What is regulated

The welding machine rod is regulated by a number of standards:

- GOST 9467-75 “Coated metal electrodes for manual arc welding of structural and heat-resistant steels. Types" reveals different types of consumables and their characteristics.

- GOST 9466-75 (ST SEV 6568-89) “Coated metal electrodes for manual arc welding of steels and surfacing. Classification and General Technical Conditions” divides rods based on suitable steel, types of coating; lists dimensions, symbols.

Shelf life of electrodes

The conditions under which consumables are kept largely influence the shelf life of welding electrodes, so if all rules are followed, this period can be as long as possible. All storage and packaging features must be observed in accordance with the regulations of GOST 9467-75 and GOST 9466-75. This applies both to manufacturers, who leave them in the finished goods warehouse, where they await shipment, and to users, who store materials before direct use. During transportation and other procedures, the electrodes are most at risk, but this can be easily corrected with drying and hardening. To maintain high quality, all conditions must be met.

Marking

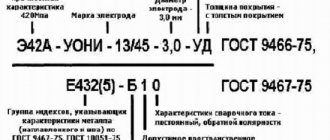

Contains the following complete information about the "cartridge". For example, E42A-UONI-13/45-3,0-UD E432(5)-B 1 0 means:

Dear readers! To solve your problem right now, get a free consultation

— contact the lawyer on duty in the online chat on the right or call: +7 (499) 938 6124 — Moscow and region.

+7 (812) 425 6761 — St. Petersburg and region. 8 (800) 350 8362 - Other regions of the Russian Federation You will not need to waste your time and nerves

- an experienced lawyer will solve all your problems!

- E42A – type, strength 42 MPa;

- UONI-13/45 – brand;

- 3.0 – diameter;

- U – purpose for carbon steels;

- D – coating thickness;

- E432(5) – metal characteristics;

- B – type of coating – basic;

- 1 – spatial position – any;

- 0 – current characteristics – constant, reverse polarity.

In addition, the GOST to which the product corresponds is indicated.

| Type | steel grade | Application | Best before date |

| SSSI-13 | High alloy corrosive | Structures made from chromium species | Unlimited subject to certain conditions |

| MR-3S | Carbon and low alloy | High welding and technological properties | |

| MR-3T | Welding of raw materials with carbon content up to 0.25% | ||

| OZS-6 | Material with tensile strength up to 490 MPa | ||

| OZS-12 | |||

| SSSI 13/55 | Designs with ductility requirements |

Shelf life of electrodes - does it exist and what does it depend on?

The shelf life of electrodes depends entirely on storage conditions. If you are new to welding, you should know that from time to time, electrodes require calcination. Even if the electrodes are stored correctly, the coating will still become damp, so after long-term storage, the electrodes need to be dried.

If the correct storage conditions are observed, the electrodes do not deteriorate, therefore, they have an unlimited period of use. However, this is only true if the electrodes are stored under proper conditions. If storage conditions are violated, irreversible consequences can occur, for example, the electrodes become so damp that they fall off the steel bar.

Timing and types

Electrodes are used for steels with different levels of alloying elements, structural, heat-resistant, ductile metals, surfacing.

Brands intended for a specific type of work are classified by coated rods. The most popular SSSIs are:

- UONI 13-45 rods contain nickel and molybdenum;

- UONI 13-65 is used for welding in difficult conditions, since work from any position is possible.

Also in demand:

- MP-3S for low-alloy raw materials;

- MP-3T for carbon steels;

- LB-52u – pipe welding;

- OK 53.70 – low carbon;

- OK 46.00;

- OZS-6;

- OZS-12.

A mandatory element is a protective coating consisting of:

- components for arc combustion;

- deoxidizers;

- kaolin, mica;

- aluminum, silicon;

- binders.

Based on the composition, the following types are distinguished:

- cellulose - used for direct and alternating current. Disadvantage: splashing;

- sour is not used for vertical position;

- rutile is not suitable for steel with high sulfur and carbon content;

- mainly effective for joining thick metal.

IMPORTANT! A combination of several types is possible.

The letters indicate the thickness of the coating:

- M – thin;

- C – average;

- D – thick;

- G – especially thick.

Subject to proper conditions, they have an unlimited shelf life and storage.

What is the actual shelf life of electrodes?

Electrodes are consumables for electric arc welding. Therefore, it is important to know the requirements and expiration date.

The law does not regulate restrictions, so the consumer can determine suitability before use.

