Manganese in construction steels

The content of manganese in building steels in an amount of up to 0.8% increases the tensile strength and yield strength, although to a lesser extent than carbon, but does not cause a noticeable decrease in ductility.

When the manganese content is more than 1%, the impact strength and corrosion resistance of steel decreases, its hardness increases and weldability deteriorates. Very low manganese content reduces tensile strength. In promising low-alloy steels, the manganese content reaches 1.8%.

Compound

Depending on the amount of carbon, carbon and alloy steel are divided. The presence of carbon gives the material strength and hardness, and also reduces viscosity and ductility. Its content in the alloy is up to 2.14%, and the minimum amount of impurities due to the manufacturing process allows the bulk to consist of iron up to 99.5%.

High strength and hardness are what characterize carbon steel.

Impurities that are constantly included in the structure of carbon steel have a small content. Manganese and silicon do not exceed 1%, and sulfur and phosphorus are within 0.1%. An increase in the amount of impurities is characteristic of another type of steel, which is called alloyed.

The lack of technical ability to completely remove impurities from the finished alloy allows the following elements to be included in carbon steel:

- hydrogen;

- nitrogen;

- oxygen;

- silicon;

- manganese;

- phosphorus;

- sulfur

The presence of these substances is determined by the steel melting method: converter, open-hearth or other. And carbon is added on purpose. If the amount of impurities is difficult to regulate, then adjusting the level of carbon in the composition of the future alloy affects the properties of the finished product. When the material is filled with carbon up to 2.4%, steel is classified as carbon.

Copper in construction steels

Copper increases the strength of steel and its resistance to corrosion. The copper content in low-alloy steel reaches 0.65%. The properties of steel also depend on the method of its manufacture. According to the method of smelting, construction steels are divided into open-hearth and converter (Bessemer and Thomas), and according to the method of deoxidation - into calm, boiling and semi-quiet (the latter is almost never produced).

Thomas steel, which has very low impact strength at normal temperatures, is not used in building structures. Open hearth steel is less porous than Bessemer steel and contains fewer harmful impurities.

Boiling open hearth steel, compared to calm steel, is more clogged with gases and has a less uniform structure. The strength of Bessemer steel is no less than the strength of open-hearth steel, but the latter, especially the quiet one, is more reliable against brittle fracture and aging.

Classification of quality carbon steels

High-quality carbon steels and structural steels can be classified according to the following criteria:

- Intended use: for use in mechanical engineering;

- for use in construction;

- ordinary quality;

- By composition: presence of carbon: low-carbon;

- medium carbon;

- high carbon;

- low alloy;

- By delivery method: forged;

- rolled;

- calibrated;

- By processing: ordinary;

- boiler rooms;

- automatic;

- According to the degree of deoxidation: boiling (kp);

- semi-calm (ps);

- calm (no designation).

Visual classification of steel types

Deoxidation affects the homogeneity of the internal structures of the metal. The best in terms of homogeneity is calm (a, d), followed by semi-calm (c, f) and lower quality boiling (b, e). The internal structure is clearly shown in the figure.

This is interesting: Methods of processing stainless steel: the most popular options

Construction steel grades and areas of their application

The steel produced by the metallurgical industry is divided according to quality and purpose into standard grades called grades.

Steel grades must meet the requirements of the standards and the additional customer requirements provided for therein. These requirements determine the basic and additional characteristics of the mechanical and technological properties of steel, as well as its chemical composition.

For building metal structures the following are used:

- Carbon steel of ordinary quality, group I, supplied according to mechanical properties: open hearth - grade St. 0, St. 2, Art. Zkp, St. 3, Art. 4, Art. 5;

- Bessemer - grade BSt.Zkp;

- G - manganese,

High-quality carbon steel for structural purposes

They are the main metal for the manufacture of machine parts (shafts, spindles, axles, gears, keys, couplings, flanges, friction discs, screws, nuts, stops, rods, hydraulic cylinders, eccentrics, chain sprockets, etc.), which, when interacting in a working machine, they perceive and transmit loads of varying magnitude. These metals are well processed by pressure and cutting, cast and welded, and are subjected to thermal, thermomechanical and chemical-thermal treatment.

Various special types of processing provide the toughness, elasticity and hardness of steels, making it possible to make parts from them that are viscous in the core and hard on the outside, which dramatically increases their wear resistance and reliability. High-quality carbon structural steels are used to produce rolled products, forgings, calibrated steel, silver steel, long steel, stampings and ingots.

