Chemical milling gives the product an ideal shape.

Chemical finishing of iron is a set of technological processes due to which the physical and chemical properties of the metal surface change. The technology is practiced only at high temperatures and in active media (solid, liquid or gaseous). The end result of chemical treatment is a change in the physical and chemical properties of the diffuse iron layer.

Thermal method

Heat treatment of products involves changing the structure of the material under the influence of:

- heating to a certain temperature;

- isothermal holding;

- cooling at a certain speed.

Depending on the modes of metal work, the final result of the operation may be:

- hardening;

- softening;

- stabilization.

Changing the structure by thermal influence

Types of heat treatment of metals and alloys:

- annealing – consists of heating a product or workpiece followed by cooling in a furnace for heat treatment of metals. As a result of the operation, residual internal stresses are removed, ductility increases and the hardness of the steel decreases;

- hardening - involves heating steel to a temperature above the critical temperature and then rapidly cooling it. As a result of hardening, the strength of the material increases, and the ductility decreases;

- tempering - consists of heating hardened steel to a given temperature, holding and cooling in air (only steel prone to temper brittleness is cooled in water). Tempering is the final heat treatment operation. As a result of this operation, internal stresses are removed (or reduced), the part becomes less fragile and more ductile. Vacation is low, medium and high;

- normalization - consists of heating followed by cooling in air. This operation is faster and more economical than annealing, since it does not require cooling with the furnace;

- aging – consists of a forced change in the properties of a material, which in nature occurs over a long time;

- exposure to cold - consists of keeping the hardened part cooled to 20

0C, in coolers (dry ice, liquid nitric acid, etc.). used for the manufacture of cutting tools in order to increase durability and productivity, measuring tools - for complete dimensional stabilization.

The process of this method of work is not easy. The science of materials science and heat treatment of metals studies the deep mysterious processes occurring inside the metal.

This is interesting: Other types of metal processing

Do-it-yourself steel cementation process

When setting up a chemical-thermal treatment process at home, the method of cementation in a solid medium is chosen. This is due to a significant simplification of the task of equipping the premises. Typically, a solid carburizer is made using a mixture of barium or calcium with charcoal, as well as sodium carbonate. The salt is ground to a powder and then passed through a sieve.

Cementation of steel in a solid carburizer

Recommendations for creating a solid mixture are as follows:

- The first method is to use salt and charcoal, which are mixed thoroughly. If you do not use a homogeneous mixture, then there is a possibility of the formation of stains with a low carbon concentration.

- The second method involves the use of charcoal, which is poured on top with salt dissolved in water. After this, the coal is dried to obtain a mixture with a moisture content of about 7%.

For knives and other products, the second method of producing carburizer is most suitable, since it allows you to obtain a uniform mixture. Cementing steel at home with graphite also involves creating a mixture using several technologies.

Cementation is carried out in special boxes, which are filled with prepared carburizers. The structure must be airtight, for which the cracks are sealed with clay. It is recommended to achieve high tightness due to the fact that when the carburizer is heated, gases are released that should not enter the environment. The box itself should be made of heat-resistant steel that will withstand high temperatures.

The process of carburizing steel in a box at home has the following features:

The part is placed in a box with the mixture. The thickness of the solid carburizer layer is selected depending on the size of the workpiece. The stove is being installed. The initial heating of the furnace is carried out to a temperature of 700 degrees Celsius. This heating is called through heating. The uniform color of the steel from which the box is made indicates the possibility of moving on to the next stage. The next step is to heat the medium to the required temperature

It is important to ensure uniform heating of the surface of parts with complex shapes, since significant problems may arise if the atomic structure is unevenly rearranged.

Cementing steel in a box at home

Today it is possible to carry out a similar procedure at home, but difficulties arise in achieving the required temperature.

General principles

The essence of this technology is to transform the outer layer of the material by saturation. Chemical-thermal processing of metals and alloys is carried out by keeping the materials being processed in environments of a specific composition of different phase states during heating. That is, it is a combination of plastic deformation and temperature effects.