What is regulated

The welding machine rod is regulated by a number of standards:

Marking

Contains the following complete information about the "cartridge". For example, E42A-UONI-13/45-3,0-UD E432(5)-B 1 0 means:

- E42A – type, strength 42 MPa;

- UONI-13/45 – brand;

- 3.0 – diameter;

- U – purpose for carbon steels;

- D – coating thickness;

- E432(5) – metal characteristics;

- B – type of coating – basic;

- 1 – spatial position – any;

- 0 – current characteristics – constant, reverse polarity.

In addition, the GOST to which the product corresponds is indicated.

| Type | steel grade | Application | Best before date |

| SSSI-13 | High alloy corrosive | Structures made from chromium species | Unlimited subject to certain conditions |

| MR-3S | Carbon and low alloy | High welding and technological properties | |

| MR-3T | Welding of raw materials with carbon content up to 0.25% | ||

| OZS-6 | Material with tensile strength up to 490 MPa | ||

| OZS-12 | |||

| SSSI 13/55 | Designs with ductility requirements |

Timing and types

Electrodes are used for steels with different levels of alloying elements, structural, heat-resistant, ductile metals, surfacing.

Brands intended for a specific type of work are classified by coated rods. The most popular SSSIs are:

- UONI 13-45 rods contain nickel and molybdenum;

- UONI 13-65 is used for welding in difficult conditions, since work from any position is possible.

Also in demand:

- MP-3S for low-alloy raw materials;

- MP-3T for carbon steels;

- LB-52u – pipe welding;

- OK 53.70 – low carbon;

- OK 46.00;

- OZS-6;

- OZS-12.

A mandatory element is a protective coating consisting of:

- components for arc combustion;

- deoxidizers;

- kaolin, mica;

- aluminum, silicon;

- binders.

Based on the composition, the following types are distinguished:

- cellulose - used for direct and alternating current. Disadvantage: splashing;

- sour is not used for vertical position;

- rutile is not suitable for steel with high sulfur and carbon content;

- mainly effective for joining thick metal.

IMPORTANT! A combination of several types is possible.

The letters indicate the thickness of the coating:

- M – thin;

- C – average;

- D – thick;

- G – especially thick.

Subject to proper conditions, they have an unlimited shelf life and storage.

How to properly store electrodes

ADVICE! You can extend shelf life using special thermal cases. They maintain the desired temperature and protect from moisture.

Welding consumables must be stored under certain conditions. So, the room:

- must be dry, humidity not higher than 50%;

- have functioning ventilation or air conditioning;

- with heating, waterproofing;

- the temperature must be maintained at a level not lower than 14 °C.

How to properly store electrodes

ADVICE! You can extend shelf life using special thermal cases. They maintain the desired temperature and protect from moisture.

Welding consumables must be stored under certain conditions. So, the room:

- must be dry, humidity not higher than 50%;

- have functioning ventilation or air conditioning;

- with heating, waterproofing;

- the temperature must be maintained at a level not lower than 14 °C.

Stored in cardboard boxes wrapped in paper or plastic film. Packages are placed on shelves or racks to avoid contact with the floor and walls.

What to check after long-term storage

The material has retained its integrity, even color, the coating should evenly cover the rod. If there is a risk of moisture, it is better to heat it before use.

IMPORTANT! Moisture is especially harmful. Water accumulates in the winding, which begins to crumble. When using such material, the seam will turn out to be of poor quality.

How to store

Since electrode coating is porous and absorbs moisture well, special conditions are required to maintain its quality. According to GOST 9466-75, electrodes for welding should be stored in a dry, heated room at +15°C, under conditions that protect them from contamination, moisture and various mechanical damage. The most optimal air humidity is no higher than 50%.

Up to 30 kg are loaded into cardboard boxes. The best place for long-term storage is a shelf or tray to prevent moisture from getting from the floor and walls.

Subject to strict adherence to storage and transportation rules, and if the packaging is not damaged, the electrodes can be stored for an unlimited period.

How long can you store after calcination?

If the product is damp, the period of acceptable use can be restored for a while by calcination:

- With rutile coating: bake for about 2 hours, store at a temperature 20° above ambient for up to 10 hours ;

- With low and very low content of diffuse hydrogen in the deposited metal: calcination for up to 6 hours, storage in an oven at 180 °C for an unlimited time, in a thermal case for up to 10 hours, in a plastic container for up to 2 weeks;

- Stainless steel: calcination for about 6 hours, storage in an oven at 125 °C for an unlimited time, in a thermal case for up to 10 hours.

