the hole should be slightly larger than the diameter of the fastener.

• The drilled hole is prepared, the dust formed during the drilling process is removed using special devices.

• The injection mass is introduced into the prepared hole by gradually pressing the dispensing gun. If the hole is deep, then a special extension is put on the chemical anchor cartridge.

• After filling the hole, the metal anchor is inserted directly into it using a rotating motion.

Anchoring is considered correctly performed if, after seating the fasteners, a small amount of the chemical anchor mass protrudes onto the base of the material.

Installation of fasteners in hollow materials using mesh sleeves:

• A hole is drilled into the base material. Please note that the diameter of the hole should be slightly larger than the diameter of the mesh sleeve.

• The drilled hole is prepared, the dust formed during the drilling process is removed using special devices.

• A mesh sleeve is inserted into the prepared hole.

• Until it is completely filled, the required amount of chemical anchor is injected into the mesh sleeve using a dispensing gun.

• After filling it, a pin or any other fastener is inserted into the sleeve with a rotational movement.

Adhesive compositions are widely used to solve various problems in construction. Today they are the most reliable systems for creating fastening connections.

You can buy chemical anchors in our online store. Simply send your request by email or call us by phone. Our managers will select the required composition, calculate the volume of chemical anchors, and also organize prompt delivery to your site.

Chemical anchor: what is it and why is it called that?

Let's start with the main thing: a chemical anchor is a special adhesive mixture that connects the steel fastener and the base in which it is installed. Europeans call this system differently: liquid anchor, injection fastener, chemical dowel. For us, it is more familiar as a chemical anchor.

The operating principle of this type of fastener is simple: a hole is made in the surface to which fastening is required, filled with glue, and a metal fastener is inserted. Afterwards, the adhesive composition hardens and firmly fixes the metal in the recess.

As a result, you get a monolithic connection that can withstand multi-ton loads

Types of chemical composition

Chemical compositions are produced in different types:

- glass ampoules;

- cartridges;

- canisters.

Glass ampoules are a ready-made mixture that needs to be placed inside the hole. In the future, all that remains is to screw in the pin - this completes the procedure. It is used in cases where there is a need for one-time use of a chemical anchor.

Cartridges are a volume in which two substances are separated. When squeezing out the solution using a gun, mixing occurs and a homogeneous mixture is obtained in a special nozzle.

The use of polymer mass in canisters is relevant mainly for impressive volumes of work. Special nozzles and pumps are used to place the mixture into the holes.

Pros and cons of chemical anchors

The building composition has many positive characteristics:

absolute tightness of the attachment point; absence of tensile loads, which is especially important for concrete foundations; versatility, ability to operate in various areas of construction and repair, suitability for any materials; ease of use, no need for special knowledge and skills; the highest strength after final hardening - an indicator greater than that of conventional metal anchors and dowels with a sleeve; significant load-bearing capacity, tolerance of serious mechanical loads, regardless of the type of base material; resistance to chemicals, corrosion, and negative atmospheric factors; Possibility of use at high humidity, under water; long service life - up to 50 years; absence of toxic compounds (not in all formulations), suitability for indoor use; approximate equality of the coefficients of thermal expansion of the composition and most building foundations, which reduces the risk of internal stresses during temperature fluctuations.

Advantages of a chemical anchor over a conventional one

The disadvantages of chemical anchors include the rather long time until complete polymerization and readiness to absorb maximum loads. So, at a temperature of about +50 degrees this time will be 5-7 hours, and at ordinary room temperatures it will be much longer.

During the cold season, the curing process may stop altogether. The shelf life of such formulations is limited - it makes no sense to use them 12 months after production, even if the packaging was sealed.

After opening, you will have to use the product in one go, so for the sake of a couple of fastenings it is better to buy ampoule anchors. The price for this type of fastener is quite high, which repels some buyers.

Installing the mount

Installation

Installation using a chemical anchor is very similar to installation using conventional fasteners, if you exclude the stage of using an adhesive composition. And, since a special tool is used, the use of CA does not delay the work.

- Mark the attachment points. In this case, the distance from the edge does not matter much.