This leads to a change in the parameters of the steel, which is the purpose of chemical-thermal treatment. Thus, the purpose of this technology is to improve hardness, wear resistance, and corrosion resistance. Compared to other technologies, chemical-thermal treatment differs favorably in that with a significant increase in strength, ductility does not decrease so much. Its main parameters are temperature and holding time.

The process under consideration includes three stages:

- dissociation;

- adsorption;

- diffusion.

The intensity of diffusion increases if interstitial solutions are formed and decreases if substitution solutions are formed instead.

The amount of a saturating element is determined by the influx of its atoms and the rate of diffusion.

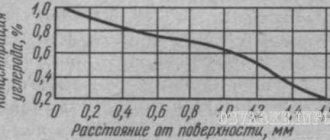

The size of the diffusion layer is affected by temperature and exposure time. These parameters are directly related. That is, with an increase in the concentration of the saturating element, the thickness of the layer increases, and an increase in the intensity of the thermal effect leads to an acceleration of diffusion, therefore, over the same period of time it will spread to a greater depth.

The solubility of the saturating element in the material of the workpiece is of great importance for the diffusion process. In this case, boundary layers play a role. This is explained by the fact that, due to the presence of many crystalline defects at the grain boundaries, diffusion occurs more intensely. This is especially evident in the case of low solubility of the saturating element in the material. With good solubility this is less noticeable. In addition, diffusion accelerates during phase transformations.

Classification

Chemical-thermal treatment of steel is divided based on the phase state of the saturation medium into liquid, solid, and gas.

In the first case, diffusion occurs on fragments of contact between the surface of an object and the environment. Due to its low efficiency, this method is not widely used. The solid phase is usually used to create liquid or gaseous media.

A chemical-thermal operation in a liquid involves placing an object in a molten salt or metal.

In the gas method, the saturation element is formed by the reactions of dissociation, disproportionation, exchange, and reduction. Most often in industry, heating of solids is used to create gaseous and active gaseous media. It is most convenient to carry out work in a purely gaseous environment due to rapid heating, easy adjustment of the composition, no need for reheating, and the possibility of automation and mechanization.

As you can see, classification based on the phase of the medium does not always reflect the essence of the process, so a classification was created based on the phase of the saturation source. In accordance with it, chemical-thermal treatment of steel is divided into saturation from solid, steam, liquid, and gas media.

In addition, chemical-thermal technology is divided according to the type of change in the composition of steel into saturation with non-metals, metals, and removal of elements.

According to the temperature regime, it is classified into high and low temperature. In the second case, heating is carried out to the austenitic state, and in the first case, it is heated higher and ends with tempering.

Finally, chemical-thermal treatment of parts includes the following methods, distinguished on the basis of execution technology: carburization, nitriding, metallization, nitrocarburization.

Diffusion metallization

This is the surface saturation of steel with metals.

Can be carried out in liquid, solid, gas media. The solid method involves the use of ferroalloy powders. The liquid medium is a molten metal (aluminum, zinc, etc.). The gas method involves the use of metal chloride compounds.

Metallization

Metallization produces a thin layer. This is explained by the low intensity of diffusion of metals in comparison with nitrogen and carbon, since instead of interstitial solutions they form substitution solutions.

This chemical-thermal operation is performed at 900 - 1200°C. This is an expensive and lengthy process.

The main positive quality is the heat resistance of the products. In view of this, metallization is used to produce items for operating temperatures of 1000 - 1200 ° C from carbon steels.

Based on the saturating elements, metallization is divided into aluminizing (with aluminum), chromium plating, boriding, and sicylation (silicon).

The first chemical-thermal technology makes the material resistant to corrosion scale, but aluminum remains on the surface. Aluminizing is possible in powder mixtures or in a melt at a lower temperature. The second method is faster, cheaper and simpler.