Calcination is a heat treatment whose purpose is to reduce the amount of liquid. The procedure is carried out immediately before use; storing hardened rods is not recommended. Allowed up to 3 times; exceeding this amount will lead to shedding of the coating. The optimal mode is indicated on the electrode packaging.

How to store welding electrodes

Any experienced craftsman will tell you that 50% of the work is quality components.

The strength and durability of the welded joint largely depends on good electrodes. At the same time, high-quality products need proper storage, otherwise all the advantages come to naught. Of course, wet electrodes can be calcined in an oven, thereby drying them, but if the rods are cracked or the coating begins to crumble, then only purchasing new materials will help. Proper storage of electrodes will avoid additional costs and save your time.

articles

- Best before date

- Storage rules

- Instead of a conclusion

Best before date

The shelf life of electrodes is unlimited, but only if you comply with the storage conditions. There is even a special GOST that establishes rules for storing and transporting rods. If you intentionally did not comply with storage conditions, you can visually determine the expiration date and understand whether the electrode can be used in your work.

Inspect the electrode carefully. If there are no visible defects on it, and the coating does not crumble or crumble, then most likely the electrode can be used. We recommend that you first test it on an unnecessary metal surface.

If you find minor defects or contamination, bake the rods in an oven at a temperature lower than the melting point of the electrode, or clean the electrode using a rag and a soft brush.

If the defects are significant and the coating crumbles in your hands, then discard the rod or use it as a training rod.

Test the electrode for strength by tapping the end of the rod on the metal surface and make sure that the electrode is dry. Proper storage will ensure many years of use. Never use damaged components in your work.

Storage rules

As you can imagine, proper storage directly affects the shelf life of welding electrodes, so take this seriously. We wrote above that the rules are established by GOST. All manufacturers, suppliers, sellers and welders are required to comply with it. Electrodes deteriorate most during transportation, so inspect them carefully after opening the package.

How to properly store electrodes? According to the rules, the rods must be stored in a dry, warm room. The optimal air temperature is 14-16 degrees Celsius, and the optimal humidity is no more than 50%. Use special devices to control temperature and humidity. They can be either hand-held, portable or stationary, mounted on a wall indoors.

The room itself must be thoroughly waterproofed. Do not have open openings through which snow, rain or wind can enter the room. If the room has windows and doors, they must have seals. The presence of large gaps between window or door openings and the wall is excluded.

The ideal option is an insulated, waterproofed warehouse, with an electronic temperature and humidity control system. But this option is not possible if you are engaged in home welding.

Therefore, use your garage or storage room as a warehouse, install an outdoor thermometer on the wall and purchase a psychrometer.

Electrodes are stored at a constant temperature; changes are also unacceptable. The electrode coating easily absorbs moisture or becomes dry, which may shorten the shelf life. The shelf life of welding electrodes can be increased if you follow our recommendations:

- Store electrodes in boxes or boxes made of thick cardboard, do not place them on the floor or open ground. It is better to put them on shelves or pallets. This will protect the rods from excessive condensation.

- Do not leave open packaging outside. If you do not have this opportunity (for example, you carry out welding work outside the workshop or garage), then protect the packaging from moisture and dust by wrapping it in thick paper or putting it in a box.

- Immediately close the package containing the electrodes.

If you usually use few materials, then the shelf life of welding electrodes can be increased by making a special case for them from PVC pipe. Below is a training video on how to make such a pencil case.

Instead of a conclusion

An electrode is one of the key tools in any welder's arsenal.

With the help of a high-quality electrode, you can improve the strength characteristics of seams, speed up work and achieve durability of the welded joint.

We told you all about how to store welding electrodes to extend their service life. Observe storage conditions and do not neglect our recommendations. Good luck!

[Total: 0 Average: 0/5]

Shelf life of welding electrodes: what is it, what does it depend on, how to extend

page » About welding » Shelf life of electrodes

If the electrodes are of poor quality, then the welding will be of poor quality. But do electrodes have an expiration date? The packages indicate the release date, but no shelf life or expiration date. And this seems logical, because we are not talking about cottage cheese or sour cream. On the other hand, complex chemical compounds, such as electrode coatings, logically cannot last forever. Let's figure it out.

