Types of electrodes

The manufacturer of Arsenal electrodes, a plant under the same name "Arsenal", presented them in only two versions - MRZ ARS and ANO-4. However, each of them deserves close attention, including for home welding.

Arsenal welding electrodes have the following advantages:

- easy arc ignition;

- the constancy of its combustion;

- easy re-ignition of the arc after it has died out;

- minor metal spattering;

- melting uniformity;

- formation of an even seam;

- easy removal of slag.

In addition to electrodes, the plant produces filler wire. Arsenal electrodes, like all manufactured products, comply with international standards, which is combined with their low cost.

What is the difference between UON and MR electrodes?

The welding electrodes themselves have many differences. The brands of electrodes, as well as their subtypes, differ. Welding electrodes are used to weld carbon steels that contain up to 0.25% carbon. They are also used for welding low-alloy steels, which have a tensile strength of up to 590 MPa.

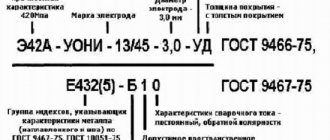

Welding electrodes differ from each other in their characteristics, for example, the spatial position of the welding seam, the type of welding current, welding performance, tendency to form pores and destruction, etc. Based on the type of coating, welding electrodes are divided into acidic, rutile, cellulose and basic. Now let’s take a closer look at the characteristics of the uoni and mr electrodes, and then you will immediately see the difference between them.

MR electrodes:

The coating of MR welding electrodes is rutile. The type of current for welding with MR electrodes is alternating or direct current of reverse polarity. You can weld with MR electrodes in all spatial positions except vertical from top to bottom.

MR electrodes are used for welding carbon and low-alloy steels. Using MR it is recommended to weld pipelines, boilers, gas pipelines, as well as oil pipelines and similar structures.

weld with MR electrodes even on the uncleaned edges of the metal being welded, as well as on an oxidized and unprepared surface. The metal that has been deposited with MR electrodes can be used to work at temperatures up to 20 degrees below zero Celsius. As you can see, MR electrodes are used for welding critical structures that will subsequently operate under non-standard conditions.

Uoni electrodes:

The coating of welding electrodes is basic. To weld with Uoni electrodes, you need to use direct current of reverse polarity. You can weld using uoni in all spatial positions except vertical from top to bottom.

The main purpose of Uoni electrodes for metal welding is welding critical structures made of carbon and low-alloy types of steel. Uoni electrodes are used if high demands are placed on the weld metal in terms of impact strength and ductility.

Uoni welding electrodes are used for welding structures that operate at low temperatures, and they are also used for welding shipbuilding structures.

They are also used for welding thick metals and welding casting defects. In order to weld with Uoni electrodes, you need to first clean the weld metal from rust, scale and traces of oil. Difference between MP and Uoni MP: use of alternating and direct current; Uoni: using direct current; Mr: welding of structures for work at temperatures both below and above zero; Uoni: welding of structures for work at temperatures below zero, as well as for welding ships; Mr: cleaning the metal before welding is not necessary; Uoni: cleaning the metal before welding must be done; Here are the main differences between MR and Uoni electrodes . Which ones should I use? – it’s up to you to decide. Electrodes tsl-11 Welding electrodes uoni-13 Electrode coatings

SSSI electrodes

This type of welding equipment is used in circumstances where the structure being welded must be as shockproof as possible. They are used for the installation of very important structures, since when they are used, the welds are of high quality and ductility.

One of the main advantages of SSSI is that the welds obtained during the work process can withstand very low temperatures (down to -40).

Welding work can be carried out in various positions. All representatives of this species are distinguished by the presence of a base coating. The most commonly used are SSSI 13/45 and SSSI 13/55.

UONI 13/55 is applicable for installation work on structures that require the ability to withstand high dynamic loads. They are also used to produce seams that are resistant to low temperatures. UONI 13/55 can weld thick metals together. Their use is possible in the construction of ships and the installation of tanks and vessels under high pressure.

UONI 13/45 is used for working in cold weather. When working with them, it is necessary to take into account that the surfaces for welding must be very well prepared: cleaned of oils and other contaminants.

Basics of choosing electrodes for welding

The main feature of any coated electrode is its coating. Each electrode coating has its own chemical composition, which largely determines the purpose of the electrode. Electrodes are available with basic, rutile and acidic coatings.

- Basic coated electrodes are used for DC welding. They have somewhat more difficult ignition than rutile electrodes, and are also more sensitive to moisture.

- Rutile-coated electrodes provide easy arc ignition, which is why they are popular among welding beginners.

- Acid-coated electrodes are used for inverter welding. However, due to the special composition of the electrode coating, it is recommended to cook with acid electrodes in a well-ventilated area.

In manual arc welding, coated piece electrodes are used. Below is the rating of electrodes in 2021, according to users.

Differences between welding electrodes

Electrodes have many differences depending on the brand and subspecies to which they belong. This tool is suitable for welding steels with a carbon content of up to 1/4 percent. They are also used when welding low-alloy steel. The difference between the electrodes is visible in many parameters, for example, in the tendency to pore formation, in the way the weld seam is located or in what its surface is covered with: basic, cellulose, etc.