- Holes are drilled according to the marks - 2 mm larger than the diameter of the anchor. Tools with a diamond drill are used, as they give the most even walls.

- Clean the holes from dust - use special brushes and blow out the holes.

- If the fastening is made into hollow brick or foam concrete, then a mesh sleeve is inserted into the holes: it prevents the adhesive from spreading. If we are talking about dense material - heavy concrete, then a sleeve is not needed.

- A mixer is placed on the cartridge and some of the contents are squeezed out. At this point, the components are mixed in the mixing spout to form a homogeneous mixture.

- The mixer nozzle is inserted into the hole until it stops. The composition is squeezed into the hole, filling it to about 2/3 of the volume.

- The fastener is inserted into the hole using rotational movements. Until the mixture has set, its position can be adjusted.

- Until the composition is completely cured, the fasteners are no longer touched.

- For the next anchor on the cartridge, change the mixer and clean the hole.

Instead of a cartridge for multiple mounting, use a larger volume tube of 400–800 ml.

Consumption

The consumption of a chemical anchor depends on the hole diameter, depth, and, of course, the size of the metal pin, if one is used. The consumption can be determined using the formula:

V= π*h(D²- d²)/4, where

- π – pi number:

- D – hole diameter;

- d – pin diameter;

- h – hole depth.

The resulting volume must be multiplied by the number of holes to obtain the total volume of the mixture that will be required for installation.

You will learn more about the price of a chemical anchor below.

Features of application

The installation process is carried out in several stages. The main ones:

- Preparing the hole.

- Train room.

- Installation of the anchor in the uncured polymer mass.

- Tightening the nut.

Each of these stages is associated with its own characteristics.

Before starting work, you need to familiarize yourself with the installation diagram and hardening time. This information is indicated on the cartridge.

For installation you will need:

- chemical anchor;

- injection gun;

- stud or threaded fittings;

- hammer drill or drill;

- Boer;

- torque wrench;

- metal brush;

- manual or industrial vacuum cleaner;

- Remedies.

Once you have the tools, you can begin installing the chemical anchor.

Preparing the hole

When working with brickwork, it is important to avoid splits and cracks in the brick. This requires refraining from using the hammer function on the equipment and drilling perpendicular to the plane.

To successfully install a chemical anchor for hollow bricks, a hole that is 2 millimeters larger than the diameter of the stud is required. It is necessary to apply a mark on the drill in advance corresponding to the length of the anchor, or use a depth limiter.

It is not recommended to use drills and drills with diamond coating due to the fact that the level of adhesion of glue to a rough surface is higher.

To improve adhesion, you need to thoroughly clean the hole from dust and crumbs. This is done using a metal brush and a hand pump, with which the hole is blown several times until there are no visible dust residues.

It is recommended to use an industrial vacuum cleaner to speed up work on large volumes.

Introducing the composition

The polymer mass is injected into the hole using an injection gun. If the mixture has a uniform gray color, then it can be used. It often happens that initially it is not possible to achieve high-quality mixing - such a mixture should not be used. To use the gun, you need to place the nozzle in the drilled cavity and fill it with the composition. After each dose of glue placed in the hole, you need to remove the tool a little until more than 65% of the cavity volume is filled.

The procedure for placing a chemical dowel into a hollow brick is characterized by a number of features. They are due to the fact that the presence of a large number of voids does not allow the formation of a natural hole. To achieve the goal, a special plastic sleeve is inserted and filled with glue. When a pin is immersed in a hollow brick, part of the chemical composition escapes through the mesh walls of the sleeve into the cavity. This promotes greater grip.

There are also special ampoules. They are placed in the hole, the composition is mixed using a pin. The second option is more suitable for piece work, when there is no need to buy cartridges with a chemical composition.

Installing a metal anchor

We place the metal structure into the hole using rotational movements. It is important to distribute the solution evenly. To do this, it is recommended to periodically pull the fastener towards you and only then tighten it. While the glue dries, you can correct the position of the anchor.

Tighten the nut

After waiting for the polymer mass to completely harden, you can proceed to installing equipment and structures. The manufacturer's instructions indicate the maximum force applied to tighten the nut. It is recommended to use a torque wrench to control the applied forces.