Shelf life of electrodes

Specialists who often perform welding work stock up on a large number of electrodes. Because it is more profitable to buy welding materials at wholesale prices rather than at retail prices. In order for the finished product to be manufactured at a high level, consumables must be of high quality.

Depends on storage conditions

To ensure the quality of the electrodes, it is necessary to store them in optimal conditions :

- the room must be dry, heated in winter, and have waterproofing ;

- the temperature should not fall below 14 degrees ;

- Constant humidity should not exceed 50% . To control this indicator, it is necessary to use air conditioners.

The production date of OK 46.00 electrodes is indicated on the packaging

Can we measure it?

So, the shelf life of welding electrodes - can we measure it? Storage conditions directly affect the shelf life of electrodes. Welding materials, like goods used in everyday life, have a shelf life.

If all the above parameters are observed, the rods can be stored for an almost unlimited period of time.

All features of contents and packaging must be observed in accordance with the standards of GOST 9467-75 and GOST 9466-75. This rule applies both to manufacturers who store rods in a warehouse before shipping to the customer, and to end users who hold welding consumables immediately before use.

If the electrodes have been stored for a long time

During transportation and during other events, consumables are exposed to great risks. It is not uncommon for welding consumables to be stored under less than ideal conditions.

The adverse effect on the rods can be corrected using the calcination procedure. The drying process will help avoid many problems: shedding of the coating; poor ignition and sticking of the rod .

He recommends calcination be carried out in specialized equipment - in mobile or stationary ovens.

How to see that welding electrodes have passed their expiration date

If there is concern that optimal maintenance conditions have not been observed, a visual inspection of the welding materials should be carried out. This will determine whether they are suitable for use.

Do not use materials with chipped coating

There are several options for the condition of consumables :

1. The electrodes are externally in normal condition and are ready for use without preliminary preparation (unless the welding mode requires it).

The mode of preliminary procedures is indicated on the packaging

2. There are some

defects that can be eliminated by carrying out preparatory procedures, such as cleaning, drying, etc.

3. The materials have completely deteriorated and are not suitable for use. In this case, they must be disposed of. They can also be used as training consumables and as additives.

When not to take risks

When carrying out work at critical sites, as well as when welding important products and structures, you should refrain from using possibly low-quality consumables.

The technician needs to be absolutely sure that the electrodes are in normal condition. Otherwise, it is recommended to purchase new welding materials.

What will help extend the shelf life

extend the shelf life of electrodes using a whole range of professional equipment.

Thermos cases allow you to keep materials in optimal conditions, thanks to the presence of a thermostat and a heat-insulating internal coating in their device.

Thermal pencil case is a structure within which a certain level of temperature and humidity is created and maintained. These units allow you to effectively solve the issue of maintaining electrodes.

Electrode storage

For frequently performed welding work, you need to stock up on a sufficient amount of electrodes, which are the main consumable raw material in welding. It is profitable to purchase larger quantities of packages than individually at retail prices.

Electrode life

In order for the electrodes to work properly, they must be stored in optimal conditions. High humidity may occur in warehouses and other areas, which will cause water to accumulate in the winding. When storing filler materials, certain conditions must be followed to ensure optimal performance of the electrodes.

How to understand what has gone bad

You can tell if a product is damaged by visual inspection. There are three states:

- completely ready for use;

- it can be used after processing (calcination), when the degree of moisture impregnation is low, the coating has not crumbled, and fits tightly to the rod;

- if the coating does not adhere to the rod, it crumbles and breaks off.

It is prohibited to use a product with the characteristics of the third option. The seam from such material will be of poor quality and may come apart at any time.

How to properly store welding electrodes!?

How to properly store electrodes? Even professionals ask themselves this question after the arcing of a high-quality electrode becomes unstable. However, such an outcome can be prevented. How, you ask. You can prevent this situation only if you adhere to the requirements that must be met for long-term storage of electrodes.

Recommendations from the OfficeTools online store specialists for storing welding electrodes:

- Welding electrodes must be stored in their original packaging

- Electrodes must be protected from rain, dampness and moisture

- Relative humidity during storage should be kept to a minimum

- Packages with welding electrodes should be stored on shelves or pallets to avoid direct contact with the floor and walls.

- When welding outdoors, measures must be taken to prevent rain and moisture from entering packs with open electrodes.

- If possible, an incompletely used pack of electrodes should be sealed to prevent moisture from entering, or a sealed tube should be used for storage.