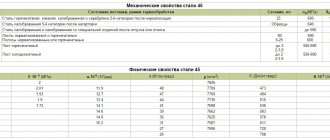

Table 3. Basic properties of high-quality carbon structural steel

| Brand | Mechanical properties | Physical properties | Technological properties | ||||||||||

| σт | σв | δ, % | an J/cm2 | NV | γ, g/cm3 | λ, W/(m °С) | α·106.1/°С | treatments- productivity cutting | weldability _ | interval temperatures forging, °C | plastic at cold processing | *hot- rolled **identify- married | |

| MPa | |||||||||||||

| 08 | 196 | 324 | 33 | — | 126 | 7,83 | 811 | 11,6 | IN | BB | 800-1300 | BB | * |

| 10 | 206 | 321 | 31 | — | 140 | 7,83 | 811 | 11,6 | IN | BB | 800-1300 | BB | * |

| 15 | 225 | 373 | 27 | — | 145 | 7,82 | 770 | 11,9 | IN | BB | 800-1250 | BB | * |

| 20 | 245 | 412 | 25 | — | 159 | 7,82 | 770 | 11,1 | IN | BB | 800-1280 | IN | * |

| 25 | 274 | 451 | 23 | 88 | 166 | 7,82 | 732 | 11,1 | IN | BB | 800-1280 | IN | * |

| 30 | 294 | 490 | 21 | 78 | 175 | 7,817 | 732 | 12,6 | IN | IN | 800-1250 | IN | * |

| 35 | 314 | 529 | 20 | 69 | 203 | 7,817 | 732 | 11,09 | IN | IN | 800-1250 | IN | * |

| 40 | 321 | 568 | 19 | 59 | 183 | 7,815 | 596 | 12,4 | IN | U | 800-1250 | U | ** |

| 45 | 363 | 598 | 16 | 49 | 193 | 7,814 | 680 | 11,649 | IN | U | 800-1250 | U | ** |

| 50 | 373 | 627 | 14 | 38 | 203 | 7,811 | 680 | 12,0 | U | U | 800-1250 | U | ** |

| 55 | 382 | 647 | 13 | — | 212 | 7,82 | 680 | 11,0 | U | N | 800-1250 | N | ** |

| 60 | 402 | 676 | 12 | — | 224 | 7,80 | 680 | 11,1 | U | N | 800-1240 | N | ** |

| Note. N - low, U - satisfactory, V - high, BB - very high. | |||||||||||||

High-quality structural steels have higher mechanical properties (GOST 1050-88) than steels of ordinary quality, due to their lower content of phosphorus, sulfur and non-metallic inclusions. According to the type of processing, they are divided into hot-rolled, forged, calibrated and silver (with special surface finishing).

The designation of the steel grade is made up of the word “Steel” and a two-digit number that indicates the average carbon content in hundredths of a percent. For example, Steel 25 contains 0.25% carbon (permissible amount of carbon - 0.220.30%), Steel 60-0.60% (permissible amount -0.57-0.65%). The degree of deoxidation is not reflected in grades of calm steels, but in grades of semi-quiet and boiling steels, as well as steels of ordinary quality, it is designated by the letters “ps” and “kp”, respectively. In high-quality structural steels of all grades, the sulfur content is allowed to be no more than 0.040% and phosphorus - no more than 0.035%.

The main properties of high-quality carbon structural steel are given in table. 3, main purpose - in table. 4. Marking colors are given in table. 5.

Table 4. High-quality carbon steel for structural purposes, their main purpose

| steel grade | Main purpose |

| Steel 08kp, 10 | Parts produced by cold stamping and cold heading, tubes, gaskets, fasteners, caps. Cemented and cyanidated parts that do not require high core strength (bushings, rollers, stops, copiers, gears, friction discs) |

| Steel 15, 20 | Lightly loaded parts (rollers, pins, stops, copiers, axles, gears). Thin parts exposed to abrasion, levers, hooks, traverses, liners, bolts, couplers, etc. |

| Steel 30, 35 | Parts experiencing low stress (axles, spindles, sprockets, rods, traverses, levers, disks, shafts) |

| Steel 40, 45 | Parts that require increased strength (crankshafts, connecting rods, ring gears, camshafts, flywheels, gears, pins, ratchets, plungers, spindles, friction discs, axles, couplings, racks, rolling rollers, etc.) |

| Steel 50, 55 | Gear wheels, rolling rollers, rods, bandages, shafts, eccentrics, lightly loaded springs and leaf springs, etc. Used after hardening with high tempering and in a normalized state |

| Steel 60 | Parts with high strength and elastic properties (rolling rolls, eccentrics, spindles, spring rings, clutch springs and discs, shock absorber springs). Apply after hardening or after normalization (large parts) |

Table 5. Marking colors for high-quality carbon steel

| Group | Paint color |

| Steel 08, 10, 15, 20 | White |

| Steel 25, 30, 35, 40 | White and yellow |

| Steel 45, 50, 55, 60 | White and brown |

Scope of application

Structural steels are widely used in the construction of instruments, machines and units. Each brand is intended for the manufacture of certain structures, which will then be involved in the assembly of a machine or unit. Alloy alloys are used for the production of:

- springs, spring bands and coil springs - grade 60С2(A);

- critical springs and springs operating at elevated temperatures – 50ХФА (ХГФА);

- large and heavily loaded springs and springs - 60C2XA;

- splined rollers, bushings, spindles, couplings – 40Х-50Х;

- parts operating at high speeds and under heavy loads - 18ХГТ, 20ХГР;

- wear-resistant, high-strength and critical elements - 40ХС, 40ХФА;

- turbines, shafts, fasteners operating at elevated temperatures - 35ХМ.

These are examples of the use of specific grades of alloys. Separation into groups also helps to determine which structural compositions are used for what.