In this article we will consider the features and possible differences between rutile MR electrodes and rods with the main coating -UONI.

How to choose a welding electrode?

Dear novice welders, in this article we will briefly talk about electrodes and give practical recommendations on their use.

- Metal thickness - (the thicker the metal, the larger the diameter of the electrode).

- Steel grade - (ferrous metal, stainless steel, heat-resistant, etc.).

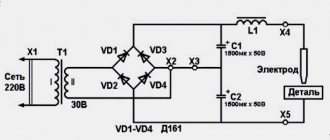

- We determine the current by the electrode!

- Welding position - (bottom, horizontal, bottom T, vertical - welding from bottom to top, ceiling, ceiling T).

Which welding electrode to choose?

MP-3 and ANO - these electrodes are best used on alternating current. They are not picky about dampness. These electrodes are not for critical structures; they are never used to weld bridges and load-bearing roof beams; they are used to weld fences, gates and greenhouses in the country, fences, and small metal structures for domestic use. If there is no overload, these are the electrodes for you. The most popular brands among amateur welders and summer residents.

UONII 13/55 are excellent electrodes, but very “specific”. UONII 13/55 is brewed by professionals. You have to cook on a short arc! These are electrodes for critical structures. They burn only on direct current, they like a stable arc and do not like voltage surges. Start working with UONII 13/55 only when you learn how to cook MP-3 and ANO.

LB-52U - we recommend buying these electrodes from the Japanese company KOBELCO. These electrodes are used for welding pipes under high pressure. Very high quality seam. LB-52U electrodes are one of the most expensive; as a rule, they are purchased by enterprises and structures involved in the repair of urban heating/water networks.

We introduced you to the most popular electrodes. Below we will briefly describe the electrodes of the ESAB Concern (Sweden), perhaps you will find exactly what you need. All ESAB electrodes begin with the letters OK - in honor of the founder of the Concern, Oskar Kelberg.

OK 46.00 ESAB (Russia) – metals can be welded with these electrodes using direct and alternating currents. Often these electrodes are called UNIVERSAL or ELECTRODE FOR STEEL. If you don’t know what to choose, take these electrodes – you won’t go wrong. Electrodes are good because they have a wide range of diameters. You can always choose the one you need.

OK 48.00 ESAB (Sweden) - DC only. Ideal for critical structures.

OK 61.30 ESAB – stainless steel/stainless steel welding (steel grades 304, 308L, 03Х18Н11, 06Х18Н11, 08Х18Н10, 08Х18Н10Т, 12Х18Н10).

OK 67.60, OK 67.62 ESAB - stainless steel/steel welding.

OK 63.30 ESAB (Russian analogs of ANV-26) - (steel grades 316 , 03Х17Н14М2, 10Х17Н13М3Т, 06Х19Н11Г2М2) are ideal for welding thin-walled pipes and thin-sheet products.

If you don’t understand what kind of steel is in front of you, you don’t know its composition - your choice is OK 68.81, OK 68.82 - these electrodes can be used to weld dissimilar steel products and steels of unknown composition.

There are many nuances when welding cast iron!

Welding cast iron steel ESAB OK 92.18 (new name OK Ni-Cl) - designed for welding thin cast iron (no more than 3 layers).

Welding cast iron; cast iron steel ESAB OK 92.60. (new name OK NiFe-Cl) - they can just cook cast iron of any thickness and cast iron with steel

Aluminum welding. Aluminum is a very complex metal, it requires heating before welding, it melts quickly and hardens quickly. Aluminum is usually welded using TIG or MIG welding. It is very difficult to weld aluminum with an electrode, but if you succeed, you can consider yourself a master!

OK 96.20 ESAB - it can be used to weld a very limited number of grades of aluminum. Study the composition carefully.

The most universal electrode for aluminum is OK 96.40 . IMPORTANT that the aluminum electrode must be used in one ignition. An unfinished electrode must be replaced with a new one. Plus, unlike steels, you need to make circular movements with the end of the electrode.

Why do you need to calcinate the electrodes?

The electrodes are calcined in order to remove moisture from them. If the electrode is damp, during welding, defects may occur in the weld seam or the electrode will constantly stick to the product.

Please note that in our online store all the electrodes are “fresh”, we purchase them from suppliers who have special heated warehouses, the electrodes are not stored in warehouses for more than a month, all packs are sealed.

Similar parameters and differences from UONI welding materials

Electrode packaging OK 48.00

Consumables of the OK 46 and UONI grades, identical in purpose, are intended for welding low-carbon and carbon steels. The difference in the rod coating material (SSSIs have a basic type) determines the following main differences in characteristics .

- By type and polarity of current. Unlike the universal power supply for OK 46 consumables, UONI electrodes operate only on direct current of reverse polarity.

- According to the characteristics of working conditions. To carry out welding technology using UONI electrodes, the surfaces of the edges must be cleaned and degreased. UONI consumables are very sensitive to working in wet conditions; OK 46 produces high-quality welds in the surrounding area with a large number of traces of water.

The above differences are good arguments not to consider UONI consumables as an analogue of OK 46 electrodes . To a greater extent, they are suitable for the purpose and technical characteristics of the following consumables from the ESAB line of electrodes: OK 48.00, OK 48.04.