Storing electrodes in unheated rooms does not exclude humidification

electrodes even in sealed packaging. The temperature in rooms intended for storing electrodes should not be lower than +15 C.

If you have any doubts about the correct storage, then the electrodes should be calcined before use in accordance with the calcination requirements.

Thus, following the rules for storing and preparing electrodes for welding can prevent the formation of inaccessible defects in the weld metal and guarantees the high quality of welded structures!

#welding electrodes #electrodes Add to favorites Saved

Is it possible to use expired

The shelf life of the electrodes is conditional and directly depends on how the rods were kept. If all requirements have been met, protection from moisture, the product can be stored indefinitely.

When a visual inspection indicates a violation of the integrity of the coating, it cannot be used for its intended purpose. The seam will be loose. This is also fraught with poor ignition, sticking of the electrode, and shedding of the layer.

Dear readers! To solve your problem right now, get a free consultation

— contact the lawyer on duty in the online chat on the right or call: +7 (499) 938 6124 — Moscow and region.

+7 (812) 425 6761 — St. Petersburg and region. 8 (800) 350 8362 - Other regions of the Russian Federation You will not need to waste your time and nerves - an experienced lawyer will solve all your problems! Or describe the situation in the form below:

When is calcination of electrodes required?

- outdoors after 2-8 hours;

- in a room with high humidity after a month;

- in a dry room after 120-180 days;

- in a sealed metal container (pencil case, tube) after a year.

If the destruction has not reached a critical value, then the electrodes can be dried or calcined. However, in some cases the coating crumbles completely or partially, and cracks appear. In this case, electrodes cannot be used.

Manufacturers can set expiration dates on products, but with proper storage, the shelf life of coated electrodes is practically unlimited. Of course, it is also important where the products were purchased, because the quality of an electrode of any type and brand also depends on storage in the warehouse of the manufacturer and seller. Therefore, buy electrodes from trusted suppliers such as Enkor24.ru.

Shelf life and storage of electrodes.

The process of manufacturing electrodes for welding is a rather labor-intensive and multi-stage process using special technologies and requiring highly qualified personnel. However, if you do not observe and control such an important aspect in production as storing the finished product in the proper conditions for it, then all the efforts of the huge number of workers who were involved in production will be reduced to zero. There will also be a risk of supplying potential customers with a product of very low quality. To prevent this from happening, you must strictly follow the recommendations for storing welding electrodes.

A generally accepted and well-known rule is that welding electrodes must be stored in specially designated warehouses ; the premises must be dry and heated in winter. The temperature should not drop below 14 degrees Celsius, with constant humidity not exceeding 50 percent. The required level of humidity is achieved by installing air conditioners, which need to be adjusted to the required level of humidity, or if the warehouse is deepened into the ground using high-quality thermal and waterproofing, and thoughtful drainage of the soil around is also necessary.

This storage system is used for long-aged wine. The temperature regime for storing welding electrodes must be stable, avoiding changes throughout the day. This is due to the fact that dew formed as a result of temperature changes provides moisture, which the packaging with electrodes absorbs over time. Therefore, conventional metal warehouses are suitable for storing electrodes only if there is a layer of insulation.

Most often, storage occurs in stacks. The main condition for such storage is to ensure the safety of the goods in the lowest boxes. In order to ensure the movement of packages, it is recommended to equip the warehouse with the necessary lifting mechanisms. It is also advisable to store welding electrodes, separating them by brand, diameter, and also by batch. If the storage method is followed, the shelf life of the electrodes can be unlimited . But long-term storage still requires repeated testing, as well as, if necessary, calcination and sorting.

Some additional recommendations for storing welding electrodes:

- boxes or boxes of electrodes must be stored on pallets or shelves for the purpose of contact with walls or floors;

- when welding in an open space, avoid getting moisture into the packaging with electrodes;

- It is necessary to hermetically pack a partially used pack of welding electrodes so that the packaging does not become damp.

Types of calcination of electrodes, based on the type of coating:

- main coating:

mandatory calcination is required before use at a temperature of 300-350°C for up to 1 hour.

— rutile-cellulose coating:

calcination before welding is not required, subject to storage conditions.

However, when moisturizing, drying is necessary for 30-60 minutes at a temperature of 110°C. - rutile coating:

if stored correctly, calcination is not required, but when moistened it is necessary, 40-60 minutes, at a constant temperature of 150°C.

Welding electrodes Zio-8 Electrodes TsCh-4 Electrodes Plazmavis