In a situation where a regular key is used, there is a possibility that the force value will be exceeded, which will contribute to turning the metal base and destroying the material.

Chemical anchors are suitable for fasteners made of steel. Due to its positive properties, the anchor can be installed in high humidity or even under water. When used correctly, it is possible to avoid destruction of the brick, which allows installation at the very edge of the surface.

Chemical anchor is a new direction in construction, thanks to which complex work is simplified. The supply market is becoming more extensive, a larger number of anchors with various new fastener characteristics are appearing.

Manufacturers and characteristics of chemical anchors

Injection anchors are offered by many manufacturers. The highest quality compounds come from European companies. Let's look at a few examples of compositions that are widely popular among our builders.

Chemical anchor "Titan" and its properties

This is a universal composition based on polyester resins. "Titan" can be used for the installation of heavy structures, for repair and restoration work. Chemical anchor “Titan” is resistant to temperature increases up to 80°C, hardens at room temperatures within half an hour, and at -5°C – within one and a half hours.

Chemical anchor "Titan"

Sormat – Finnish quality

The composition from this manufacturer is intended for installation of medium-heavy elements in cellular concrete and hollow bricks. Chemical anchor Sormat is sold in cylinders with a disposable nozzle. Its composition is based on a two-component polyester resin.

Chemical anchor Sormat

Low temperature mixture under the BIT brand

Chemical anchor “BIT” is a mixture for reliable fastening of structural parts even at low temperatures. Such anchors can be installed even in frosty weather – at -18ºC. The liquid dowel is based on a high molecular weight epoxy acrylate resin. The BIT-EA chemical anchor in a 400 ml tube has a low viscosity, which makes it easy to squeeze the composition out of the tube and evenly fill the bolt holes with it.

Such anchors do not have a specific odor, so they can be used in residential areas.

Low temperature BIT mixture

Series of liquid dowels “Moment”

Synthetic dowels under the Moment brand can be used for mounting heavy structures on hollow bricks and porous concrete. Chemical anchor "Moment" is popular due to its rapid hardening and high strength. There is no styrene in the mixture, which means there will be no toxic emissions or pungent odor during operation.

These injection anchors can be used to mount gates, railings and satellite dishes. Temperature for working with the composition is from +20°C.

Liquid dowel Moment

Hilti injection anchors

Hilti epoxy adhesive can be used in the temperature range from -40°C to +70°C. These anchors are suitable for use in seismically active areas and can be installed underwater. The range of Hilti chemical anchors is presented in the company's catalog. The composition polymerizes at temperatures down to -5°C. It is used when installing metal structures of any complexity, as well as when electrical insulation of parts is necessary.

Chemical anchor Hilti HIT-RE 500. The price of the tube is about 2350 rubles Chemical anchor Hilti HIT-RE 500

How to make a chemical anchor yourself?

If the price of a chemical anchor is too high, you can try making it yourself. You can use an epoxy mixture for this. It is well mounted in building materials, has great strength and adhesion to concrete. Such mixtures usually consist of the following components:

- epoxy resin (ED-20) – x;

- hardener (UP-583) – y;

- filler (cement, gypsum) – z;

- plasticizers and other additives (DBP, DEG-1) – w, w2.

Procedure: xw (5-10%) = mix well Z = mix well y (ratio 1:8 – 1:10) = required adhesive.

Characteristics of this mixture:

- Has high strength.

- Hardens in 3-4 hours, completely hardens up to 12 hours.

- Works only in dry environments.

- Phenol release during operation.

- Operating temperature -10 o C - 30 o C.

Return to contents

Installation of anchor in concrete

If you can use a simple screwdriver to screw in a self-tapping screw, then to install the anchor in concrete we will need to prepare tools and consumables.

Here is a list of tools needed for the job:

- Hammer (or drill with hammer function).

- Drills for concrete.

- Hammer and mallet.

- Wrenches, pliers.

- Vacuum cleaner (rubber blower or construction syringe for blowing holes).

- Tools for marking.

Drilling

Installation of fasteners of any type always begins with marking and drilling. Mark the installation location. Please note that the distance from the edge of the wall should be at least 2.5 times the length of the bolt.