Chrome plating also increases resistance to corrosion and scale, as well as to acids, etc. For high and medium carbon steels, it also improves wear resistance and hardness. This chemical-thermal operation is mainly carried out in powder mixtures, sometimes in a vacuum.

The main purpose of boriding is to improve resistance to abrasive wear. Electrolysis technology using molten boron-containing salts is widespread. There is also an electrolysis-free method that involves the use of chloride salts with ferroboron or boron carbide.

Sicylation increases resistance to corrosion in salt water and acids, wear and scale of some metals.

General information about the steel carburization process

Steel carburization is a special thermal process with many features:

- With uniform heating, the metal is processed in a liquid, solid or gaseous environment. At the same time, the properties of steel change.

- The quality of the cemented layer improves due to the fact that carbon penetrates into the metal during smooth heating. Its strength and wear resistance increases.

- Cementation can be carried out at different temperatures. When carrying out manipulations in production, the heating temperature reaches 1200 degrees. When processing at home, the optimal temperature is considered to be 500 degrees.

- The metal surface obtains identical characteristics as during re-hardening. This is explained by the fact that the process of uniform heating changes the atomic lattice of the material.

To summarize, we can say that steel carburization is similar to the hardening process, however, with this treatment the metal receives higher performance characteristics.

Carburization (cementation)

This is the saturation of the surface of steel objects with carbon. This operation improves the hardness, wear resistance, and endurance of the material surface. The underlying layers remain viscous.

This chemical-thermal technology is suitable for items made of low carbon steel (0.25%) subject to contact wear and variable loads.

Mechanical processing is required first. Non-cemented areas are covered with a layer of copper or coatings.

The temperature regime is determined by the carbon content in the steel. The lower it is, the higher the temperature. For carbon adsorption and diffusion, in any case, it should be 900 - 950 ° C and higher.

Steel Cementation

Thus, by saturating the surface of steel parts with carbon, a concentration of this element in the upper layer of 0.8 - 1% is achieved. Larger values lead to increased brittleness.

Cementation is carried out in a medium called carburizer. Based on its phase, the technology is divided into gas, vacuum, pastes, solids, and ionic.

The first method uses coal semi-coke, charcoal, and peat coke. To speed things up, activators are used and the temperature is increased. Upon completion, the material is normalized. Due to the duration and low productivity, this chemical-thermal technology is used in small-scale production.

The second technology involves the use of suspensions, coatings or slips.

The gas environment is most often used in carburization due to speed, simplicity, the possibility of automation, mechanization and the achievement of a specific carbon concentration. In this case, methane, benzene or kerosene are used.

A more advanced method is vacuum cementation. This is a two-step process under reduced pressure. It differs from other methods in speed, uniformity and light layer surface, absence of internal oxidation, better production conditions, and equipment mobility.

The ion method involves cathode sputtering.

Cementation is an intermediate chemical-thermal operation. Next, hardening and tempering are carried out, which determine the properties of the material, such as wear resistance, endurance during contact and bending, and hardness. The main disadvantage is the duration.

Steel Cementation

Cementation is a process that saturates a steel structure with carbon. The core remains soft, however, thanks to the coating layer, the surface strength increases. During use, such parts are not exposed to external influences, are not deformed by impacts and are not erased.

Cementation is applied to elements made of carbon or alloy steel, the carbon content of which is not less than 0.08% and not more than 0.35%. Carbon-rich compounds are used for cementation. They are called carburizers. Such compositions can be liquid, solid and even gaseous.

Cementation of steels occurs through heating of parts pre-packed in boxes made of iron, and a carburizer is also placed there. The solid consists of 70% charcoal, 20–25% barium carbonate, and the remainder calcium carbonate (3–5%).

Cementation is carried out at a temperature of 920–930 °C, this indicator allows you to make the process as fast as possible. Enrichment of the steel layer occurs when coal particles come into contact with the surface of the element. The carbon transmitter in this situation is the gaseous medium. Properly organized cementation of the surface layer of a steel part lasts from 5 to 14–15 hours.

It is customary to subject small-sized products made of carbon or alloy steel to cementation in a liquid medium. They are dipped for some time in salt baths that contain molten substances:

- soda;

- table salt;

- silicon carbide.

Steel carburization scheme

Gas cementation

The essence of gas carburization is that an alloy steel part must first be heated and then calcined in a furnace, the temperature in which is from 920 to 950 °C. Gas containing methane is supplied to the furnace chamber throughout the entire carburization period.

When using this method, the duration of carburization of a steel part is reduced several times. Thus, the depth of the cementation layer of 1.2 m can be recorded after 4–5 hours of the part being in the gas chamber.

Gas carburization of steels has clear advantages over the first two methods:

- the ability to regulate the process by changing the quantitative and qualitative composition of the gas;

- lack of large equipment;

- relative purity of the process, absence of coal dust;

- the ability to harden steel directly in the furnace chamber.

Gas carburization is quite economical compared to the use of solid and liquid carburizers.

Nitriding

This term refers to the saturation of the material with nitrogen. This process is carried out in ammonia at 480 - 650°C.

With alloying agents, this element forms nitrides, characterized by dispersion, temperature stability and hardness.

This chemical-thermal treatment technology increases hardness, resistance to corrosion and wear.

Preliminary mechanical and thermal treatment is required to achieve final dimensions. Non-nitrided fragments are coated with tin or liquid glass.

Typically a temperature range from 500 to 520°C is used. This gives a 0.5 mm layer in 24 - 90 hours. Thickness is determined by duration, material composition, temperature.

Nitriding

Nitriding leads to an increase in the number of processed parts due to an increase in the volume of the top layer. The amount of growth is directly determined by its thickness and temperature conditions.

In the liquid method, cyanide-containing, less often cyanite-free and neutral salts are used. Ionic chemical-thermal operation is characterized by increased speed.

Nitriding is divided according to its target properties: it achieves either improved corrosion resistance or increased wear resistance and hardness.

This is interesting: Passivation of metal: purpose, technology, methods

Cyanidation, nitrocarburization

This is a technology for saturating steel with nitrogen and carbon. In this way, steels with a carbon amount of 0.3 - 0.4% are processed.

The ratio between carbon and nitrogen is determined by temperature. As it grows, the share of carbon increases. If oversaturated with both elements, the layer becomes brittle.

The layer size is affected by exposure time and temperature.

Cyanidation is carried out in liquid and gaseous media. The first method is also called nitrocarburization. In addition, according to the temperature regime, both types are divided into high and low temperature.

In the liquid method, salts with sodium cyanide are used. The main disadvantage is their toxicity. The high-temperature version differs from carburization in speed, greater wear resistance and hardness, and less deformation of the material. Nitrocarburization is cheaper and safer.

Nitrocarburization of steel

The final mechanical treatment is first carried out, and the fragments that are not subject to cyanidation are covered with a layer of copper 18 - 25 microns thick.

Gas cementation

In mechanical engineering, the technology of saturating the top layer of steel products with carbon in an atmosphere of carbon-containing gases is widespread. It is known that such production is convenient for mass processing of parts, since:

- Adjustment of gas density is allowed; thereby forming a carbon layer with the desired properties.

- The full heat treatment cycle (cementation, hardening, washing and tempering) takes place in one place - in a shaft (cementation) furnace.

- The process is economical, mechanized and automated.

- Boxes with a carburizer do not require heating, which reduces the time of carburization.

- The rate of carburization of parts increases by 2–3 times (compared with other methods), and the uniformity of the layer is higher.

- The temperature of the gas mixture of hydrocarbons (methane and carbon monoxide) is adjusted to 900-950°C.

- After carburization, the technological chain is completed by tempering (hardening).