To drill a hole of the appropriate diameter, first study the hardware markings. The bushing should enter the gap with some force, so that friction is felt. The length of the hole should be equal to the length of the sleeve. For convenience, make a color mark on the drill.

An important point in preparation for installation is to clear the drilled gap from dust and concrete particles. This can be done with a vacuum cleaner, or, in extreme cases, with a rubber bulb. If it is impossible or impossible to completely clean the hole, just make it a couple of centimeters longer.

Installation of anchor with nut

Let's consider a universal installation method that can be used for similar types of fasteners. Study the following diagram and, with practice, you will understand the principle of installing anchors for concrete.

Sequencing:

Take the anchor and use a mallet to hammer it into the hole so that the edge of the sleeve is flush with the wall. Remove the nut and install on the stud the element that will hold the suspended structure. For example, let it be a metal corner. Install the nut and start tightening it

Please note that you need to tighten it as long as possible.

Chemical anchor installation

Here, during installation, approximately the same thing will happen as when installing a bolt and nut. But in addition to the listed tools, we will need a special chemical composition for fastening.

The diagram describes in detail the process of laying a chemical anchor. It is as follows:

- First you need to drill a hole and clean it well from dust. You can use a vacuum cleaner, a brush, or a can of compressed air.

- It is recommended to install a mesh sleeve inside, which will help retain the adhesive composition.

- You need to place an ampoule with glue into the hole or fill the hole from the dispenser to 2/3 of the length.

- Slowly screw in the bolt or stud, allowing the compound to distribute evenly.

- Next, you should wait the required time for the glue to set. This information is usually written on the packaging.

- You need to install the element to be attached to the rod and tighten the nut.

Please note that many chemical compounds do not work at low temperatures

Installation nuances

Now let's figure out how to install a chemical anchor with your own hands.

There are two methods, not counting the option with a metal sleeve, which is suitable for hollow bricks.

First of all, we drill a strictly perpendicular hole for mounting the anchor.

- Then, using a brush, a small brush or an ordinary medical bulb (enema), we remove all the remaining debris and dust from inside.

- We fill the hole about 3/4 full with the injection solution - no more is needed, since it will be squeezed out when installing the rod.

- Screw the fastener into the glue, making sure it is centered and level. We stop when we reach the mark on the thread. Carefully remove excess mixture.

- The solution is left to dry for the time specified by the manufacturer of the composition.

- Once dry, you can hang weights on the threaded fastener and secure them with a nut.

Reinforced joint

The following method is not technically very different, but creates a stronger joint - it is suitable for more porous materials.

To implement it, you will need a metal stop for the drill so as not to destroy the edge of the block.

- We drill a hole, having previously installed the limiter;

- Once the desired depth is reached, the drill begins to make circular movements to create an expanding cavity inside, as in the picture above.

- The rest of the installation is similar - we clean the hole from dust, fill it with a hardening mixture, insert the fastening rod, and wait for it to dry.

As you can see, anchoring aerated concrete blocks is not such a difficult task, and given the softness of this material and the ease with which it is drilled, the work is often done even easier and faster than with classic dowel screws on concrete. For a more detailed introduction to chemical anchors, we recommend that you watch the video in this article.

Popular brands and prices

Chemical anchors are not such a common fastener, so there are few well-known manufacturers on the market. The leaders are considered to be Great Britain and Liechtenstein.

- HILTI is a well-known manufacturer in the field of chemical anchors, presenting capsules and double plastic tubes. An undoubted advantage is the large temperature range of use: from -18 to +40 C. Capsules are used for holes from 8 to 30 mm with a wide variety of fasteners, including fittings. Capsules are equipped with different dispensers and can be equipped with standard or special fasteners. The HILTI injection dowel allows you to do without a metal body. It is enough to fill the holes in the two parts to be joined through a syringe nozzle, and when it hardens, the adhesive composition provides the strongest fastener. The cost is determined by the type of composition and volume. So, 300 ml of HIT-RE cost from 4400 rubles. per package, and 1400 ml of it costs 10,014 rubles. The mesh sleeve is a HILTI offering and is now widely used.