Electrochemical processing

This method is based on the laws of electrochemistry. The following electrochemical methods of metal processing exist:

- surface treatment. Its essence is to dissolve the material (anode). Moreover, the protruding parts of the surface dissolve first. As a result, it is leveled out;

- dimensional electrochemical processing. This method includes:

- anodic-hydraulic treatment;

- anodic mechanical treatment.

Anodic-hydraulic treatment is based on the following property of metals: the rate of anodic dissolution is directly dependent on the distance between the electrodes. When the electrodes approach, the surface of the anode (workpiece) completely follows the contours of the tool (cathode). But as a result of the process, by-products accumulate between the cathode and anode, which have to be removed from there. This can be done by pumping the electrolyte. Or you can use a combined method - anodic-mechanical.

Anodic mechanical treatment is a combination of anodic dissolution and erosion of the outer layer of the workpiece: a rotating disk is attached to the cathode, which mechanically removes the oxide film from the protruding parts of the treated surface.

Welder: 7th category, experience in manual arc, argon-arc, gas welding - 10 years, possession of a NAKS NGDO, OKHNVP, KO certificate.

Chemical-thermal method

The chemical-thermal technique is designed to change the composition of steel in a certain layer. This group of methods includes:

- carburization – enrichment with carbon (carburization) of the surface layer of steel. Using this method, a product with combined properties is obtained: a soft core and a hard surface layer;

- nitriding – enrichment of the surface layer with nitrogen to increase corrosion resistance and fatigue strength of the product;

- boriding – saturation of the surface layer of a metal with boron. The boride layer gives the product increased wear resistance, especially during dry sliding and friction. In addition, boriding practically eliminates the adhesion (or weldability) of parts in a cold state. Borated parts are highly resistant to acids and alkalis;

- aluminizing – saturation with aluminum. It is used to make steel resistant to aggressive gases (sulfuric anhydride, hydrogen sulfide);

- chrome plating – saturation of the surface layer with chromium. Chromium plating of low-carbon steels has virtually no effect on their strength characteristics. Chromium plating of steels with a higher chromium content is called hard chrome plating, since as a result of the operation, chromium carbide is formed on the surface of the part, which has:

- high hardness;

- scale resistance;

- corrosion resistance;

- increased wear resistance;

Electrophysical methods of metal processing

This group includes methods of carrying out work using electric current, electrolysis in combination with physical impact.

Electroerosive method

During the process of electrical discharge machining of metal, metal particles are ejected from the surface of the part by a pulse of electric current. The pulses are so short that during this time only a small amount of the substance has time to melt and evaporate. In this case, heat does not spread deep into the part.

The electroerosive method includes:

- electric spark processing of metals;

- electric pulse

The electric spark method is based on the use of a spark discharge. In the discharge channel the temperature reaches 10,000

0

C, but the pulse action time is short. The result is a good surface. But this method is not characterized by high productivity, and tool wear is equal to the volume of material removed. The method is used for particularly precise (precision) fitting of small parts, cutting parts of carbide dies along the contour, and stitching small holes.

Electric pulse processing is based on the use of arc discharge pulses. The temperature in the working area reaches 4000 - 5000

0

C, which makes it possible to use high powers (several tens of kilowatts). As a result, material processing productivity increases.

When welding dissimilar metals, it is necessary to know the properties and characteristics of each of them.

To engage in artistic forging, you need to have a set of special equipment. Read more about this in our article.

Disadvantages of cementation

As mentioned above, the main disadvantage after carburization remains a change in the structure of the metal. In this regard, additional processing is required, which increases the time of the already long cementation process.

To carry out the work, trained and highly qualified personnel are required. Among the disadvantages, the need to prepare the carburizer should be highlighted.

In conclusion, it is worth noting that carburization allows the use of steels with low carbon content for the manufacture of critical parts with a long service life, which significantly reduces the final cost.

To protect surfaces not intended for cementation, pastes, copper plating, or increased processing tolerances are used.