- BIT United Ltd produces both capsules and cartridges for working with a pistol. For the coaxial anchor, plastic tubes are made with double cavities for glue and catalyst. The cost of the product is much more affordable: 400 ml of the mixture costs from 650 to 950 rubles, and each cartridge comes with 2 mixers. In addition, BIT offers a cartridge with a spiral-shaped turbo divider for chemical anchors, which can be used without a gun. The portion is measured using a measuring scale marked on the tube.

- "Chemofast" is the creator of a chemical anchor based on vinyl ester resin "Moment Fastener". Its variety, “Moment Fastener CF900,” is today the strongest anchor bolt for fastening in conditions of high humidity. 280 ml of this composition will cost 1,228 rubles.

- Fischer – chemical anchors for use in old masonry, when installing or repairing facades, suitable for fastening in old weathered joints. The fastener includes a cartridge with an injectable composition and a mesh sleeve (plastic). And a profiled stainless steel rod. The cost depends on the volume of the mixture and the diameter of the anchor. So, 6 pcs. 100 ml will cost 856 rubles, and 6 pcs. 360 ml - 1190 rub.

- Sormat – produces injection mixtures based on polyester, vinylester, epoxy resin. Release form: tube with a volume of 300 or 380 ml or glass ampoule. There are mixtures designed to work in the cold season - from -18 C. Galvanized pins are used as the metal body. The cost of an ampoule ranges from 95 to 115 rubles.

- Mungo – injection mixtures based mainly on polyester and vinylester. Designed to work in both solid and hollow structures and materials. Studs, bolts, anchor bushings, and so on can be used as a metal body. The volumes of the cylinders are different - from 385 to 1400 ml, but, as a rule, such volumes are rare. Ampoule anchors are also produced. 400 ml of HA from Mungo cost from RUR 1,075.

Chemical anchor is an ultra-reliable fastener and is designed for use under the heaviest loads. Such fasteners must be used for appropriate work. When it is necessary to fasten heavy structures to hollow materials, it is simply irreplaceable.

This video will tell you about testing a chemical anchor on different surfaces:

https://youtube.com/watch?v=OTKTYMHAqos

Installation instructions

To correctly install chemical anchors with your own hands, you need to carry out a number of operations:

- Preparing the hole. For fastenings that do not require high precision, a hole is drilled with a diameter 1.5-2 times larger than the cross-section of the stud. Regarding critical connections using chemical anchors, the instructions provide clear instructions.

- Dust removal of the hole. To ensure adhesion of the adhesive mass to the base material, the hole is treated with a brush, blown with a pump, a rubber blower, or small particles are removed with a vacuum cleaner. Deep holes are washed with an aqueous solution of PVA and cleaned with compressed air. Mesh bushings are inserted into the cavities of porous structures to uniformly distribute the mixture throughout the volume.

- The installation of capsule and cartridge type anchors is somewhat different. In the first case, an ampoule is placed in the hole, then a pin is inserted and screwed in using a drill at low speeds. Excess solution is removed. In the second, a mixer attachment is put on the tube, installed in a construction gun and inserted into the hole. By pressing the lever, fill the hole 2/3 with the mixture. Then the metal fastener is placed in the glue until it stops. When the length of the hardware is more than 500 mm, a jig with mechanical feed is used.

- After the curing time specified in the instructions, the connection can be used. Usually this is 0.5-10 hours.

Using a chemical anchor is easy, and the benefits of high-quality, durable fasteners are truly great. If it was not possible to buy a ready-made solution, it can be obtained by mixing epoxy resin, plasticizer, cement or gypsum and a hardener.

Important options to select

So, we can summarize and determine which anchor for concrete is better and what characteristics of hardware are important to obtain a high-quality result.

Diameter, length and metal composition are the main qualities of concrete anchors. At the same time, do not forget that the fastener option is chosen knowing the quality of the concrete wall and the weight of the item being installed. The thicker and longer the bolt, the greater the load it can withstand.

A mandatory requirement for all hardware used for concrete is an anti-corrosion coating. It protects the metal from the aggressive alkaline environment of the concrete composition and moisture. The highest quality hardware that will last a century is made from stainless steel with a zinc coating. To avoid buying a fake, it is better to buy products from well-known manufacturers.